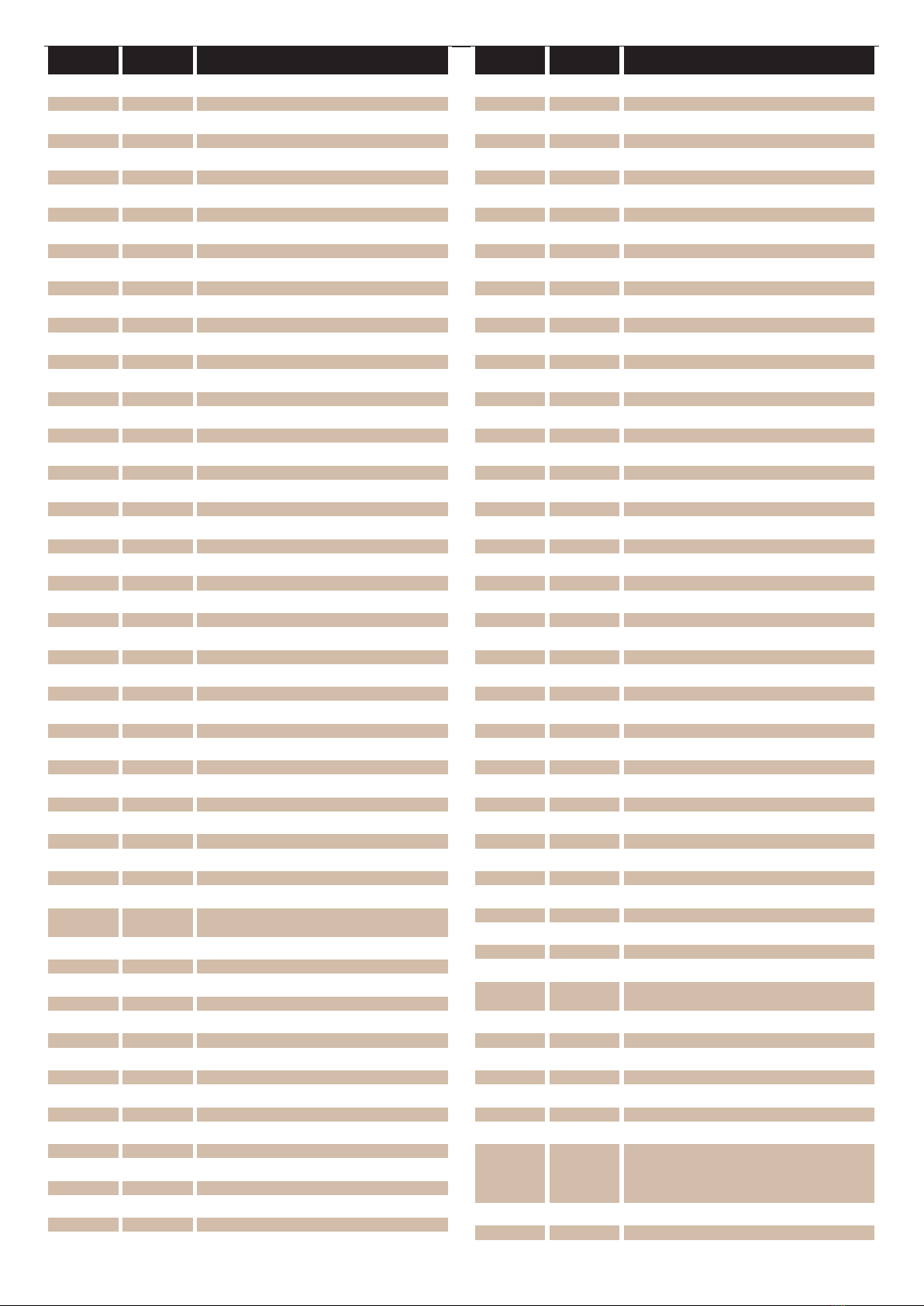

6

Spare part overview article numbers

Nr. Art.Nr. Description

1 B17160 Decorative door

2 N100173 Washer M06

3 N103964 Hexagonal screw

4 N112551 Round sealing strip grey D11

5 N103693 Flat seal black 8x2

6 Z34977 Hinge plate

7 N111846 Hexagon socket 06x12

8 Z35245 Hinge

9 N105179 Hexagonal nut M10

10 Z34983 Combustion chamber door glass

11 N111964 Hexagonal screw

12 L00475 Glass holder

13 B17188 Combustion chamber door black assy

14 N111950 Hexagonal screw M05x10

15 N111965 Washer M05

16 L02220 Lock tongue

17 N107521 Hexagonal screw M05x12

18 L02216 Closure flap

19 N111801 Grub screw

20 Z34978 Locking bolt

21 Z35251 Locking pipe

22 L02219 Holder plate

23 N111856 Hexagonal countersunk screw M04x12

24 N112018 Key

25 N112047 Hexagon socket screw M08x35

26 Z34846 Cover

27 N100485 Round sealing strip black D12

28 *1 Z34872 Baffle 2

28 *2 Z36343 Baffle plate 2

29 Z35095 Baffle plate 1

30 Z36574 Cast rear panel

31 Z36594 Firebrick lining rear right

32 Z36592 Firebrick lining front right

33 N103066 Round sealing strip black D06

34 B16310 Fire trough holder

35 Z35061 Support firebrick lining

36 N111846 Hexagon socket 06x12

37 L02215 Ash drawer

38 N111959 Square nut M05

39 *3 Z35244 Cleaning cover

39 *4 B17320 Cleaning cover compete

N103066 Round sealing strip black D06

40 Z35060 Fire trough

41 Z36593 Firebrick lining front left

42 Z36595 Firebrick lining rear left

Z36806 Firebrick lining rear left till serial number

1314344

43 LB00554 Convection cover black

LB00558 Convection cover silver

44 LB00552 Rear wall black (from serial no. 1317485)

B17317 Rear wall black (till serial no. 1317484)

LB00556 Rear wall silver (from serial no. 1317485)

B17318 Rear wall silver (till serial no. 1317484)

45 B17171 Side panel glass black right

B17156 Side panel rust effect right

B17163 Side panel rust effect metallic right

B17167 Side panel slate white right

B17170 Side panel slate black right

L02421 Side casing panel, right black

46 L02334 Rear panel black

L02339 Rear panel silver

47 L02327 Botton side panel holder ( stone )

48 *5 N111695 Height adjustment screw

Nr. Art.Nr. Description

48 *6 N112490 Levelling screw black

