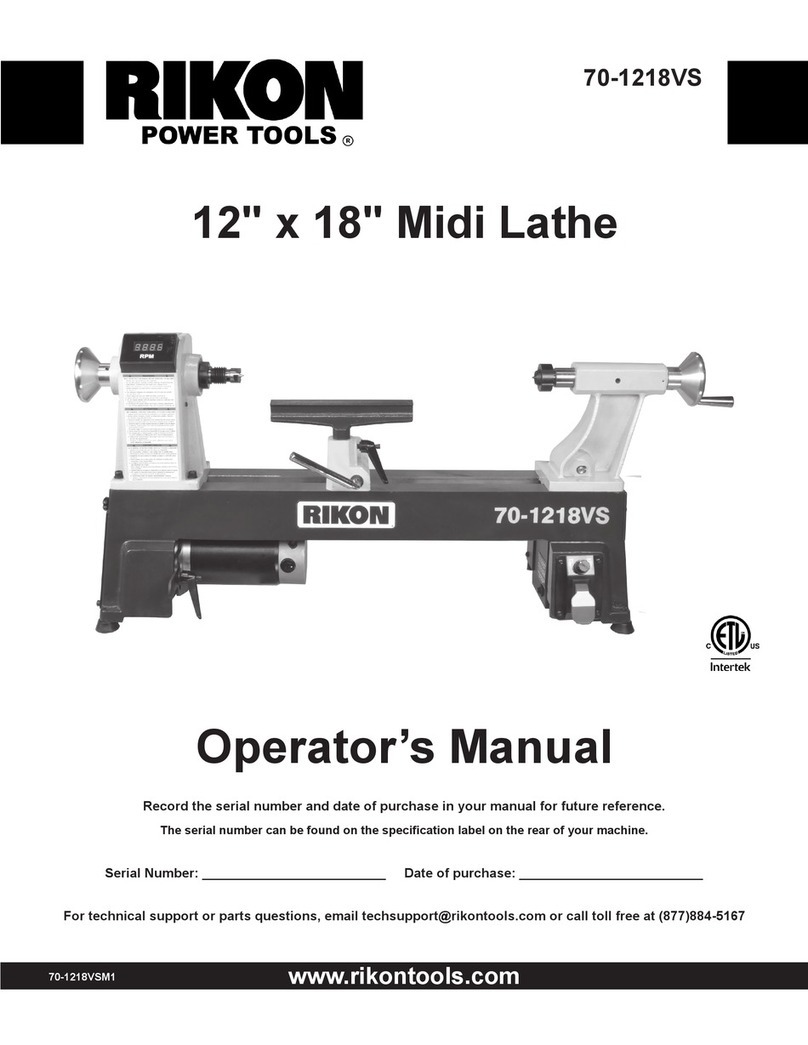

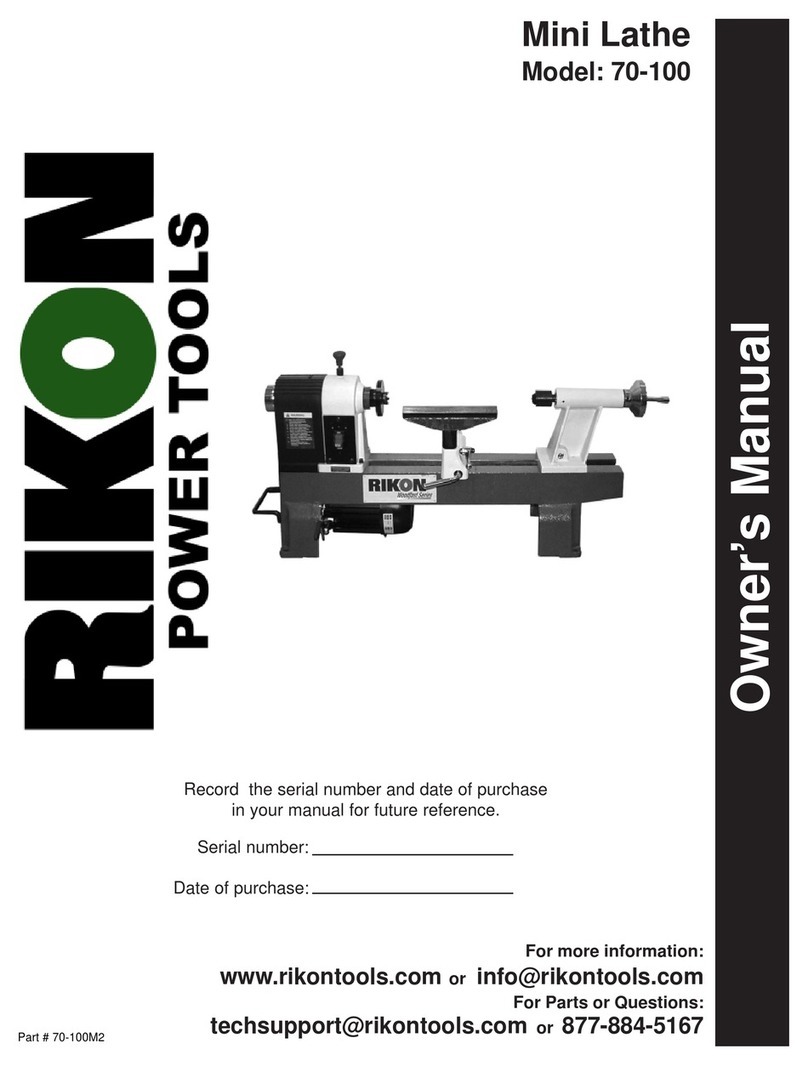

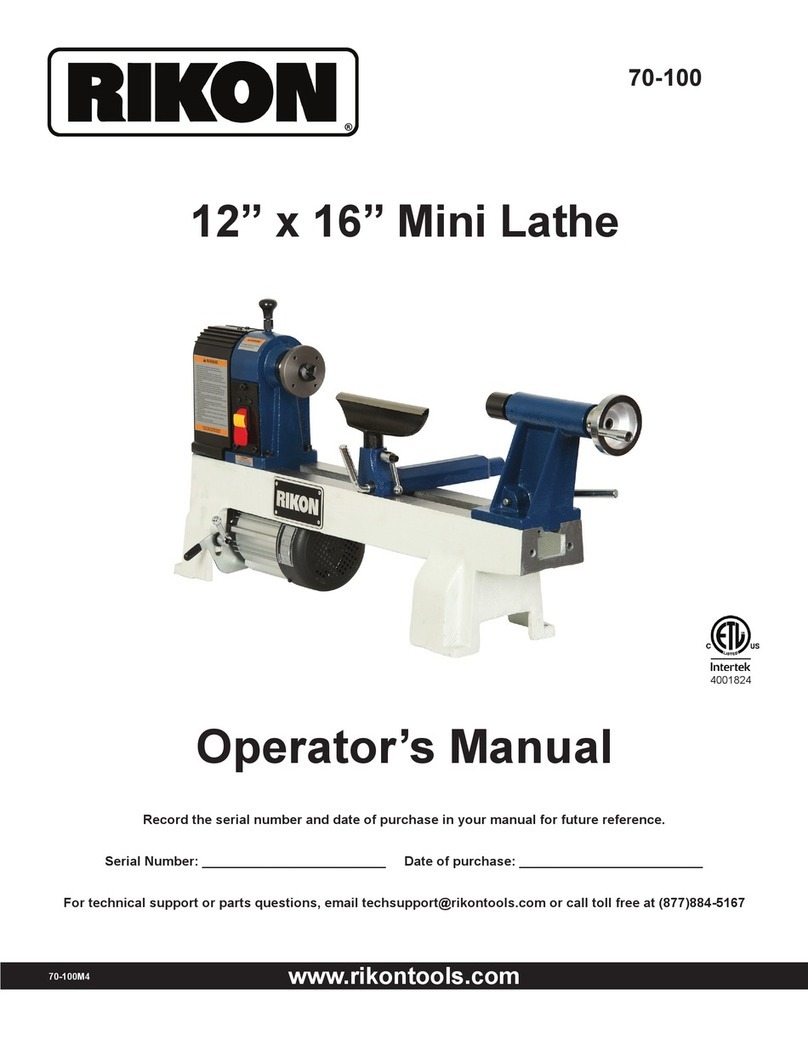

70-100

12”

9-1/2”

16”

1/2HP,1Ph,115V only

6

430,810,1230,1810,2670,3900 RPM

1”x8

MT2

MT2

3/8”

2-1/2”

31-3/4”(L)x18”(W)x11-1/2”(H)

88.5 lbs

ModelNumber

SwingOverBed

SwingOverToolRestBase

WorkingDistanceBetweenCenters

Motor

Speeds

Speed Ranges

SpindleNosein xTPI

HeadstockTaper

TailstockTaper

HoleThroughSpindle

RamTravel

OverallDimensions

NetWeight

Table of Contents

SafetyWarnings.....................................................................................................................................................2

