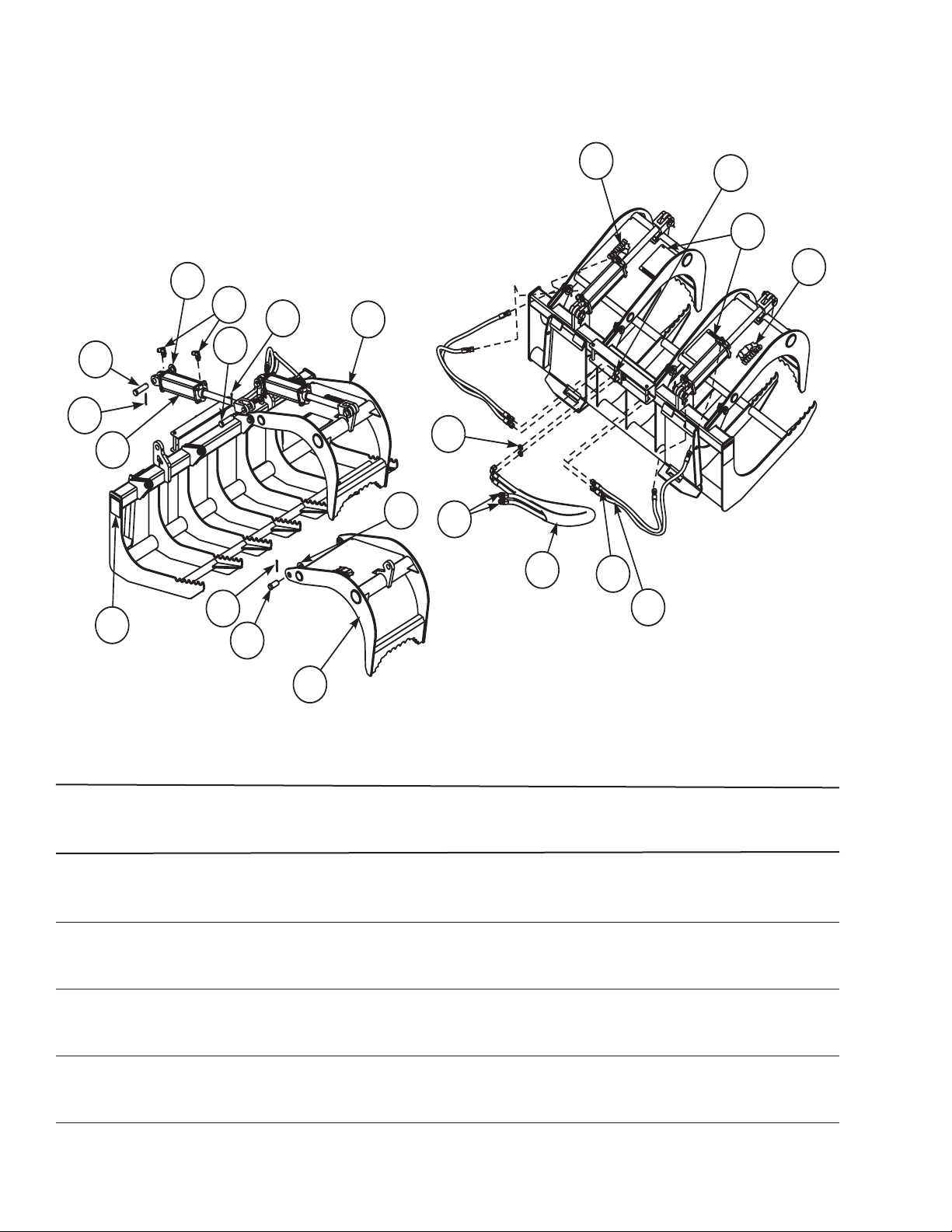

2-7741 2-7748

2-7742 2-7749

2-7743 2-7750

Page 4 of 6F-4315 1-20-10

ATTACHING BRUSH GRAPPLE TO

LOADER BOOM

No tools are needed to install quick attach

brush grapple. Loader must be equipped

with skid steer quick attach male coupler.

