PUSHCORP, INC.

SBS81 Series Manual 4

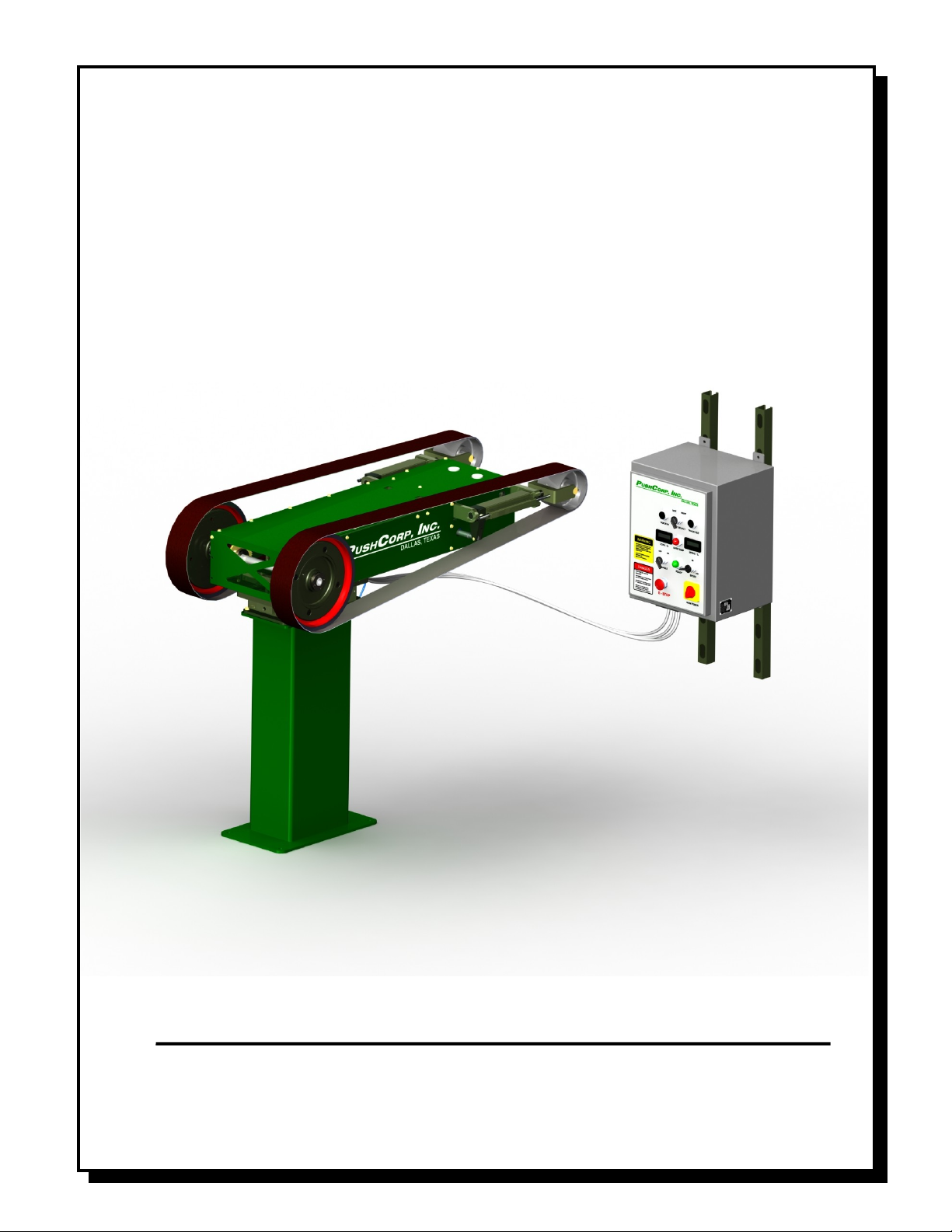

2.0 General Overview

The PushCorp SBS81 Series Servo Belt Stand co bines passive co pliant force

control and closed-loop servo otor speed control technology. The SBS81 has been

designed fro the ground up as a belt stand for robotic finishing with any new and

unique features. Accurate force and speed control allows you to achieve unprecedented

levels of quality and consistency. The SBS81 enables axi u flexibility for any part-

in-hand grinding, sanding, buffing or polishing application. Linear co pliance with 1.6

inches (40 ) of travel and excellent access allow a robot to easily anipulate parts

over the Belt Media. An i portant feature of the SBS81 Belt Stand is the high torque

servo otor and belt drive. The belt drive syste provides a 2:1 increase in torque at

the contact wheels for heavy aterial re oval.

The force control technology in the SBS81 is based on the PushCorp Passive AFD80

Series Force Devices. This technology has proven itself in thousands of hours of

production robotic applications. A basic regulator supplied with SBS81 allows the

SBS81’s force to be varied fro 0 to 50 lbs. (0 to 222 N). This regulator has a coarse

adjust ent and ust be anually set to the desired force output. If the force ust vary

during the finishing process, then an electrically controlled proportional regulator is

required. Very accurate force output requires a precision regulator that operates in a

narrow pressure range.

The SBS81 has a nu ber of notable features that contributes to ease-of-use, and

greater throughput. The Belt Media can be tracked re otely outside the work cell for

convenience and user safety. When the Belt Media needs replacing the operator

anually releases the tension using a lever ounted right on the unit. A belt tension

sensor is provided to notify the user that the Belt Media has not been tensioned. A belt

break sensor is also provided to notify the user if the Belt Media should break. These

sensors can be used by the custo er to progra faults to prevent the syste fro

starting should the Belt Media not be tensioned, or to ove the robot away, and stop the

syste should a belt break. These features protect the user and equip ent, while also

reducing downti e.

In ost any finishing process, consistency is of para ount i portance. For this reason

the SBS81 is powered by a high torque servo otor with adjustable speed control that

can be varied at any ti e during the finishing process. The SBS81 has a 5.7

horsepower (4.28 kW) otor that supplies 14.7 lbft (20 N) of torque and a axi u

speed of 2000 RPM at the contact wheels. This provides a range of Belt Media surface

speeds up to 7330 SFPM (Surface Feet Per Minute). The SBS81 requires 14 inch (356

) dia eter Contact Wheels with a width of 2”, 3”, or 4”. The unit is setup to use

standard 132 inch long Belt Media. For ulti- edia finishing applications, the rubber

contact wheel can be replaced with Scotchbrite, or cloth wheels. This flexibility allows

the SBS81 to perfor a wide variety of finishing applications.

Copyright PushCorp, Inc. 2019. All rights reserved