TABLE OF CONTENTS

SAFETY SECTION .............................................................................................................. 1-1

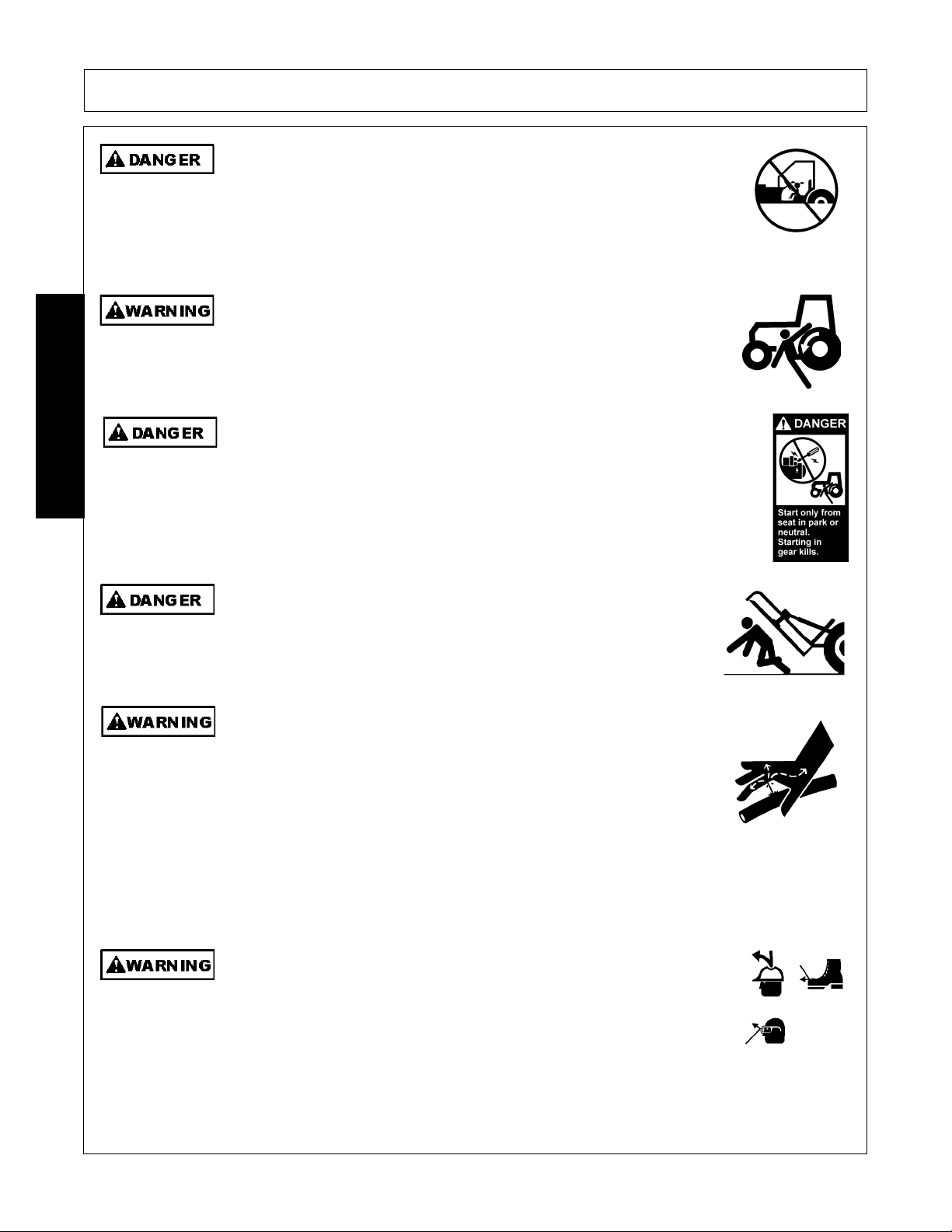

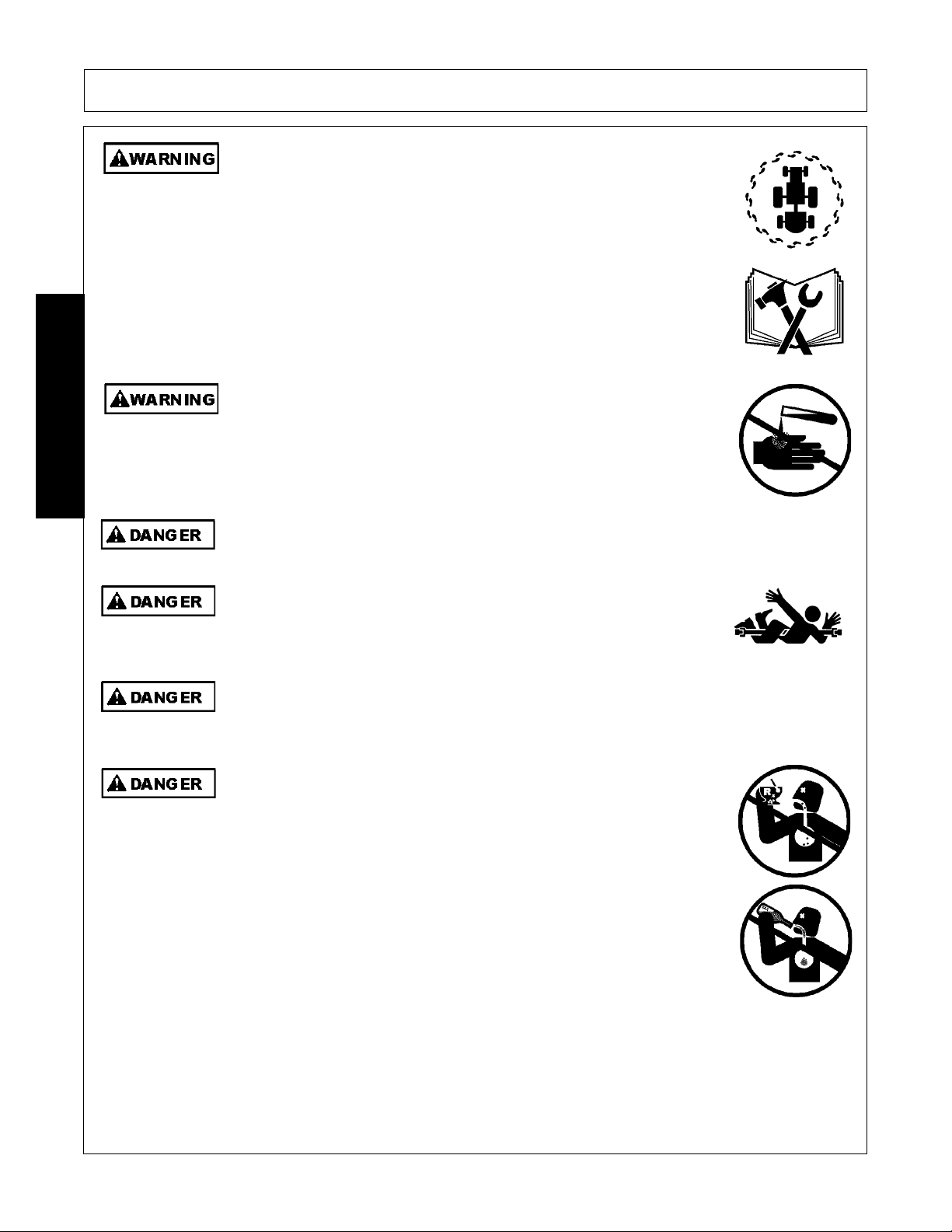

General Safety Instructions and Practices ......................................................................................................... 1-2

PARTS INFORMATION ..................................................................................................................................... 1-8

Decal Location ...................................................................................................................................................1-9

Decal Description .............................................................................................................................................1-10

Federal Laws and Regulations ........................................................................................................................1-11

INTRODUCTION SECTION ................................................................................................. 2-1

RHINO LIMITED WARRANTY ........................................................................................................................... 2-4

ASSEMBLY SECTION ........................................................................................................ 3-1

OPERATION SECTION ....................................................................................................... 4-1

Standard Equipment and Specifications ............................................................................................................ 4-3

OPERATOR REQUIREMENTS .........................................................................................................................4-4

TRACTOR REQUIREMENTS ............................................................................................................................4-5

ROPS and Seat Belt ..........................................................................................................................................4-5

Tractor Horsepower ...........................................................................................................................................4-5

Tractor 3-Point Hitch ..........................................................................................................................................4-6

Front End Weight ...............................................................................................................................................4-6

GETTING ON AND OFF THE TRACTOR .........................................................................................................4-6

Boarding the Tractor ..........................................................................................................................................4-6

Dismounting the Tractor ..................................................................................................................................... 4-7

