Ricoma Quick Start Guide10

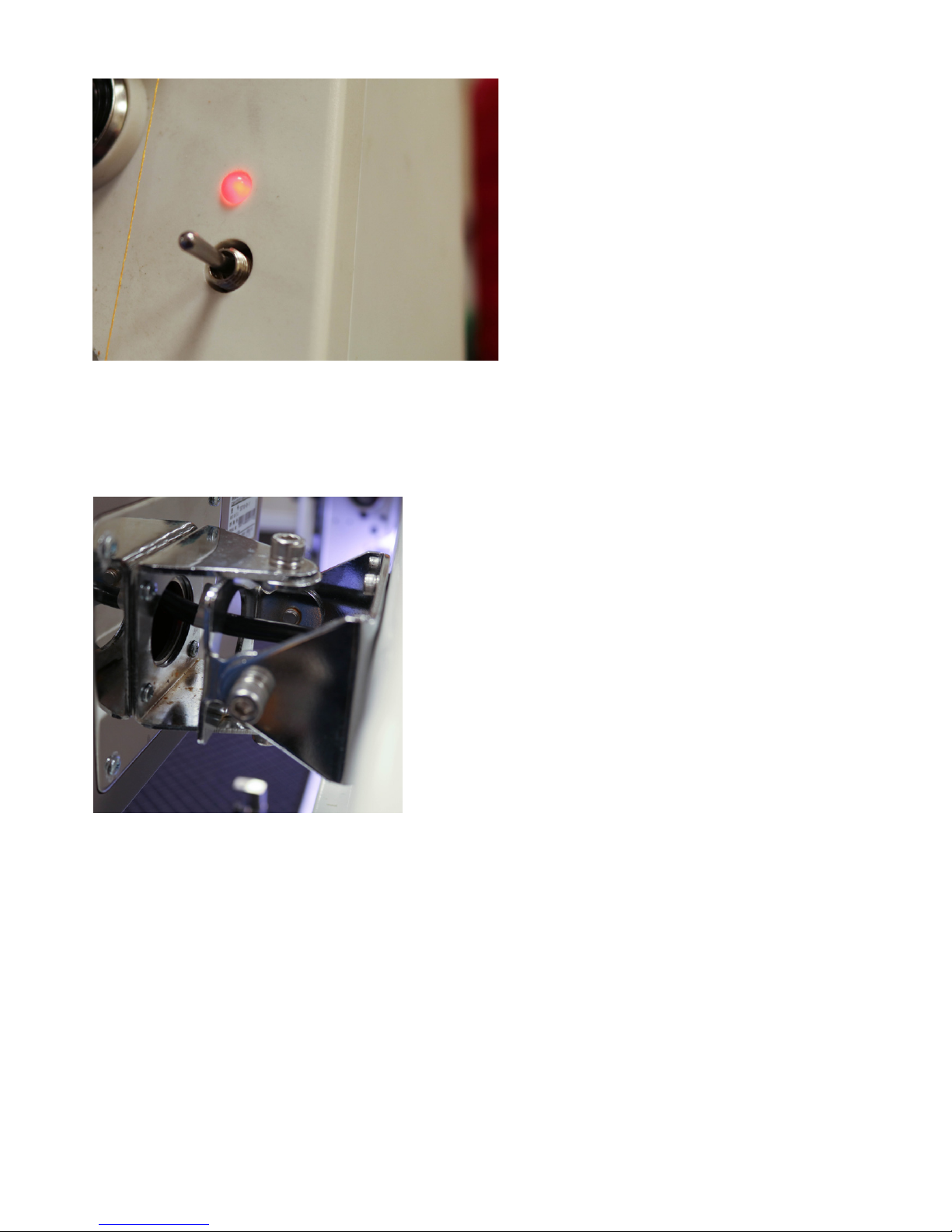

Because your machine comes pre-threaded, you will only need

to replace the spools at rst rather than threading the machine

from the very beginning. To do so, clip the thread from the

existing thread spool. Make sure you clip the thread right above

the spool and not inside the thread path. See Figure 13.

Then, replace the existing spool with a new spool. Next, take the

loose end of the thread from the existing spool and tie it to the

loose end of the new thread in a simple knot. See Figure 14 and

15. Repeat this process on all spools before proceeding.

Now, go to the front of your machine and make sure the threads are separated on their individual thread

paths. Next, unthread the needle and pull each thread carefully

all the way through until you no longer see any of the old thread.

While you pull the thread, you’ll see the new thread and the knot

you created traveling through the thread path. Continue to pull

until you see the knot you created reaches past the needle bar.

