Ricoma Quick Start Guide8

THREAD RACK, PANEL

AND EMERGENCY STOP

Adjusting the position of the panel

Raising the thread rack

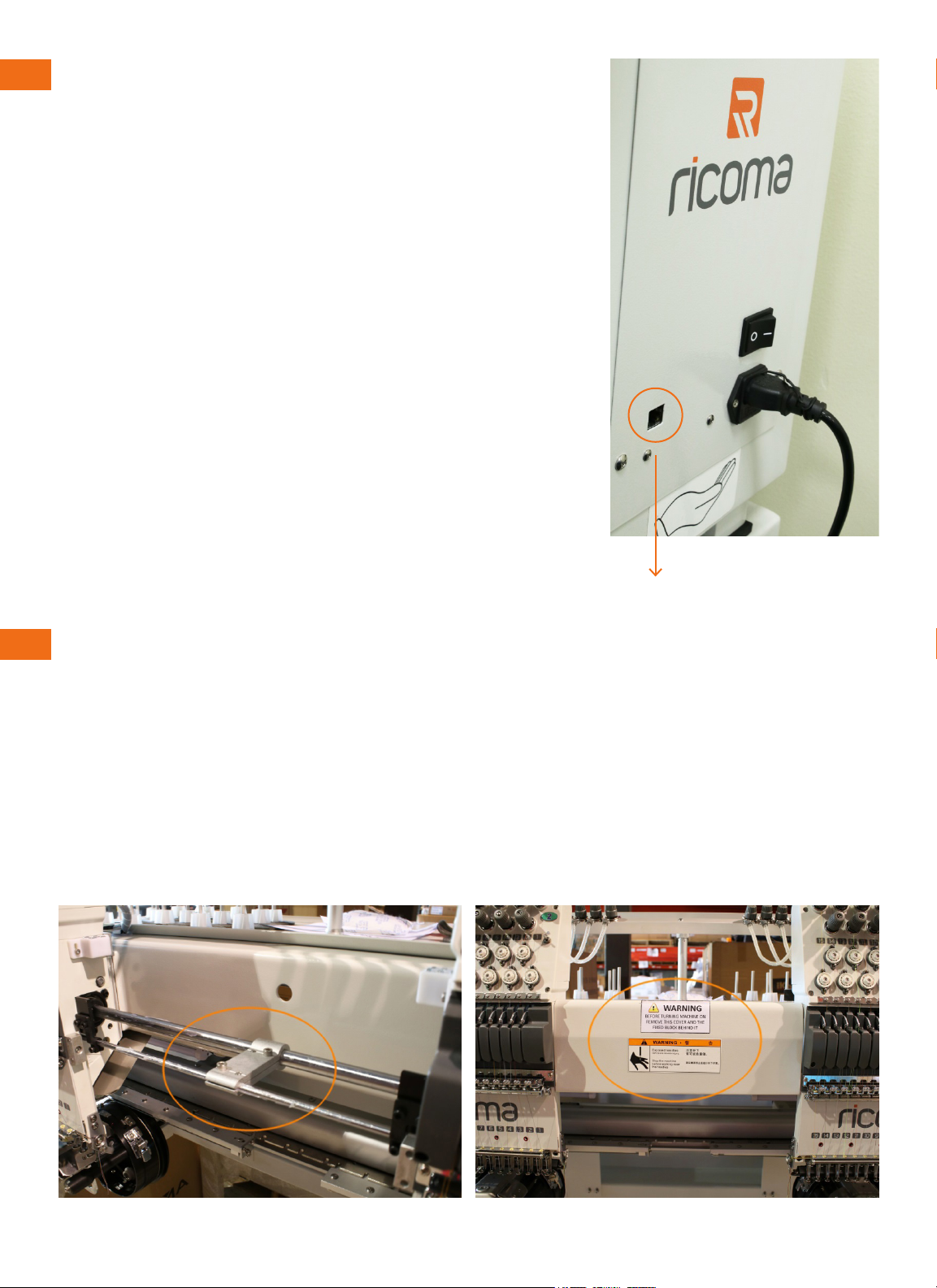

Before threading your machine, you must rst raise the thread rack. See Figure 6. To do so, locate the

knob on each side of the thread rack support. See Figure 7. Rotate each knob counterclockwise to

loosen them. Now, lift the thread rack as far up as possible, making sure both sides of the rack remain

even as it rises. Last, rotate each knob clockwise to secure the rack into place.

First, be sure to remove the plastic wrap that

protects the panel. After removing it, you will nd

two Phillip screws, which will allow you to adjust

the placement of the panel. Your touch-screen

panel can be adjusted in two ways: up and down

or from side to side. To adjust the panel, use the

Phillip screw driver included in your tool box.

To move the panel from side to side, loosen the

screw with the adjustment path located on top of

the panel arm. See Figure 8. Then, adjust the panel

assembly until it’s facing the desired position.

Next, tighten the screw.

To move the panel up or down, loosen the screw

with the adjustment path located on the side of

the panel arm. See Figure 8. Next, adjust the panel

assembly until it’s facing the desired position.

Last, tighten the screw.

TIP:

If possible, raise

the thread rack on

both sides while

adjusting it. This

will ensure it is

positioned evenly.

Figure 6 Figure 7

Figure 8

KEEP IN MIND:

This step is important, as you need to position

the panel away from the machine head in order

to avoid the head hitting the panel when it

moves to the far right.