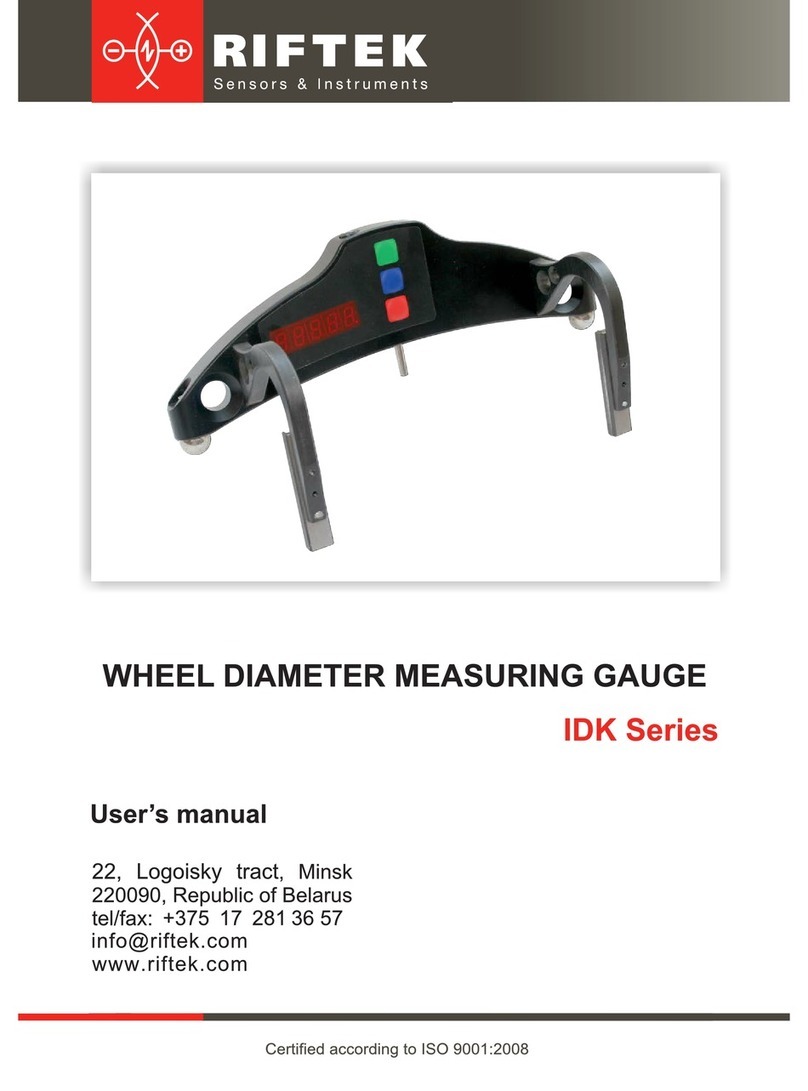

Wheel diameter measuring gauge, IDK-BT

IDK-BT [Revision 2.2] 4th September 2017

Contents

1. Safety precautions and measurement conditions..................................................................................3

2. Electromagnetic compatibility.................................................................................................................3

3. General information................................................................................................................................3

4. Basic data and performance characteristics..........................................................................................3

5. Example of item designation when ordering..........................................................................................4

6. Complete set to be supplied...................................................................................................................4

7. Design....................................................................................................................................................5

7.1. Electronic gauge............................................................................................................................5

7.2. Indication device (option) ..............................................................................................................5

8. Operation principle.................................................................................................................................7

9. Working with the gauge and working in autonomous regime ................................................................7

9.1. Gauge turn-on ...............................................................................................................................7

9.2. Single measurement......................................................................................................................7

9.3. Measurement with averaging ........................................................................................................8

9.4. Gauge turn-out ..............................................................................................................................8

10. Indication parameters setup...................................................................................................................8

10.1. Bluetooth ON/OFF.........................................................................................................................8

10.2. Image rotation................................................................................................................................9

10.3. Image brightness set-up..............................................................................................................10

10.4. Millimeters-Inches -Tapes display set-up....................................................................................10

11. Service operation modes .....................................................................................................................11

11.1. Calibration conditions..................................................................................................................11

11.2. Get into operational modes .........................................................................................................11

11.3. Calibration of the sensor zero .....................................................................................................11

11.4. Calibration of the device base.....................................................................................................12

12. Working with the gauge and PDA........................................................................................................13

12.1. Operation principle ......................................................................................................................13

12.2. Gauge and PDA activation..........................................................................................................13

12.2.1. Gauge turn-on ........................................................................................................................13

12.2.2. PDA turn-on............................................................................................................................13

12.3. On-line measurement..................................................................................................................14

12.4. Measurements with database maintenance................................................................................15

12.5. Browsing the database................................................................................................................16

12.6. Saving database on flash memory card......................................................................................17

13. PDA program setting............................................................................................................................17

13.1. Selection of measurement units..................................................................................................17

13.2. Data and Time settings................................................................................................................18

13.3. Tolerances settings .....................................................................................................................18