Now, clip the thread right above the knot, and repeat the process

on all remaining needles. Once you have completed all needles,

it’s time to thread the needle. Pass the thread through the eye of

the needle starting from the front to the back. Once you made

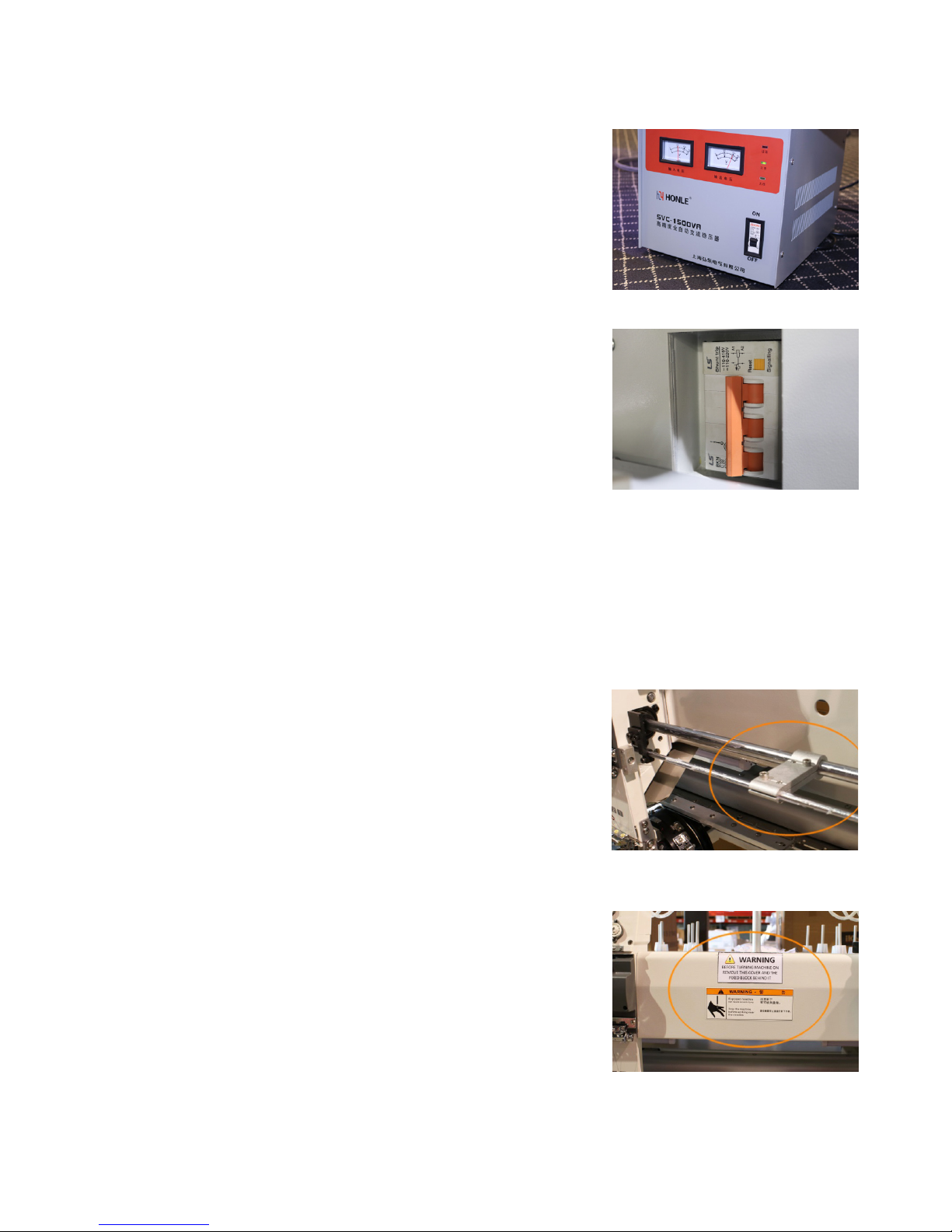

In case of an emergency, press the red emergency stop button

located on the metal cover in between the machine’s heads. Hitting

this button will kill the power immediately. To restart the machine,

rotate the knob clockwise following its directional arrows. The knob

will then release, allowing the machine to be powered on again. Keep

in mind, you need to turn your machine back on to commence. To

turn your machine back on, click on the orange reset button located

next to the power switch. Then, ip the power switch back on. See

Figure 12.

Figure 12

Figure 13

Figure 14

THREADING

Emergency stop button

How to replace a spool