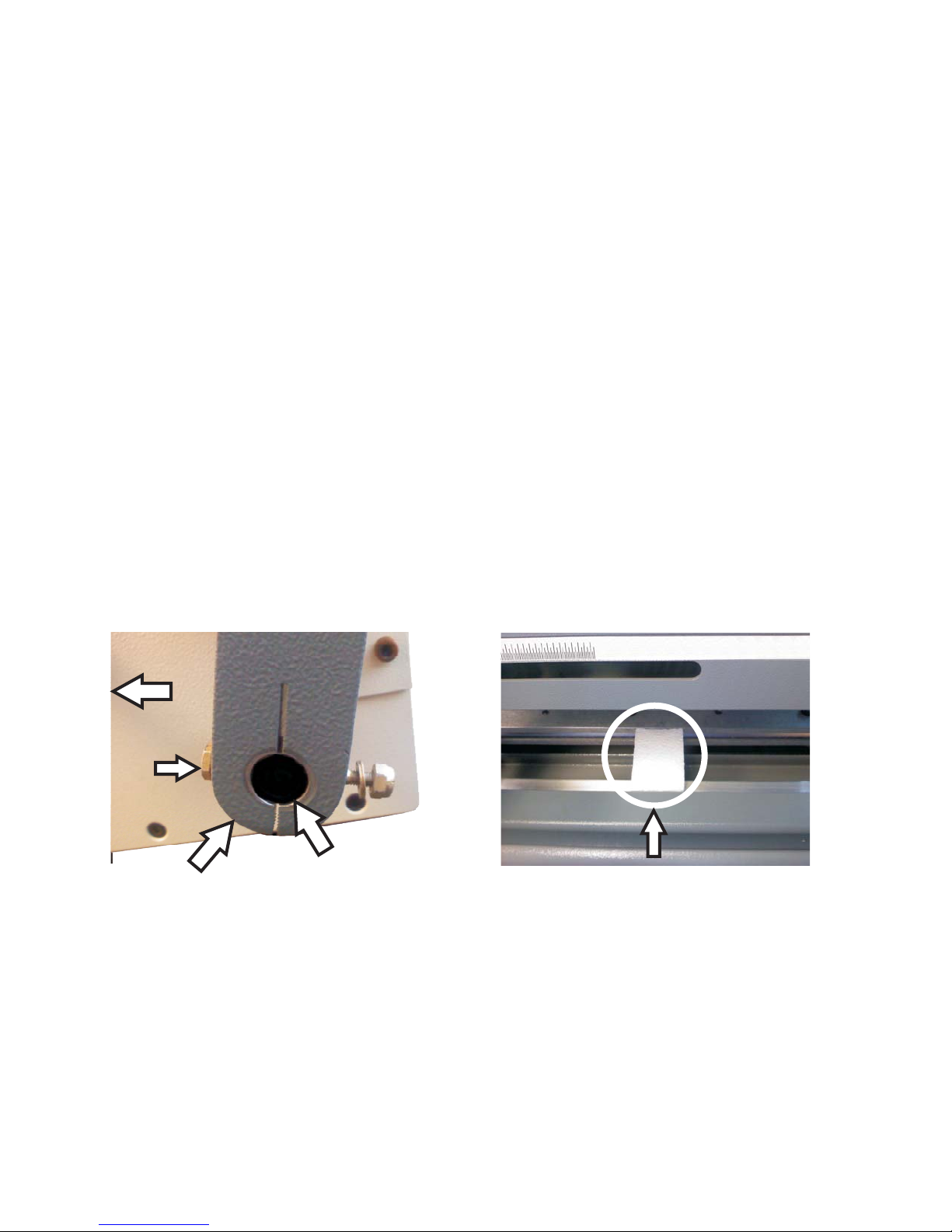

Safety Alert Symbols

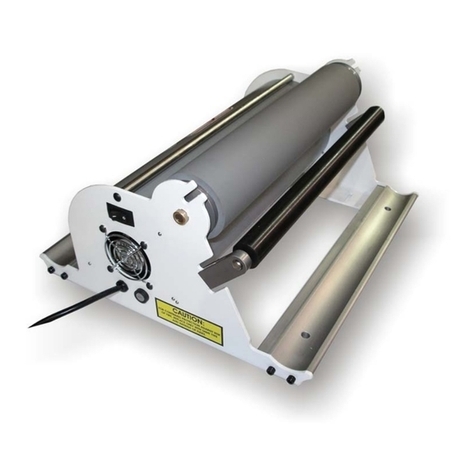

uThe OD4012 and OD4000 need to be plugged into a wall outlet that

provides a 15-amp, 120 volt service (16-amp, 220 volt for European

installations) and is protected by a fuse or circuit breaker at the main

electrical panel.

uIf machine cycles on its own, turn off power switch, unplug machine

from the wall outlet and call your dealer immediately for service.

uMake sure you read this section very carefully! Learn to recognize

these The OD4012, OD4000 and OD4800

have been designed to provide a high level of protection to an

operator. Follow the guidelines below while installing, operating and

maintaining your machine.