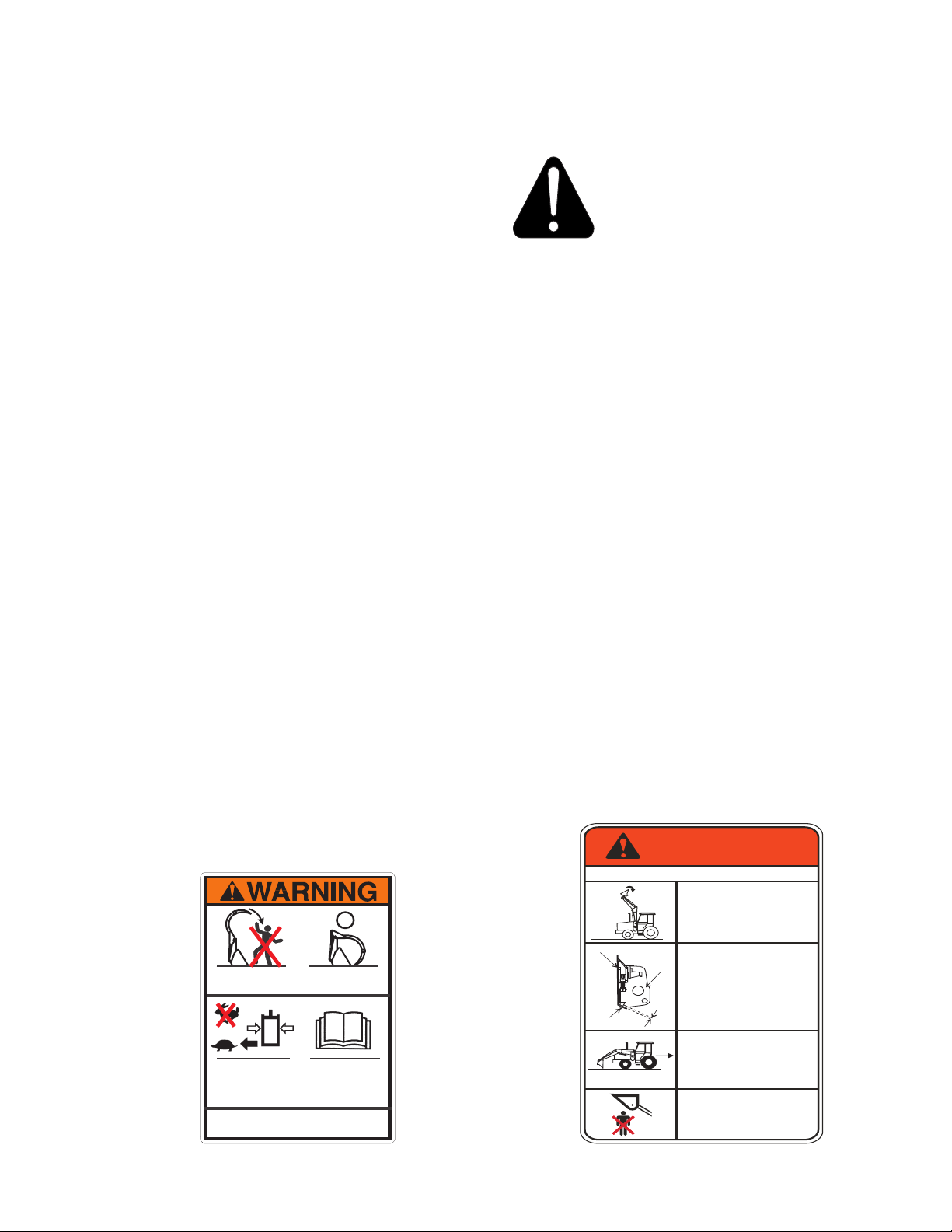

WARNING: To avoid injury during

attachment or detachment, do not

allow bystanders within 10 feet of

loader or attachment.

1. Remove attachment from loader and store

properly.

2. Locate tractor and brush grapple on level

ground. Lower boom to rest on ground.

Extend the bucket cylinders slightly, while

raising the boom to provide 3 to 5” of

ground clearance. Drive the tractor forward

slowly toward the brush grapple, aligning

the loader quick attach device.

3. While driving the tractor ahead slowly to

maintain contact with the brush grapple,

activate the lift cylinders to raise the loader

boom until the male quick attack engages

the female attachment lip.

4. Activate the bucket cylinders to retract,

continuing to roll the brush grapple back

completely.

5. Place tractor in neutral, set parking brake,

and shut off tractor. Rotate the quick

attach latch handles down in engage the

latch pins.

6. Start tractor and raise brush grapple 1

to 2 feet off ground and extend bucket

cylinders to tilt brush grapple at a slight

downward angle, so quick attach latch

pins are visible. Visually inspect the brush

grapple to verify the pins are engaged

through the latch plate on the back of the

brush grapple.

NOTE: If the brush grapple is not securely

attached, follow the instructions for

detaching it and repeat the above

procedure.

7. Lower loader boom to ground, place

tractor in neutral, set parking brake, and

shut off tractor. Move valve joystick to

relieve hydraulic pressure in all lines.

Connect brush grapple hydraulic hoses to

auxiliary hydraulic source (rear remotes,

3rd function kit) to operate the claws. Set

hydraulic speed control to “slow” for claw

operation.

8. Start tractor and cycle the grapple claws

a number of times to purge air from

cylinders. Check tractor hydraulic reservoir

and replenish with tractor manufactures

recommended hydraulic uid.

OPERATING BRUSH GRAPPLE

Operation of your tractor and loader with brush

grapple attachment requires additional consid-

erations from bucket operation. You now have

to operate the brush grapple while already op-

erating the tractor and loader. You need to also

take into account additional space require-

ments (added length and height) needed be-

cause of attached brush grapple.

GRASPING BRUSH

o Approach the pile with claw open and

bottom level. Use loader boom oat

position, if material is on the ground.

o Ease valve control lever for grapple claw

forward to close grapple claw around

material pile.