© RISCO Group 01/2012 5IN1749

EN 50131-1

EN 50131-2-4

Grade 2

Environmental Class II

CE Compliance Section:

Risco Ltd. hereby declares that this equipment is in compliance with the essential

requirement and other relevant provisions of Directive 1999/5/EC.

For the EC Declaration of Conformity please refer to our website: www.riscogroup.com

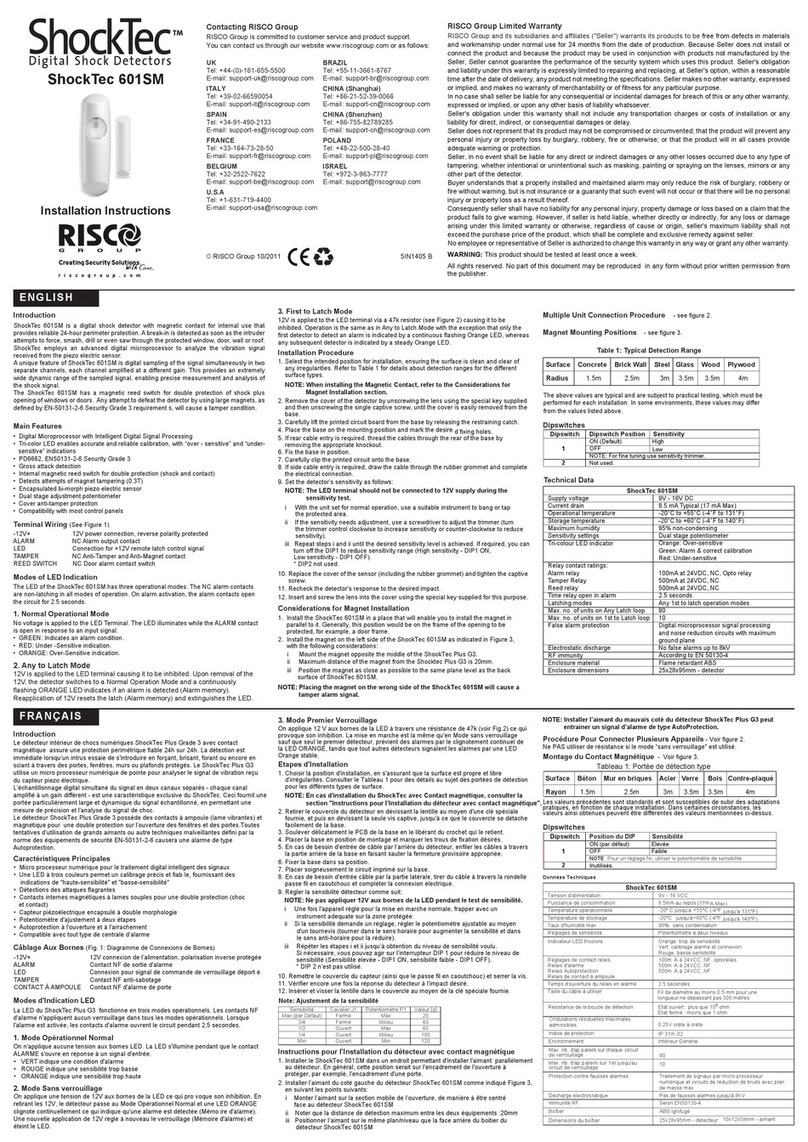

U.S. Patent Number:

This product is protected under Patent No. US 7,126,476 B2.

Other patents pending.

RISCO Group Limited Warranty

RISCO Group and its subsidiaries and affiliates ("Seller") warrants its products to be free

from defects in materials and workmanship under normal use for 24 months from the date

of production. Because Seller does not install or connect the product and because the

product may be used in conjunction with products not manufactured by the Seller, Seller

cannot guarantee the performance of the security system which uses this product. Seller's

obligation and liability under this warranty is expressly limited to repairing and replacing, at

Seller's option, within a reasonable time after the date of delivery, any product not meeting

the specifications. Seller makes no other warranty, expressed or implied, and makes no

warranty of merchantability or of fitness for any particular purpose.

