Ricoma Quick Start Guide2Ricoma Quick Start Guide 3

TABLE OF CONTENTS

EMBROIDERING WITH THE EXTENDED TABLE

How to install the extended table .................................................................................................................21

Hooping and attaching the sash frame........................................................................................................22

How to hoop the sash frame.........................................................................................................................22

Attaching the sash frame..............................................................................................................................23

HOOPING

Centering a left-chest logo ............................................................................................................................23

Hooping recommendations ..........................................................................................................................24

Hooping at garments...................................................................................................................................25

Hooping the front or sides of a cap ..............................................................................................................25

Hooping the back of a cap using a round hoop ...........................................................................................26

CONTROL PANEL OVERVIEW

Full embroidery process from start to nish................................................................................................28

How to change your embroidery status .......................................................................................................29

Design menu ..................................................................................................................................................29

How to import and select a design ..............................................................................................................29

How to export a design..................................................................................................................................30

How to delete a design from your machine’s memory ............................................................................... 30

Onboard Lettering ..........................................................................................................................................31

Hoop Selection...............................................................................................................................................31

Design Settings Menu ...................................................................................................................................32

Color Sequence Settings...............................................................................................................................35

Design Tracing ...............................................................................................................................................37

Embroidery Speed..........................................................................................................................................38

Directional Arrows .........................................................................................................................................38

Frame Shift Direction/Speed Increments.....................................................................................................38

Stitch Mode/Emb Mode ................................................................................................................................39

Floating Menu ................................................................................................................................................39

Manual Color Change/Needle Display..........................................................................................................40

Return to Stop Point ......................................................................................................................................40

Trimming ........................................................................................................................................................40

GETTING STARTED: MACHINE OVERVIEW

Machine Contents............................................................................................................................................ 6

Machine Components .....................................................................................................................................8

Machine Setup ................................................................................................................................................. 9

Assembling the Stand ....................................................................................................................................9

Adjusting the position of the panel...............................................................................................................10

Raising the thread rack..................................................................................................................................11

Turning on the machine – power cord connection......................................................................................11

THREADING

How to replace a spool..................................................................................................................................11