Safety Alert Symbols.

4

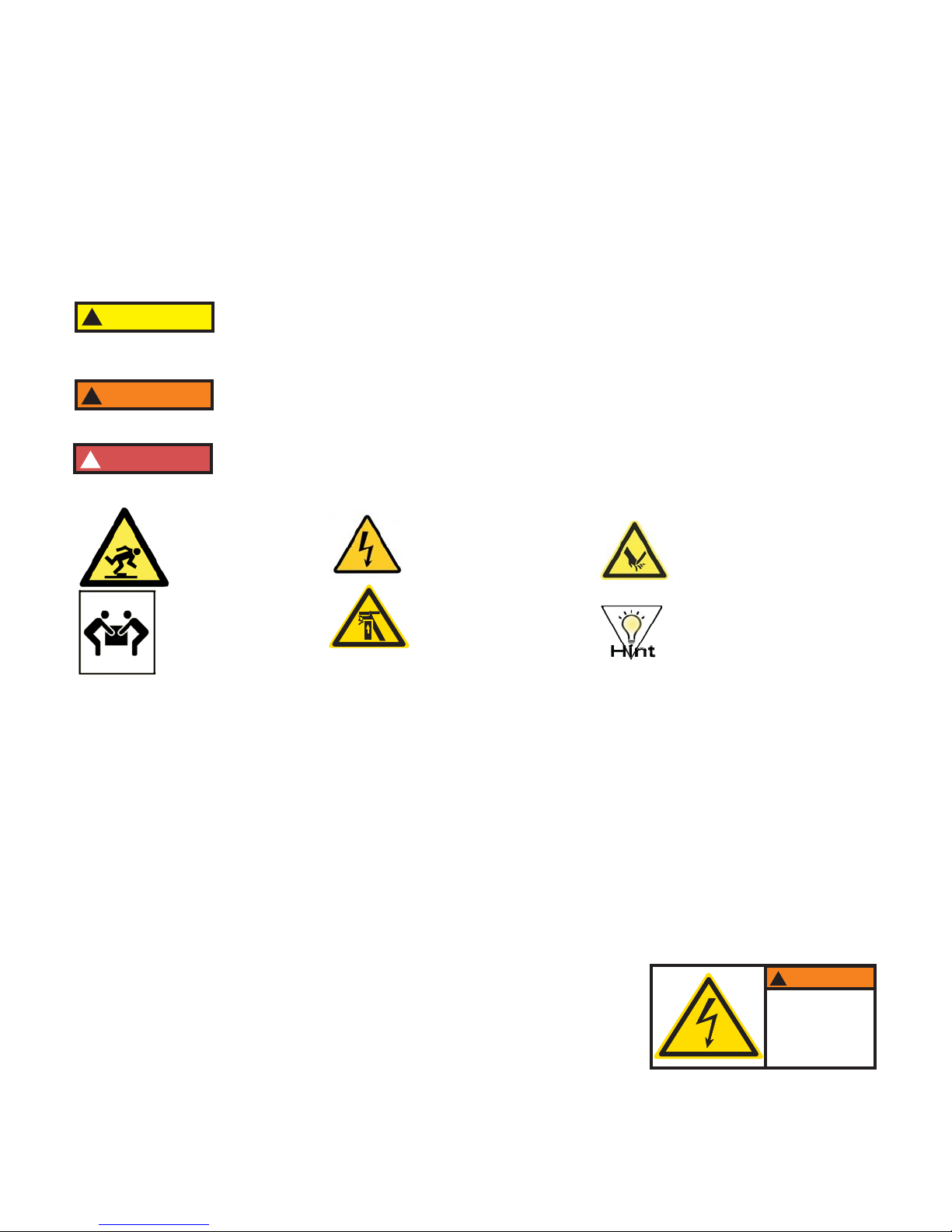

!DANGER

!WARNING

Safe Operating Guidelines

!CAUTION CAUTION: Indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury. It may also be used without the safety alert symbol as

an alternative to "Notice".