In no case shall seller be liable for any consequential or incidental damages for breach of

this or any other warranty, expressed or implied, or upon any other basis of liability

whatsoever.

Seller's obligation under this warranty shall not include any transportation charges or costs

of installation or any liability for direct, indirect, or consequential damages or delay.

Seller does not represent that its product may not be compromised or circumvented; that

the product will prevent any personal injury or property loss by burglary, robbery, fire or

otherwise; or that the product will in all cases provide adequate warning or protection.

Seller, in no event shall be liable for any direct or indirect damages or any other losses

occurred due to any type of tampering, whether intentional or unintentional such as

masking, painting or spraying on the lenses, mirrors or any other part of the detector.

Buyer understands that a properly installed and maintained alarm may only reduce the risk

of burglary, robbery or fire without warning, but is not insurance or a guaranty that such

event will not occur or that there will be no personal injury or property loss as a result

thereof.

Consequently seller shall have no liability for any personal injury, property damage or loss

based on a claim that the product fails to give warning. However, if seller is held liable,

whether directly or indirectly, for any loss or damage arising under this limited warranty or

otherwise, regardless of cause or origin, seller's maximum liability shall not exceed the

purchase price of the product, which shall be complete and exclusive remedy against

seller.

No employee or representative of Seller is authorized to change this warranty in any way

or grant any other warranty.

WARNING: This product should be tested at least once a week.

CAUTION: risk of explosion if battery is replaced by an incorrect type.

Dispose of used batteries according to local regulations.

RISCO Group Contacting Info

RISCO Group is committed to customer

service and product support. You can contact

us through our website (www.riscogroup.com)

or at the following telephone and fax numbers:

