8

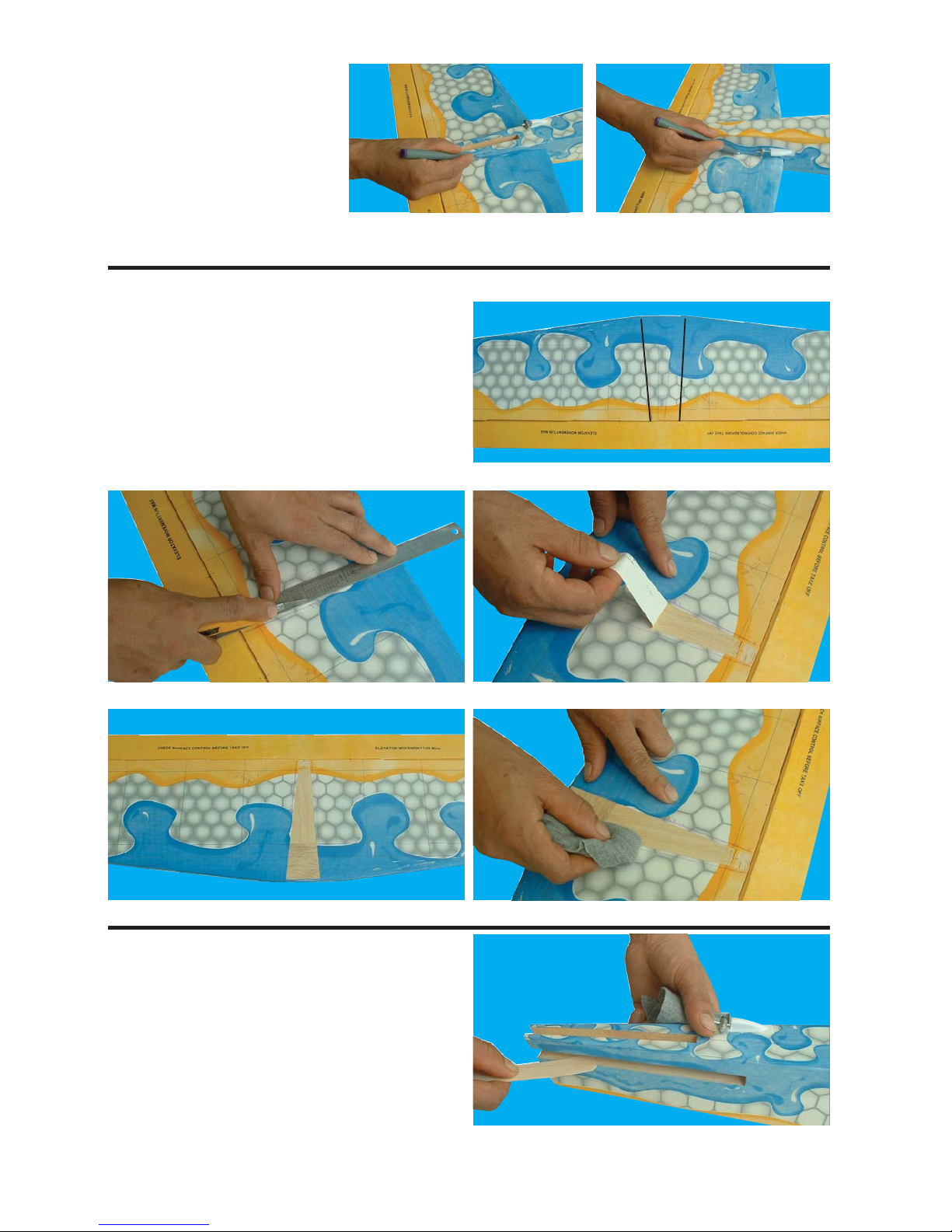

STAGE 13 - INSTALLING THE LANDING GEAR

The HORNET has a tricycle gear configura-

tion (trike gear) using a steerable nose

wheel and main landing gear. Trike gear is

recommended in trainers and makes it

