Rinstrum-5230 ApplicationsManual 5200-604-120

Page 3

TableofContents

1. INTRODUCTION.....................................................................................................................4

1.1. Audience.......................................................................................................................4

1.2. Scope............................................................................................................................4

1.3. Manuals.........................................................................................................................4

2. PRELIMINARYFUNCTIONS...................................................................................................5

2.1. Creating IDsPriortoaTransaction...............................................................................5

2.1.1. Creating Truck IDs.........................................................................................5

2.1.2. Creating Product IDs......................................................................................5

2.1.3. Creating Destination IDs................................................................................6

2.2. Creating IDsDuring aTransaction................................................................................6

2.3. Altering the ReferenceID..............................................................................................6

2.4. PrinterSetup (SerialPort 2)..........................................................................................7

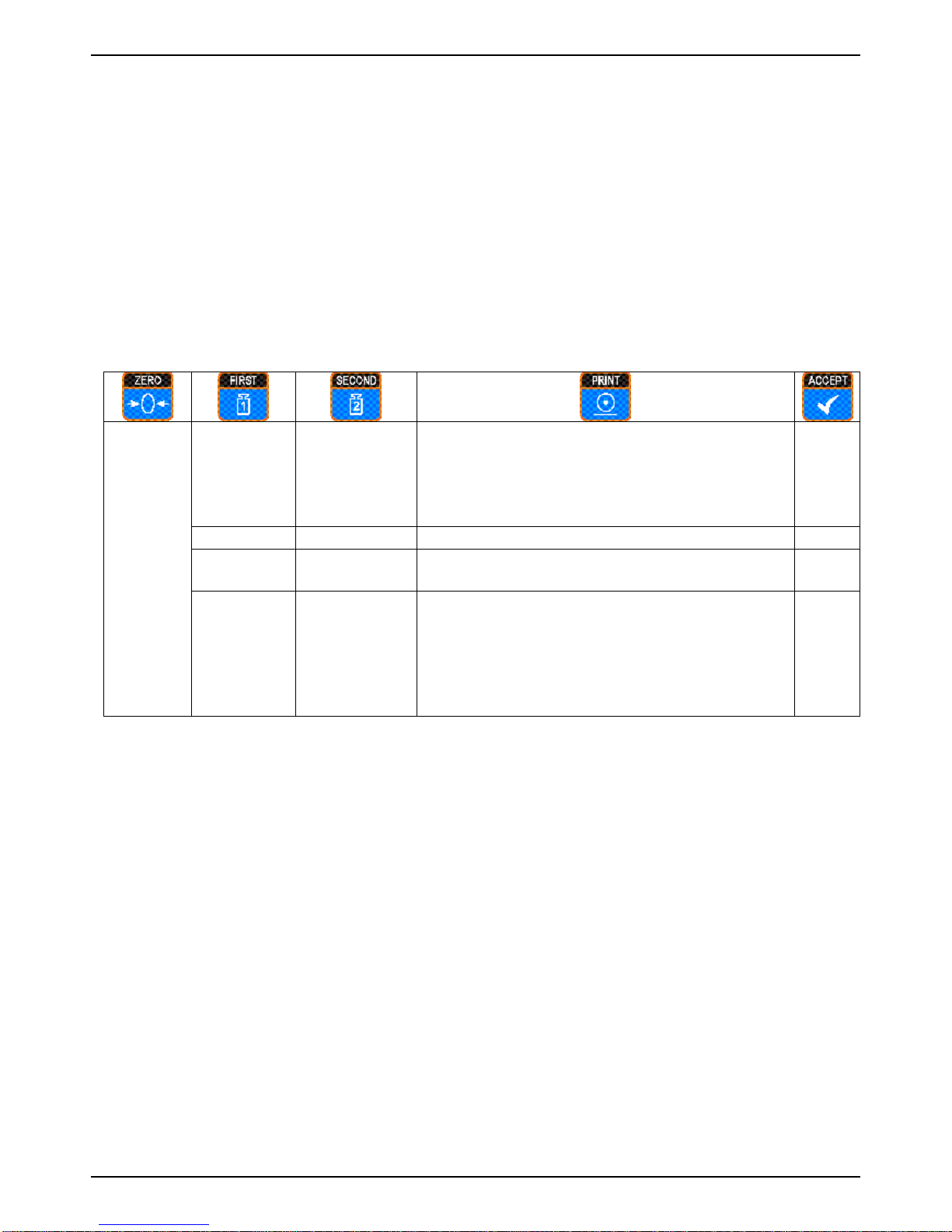

3. SINGLEWEIGHTTICKETING (ONEPASS ONLY)...............................................................8

3.1. Operation ......................................................................................................................8

3.2. SamplePrint Ticket (FIXED.1)......................................................................................8

3.3. Setup (SingleWeight Ticketing (One Pass Only))........................................................9

4. SINGLEWEIGHING (IN-OUT)..............................................................................................10

4.1. Operation ....................................................................................................................10

4.2. SamplePrint Tickets(FIXED.1)..................................................................................11

4.3. Setup (SingleWeighing (In-Out))................................................................................11

5. SINGLEWEIGHING WITH7DAYPRESETTARE(IN-OUT)...............................................12

5.1. Operation ....................................................................................................................12

5.2. SamplePrint Ticket (FIXED.1)....................................................................................12

5.3. Setup (SingleWeighing with7DayPreset Tare(In-Out))..........................................13

6. BATCH PROCESS SINGLEWEIGHING (IN-OUT)...............................................................14

6.1. Operation ....................................................................................................................14

6.2. SamplePrint Ticket (FIXED.1)....................................................................................14

6.3. Setup (BatchProcess SingleWeighing (In-Out))........................................................15

7. MULTIPLEAXLEWEIGHING (IN-OUT)...............................................................................16

7.1. Operation ....................................................................................................................16

7.2. SamplePrint Ticket (FIXED.2)....................................................................................17

7.3. Setup (MultipleAxleWeighing (In-Out)).....................................................................17

8. VARIABLEAXLEWEIGHING (IN-OUT)...............................................................................18

8.1. Operation ....................................................................................................................18

8.2. SamplePrint Ticket (FIXED.3)....................................................................................20

8.3. Setup (VariableAxleWeighing (In-Out)) ....................................................................20

9. AUTOMATICMULTIPLEAXLEWEIGHING (IN-OUT).........................................................21

9.1. Operation ....................................................................................................................21

9.2. SamplePrint Ticket (FIXED.2)....................................................................................23

9.3. Setup (Keypad)...........................................................................................................23