Stage 4

Stage 5

4

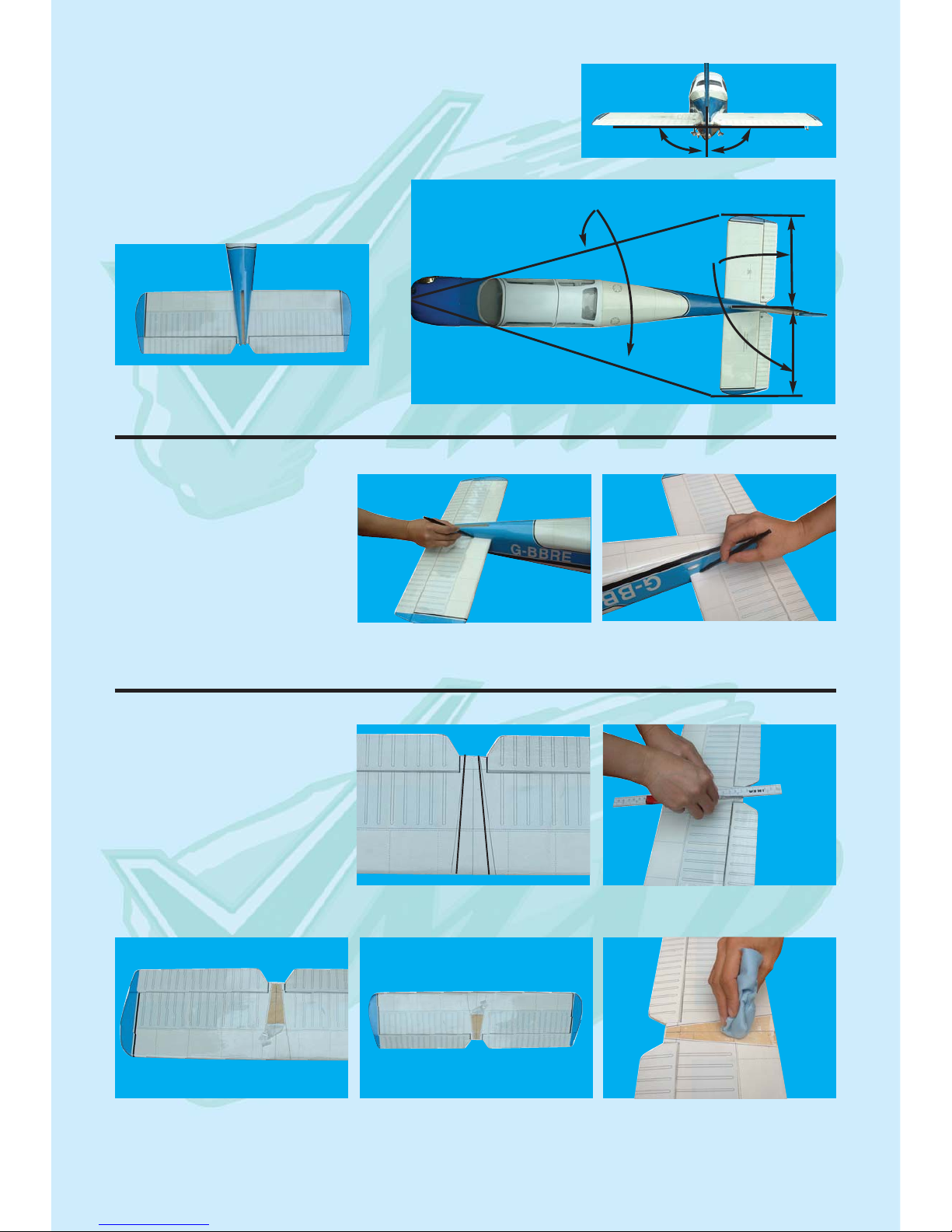

Carefully remove the white cover plates from the aileron

servo cavities. Ensure you know which cover plate is for the

right wing and which is for the left. Remove the white cover

plates and retain the mounting screws. Notice that there are

wooden servo rails pre-installed into each servo cavity end.

Locate the wiring harness tubes that are protruding slightly

into each aileron servo cavity. The tube can be moved slight-

ly at this point. Check out the other end of each tube for a

clean position and then using C/A glue secure the wiring har-

ness tubes at the aileron servo cavity end.

Install a servo in each aileron servo cavity and connect the

servo wire to the servo extension wires and run the extension

wires through wiring harness tubes to the centre of the wing

Install the aileron control horns

Aileron servos cavity

4.2 Aileron servos location

4.3 Aileron servos mount 4.4 Screw servo in position 4.5 Install aileron control horn

Step 1 Consult your radio instruction manual and center each aileron servos by plugging it into the aileron channel

in the receiver. Turn on the transmitter and then the receiver. Center the aileron trim lever on the transmitter.