49 LB00553 Front panel black (from serial no. 1317485)

B17315 Front panel black (till serial no. 1317484)

LB00557 Front panel silver (from serial no. 1317485)

B17316 Front panel silver (till serial no. 1317484)

50 B17172 Side panel glass black left

B17157 Side panel rust effect left

B17165 Side panel rust effect metallic left

B17168 Side panel slate white left

B17169 Side panel slate black left

L02420 Side casing panel, left black

51 L01502 Lock washer

52 N110461 Double ball catch

53 L01446 Lock washer

54 L01445 Switch spacer

55 N111733 Solenoid switch bottom part

56 N111732 Magnetic switch top part

57 N111731 Container seal

58 L02331 Container lid black

L02338 Container lid silver

59 L01976 Hinge guidance

60 L01977 Hinge part

61 L01975 Hinge guidance

62 B16114 Temperature sensor

63 B15248 Sensor tube

64 Z35183 Friction bearing Di10

65 B16967 Auger

66 *7 Z35182 Friction bearing Di16

67 Z11915 Lock ring conveyer screw

68 N111058 Setscrew with pin

69 N112030 Screw motor, stepless

70 Z35239 Seal

71 Z35240 Spacer

72 B16155 Induced draft fan housing

73 N111581 Induced draft fan motor

74 N111551 Silicon hose

75 N112102 Differential pressure switch

76 N111604 Fuse 2,5 A

77 B16561 Mainboard USB11

78 B16030 Additional motherboard for motor, incl. cable

79 B17014 Ceramic ignition

80 B17158 Touch-display screwable

80 *8 B16574 Touch-display plug-in

81 N112032 Screw 2,5x7

B17333 Wiring harness

Z35018 Cable for touch-screen 1,25 m

Z34841 Cable for additional motherboard

L00797 Motor plate

N112068 Two-component adhesive

B18055 Combustion chamber kit till serial number

1314344

*9 B18056 Combustion chamber kit

*1 till serial number 1356409

*2 from serial number 1356410

*3 till serial number 1323548

*4 from serial number 1323549

*5 till serial number 1361657

*6 from serial number 1361658

*7

up to serial number 1331613 the motor

plate (L00797) must be supplied as a spare

part when replacing the plastic bearing Di16

(Z35182).

*8 for execution side panel steel

*9 serial number 1314345 till 1376106

Note: Please consider the powdercoated parts can differ slightly in colour and colour effects though they are elaborated in high quality.