RT8509A

8

DS8509A-00 November 2013www.richtek.com

©

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

Application Information

The RT8509A is a high performance step-up DC/DC

converter that provides a regulated supply voltage for panel

source driver ICs. The RT8509A incorporates current mode,

fixed frequency, Pulse Width Modulation (PWM) circuitry

with a built-in N-MOSFET to achieve high efficiency and

fast transient response. The internal driver power is

supplied from the VOUT pin and that will increase efficiency

when low input voltage condition. The following content

contains detailed description and information for

component selection.

BoostRegulator

The RT8509A is a current mode Boost converter integrated

with a 24V/5A power switch, covering a wide VIN range

from 2.8V to 14V. It performs fast transient responses to

generate source driver supplies for TFT-LCD display. The

high operation frequency allows the use of smaller

components to minimize the thickness of the LCD panel.

The output voltage can be adjusted by setting the resistive

voltage-divider sensing at the FB pin. The error amplifier

varies the COMP voltage by sensing the FB pin to regulate

the output voltage. For better stability, the slope

compensation signal summed with the current sense

signal will be compared with the COMP voltage to

determine the current trip point and duty cycle. The Boost

minimum gain ratio depends on minimum on-time. It's

suggested that VOUT higher than 1.2 x VIN for better

performance.

Soft-Start

The RT8509A provides soft-start function to minimize the

inrush current. When powered on, an internal constant

current charges an external capacitor. The rising voltage

rate on the COMP pin is limited from VSS = 0V to 1.24V

and the inductor peak current will also be limited at the

same time. When powered off, the external capacitor will

be discharged until the next soft-start time.

The soft-start function is implemented by the external

capacitor with a 5μA constant current charging to the soft-

start capacitor. Therefore, the capacitor should be large

enough for output voltage regulation. A typical value for

soft-start capacitor is 33nF. The available soft-start capacitor

range is from 10nF to 100nF.

OUT REF REF

R1

V = V x 1 , where V = 1.25V (typ.)

R2

The recommended value for R2 should be at least 10kΩ

without some sacrificing. Place the resistive voltage divider

as close as possible to the chip to reduce noise sensitivity.

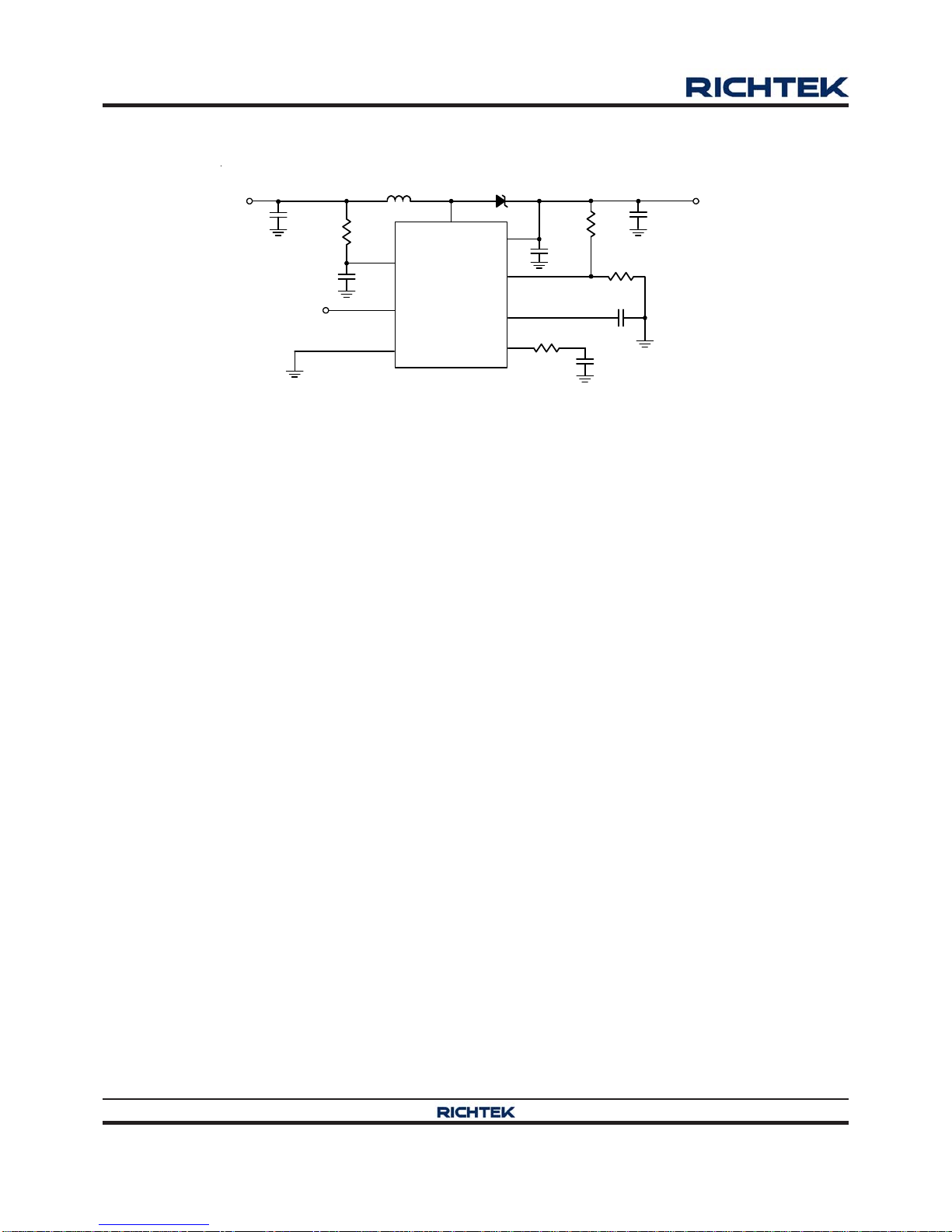

Loop Compensation

The voltage feedback loop can be compensated with an

external compensation network consisting of R3. Choose

R3 to set high frequency integrator gain for fast transient

response and C1 to set the integrator zero to maintain

loop stability. For typical application, VIN = 5V,

VOUT = 13.6V, COUT = 4.7μF x 3, L1 = 4.7μH, while the

recommended value for compensation is as follows :

