Beverage is not discharged

Make sure to check KEG and CO2 gas valve before use

If valve is locked, then beverage is not discharged.

Make sure to check residual beverage in KEG before use

If beverage is insufficient, beverage is not discharged.

Make sure to check residual CO2 before use

If CO2 is insufficient, beverage is not discharged.

When lots of bubble is generated

Make sure to check that valve and nozzle is cooled before use

When this product is first installed, lots of bubble may be generated from

nozzle and valve due to differences in temperature.

Remove bubble in beverage pipe before using this product

Bubble may be generated due to residual bubble in pipe

Before using this product, make sure to remove leakage in connecting

area of various pipes

Leakage in pipe connection may generate bubble

Make sure to fit flow rate by adjusting valve in beverage pipe

Bubble may be generated due to rapid flow rate

Use this product after temperature of beverage is cooled

High temperature of beverage may cause bubble

Use the product when beverage in KEG is sufficient

If beverage is insufficient, bubble may be generated.

C

H

E

C

K

L

I

S

T

B

E

F

O

R

E

U

S

E

6

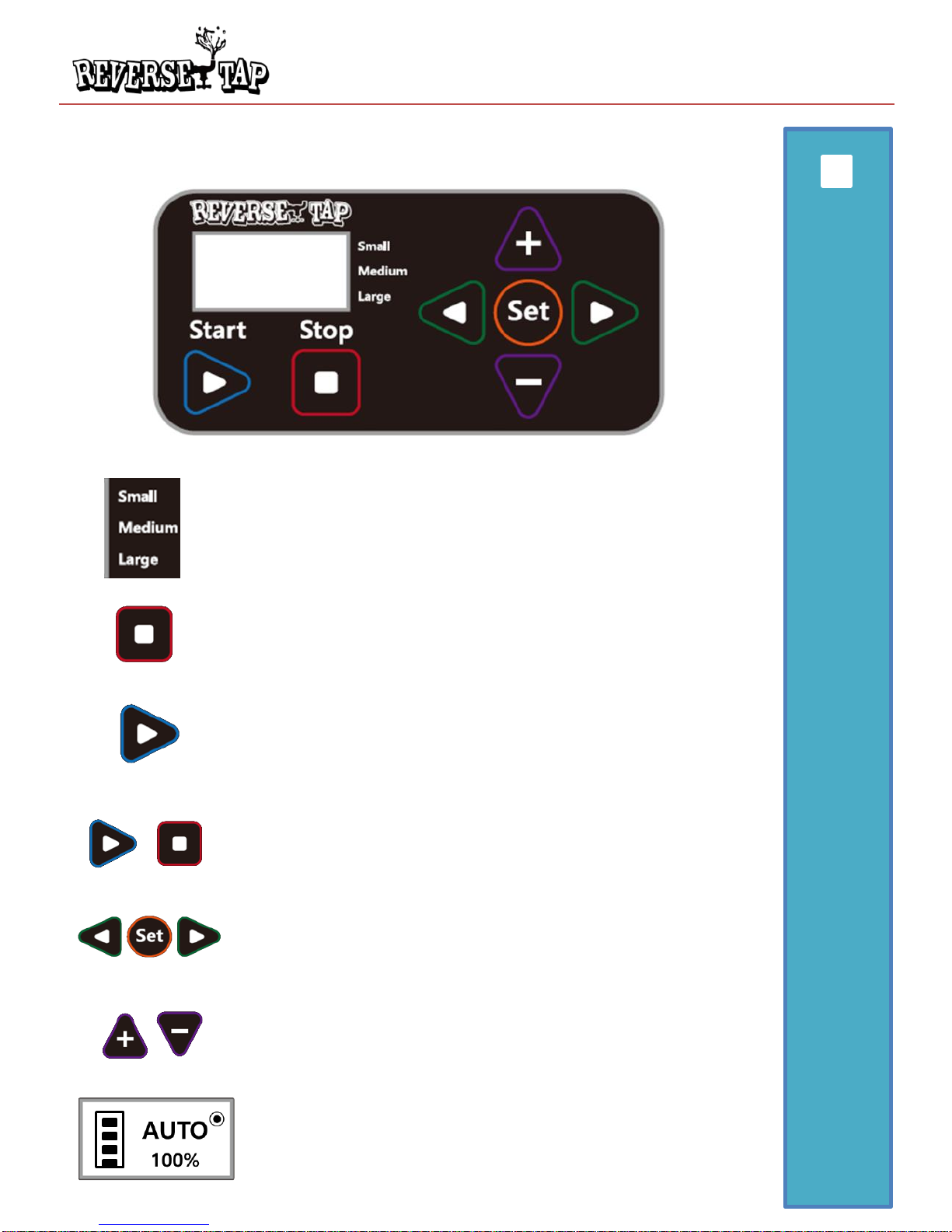

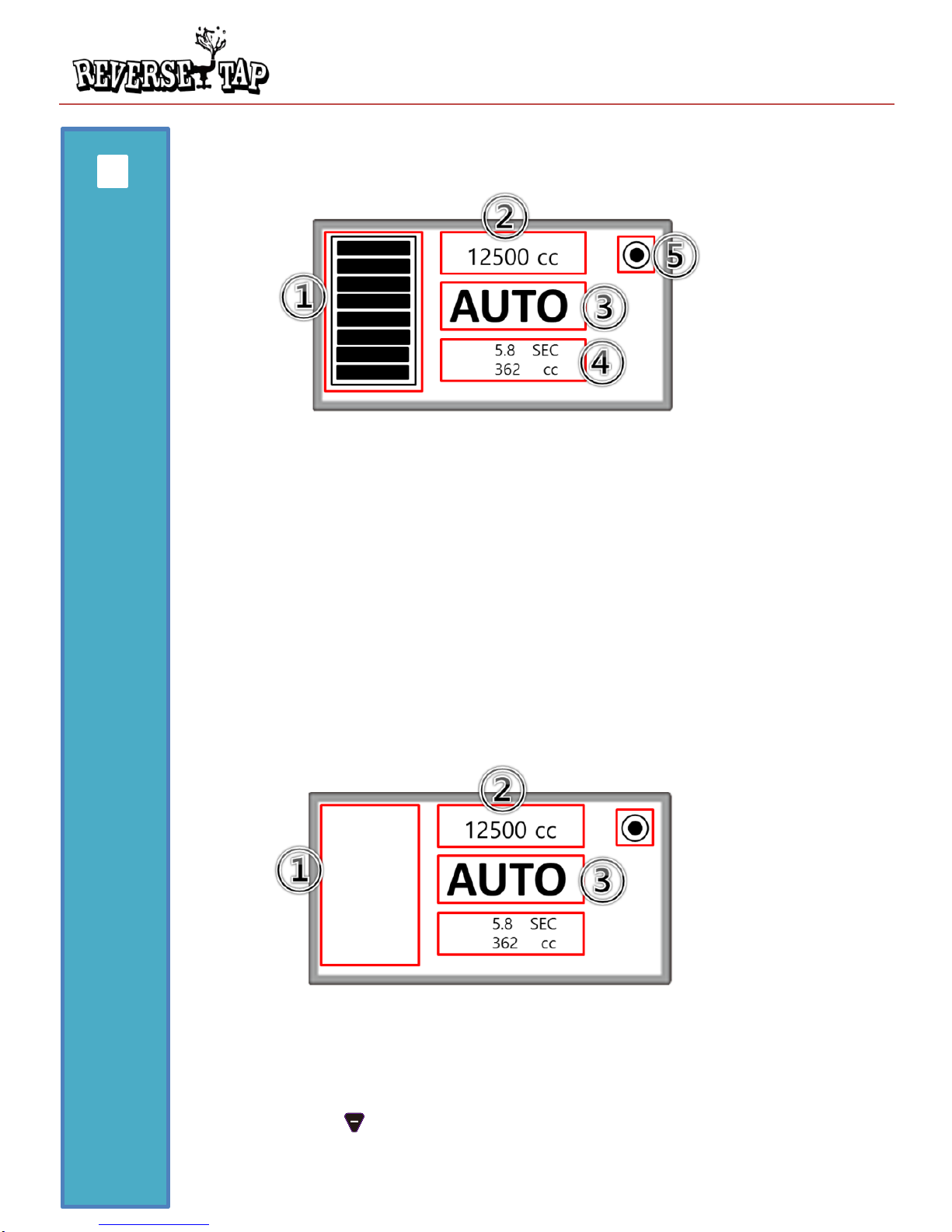

Configuration Item

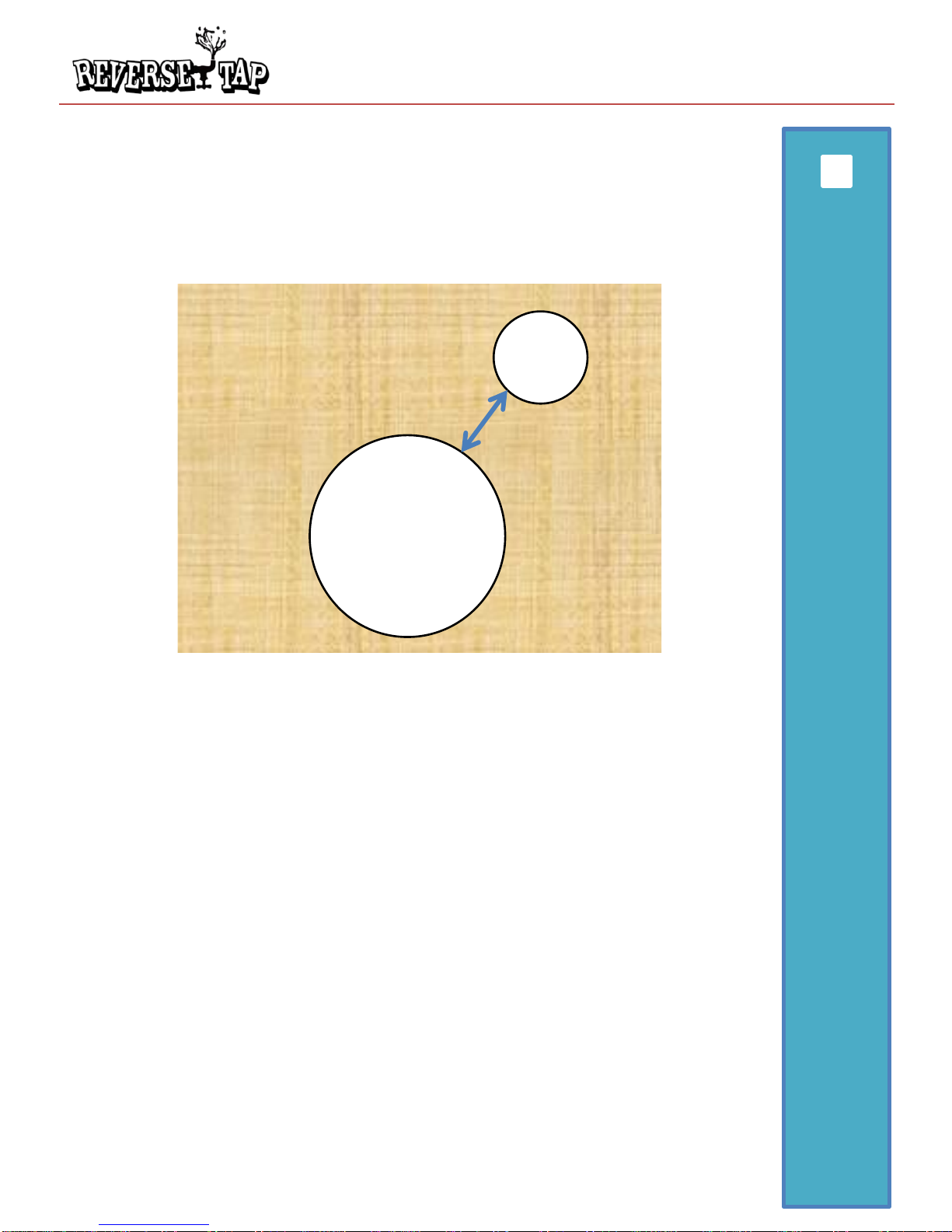

1. Top cover 2. Top cover cap 3. Gripper

5. DC power adaptor 6. Hose band 7. Drain hose