KJ-2200 Water Jetter Machine

Ridge Tool Company 3

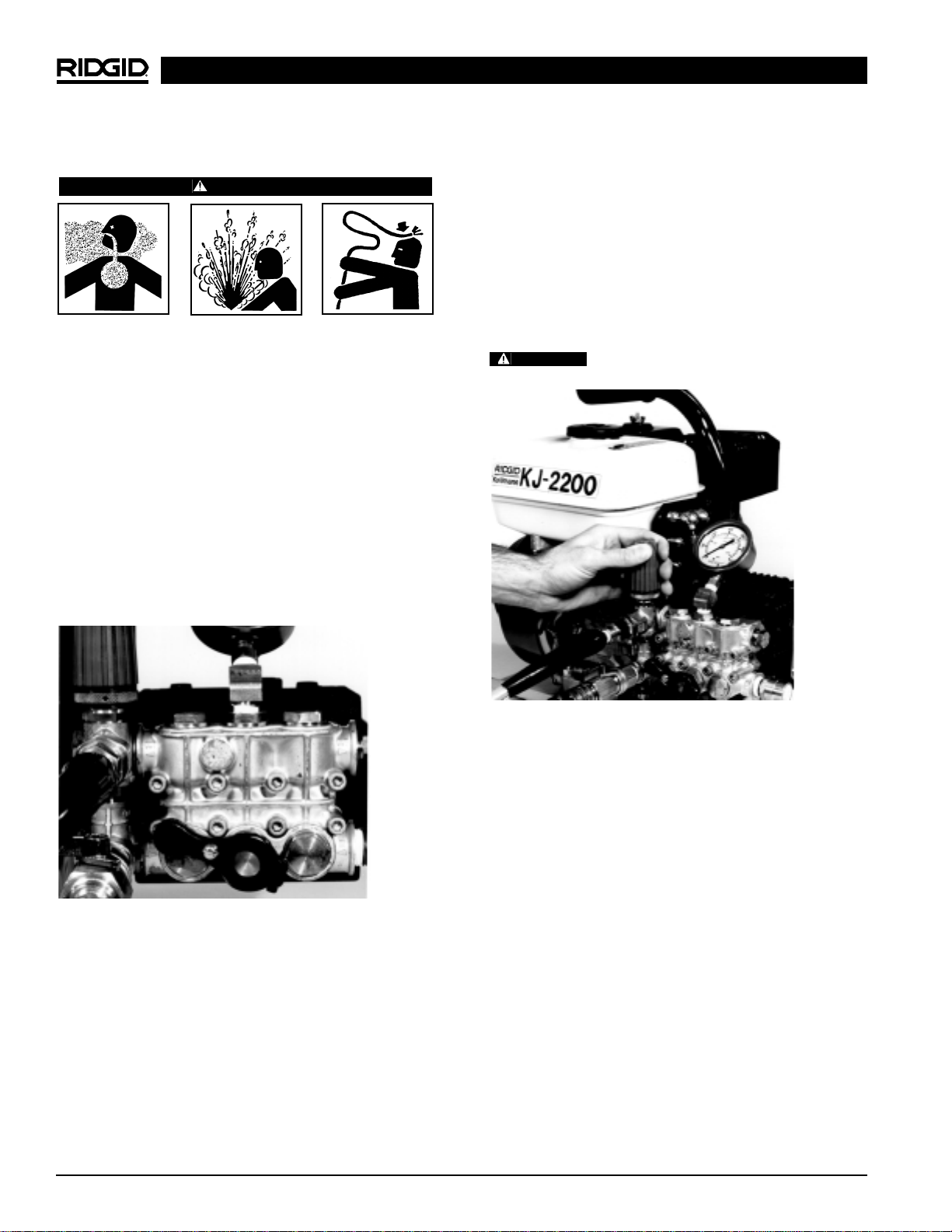

pipe being cleaned. Hose can whip and nozzle spray

can penetrate the skin causing serious injury.