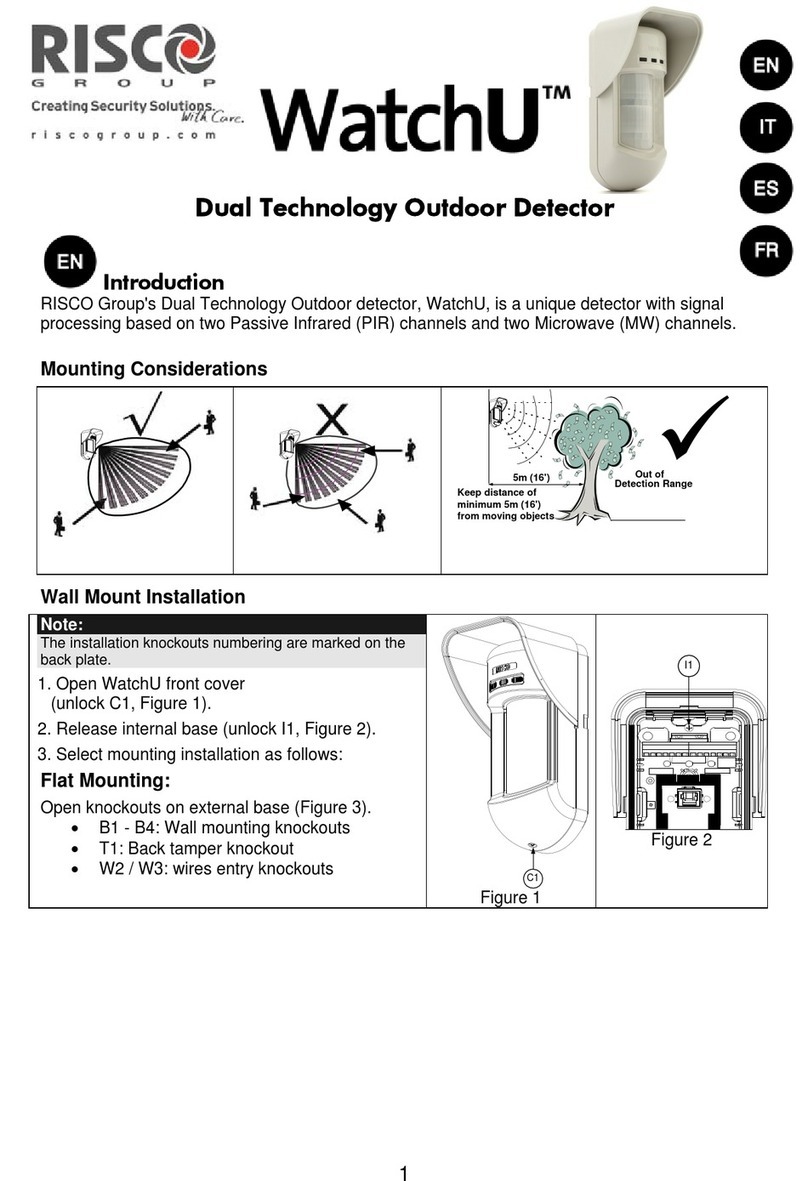

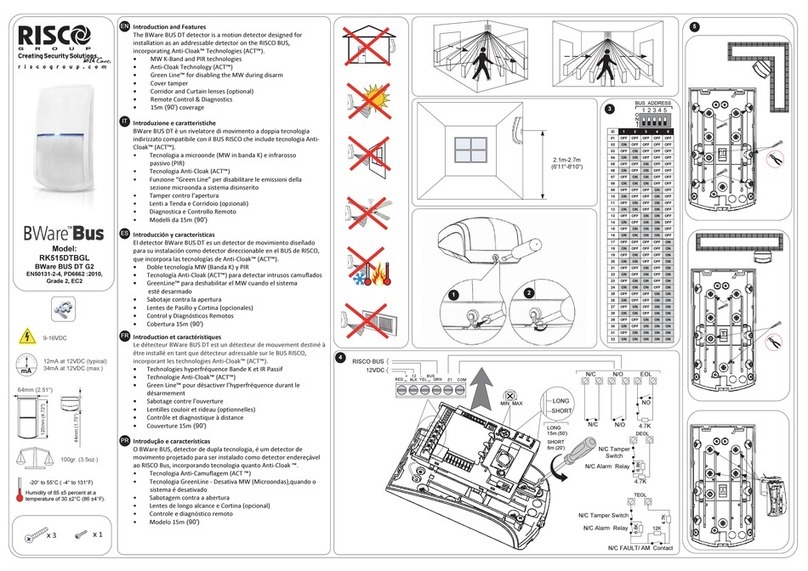

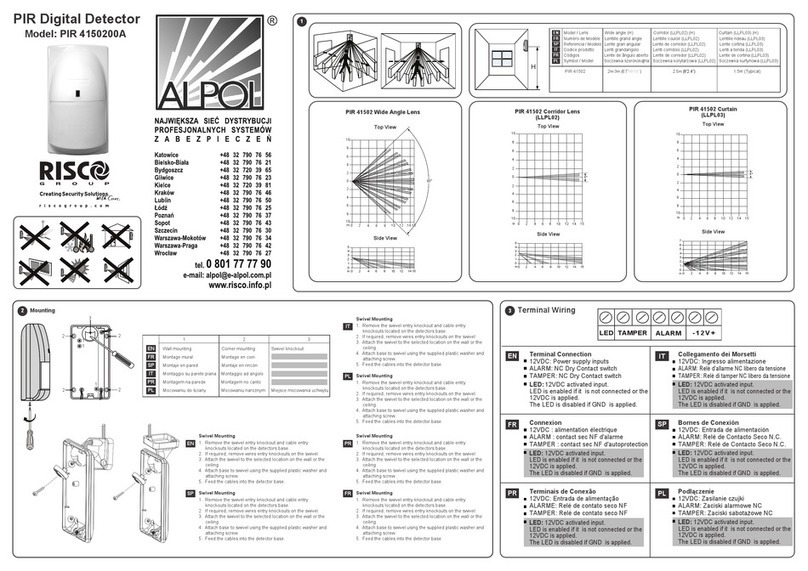

Mounting Height L - LONG S - SHORT

2.1m-2.7m (6'11"-8’10") 15m (50’) 6m (20’)