much easier to steer your model on the

ground and to control it during take off

STAGE 14 - FITTING THE MAIN LANDING GEAR

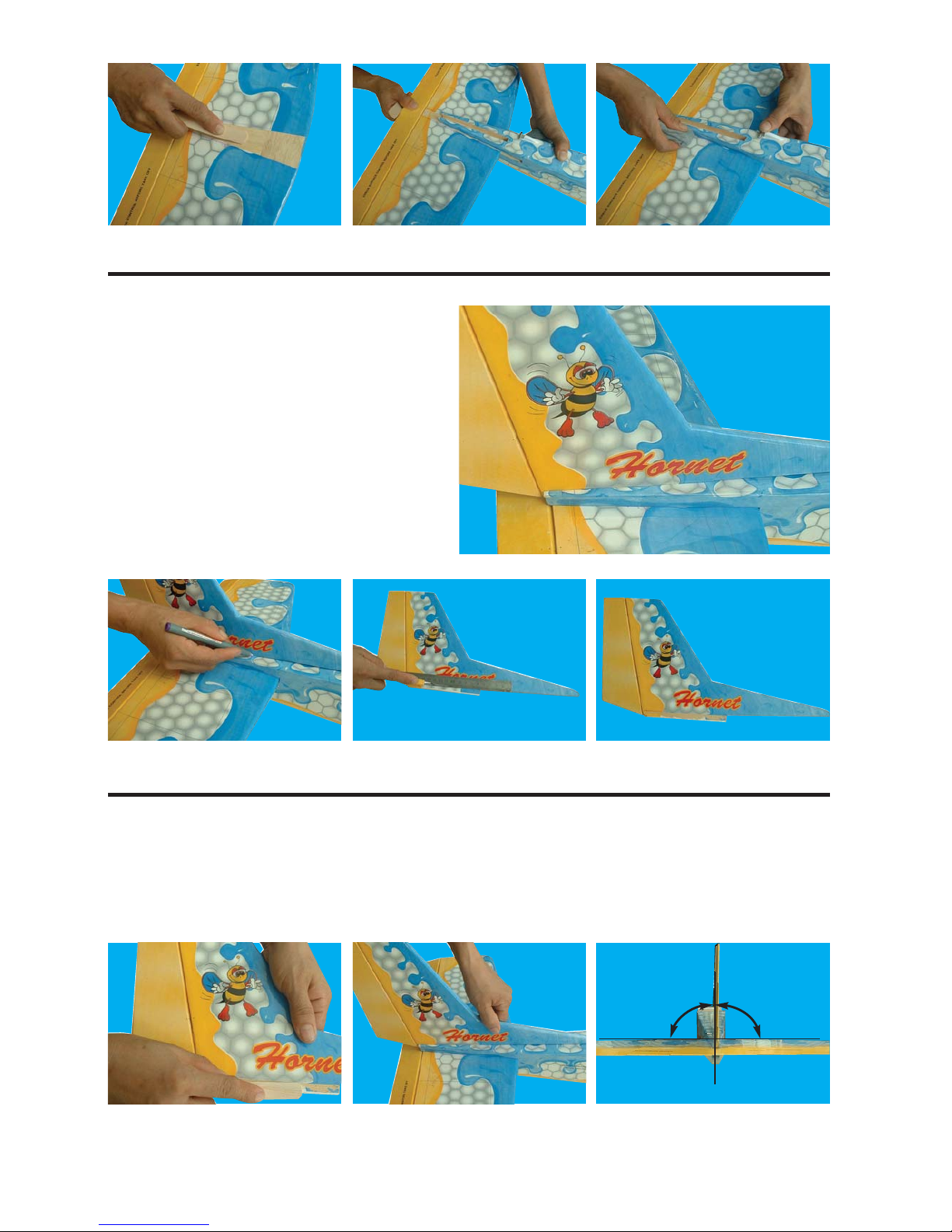

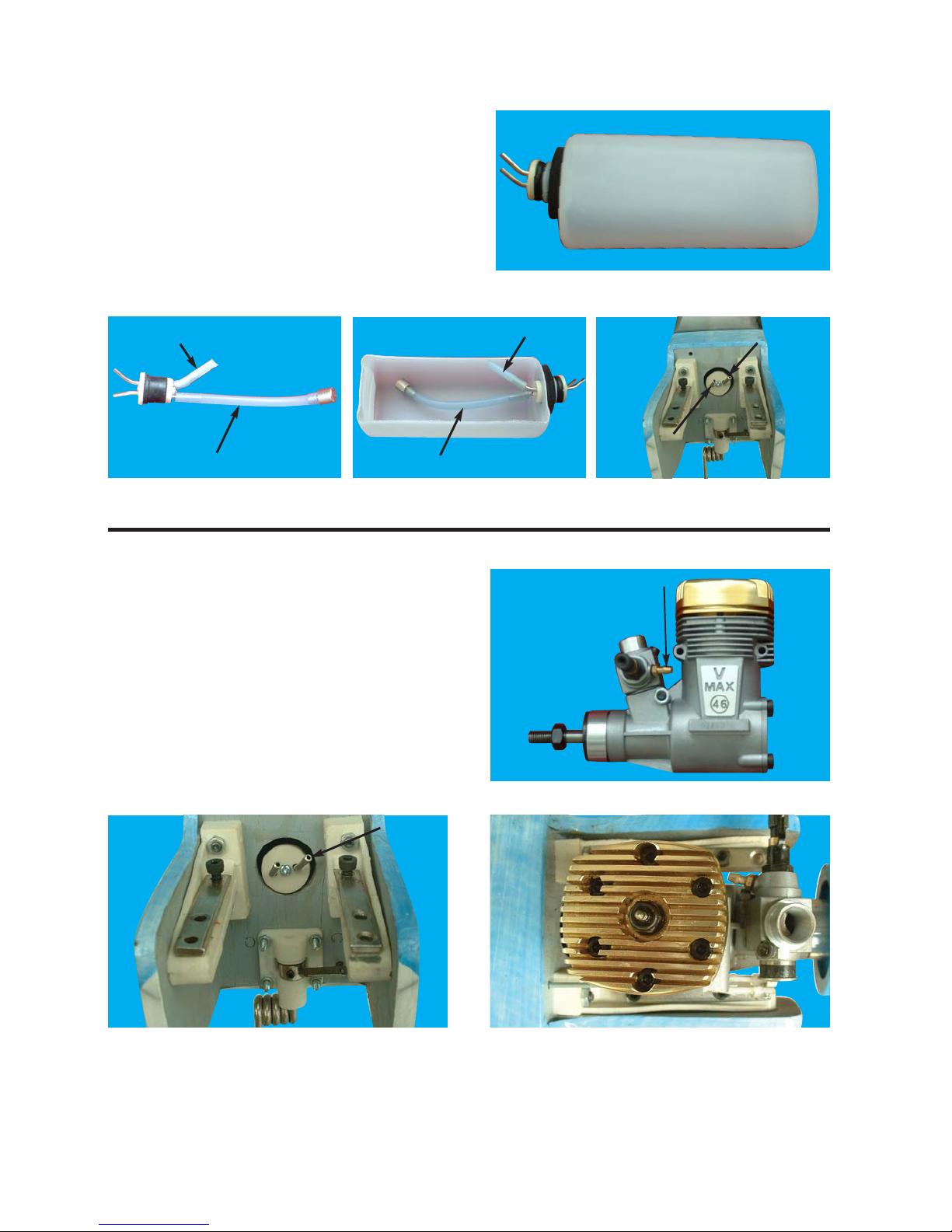

Identify the main landing gear components shown below

- 2 pre-bent main landing gear wires

- 2 main wheels 2-7/16” ( 60mm)

- 4 sheet metal screws and 2 straps

- 4 wheel collars

14A- Main landing gear components

14B- Installation of collars and

wheel to the pre-bent main land-

ing gear wire.