•Use caution when handling gasoline. Refuel in

well-ventilated area. Do not overfill fuel tank and do

not spill fuel. Make sure tank cap is closed prop-

erly. Gasoline is extremely flammable and is explosive

under certain conditions.

•Never run the engine in an enclosed or confined

area. Exhaust contains poisonous carbon monoxide

gas; exposure may cause loss of consciousness and

may lead to death. Exhaust also contains chemicals

that the State of California believes may cause cancer

or reproductive harm.

•Be careful not to touch the muffler while it is hot.

To avoid severe burns or fire hazards, let the en-

gine cool before transporting or storing it indoors.

The muffler becomes very hot during operation and re-

mains hot for a while after stopping the engine.

•Water spray should not be pointed at any human.

High pressure spray can result in serious injury. If

fluid seems to have penetrated skin, seek emergency

medical attention at once.

•Be careful when cleaning drains where cleaning

compounds have been used. Avoid direct contact

with skin and eyes. Serious burns can result from

some drain cleaning components.

•Jetter is designed to clean drains. Follow instruc-

tions in Operator’s Manual on machine’s uses.

Other uses may increase the risk of injury.

•Do not spray flammable liquids. Spraying flammable

liquids could cause a fire or explosion.

•Do not spray toxic chemicals such as insecticide or

weed killer. Chemicals can be harmful to personnel.

•Never clean the machine using its own spray wand.

High pressure spray may damage machine compo-

nents.