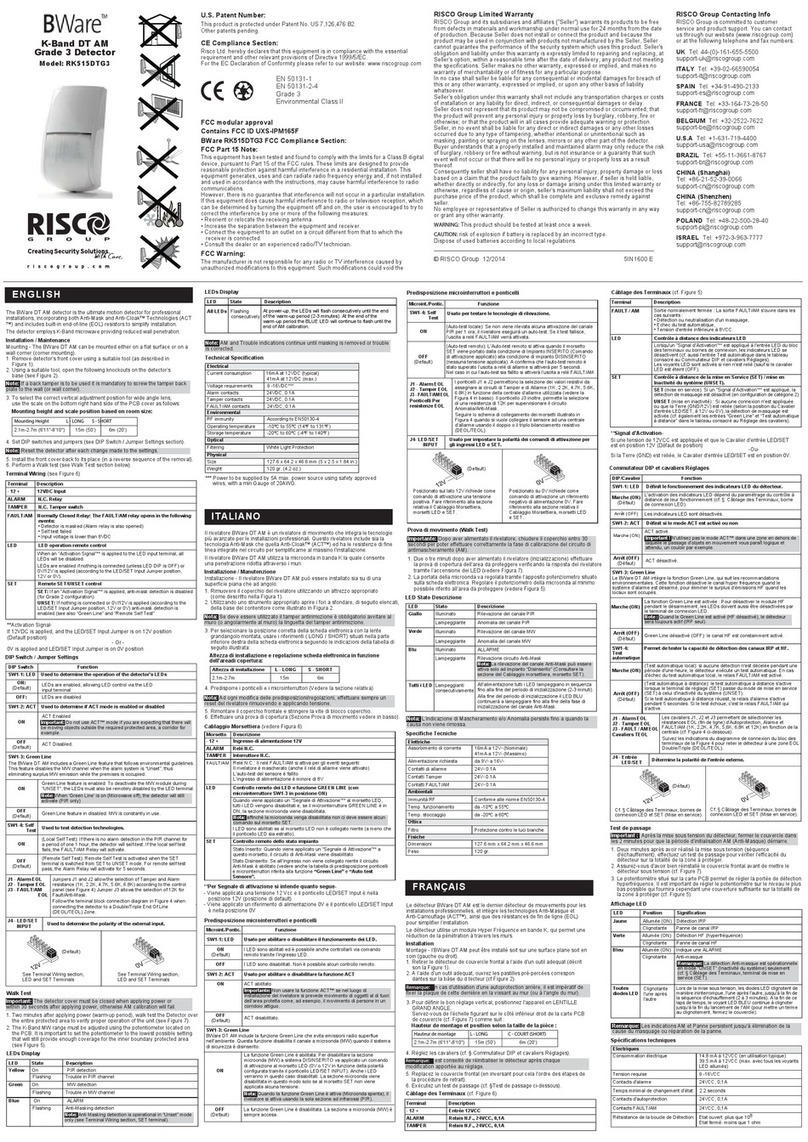

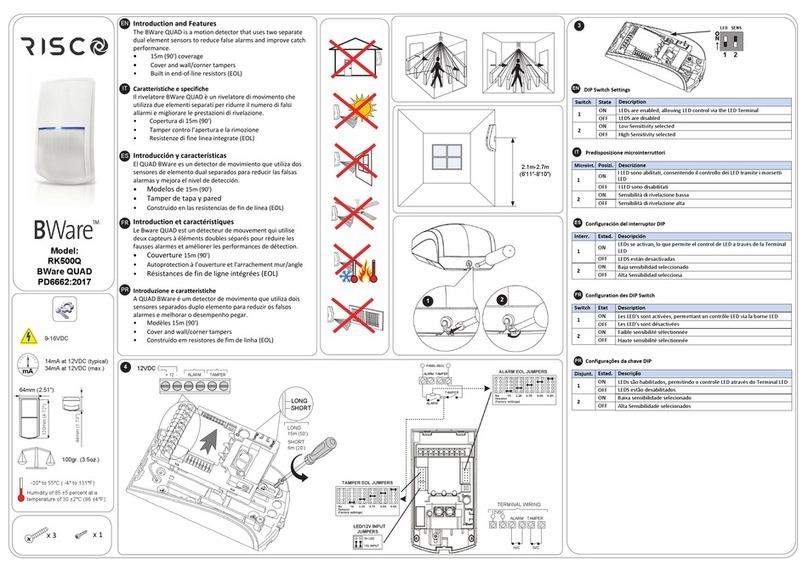

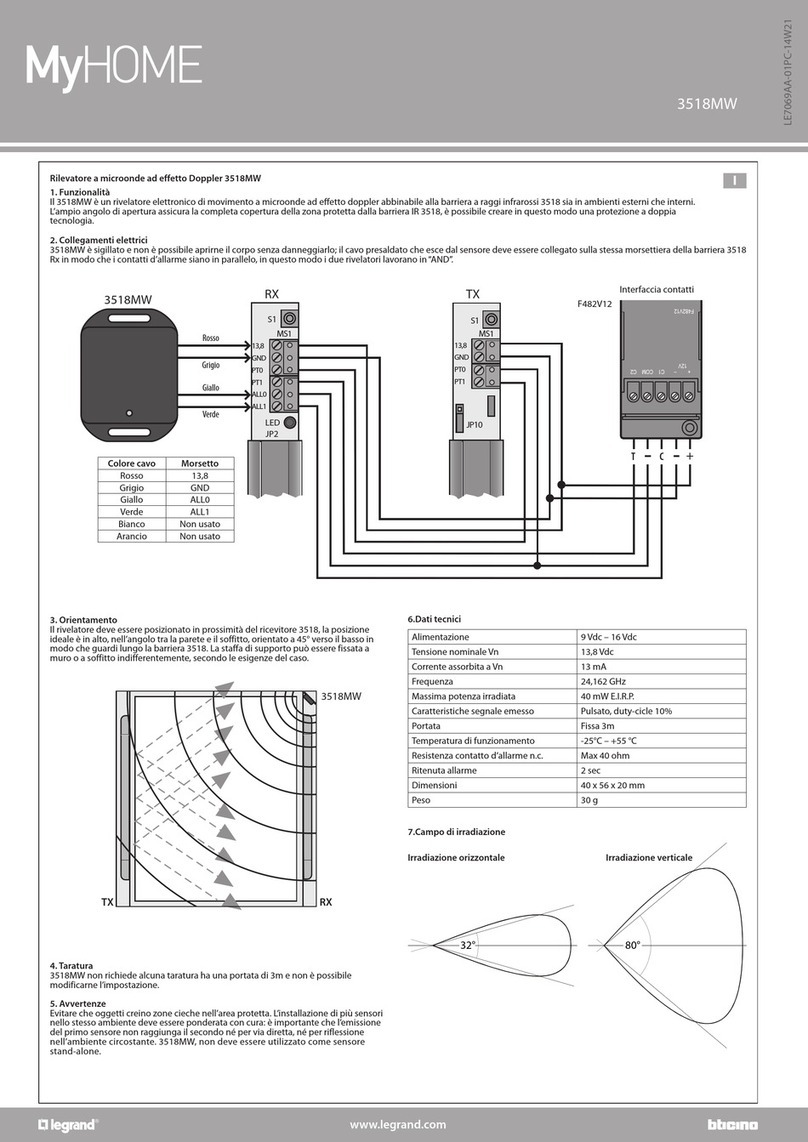

Terminal Description

- 12 + 12VDC Input

ALARM N.C. Relay

TAMPER N.C. Tamper switch

LED LED operation remote control

When an ”Activation Signal”** is applied to the LED input

terminal, all LEDs will be disabled.

LEDs are enabled if nothing is connected (unless LED

jumper is OFF) or 0V/12V is applied (according to the LED

Input Jumper position, 12V or 0V).

**Activation Signal-

If 12VDC is applied, and the LED Input Jumper is on 12V position

(Default position)

- Or -

0V is applied and LED Input Jumper is on 0V position

Jumper Settings

SW1-2: ACT Used to determine if ACT mode is enabled or disabled

ON ACT Enabled

Important: Do not use ACT™ mode if you are expecting that

there will be moving objects outside the required protected area,

a corridor for example.

OFF

(Default) ACT Disabled.

Jumper Function

SW1-1: LED Used to determine the operation of the detector’s LEDs

ON:

(Default) LEDs are enabled, allowing LED control via the LED input

terminal

OFF: LEDs are disabled

Walk Test

1. Two minutes after applying power (warm-up period), walk test the

Detector over the entire protected area to verify proper operation of the

unit (see Figure 7).