14C- Insert the main landing gear

wires into the fuselage

14D- Use 4 sheet metal screws

and 2 straps to mount the main

landing gears onto the fuselage

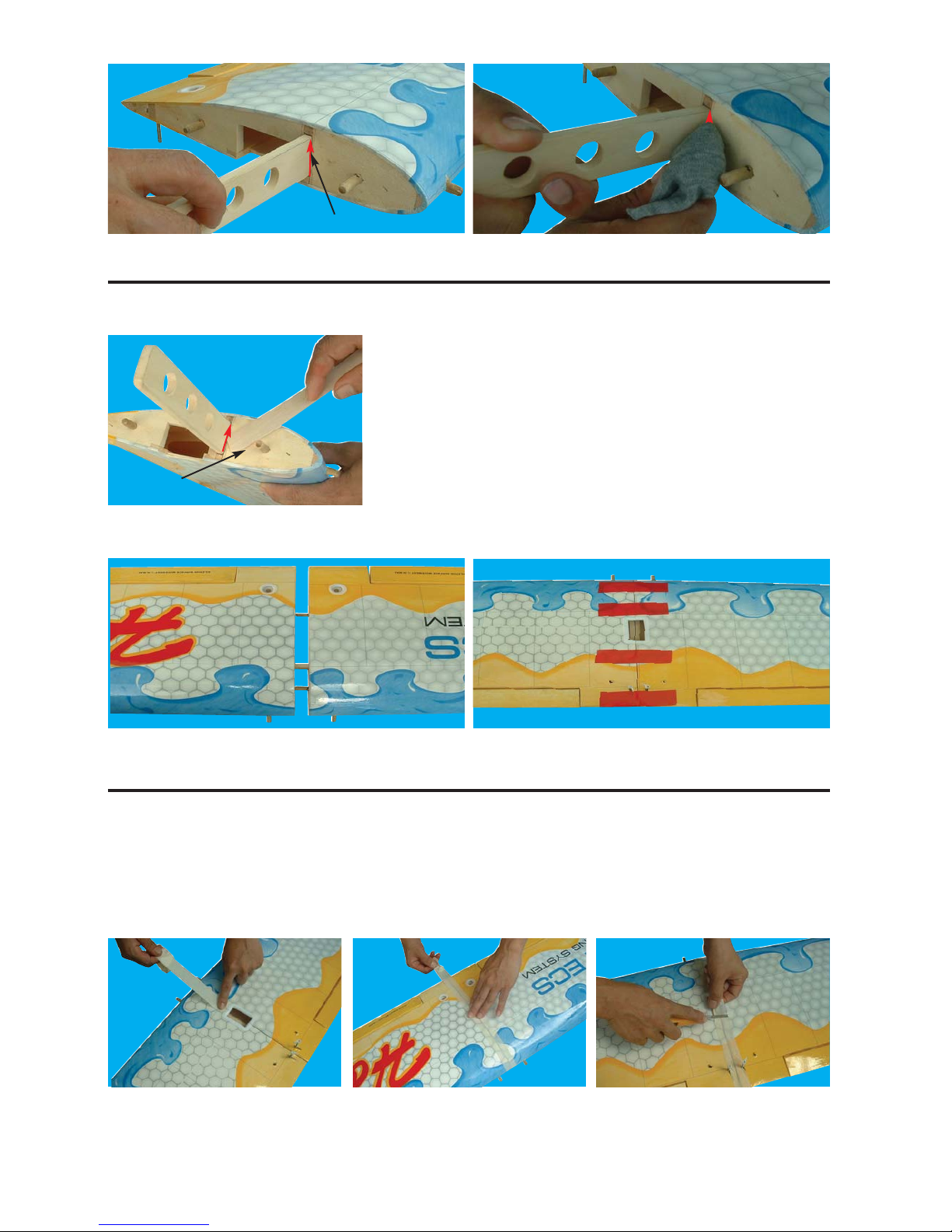

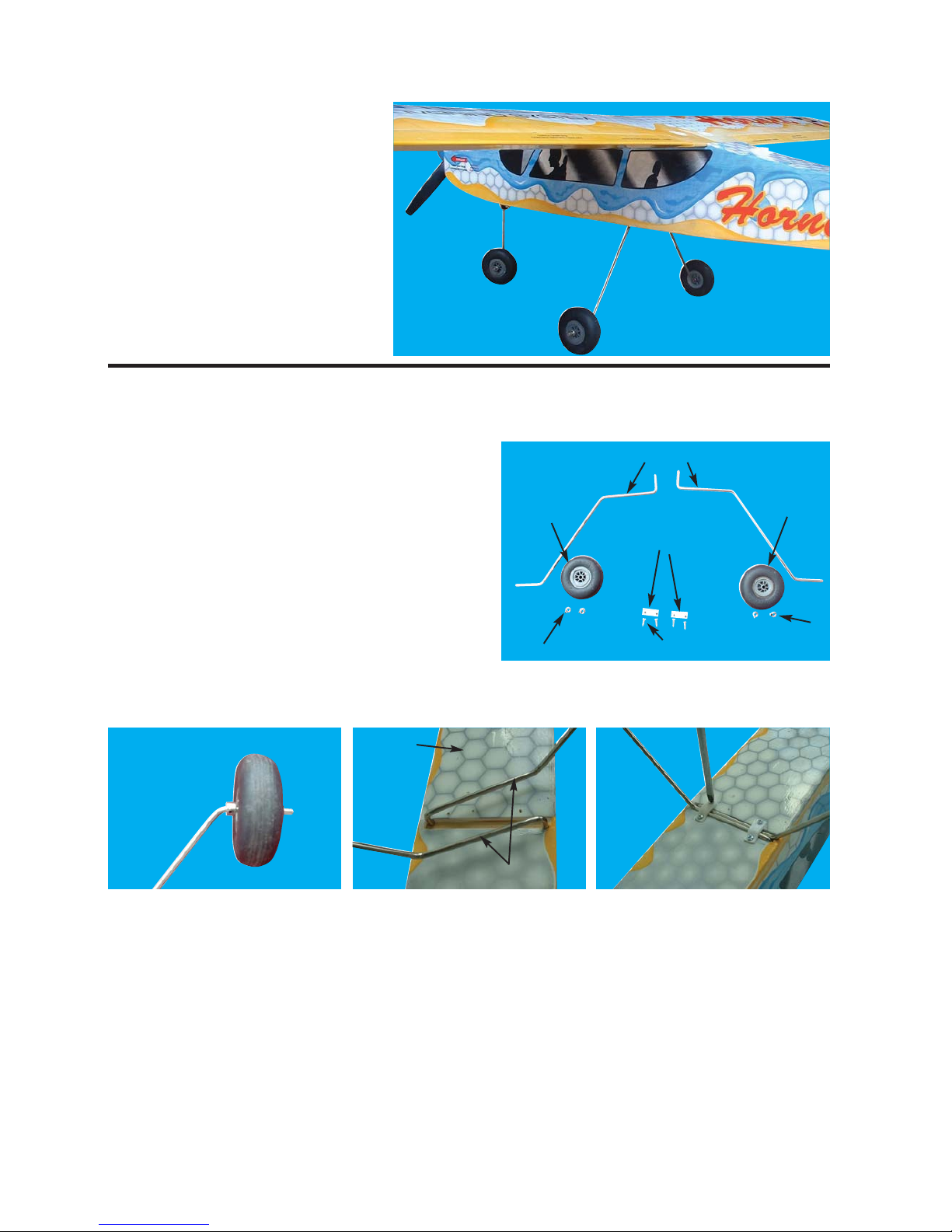

14.1 Place one of the wheel collars

on the pre-bent main landing gear

wires. Tighten the collar set screw.

14.2 Place one of the main wheels

on the pre-bent main landing gear

wires

14.3 Install the second wheel collar

on to the pre-bent main landing gear

wires. Leave enough gap to allow

the wheel to rotate freely (see 14B).

Tighten the collar set screw.