13.4. Database selection......................................................................................................................19

13.5. Selection and formation of measurement scheme......................................................................20

13.5.1 Selection or removal of the measurement scheme.................................................................20

13.5.2 Formation of a new measurement scheme.............................................................................20

13.5.3 Loading of a new measurement scheme ................................................................................21

13.6. New electronic gauge connection ...............................................................................................21

13.7. Selection and changing of language and terminology ................................................................21

13.7.1 Preparation and installation of language support file ..............................................................21

13.8. PDA software version viewing.....................................................................................................22

13.9. Deactivation.................................................................................................................................22

14. Working with the gauge and PC...........................................................................................................22

14.1. Program starting..........................................................................................................................22

14.2. IDK-PC connection......................................................................................................................23

14.3. Measurement...............................................................................................................................23

15. Database maintenance software .........................................................................................................24

16. Charging of built-in accumulator battery ..............................................................................................24

17. Warranty policy.....................................................................................................................................24

18. Annex 1. Procedure of installation of Bluetooth connection between IDK and PC..............................24

19. Distributors...........................................................................................................................................28

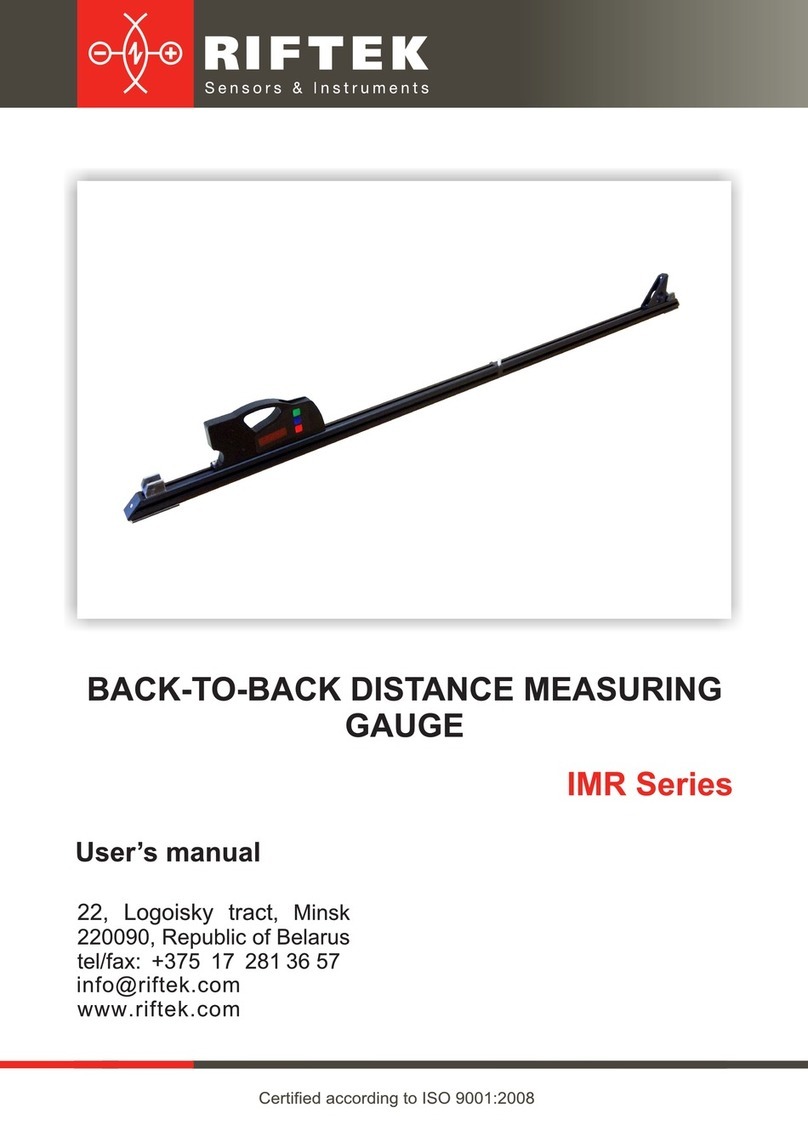

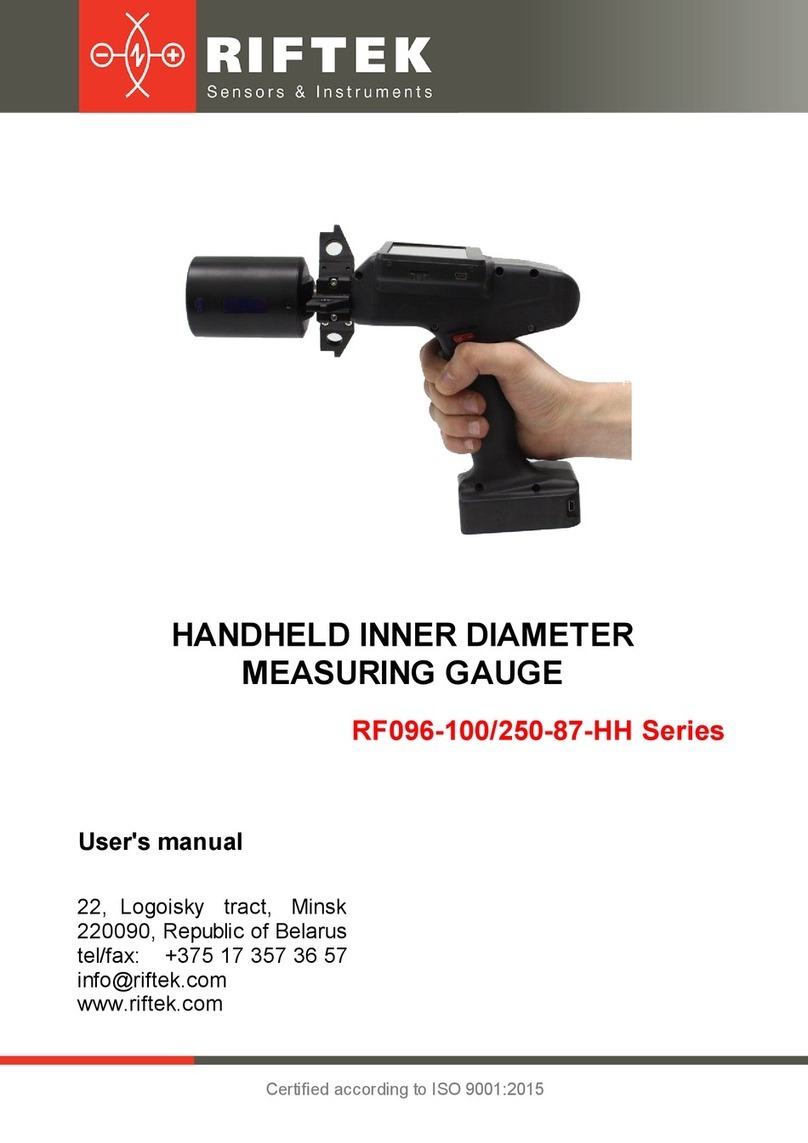

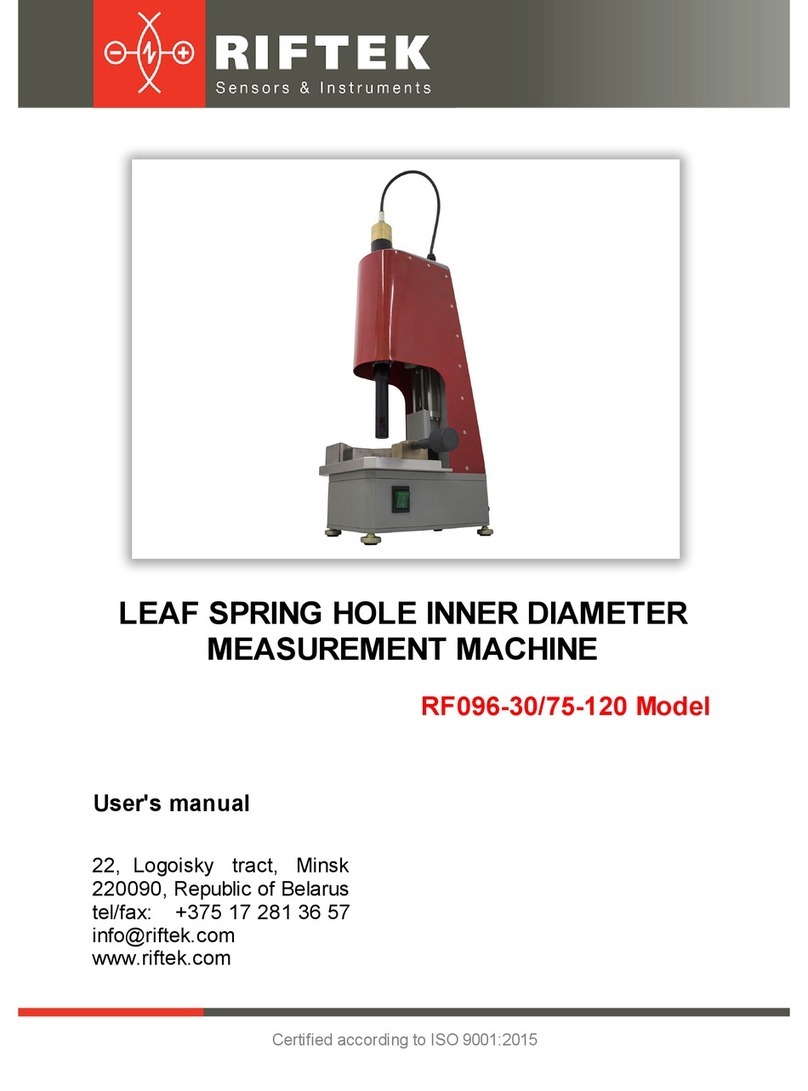

20. Annex 2. RIFTEK’s measurement devices for railway transport .........................................................31