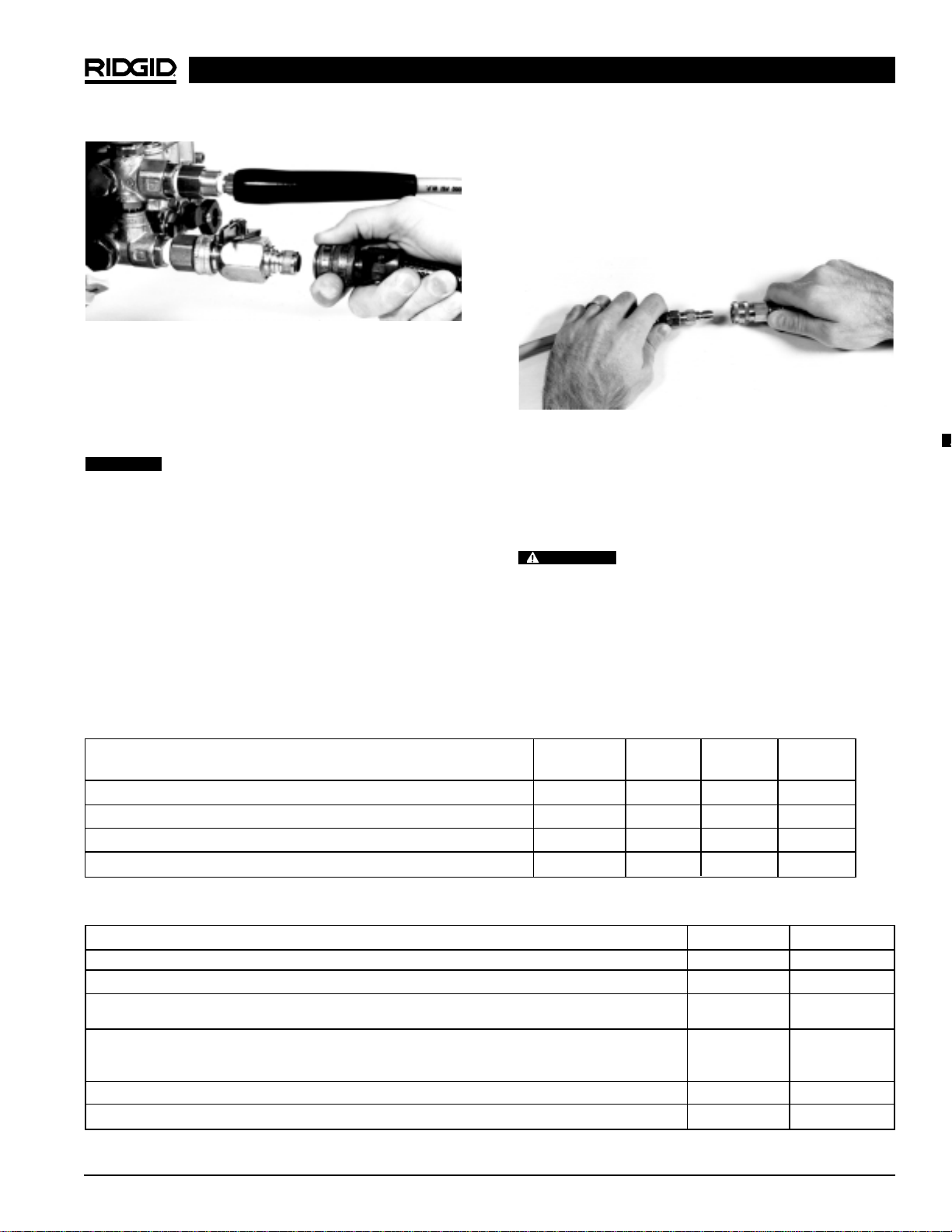

Description, Specifications and

Standard Equipment

Description

The RIDGID KJ-2200 is a portable water jetter designed

to use the combination of water pressure and flow to

clear grease and sludge out of 11/4″to 6″drain lines. The

Jetter can be either hand carried or combined with a two

wheeled cart and hose reel. The KJ-2200 has a 5.5 HP

gasoline engine with a 2200 psi pressure rating and a 2.4

gpm flow rate.