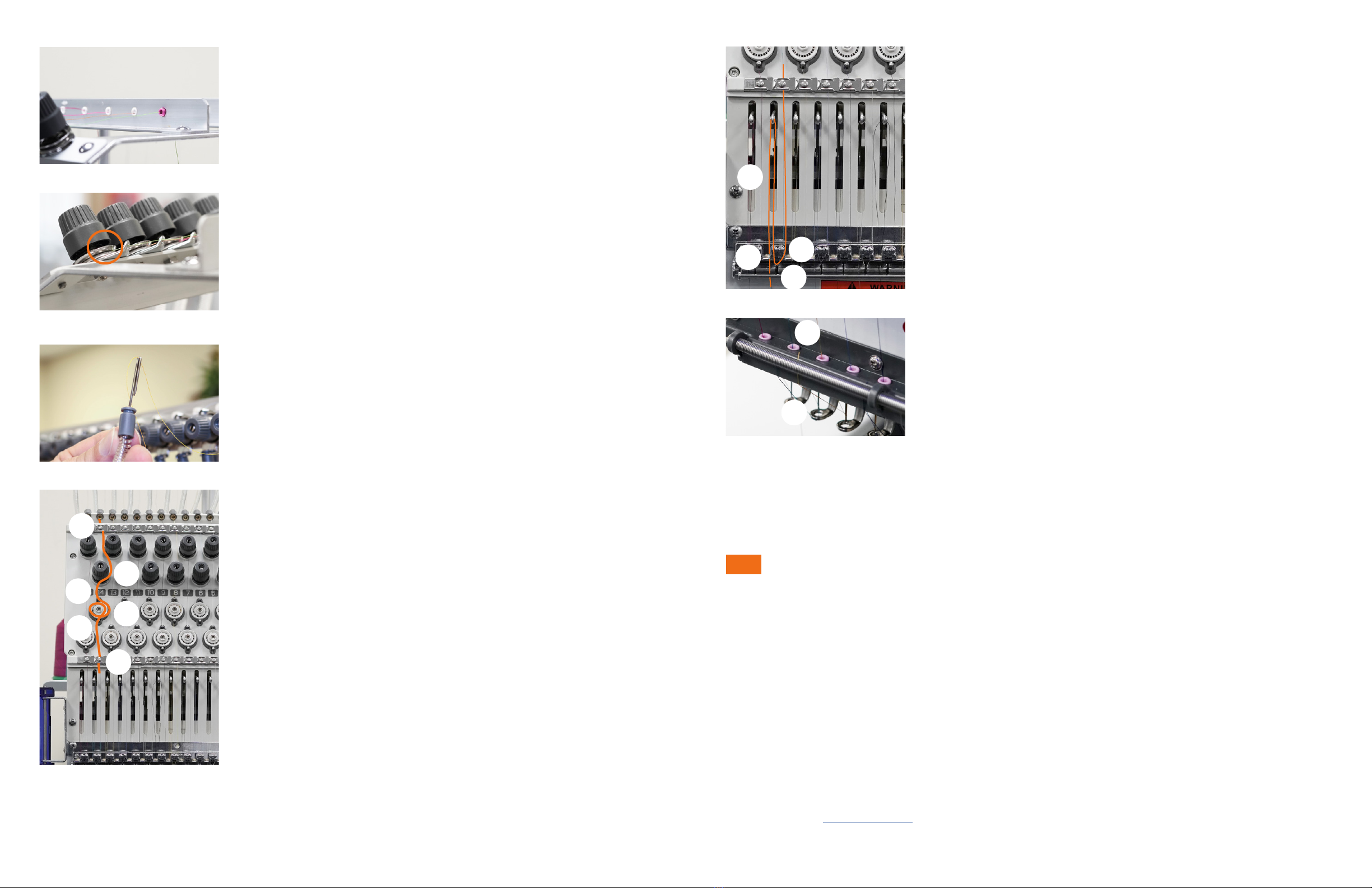

Threading the needle .....................................................................................................................................12

Threading the machine from start to nish..................................................................................................12

INSTALLING THE NEEDLE

Selecting a needle..........................................................................................................................................15

How to install the needle...............................................................................................................................16

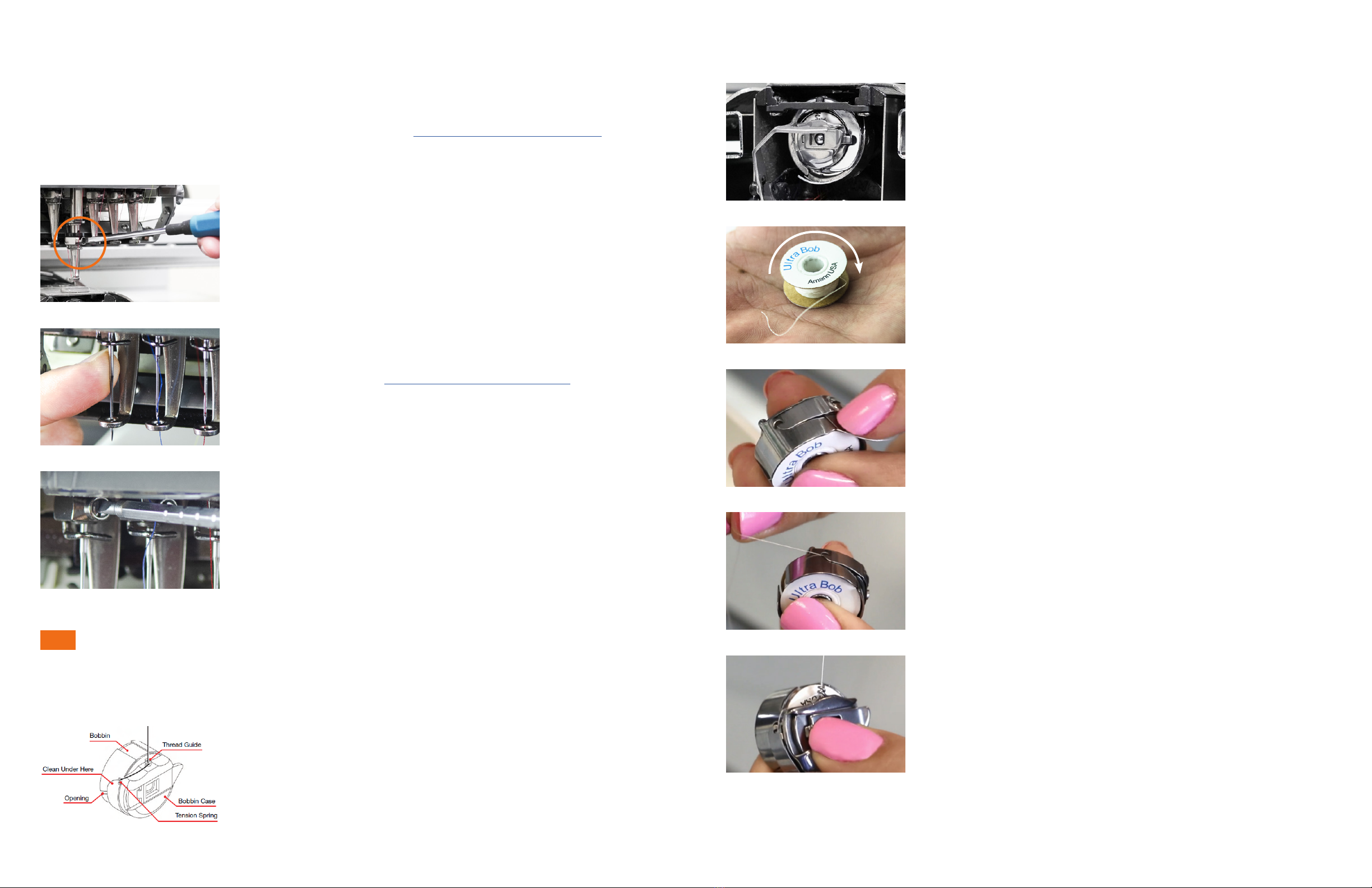

INSTALLING THE BOBBIN

The anatomy of the bobbin case ..................................................................................................................16