WARNING: Indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

DANGER: Indicates a hazardous situation which, if not avoided, will result in

death or serious injury. This signal word is to be limited to the most extreme

situations.

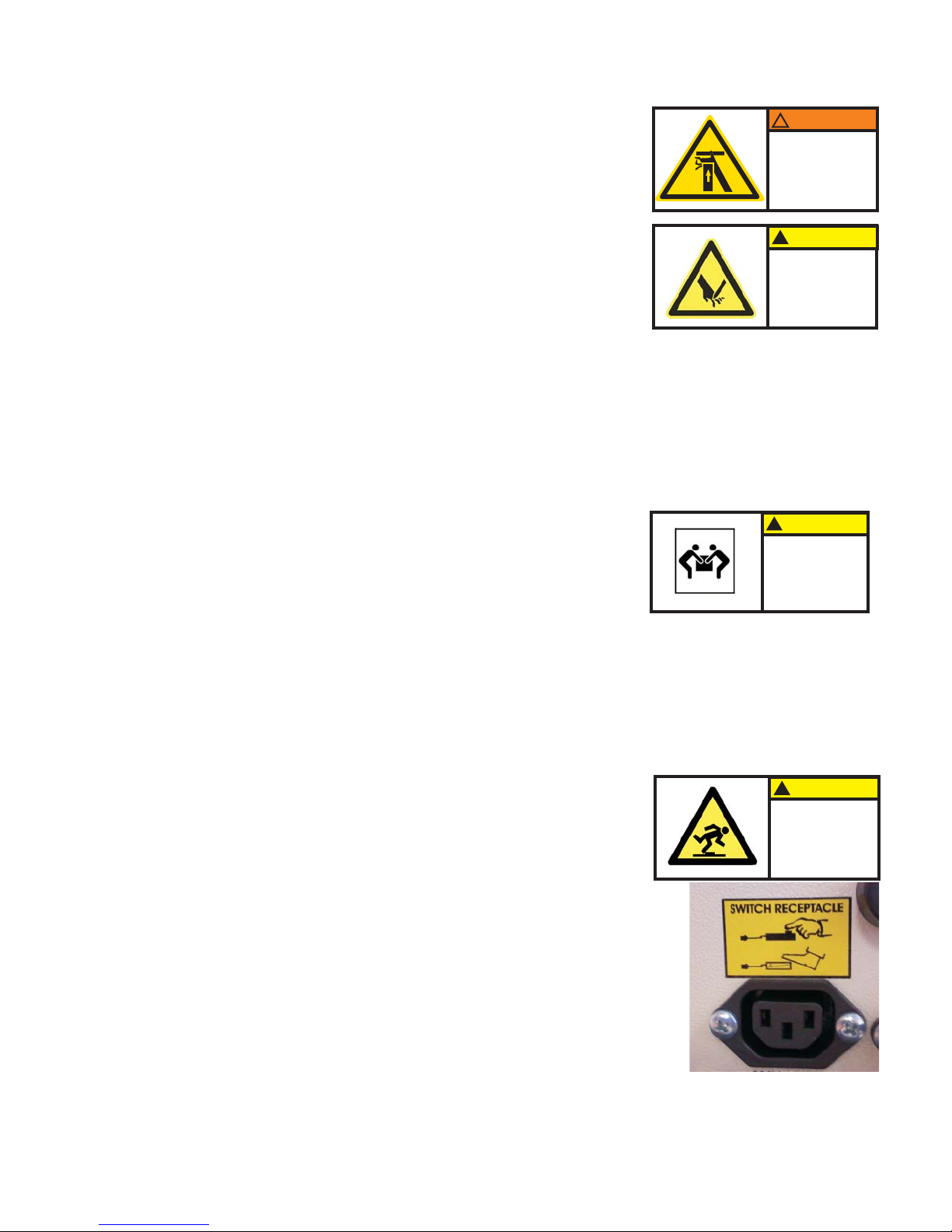

Trip Hazard

Two Person LIft

Electric Shock

Crushing Hazard

uAlways replace any fuse with the same type and

amperage fuse as indicated on the machine.

Hazardous voltage

inside.

Disconnect power

before servicing.

!WARNING

Cutting Hazard

Hint or Suggestion

uAlways keep this instruction manual with the machine for reference to

safe operating guidelines and correct operation of the machine.