R3 = 56kΩ, C1 = 1nF.

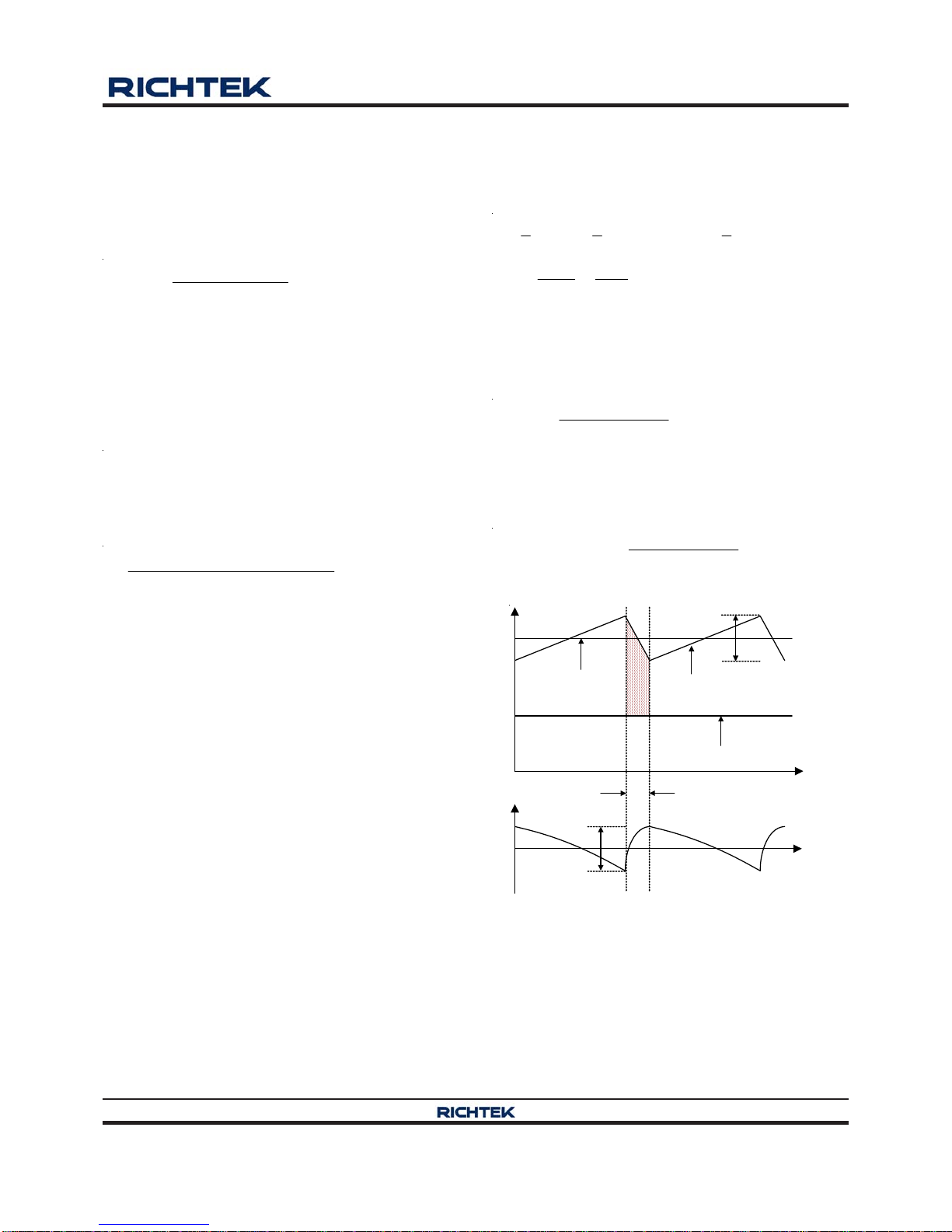

Over-Current Protection

The RT8509A Boost converter has over-current protection

to limit the peak inductor current. It prevents the inductor

and diode from damage due to large current. During the

On-time, once the inductor current exceeds the current

limit, the internal LX switch turns off immediately and

shortens the duty cycle. Therefore, the output-voltage

drops if the over current condition occurs. The current

limit is also affected by the input voltage, duty cycle, and

inductor value.

Over-Temperature Protection

The RT8509A Boost converter has thermal protection

function to prevent the chip from overheating. When the

junction temperature exceeds 155°C, the function shuts

down the device. Once the device cools down by

approximately 10°C, it will automatically restart to normal

operation. To guarantee continuous operation, do not

operate over the maximum junction temperature rating of

125°C.

If CSS < 220pF, the internal soft-start function will be turned

on and period time is approximately 1ms.

Output Voltage Setting

The regulated output voltage is shown as the following

equation :