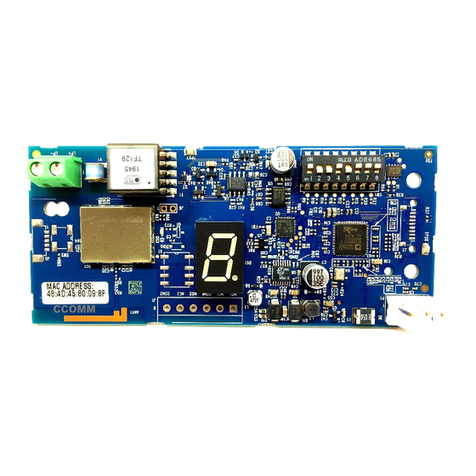

2. The K-Band MW range must be adjusted using the potentiometer located

on the PCB. It is important to set the potentiometer to the lowest possible

setting that will still provide enough coverage for the inner boundary

protected area (see Figure 5).

Blue On ALARM

All LEDs

Flashing

consecutively

At power-up, the LEDs will flash consecutively until the

end of the warm-up period (2-3 minutes).

LEDs Display

LED State Description

Yellow On PIR detection

Flashing Trouble in PIR channel

Green On MW detection

Flashing Trouble in MW channel

Technical Specification

Electrical

Current consumption 16mA at 12VDC (typical)

41mA at 12VDC (max.)

Voltage requirements 9 -16VDC***

Alarm contacts 24VDC, 0.1A

Tamper contacts 24VDC, 0.1A

Environmental

RF immunity According to EN50130-4

Operating temperature -10ºC to 55ºC (14ºF to 131ºF)

Storage temperature -20ºC to 60ºC (-4ºF to 140ºF)

Optical

Filtering White Light Protection

Physical

Size 127.6 x 64.2 x 46.6 mm (5 x 2.5 x 1.84 in.)

Weight 120 gr. (4.2 oz.)

*** Power to be supplied by 5A max. power source using safety approved

wires, with a min Gauge of 20AWG.

SW1-4: Self Not applicable in this version.

Test

SW1-3: Green Line

The BWare DT includes a Green Line feature that follows environmental

guidelines. This feature disables the MW channel when the alarm system is

“Unset”, thus eliminating surplus MW emission while the premises is occupied.

ON Green Line feature is enabled: To deactivate the MW module

during “UNSET”, the LEDs must also be remotely disabled by

the LED terminal.

Note: When ‘Green Line’ is on (Microwave off), the detector will

still activate (PIR only)

OFF

(Default) Green Line feature in disabled: MW is constantly in use.

(Default)

J4 - LED Used to determine the polarity of the external LED input.