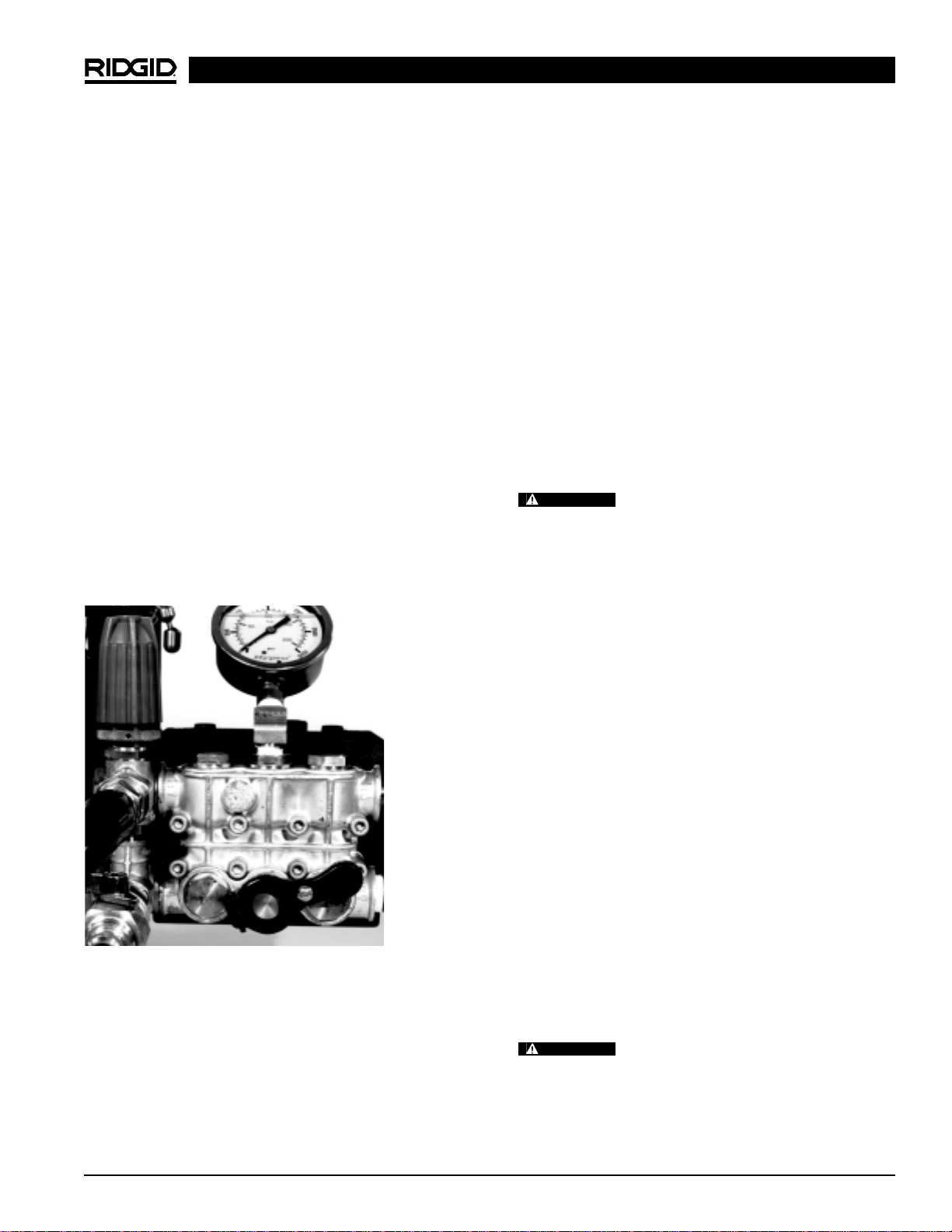

Specifications

Line Capacity.................Recommended for 11/4″to 6″

drain lines through 200 feet

Engine...........................5.5 HP Gasoline Engine

Pump:

Type...........................Triplex Plunger

Pressure.....................2200 PSI

Flow Rate...................2.4 GPM

Weight (Jetter Only) ......59 lbs. (26.8 kgs.)