LatheSafetyRules...............................................................................................................................................3

Specifications.........................................................................................................................................................4

UnpackingandContents......................................................................................................................................5

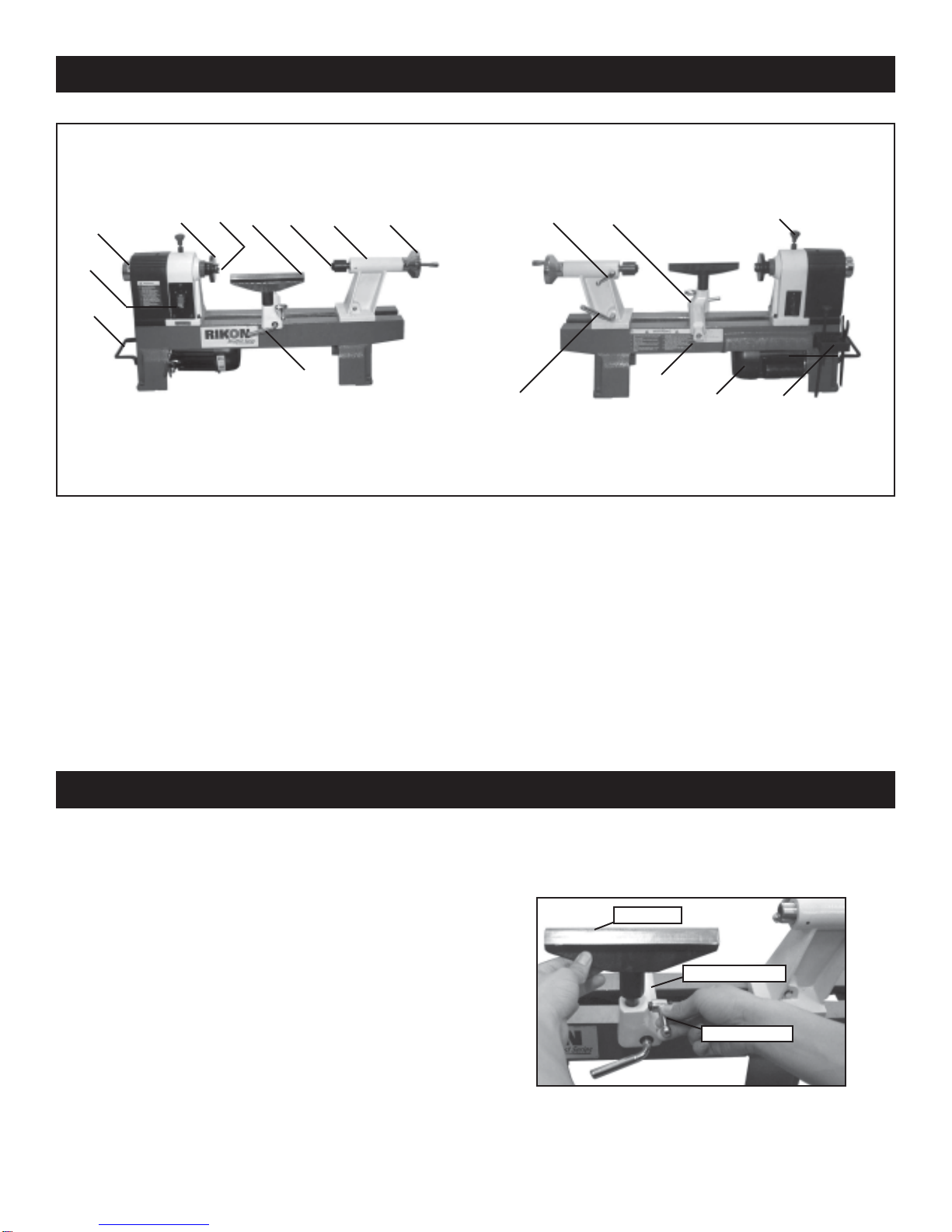

GettingtoKnowYourLathe...................................................................................................................................6

Assembly................................................................................................................................................................6

InstallingtheToolRest...........................................................................................................................................6

InstallingSpindleLock...........................................................................................................................................7

AttachingtheSpurCenter.....................................................................................................................................7

AttachingtheLiveCenter......................................................................................................................................7

InstallingtheFaceplate..........................................................................................................................................8

InstallingtheToolHolder........................................................................................................................................8

SecuringtheLathetoaWorksurfaceorStand..................................................................................................8

