EM-1010 computerized Embroidery Machine Operation Manual V2.0

CONTENTS

PART 1 CONTROL SYSTEM INTRODUCTION.........................................1

1.1 SYSTEM OVERVIEW......................................................................................................... 1

1.2 PRECAUTIONS .................................................................................................................. 1

1.3WORKING ENVIRONMENT............................................................................................... 2

1.4 SYSTEM POWER SUPPLYAND EARTHING........................................................................ 2

1.5 OPERATION PANELAND KEY FUNCTION INTRODUCTION .............................................. 3

1.5-1 Key Function Introduction.....................................................................................................3

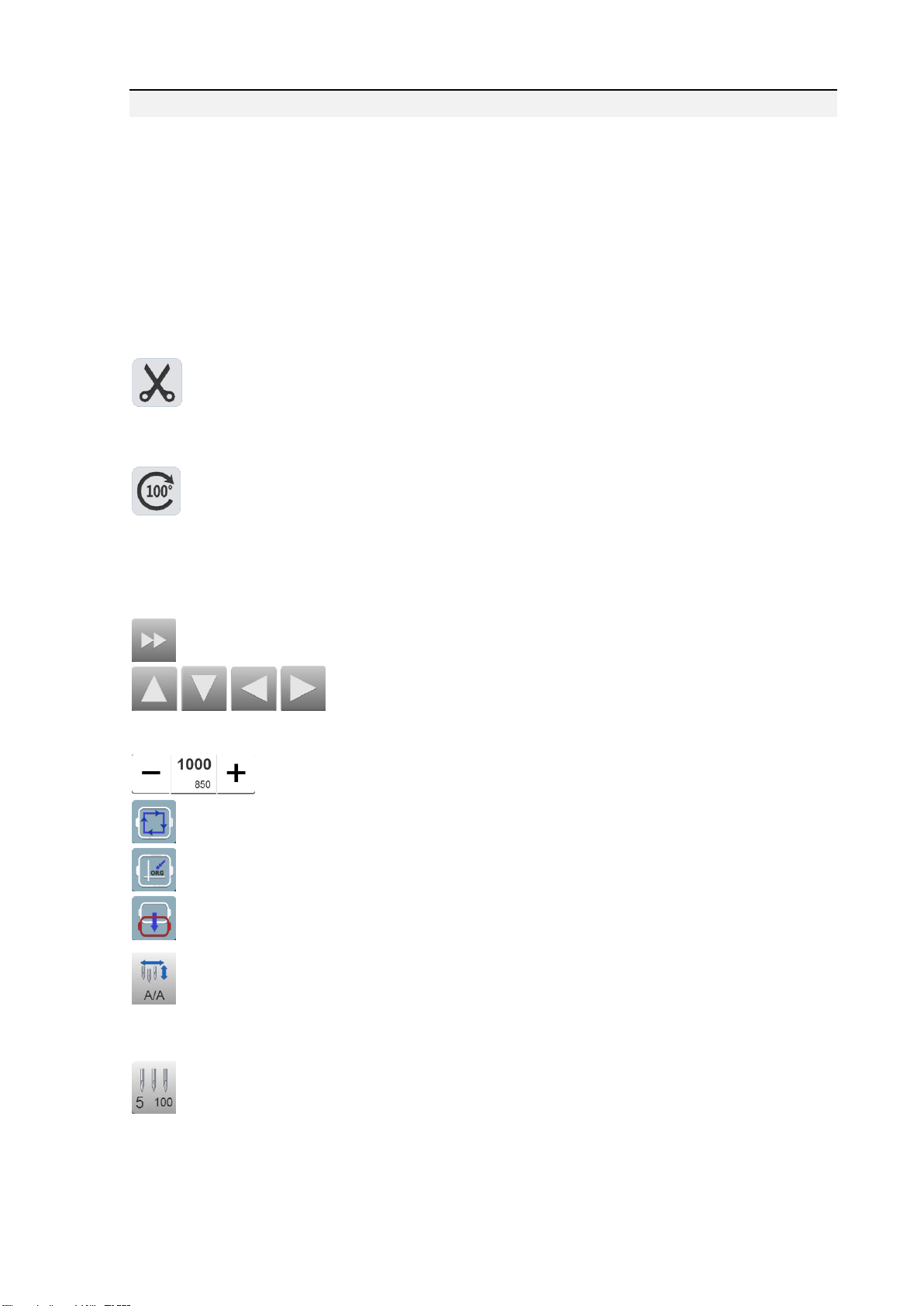

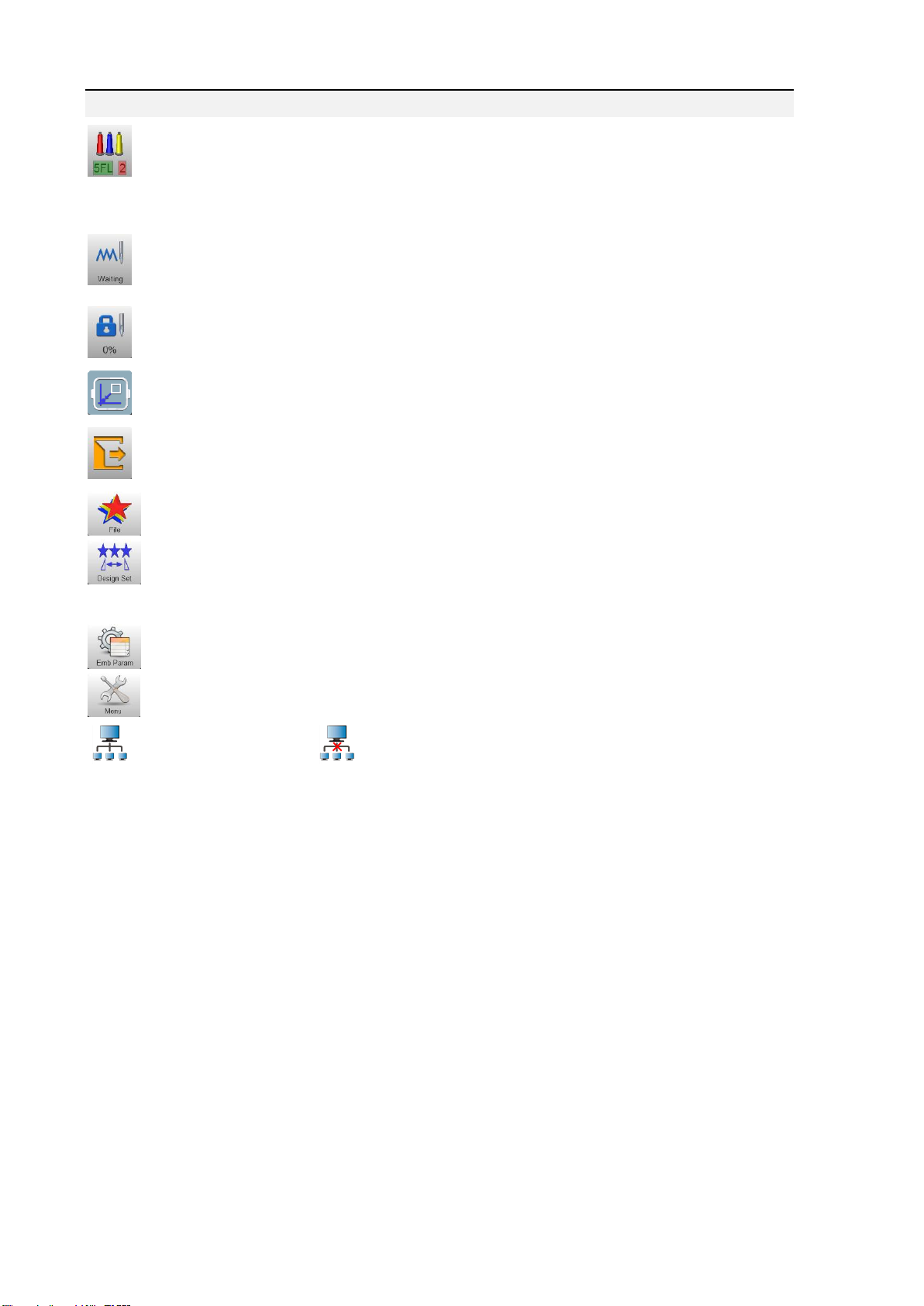

1.5-2 Icons Description of Touch Keys................................................................................................3

1.5-3 Function Introduction.................................................................................................................4

PART 2 EMBROIDERY CARD INPUT OPERATION ................................6

2.1 INPUT U-DISK EMBROIDERY CARD TO MEMORY ........................................................... 6

2.2 DELETE U-DISK EMBROIDERY CARD.............................................................................. 7

PART 3 EMBROIDERY CARD MANAGEMENT........................................8

3.1 SELECT EMBROIDERY CARD FOR EMBROIDERING ........................................................ 8

3.2 DELETE SINGLE EMBROIDERY CARD ............................................................................. 8

3.2 OUTPUT EMBROIDERY CARD TO U-DISK ........................................................................ 9

PART 4 EMBROIDERY CARD .....................................................................10

4.1 EMBROIDERY STATUS SWITCHING................................................................................ 10

4.2 PREPARATION STATUS ....................................................................................................11

4.2-1 Set Embroidery Card Parameters...........................................................................................11

4.2-2 Switch Tabouret.........................................................................................................................12

4.3WORKING STATUS.......................................................................................................... 13

4.3-1 Embroidery Card Origin (Starting Point) Setting..................................................................13

4.3-2 Offset Point (Highest Point of Tabouret Center) Setting.......................................................13

4.3-3 Return to Origin (Starting Point).............................................................................................14

4.3-4 In and Out Tabouret Operation...............................................................................................14

4.3-5 Return to Stop Point..................................................................................................................14

4.3-6 Set Color Changing...................................................................................................................14

4.3-6-1 Set Color Changing Sequences .............................................................................................15

4.3-6-2Applique Offset, Low Speed Embroidering and Needle Bar Replacement.......................16

4.3-6-3 Multi-tinsel Design.................................................................................................................16

4.3-7 Change Working Mode.............................................................................................................17

4.3-8 Embroidering Mode Switching................................................................................................17

4.3-9 Embroidery Card Contour Operation ....................................................................................19

4.3-10 Operation of Returning to Embroidering Point in Power Failure......................................19