KF-50-OTM Instruction Book KF-50 Issue 1 Page 2 KF-50 Patent Pending

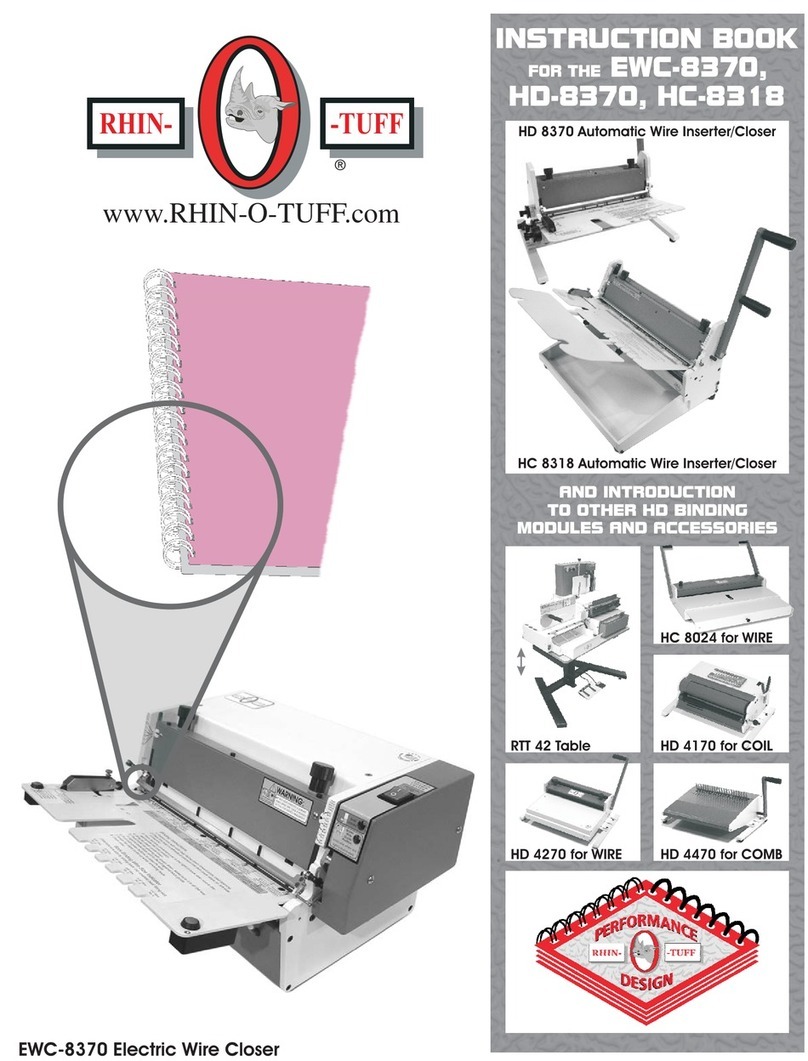

There are helpful accessories and other modules to benefit your binding

station. These are just a few of our many accessories and modules. Please visit

us at www.RHIN-O-TUFF.com to see the complete line of punching and binding

equipment.

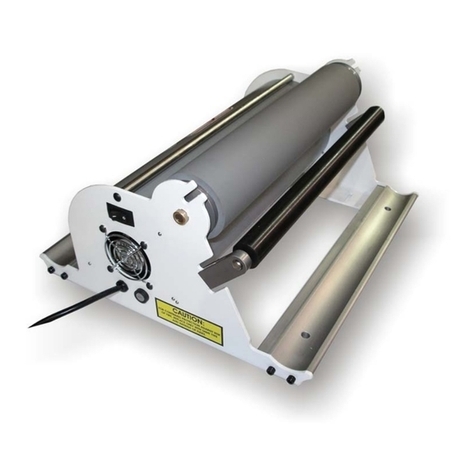

HD-4170 Coil Inserter

The HD-4170 "Rhin-O-Roll" Coil Inserter Module has 12" dual powered

adjustable rollers for easier more accurate coil insertion. It has gauges for book

thickness and coil sizing. The HD 4170 can be used as a stand-

alone production coil inserter or it can be attached on any OD or

HD Series punch (except the HD-7500 and horizontals). All

pitches and diameters can be inserted using it. The HD 4170

comes with a crimper pliers holder and pliers.

HD-e4100 Economical Coil Inserter

he HD-e4100 uses the unique Rhin-O-Roll gripping roller along

with an adjustable lower roller for faster and more accurate coil

insertion. Shown in the stand-alone configuration, it also can be

mounted as a module to any vertical punch.

HD-4101 EZ Coil Book Former

The HD 4101 forms the spine of your book for EZ-Coil Insertion of 6MM to 50MM

Coil. Up to 14" (356mm) binding edge capacity for any size.

Attachable to HD-e4100 Coil Inserter: The HD-4102 Docking

Station Links the HD-e4100 Coil Inserter with the HD-4101

Book Former, Providing Controlled EZ-Coil Insertion with

larger coil sizes up to 50MM. The HD-4104 Coil Chute Keeps

the coil tangle free.

PC-248 Punch & Electric Coil Insertion System

The first fully featured Manual Punch and Electric Coil Inserter

with Heavy Duty Features at an affordable price. Offers

significant productivity gains through operator driven common

sense solutions.