Pre-bent main landing gear wires

Main wheel

Wheel collars

Landing gear straps

Metal screws

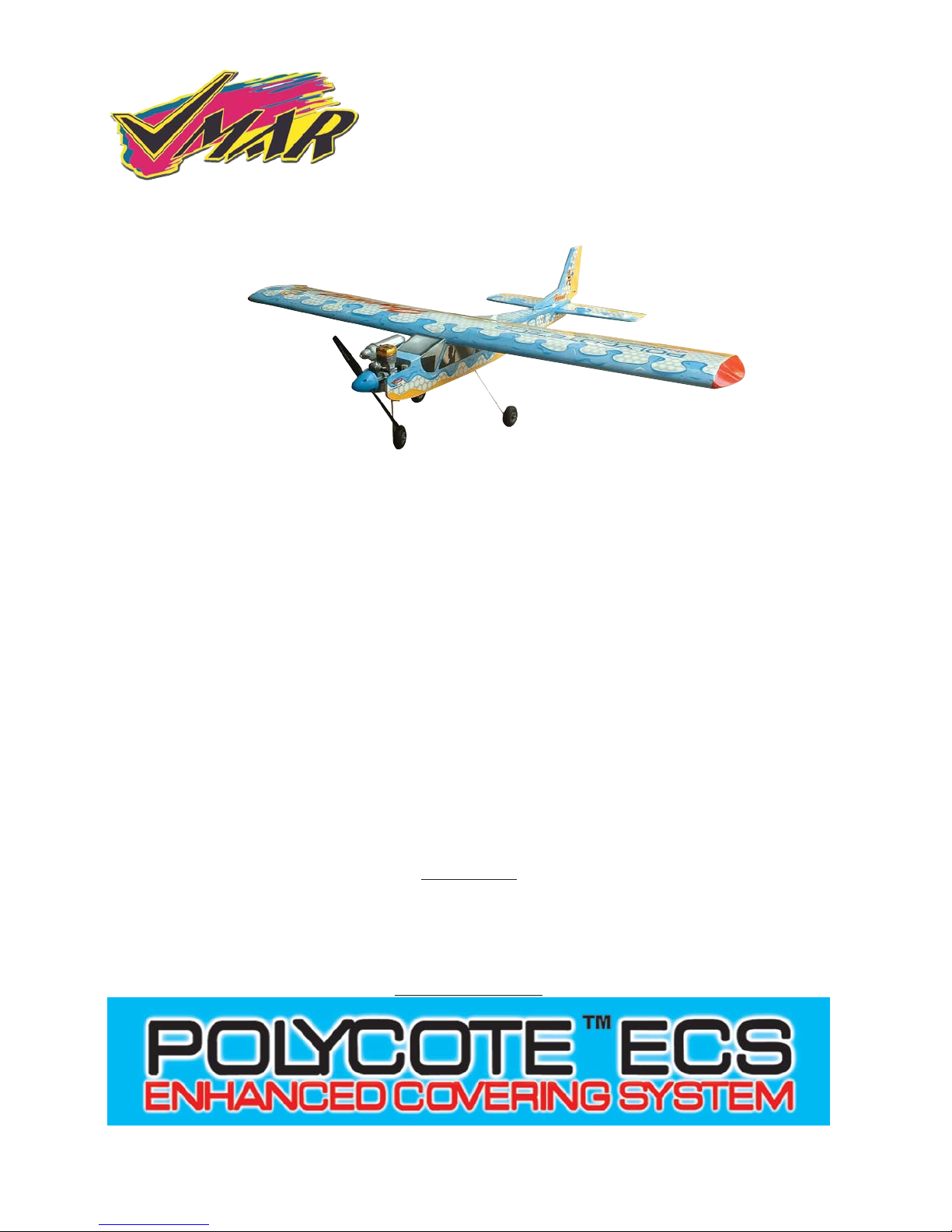

14.4 Turn over the fuselage, identify

the main gear slot.

14.5 Insert the wires into the pre-

drilled holes at the ends of the slot.

14.6 Rotate the wires back and forth

and wiggle the wires down into the

holes until the landing gear is just

slightly away from contacting the

fuselage. See the illustration 14C

14.7 Rotate the two main landing

gear assemblies so that they line up

with the slot in the fuselage. Press

the wires down firmly into the slot.