INPUT

See Terminal Wiring section,

LED Terminal See Terminal Wiring section,

LED Terminal

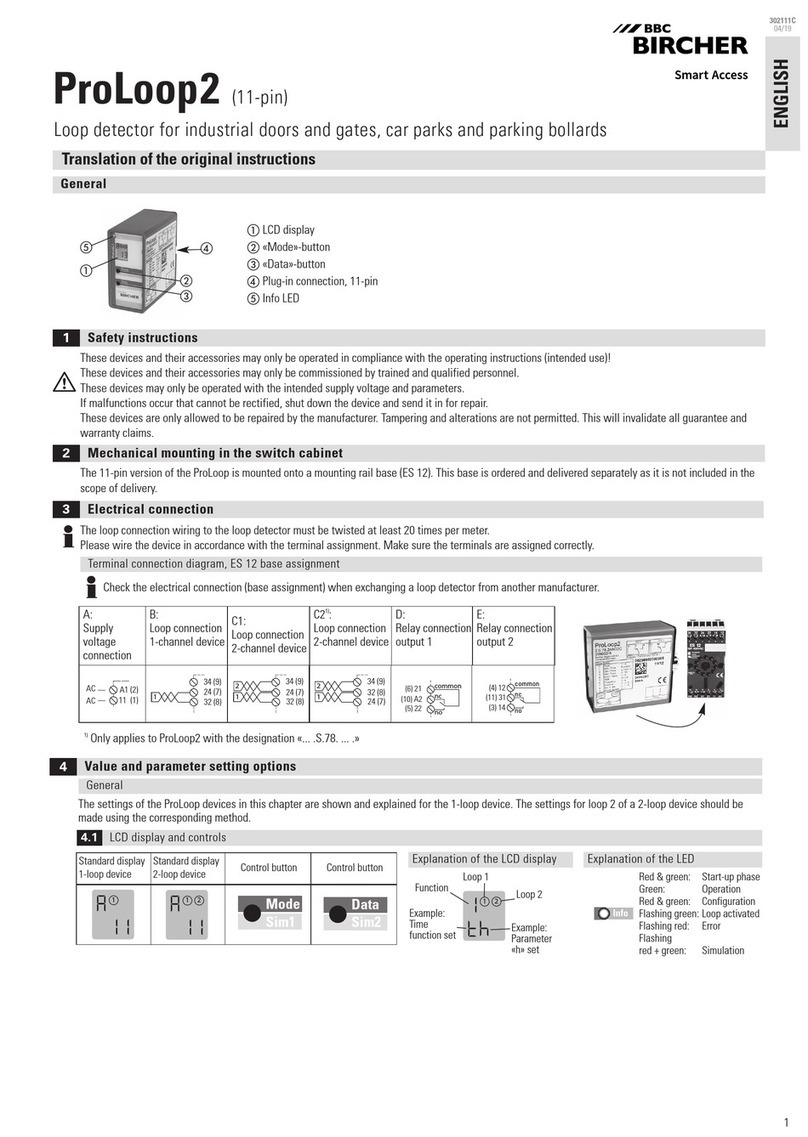

J1 - Alarm EOL

J2 - Tamper EOL

Jumpers J1 and J2 allow the selection of Tamper and Alarm

resistance (1K, 2.2K, 4.7K, 5.6K, 6.8K) according to the

control panel (see Figure 4).

.

Follow the terminal block connection diagram in Figure 4

when connecting the detector to a Double End Of Line

(DEOL) Zone.

