Comb dies are the only kind to have an adjustable backstop.

These

are

specia/

order dies and

are

not

standard. To change the position of the hole placement

(margin) to the back edge of the sheet, first install the die into the OD 4000.

Pull

on the black handle, which is

part

of the die. There are four placement positions.

Choose the position best suited for your job. Push

the

handle towards

the

right

for

the

larger combs and

pull

it

out

to

the

left

for smaller combs. The exact

position will be left up to the operator’s preference.

1) Punching Paper:

Position the paper that needs to be punched either to the left, right or on top of

the machine. This is up to the individual operator. Remove 10 to

15

sheets (2Olb

bond copy paper) from the pile and slide it down vertically into the opening of the

die. When the paper is fully down, slide it to the left so it comes in contact with

the paper guide. Make sure all the edges of the sheets are flush by tapping the

top and the right hand side of the sheets before pressing the foot pedal. After

punching the sheets, place the paper on the punched pile making sure the

sheets remain in exact order.

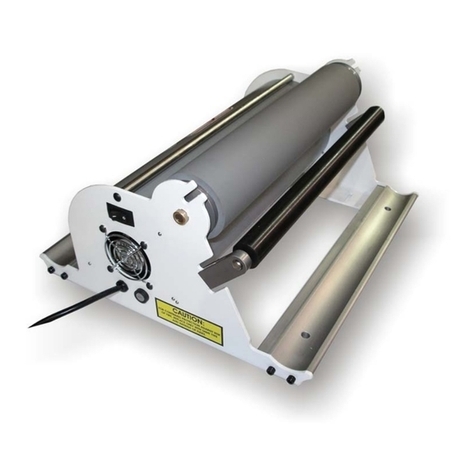

2) Removing paper waste: Diagram 3

The paper waste is removed by pulling towards you the paper

waste

drawer (3).

It is located directly below the die. This should be checked frequently while

punching not to allow it to fill up and spill into the machine.

3) Paper Jam: (Reverse knob) Diagram 3

Unplug

and

turn

the power oft to the

machine

before proceeding. The reverse

knob is only utilized if a paper jam occurs in the die or if the die is installed

incorrectly. When a paper jam occurs, the fuse protecting the motor may have to

be replaced. This is normal and allows maximum protection for the punch motor.

+

Push in and turn the reverse knob (1) counter clockwise about

8-10

times so

the punch pins (2) start to move

out

of the paper in which it had jammed.

This should be enough to allow the paper to become free of the die. (This

knob is normally tight and requires a firm grip to turn it the small amount

necessary to remove the paper from the die.)

+

Plug the machine back into the wall outlet and turn the main power switch on

+

Press the foot pedal to see if the machine operates. If yes, reinstall the die

and continue punching the job. If the machine does not function, see

replacing the fuses in the troubleshooting section of this manual.