Remove the servo arm mounting screw and the servo arm.

Step 2 Mount the servo arm back on the servo. Position the arm to be parallel with the back edge of the wing. Screw

the arm into place with the servo arm mounting screw supplied with the servo.

Locate the two aileron control rods in the hardware bag. Ensure the clevises are screwed well onto the threaded

portion of the rod. Rotate and tug aggressively on the clevises and ensure that they are not loose on the rods.

Tape the ailerons into their neutral position so that they are even with the trailing edge of the wing and not pointing

either up or down.

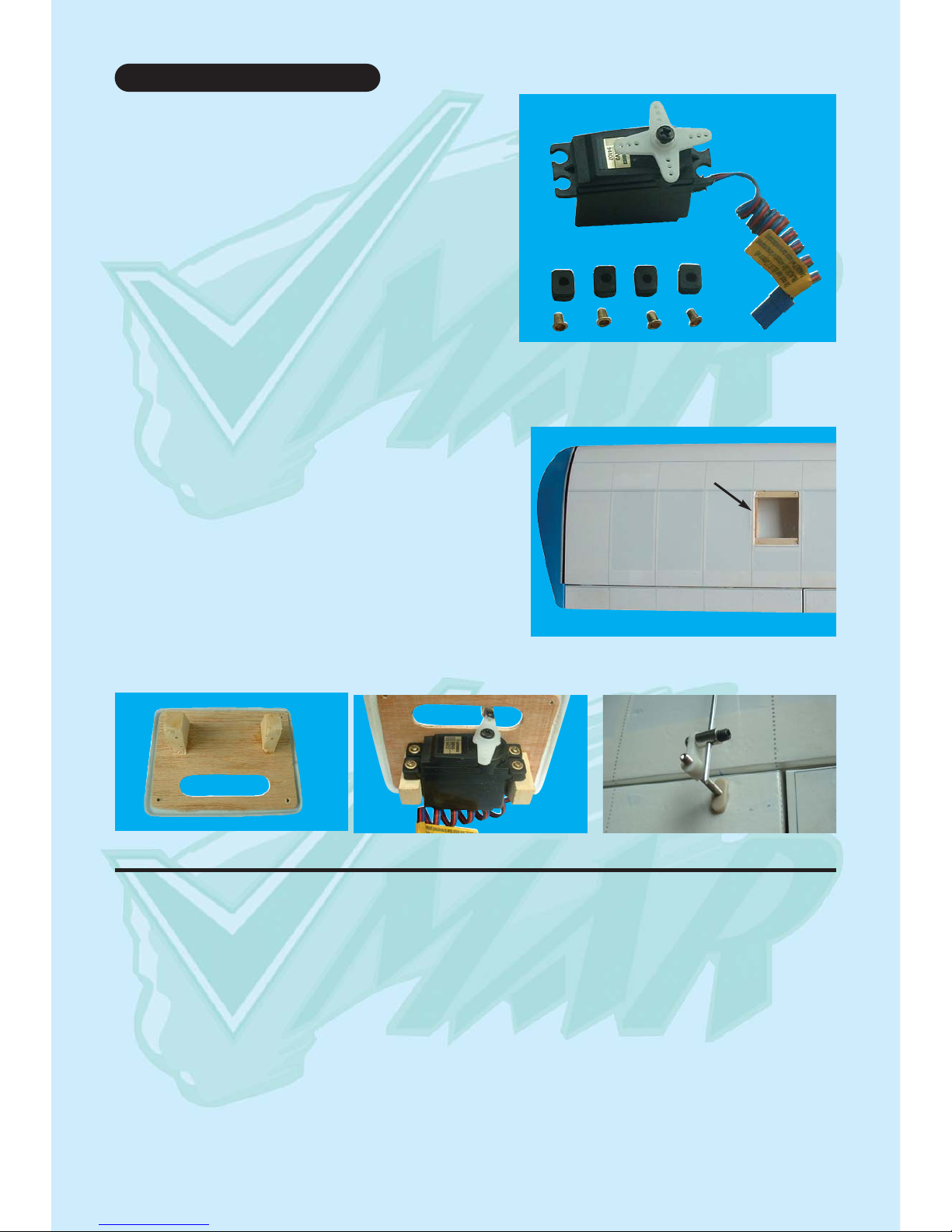

To install the aileron servos into the wing you will need the

following items :

- 2 servos

- Servos mounting screws and grommets as supplied with

servos.

- Servo control arms as supplied with the servos.

- Two aileron control rod assemblies supplied with the kit.

The assemblies consist of a metal rod with a clevis screwed

onto one end.

- Low tack masking tape.

- 2 aileron control horn assemblies

- 1 servo Y connection wire

FITTING AILERON SERVOS

4.1 Prepare the servos by fitting the rubber

grommets & ferrules supplied with your radio