Inserting the bobbin.......................................................................................................................................17

HOOPS AND BRACKETS

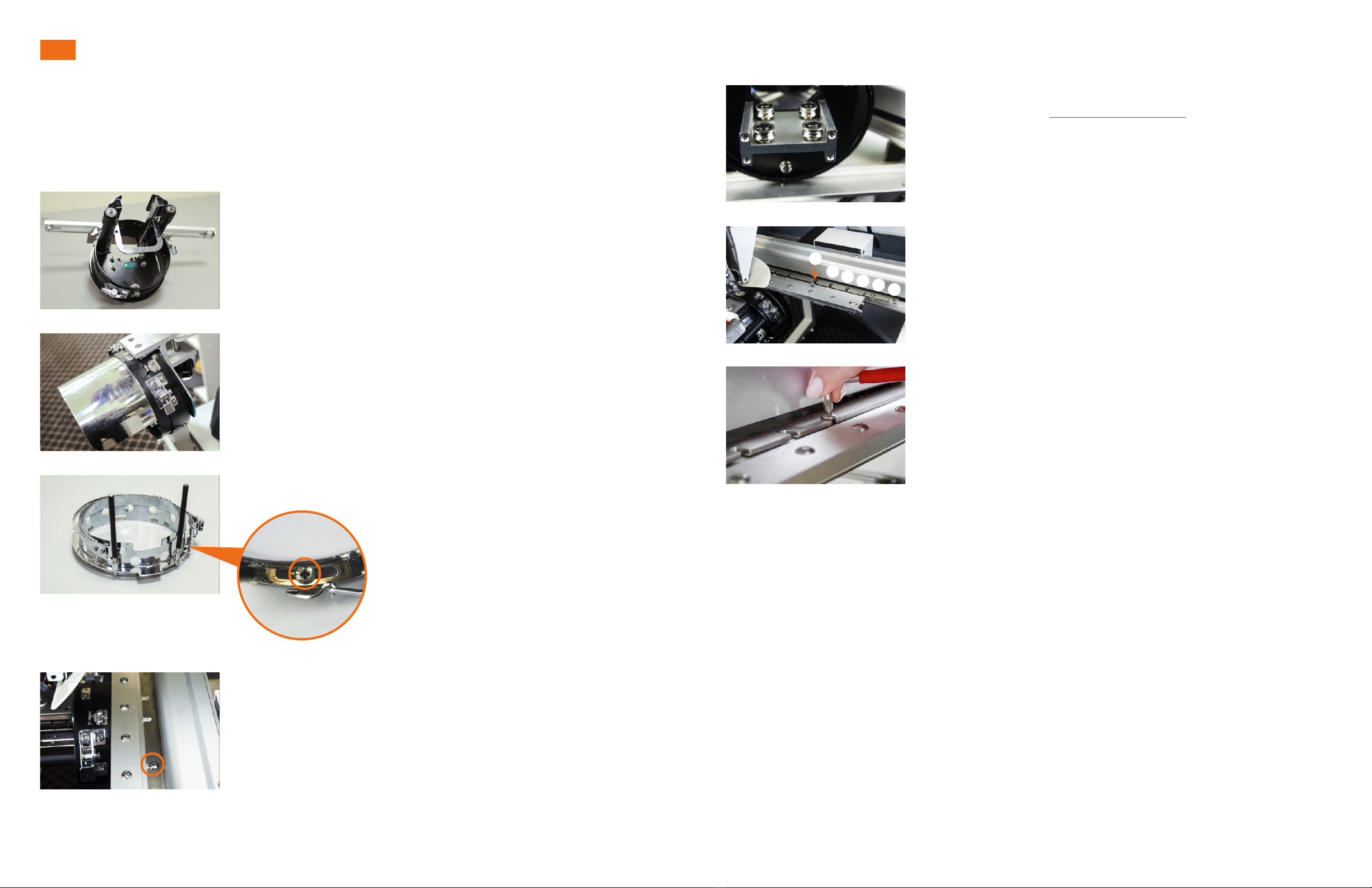

Cap rings and cap attachments....................................................................................................................18

How to remove the cap driver .......................................................................................................................18

Installing the cap driver.................................................................................................................................19

Flat hoops and brackets................................................................................................................................19

How to attach the at frame bracket............................................................................................................20

How to remove the at frame bracket..........................................................................................................20

How to insert the hoop into the machine..................................................................................................... 20

How to remove the hoop from the machine.................................................................................................21