STARTING THE TRACTOR .............................................................................................................................. 4-8

CONNECTING THE IMPLEMENT TO THE TRACTOR .................................................................................... 4-8

Connecting the Plow .......................................................................................................................................... 4-9

PRE-OPERATION INSPECTION AND SERVICE ...........................................................................................4-10

Tractor Pre-Operation Inspection/Service ........................................................................................................4-10

Plow Pre-Operation Inspection/Service ...........................................................................................................4-11

DRIVING THE TRACTOR AND IMPLEMENT ................................................................................................. 4-14

Starting the Tractor .......................................................................................................................................... 4-15

Brake and Differential Lock Setting ..................................................................................................................4-15

Driving the Tractor and Implement ................................................................................................................... 4-16

OPERATING THE TRACTOR AND IMPLEMENT ...........................................................................................4-16

Operating the Plow ..........................................................................................................................................4-16

Shutting Down the Implement ..........................................................................................................................4-17

DISCONNECTING THE PLOW FROM THE TRACTOR ................................................................................. 4-17

PLOW STORAGE ............................................................................................................................................ 4-18

TRANSPORTING THE TRACTOR AND IMPLEMENT ...................................................................................4-18

Transporting on Public Roadways ................................................................................................................... 4-20

Hauling the Tractor and Implement ..................................................................................................................4-22

TROUBLESHOOTING GUIDE ........................................................................................................................4-23

MAINTENANCE SECTION .................................................................................................. 5-1

Replacing Plow Points .......................................................................................................................................5-2

Proper Torque For Fasteners ............................................................................................................................ 5-2