Adjustments............................................................................................................................................................8

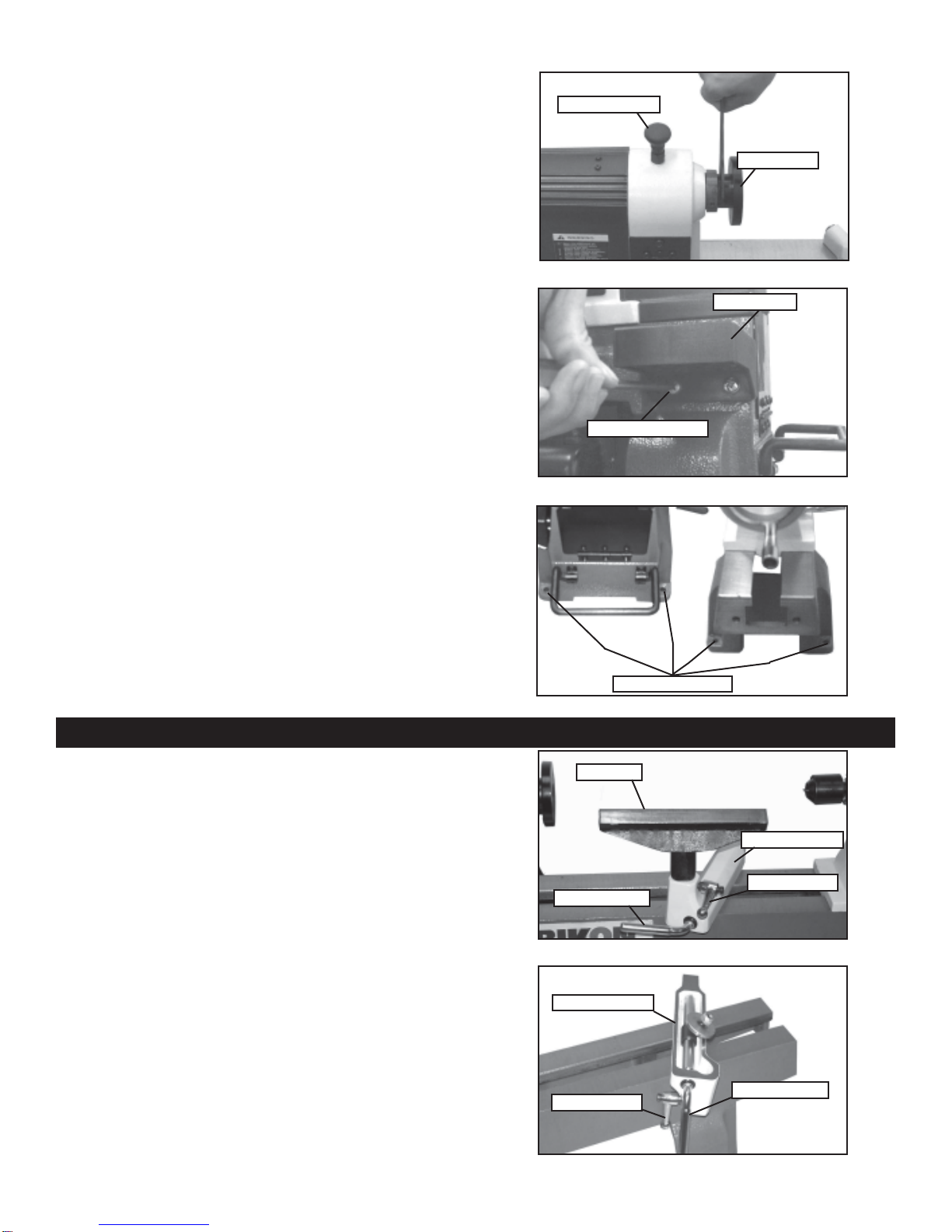

AdjustingtheToolRest..........................................................................................................................................8

AdjustingtheTailstock...........................................................................................................................................9

ChangingSpindleSpeeds....................................................................................................................................9

TypicalOperations.................................................................................................................................................9

Indexing/SpindleLock........................................................................................................................................10

Maintenance.........................................................................................................................................................10

ElectricalRequirements...............................................................................................................................................11

WiringDiagram......................................................................................................................................12

Troubleshooting....................................................................................................................................................13

ExplosionDiagram..............................................................................................................................................14

PartsList...............................................................................................................................................................15

Warranty.................................................................................................................................................................16

Notes......................................................................................................................................................................17

Specifications

4