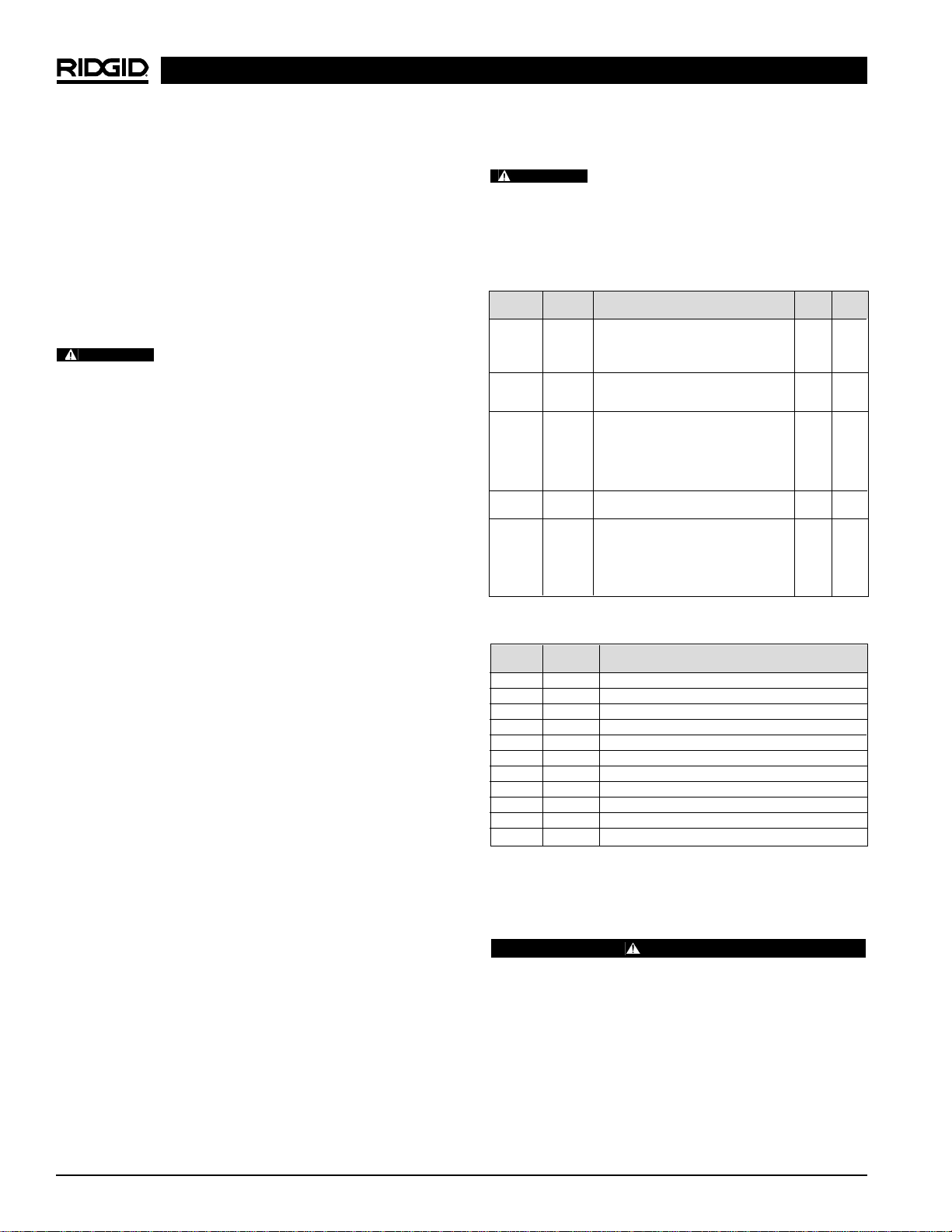

Standard Equipment

Catalog Model Hose Hose

No. No. Description I.D. O.D.

64772 H-61 Propulsion Nozzle 1/8″NPT

64777 H-62 Penetrating Nozzle Fits 1/4″Hose

64782 H-64 Drop Head Nozzle

82842 H-65 Spin Nozzle 2200

64787 H-71 Propulsion Nozzle 1/4″NPT

64792 H-72 Penetrating Nozzle Fits 1/2" Hose

82852 H-75 Spin Nozzle 2200

47592 H-1425 1/4″x 25′3/16″1/4″

47597 H-1435 1/4″x 35′3/16″1/4″

47602 H-1450 1/4″x 50′1/4″Trap Hose 3/16″1/4″

49272 H-1475 1/4″x 75′3/16″1/4″

49277 H-1400 1/4″x 100′Orange 3/16″1/4″

64732 H-1415 1/4″x 150′3/16″1/4″

50002 HL-1 Flexible Leader, 1/4″1/8″3/16″

50007 HL-2 Flexible Leader, 1/2″1/8″3/16″

47607 H-1250 1/2″x 50′1/4″1/2″

47612 H-1275 1/2″x 75′1/4″1/2″

47617 H-1200 1/2″x 100′1/4″1/2″

51587 H-1211 1/2″x 110′1/2″Jet Hose 1/4″1/2″

49487 H-1215 1/2″x 150′1/4″1/2″

51597 H-1220 1/2″x 200′Black 1/4″1/2″

Catalog Model

No. No. Description

62882 H-5 Mini Hose Reel (No Hose included)

64737 H-30 H-30 Cart with Hose Reel

62877 H-30 WH H-30 Cart with Hose Reel and 110′x 1/2″Jet Hose

64077 HP-22 Pressure Wash Package, KJ-2200

64767 HW-22 Wash Wand, KJ-2200

51572 H-1235 Wash Wand Hose 1/2″x 35′

48157 FV-1 Foot Valve

66732 HF-4 Quick Connect Hose

48367 H-25 Winterizing Kit

47542 H-21 Nozzle Cleaning Tool

67187 H-32 Jet Vac

Jetter Nozzles and Hoses

Jetter Accessories

Catalog Model

No. No. Description Wt.

63877 KJ-2200 KJ-2200 Jetter with Pulse

–H-61, H-62, and H-64 1/8″NPT Nozzles 65 lb.

–H-71 and H-72 1/4″NPT Nozzles (29,5 kg)

–75′x 1/4″Trap Hose

–FV-1 Foot Valve

–Nozzle Cleaning Tool

63882 KJ-2200-C Above With:

–H-30 Cart 145 lb.

–110′x 1/2″Jet Hose (65,8 kg)