rheemthermal.com.au

INSTRUCTION SHEET FOR

PROGRAMMING ‘DEMAND HEAT’

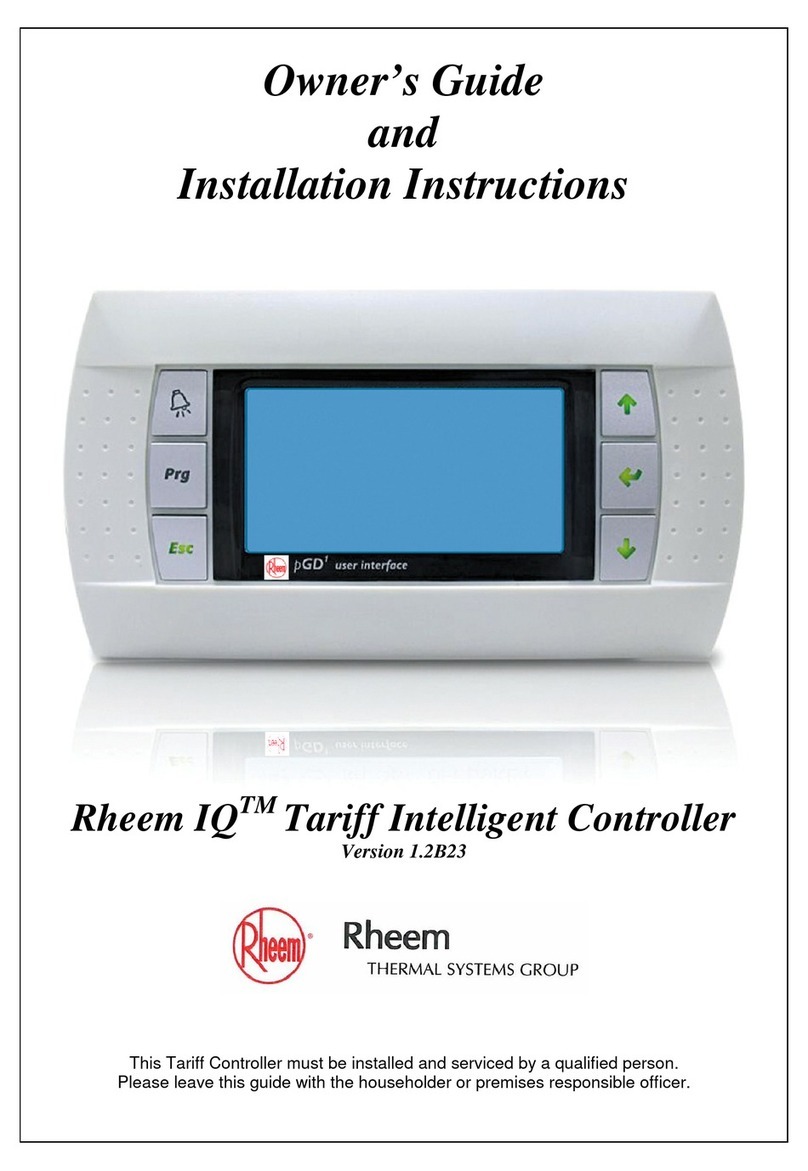

Programming Demand Heat on your RHEEM THERMAL HEAT PUMP CONTROLLER

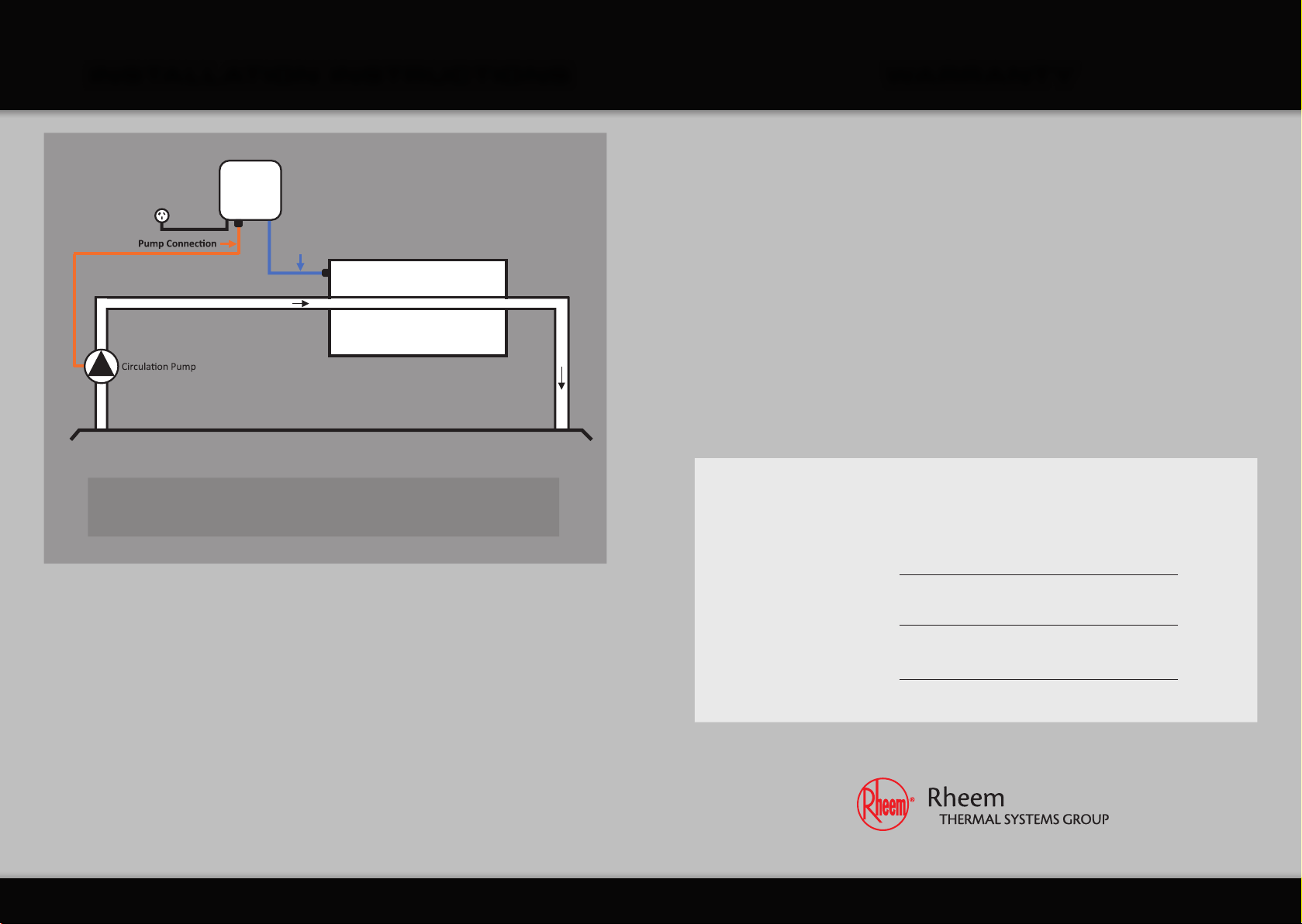

The Rheem Thermal heat pump comes with an advanced Rheem IQ®control that is designed to

communicate with your Rheem IQ®- Link DPi Digital Pump Interface control.

The ‘Cycle to Test Temperature’ setting in Rheem IQ®is designed to control operation of the

system water pump(s). With this function activated, Rheem IQ®will turn the water pump ‘ON’ so

that the heat pump can check the current pool or spa water temperature. If heating is required,

the water pump remains ‘ON’ until the pool or spa has reached temperature and the pump is

switched ‘OFF’. The heat pump will ‘Cycle to Test Temperature’ throughout the day determined

by the time setting programmed by the owner.

To activate the Demand Heat function, ‘Cycle to Test Temperature’ needs to be set to ‘ON’

and ‘Enable Unit on/off by Flow Switch’ needs to be set to ‘No’.

Adjust the set points at the Rheem IQ®controller screen on your heat pump as follows:

1. Whilst in the home screen, press and release . The screen will change to the ‘Main menu’.

2. Press and release or until ‘A. On/Off Unit’ is selected.

3. Press and release . The screen will change to show ‘ON’ or ‘OFF’.

4. Press and release or . The screen will change to show ‘Type of circulating pump

control’ and the current setting.

5. Press and release . The first letter in the current setting will start flashing.

6. Press and release or until the desired setting is displayed.

7. Press and release to confirm the selection. With ‘CYCLE TO TEST TEMP’ selected,

proceed to step 8.

8. The first digit in the ‘temp test cycle’ time will now be flashing. Press and release or

until the desired time setting is displayed. The time setting can be changed in 0.5 hour

increment from 0.5 to 5.0 hours.

9. Press and release to confirm the time selection. The first digit in the ‘temp test cycle’ time

will stop flashing and the setting will be saved.

10. Press and release twice to go back to the home screen.

11. Whilst in the home screen, press and release or to change to the ‘Main menu’ screen.

12. Press and release or until ‘G. Service’ is selected.