1. PREFACE....................................................................................................................................... 4

1.1 PURPOSE ...................................................................................................................................... 4

1.2 SYMBOLS AND CONVENTIONS............................................................................................................. 4

1.3 ABOUT THIS MANUAL....................................................................................................................... 4

1.3.1 CONVENTIONS......................................................................................................................................... 4

1.4 DOCUMENT ISSUE ........................................................................................................................... 5

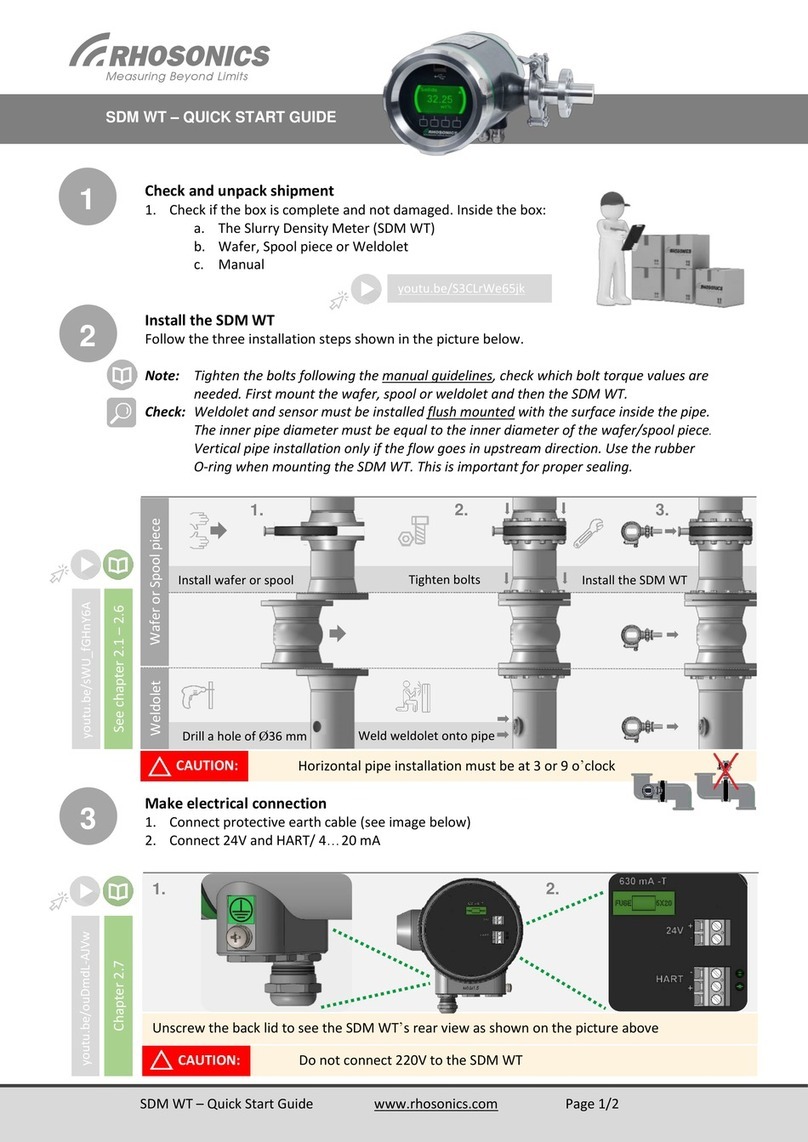

2. INSTALLATION .............................................................................................................................. 6

2.1 INTRODUCTION............................................................................................................................... 6

2.2 INSTALLATION OF THE B31 ................................................................................................................ 7

2.2.1 DIMENSIONS........................................................................................................................................... 7

2.2.2 MOUNTING B31 ..................................................................................................................................... 8

2.2.3 CONNECTING PROCESS TUBE /PIPE ............................................................................................................. 9

2.3 ELECTRICAL CONNECTIONS B31 .........................................................................................................10

2.3.1 POWER SUPPLY......................................................................................................................................10

2.3.2 POWER CABLE AND GLAND .....................................................................................................................10

2.3.3 RS232 OUTPUT AND GLAND ...................................................................................................................10

2.3.4 USB PORT ............................................................................................................................................11

2.3.5 CONNECTION 24 VDC POWER AND RS232................................................................................................11

2.3.6 RS232 (MODBUS RTU PROTOCOL).......................................................................................................... 13

2.3.7 MODBUS (SLAVE)-PLC (MASTER).........................................................................................................13

2.3.8 ATTACHMENT A: INTERPRET THE INPUT DATA.....................................................................................15

2.3.9 CONNECTION USB-PORT TO A PC ............................................................................................................16

3. OPERATION .................................................................................................................................18

3.1 INTRODUCTION..............................................................................................................................18

3.1.1 FUNCTIONALITY PER USER INTERFACE ........................................................................................................ 19

3.2 LCD SCREEN .................................................................................................................................20

3.2.1 SCHEDULE OPERATION LCD SCREEN..........................................................................................................20

3.2.2 CONVENTION ........................................................................................................................................ 20

3.2.3 STATUS ANALYZER.................................................................................................................................. 21

3.3 USB-PORT ...................................................................................................................................23

3.3.1 SOFTWARE UPDATE................................................................................................................................23

3.3.2 RHOSONICS SERVICE APPLICATION (RHOSONICS SA 9D)...............................................................................23

4. CONFIGURATION .........................................................................................................................24

4.1 INTRODUCTION..............................................................................................................................24

4.2 LCD SCREEN .................................................................................................................................24

4.2.1 HOME PAGE /MEASURED VALUES ...........................................................................................................24

4.2.2 MAIN MENU .........................................................................................................................................24

4.2.3 DECAY TIME..........................................................................................................................................25

4.2.4 BACK-LIGHT ..........................................................................................................................................25

4.2.5 DISPLAY LINES .......................................................................................................................................25

4.2.6 ACCESS CODE........................................................................................................................................26

4.2.7 ADVANCED FUNCTION ............................................................................................................................26

4.2.8 LIQUID SELECT.......................................................................................................................................27

4.2.9 SET BAUD RATE.....................................................................................................................................27