Tapping with a handle of a screw-

driver will help seat the gear wires

into the slot.

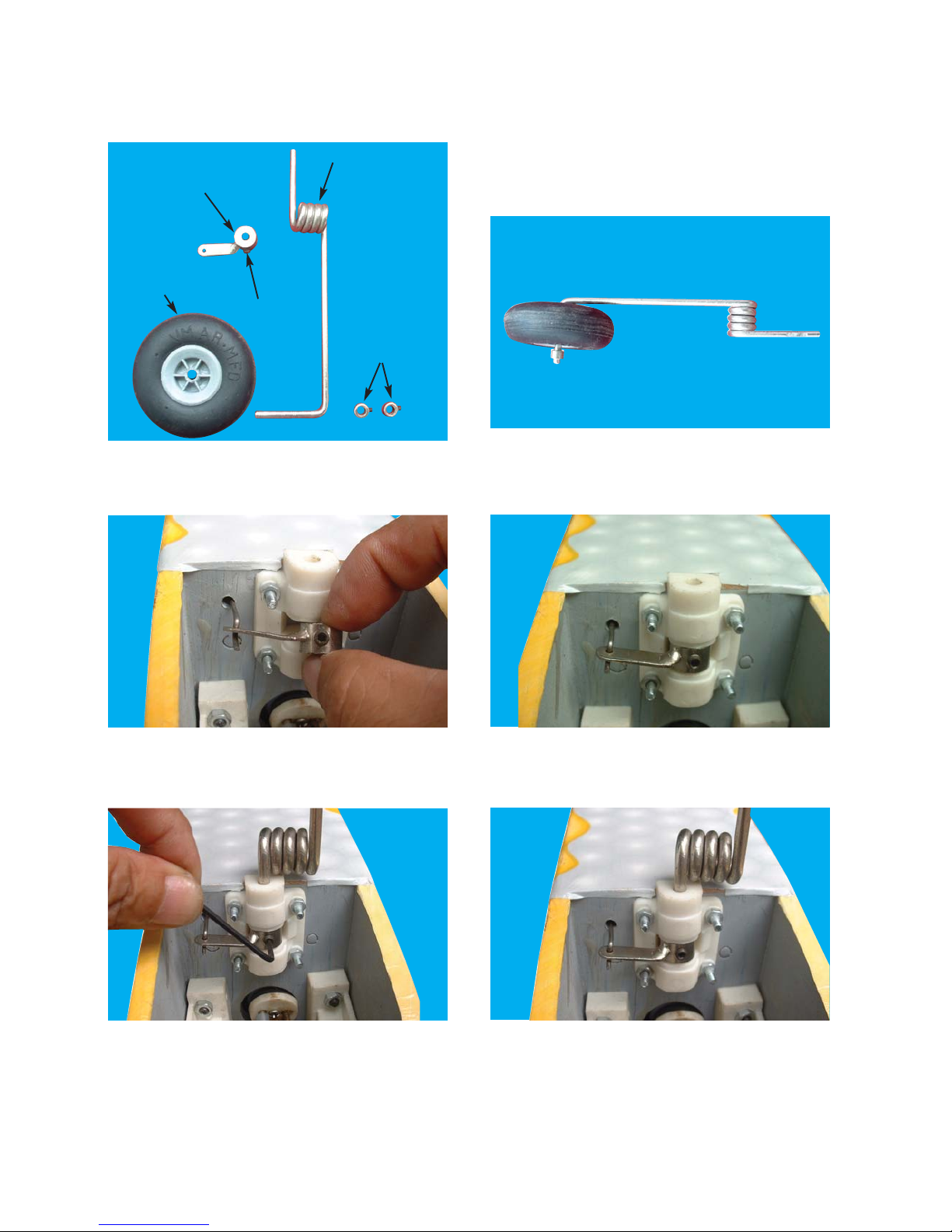

14.8 Use 4 metal screws and 2

straps to secure the main landing

gear assemblies into the slot. See

illustration 14D

Bottom of

fuselage

Main landing gear wires

Main wheel

Wheel collars