ENGLISH

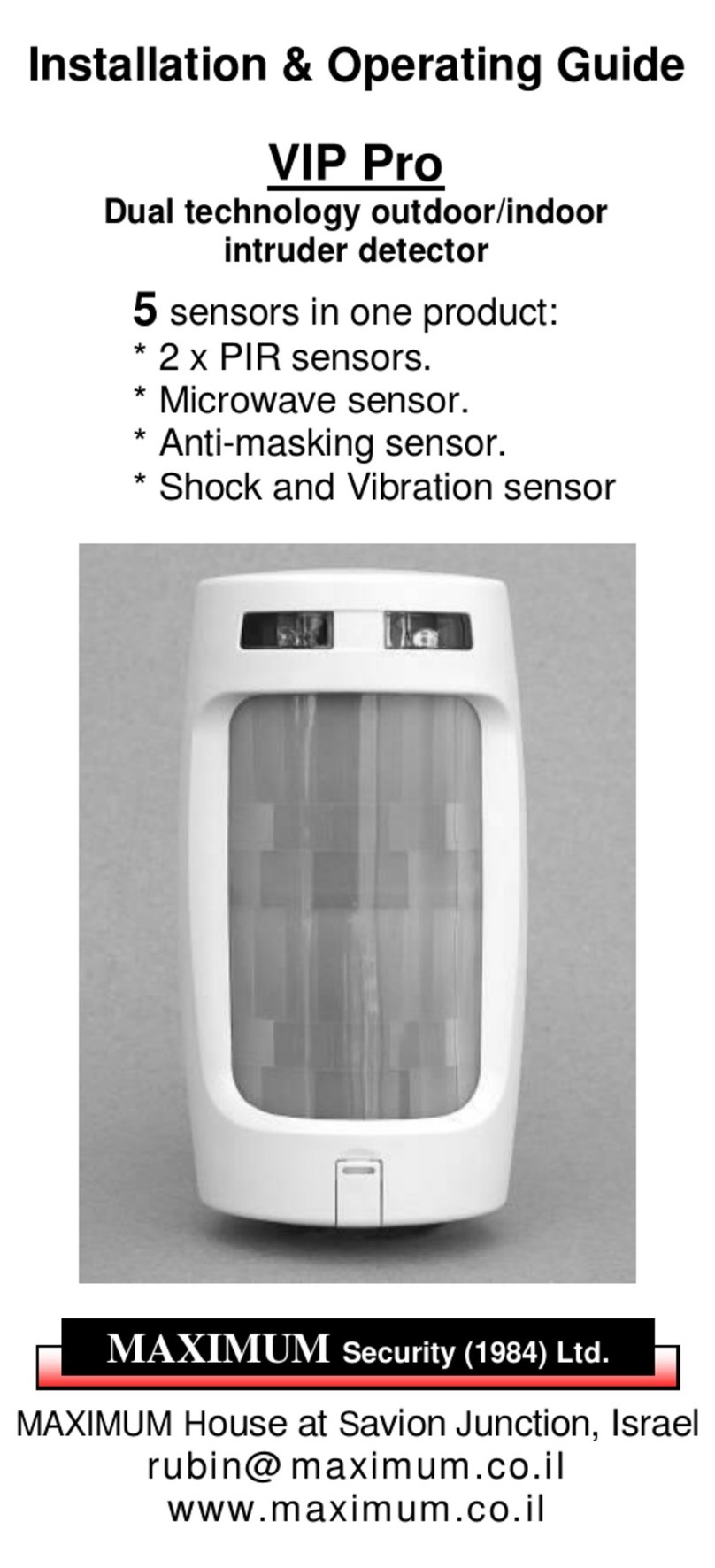

The BWare DT detector is the ultimate motion detector for professional

installations, incorporating Anti-Cloak™ Technologie (ACT™) and includes

built-in end-of-line (EOL) resistors to simplify installation.

The detector employs K-Band microwave providing reduced wall

penetration.

Installation / Maintenance

Mounting - The BWare DT can be mounted either on a flat surface or on a

wall corner (corner mounting).

1. Remove detector’s front cover using a suitable tool (as described in

Figure 1).

2. Using a suitable tool, open the following knockouts on the detector’s

base (see Figure 2).

3. To select the correct vertical adjustment position for wide angle lens,

use the scale on the bottom right hand side of the PCB cover as follows:

Mounting height and scale position based on room size:

4. Set jumpers (see Jumper Setting section).

Note: Reset the detector after each change made to the settings.

5. Install the front cover back to its place (in a reverse sequence of the

removal).

6. Perform a Walk test (see Walk Test section below).

Terminal Wiring (see Figure 5)

UK Tel: 44-(0)-161-655-5500

ITALY Tel: +39-02-66590054

SPAIN Tel: +34-91-490-2133

FRANCE Tel: +33-164-73-28-50

BELGIUM Tel: +32-2522-7622

U.S.A Tel: +1-631-719-4400

BRAZIL Tel: +55-11-3661-8767

CHINA (Shanghai)

Tel: +86-21-52-39-0066

CHINA (Shenzhen)

Tel: +86-755-82789285

POLAND Tel: +48-22-500-28-40

ISRAEL Tel: +972-3-963-7777

K-Band DT Grade 2

Model: RK515DTGL

LED Stato Descrizione

LED Stato Descrizione

Giallo Illuminato Rilevazione del canale PIR

Lampeggiante Anomalia del canale PIR

Verde Illuminato Rilevazione del canale MW

Lampeggiante Anomalia del canale MW

Blu Illuminato ALLARME

Tutti i LED

Lampeggianti

consecutivamente

All’alimentazione tutti i LED lampeggiano in

sequenza fino alla fine del periodo di

inizializzazione (2-3 minuti).

Specifiche Tecniche

Elettriche

Assorbimento di corrente 16mA a 12V−(Nominale)

41mA a 12V−(Massimo)

Alimentazione richiesta da 9V−a 16V−

Contatti di allarme 24V−0.1A

Contatti Tamper 24V−0.1A

Ambientali

Immunità RF Conforme alle norme EN50130-4

Temp. funzionamento da -10ºC a 55ºC

Temp. stoccaggio da -20ºC a 60ºC

Ottica

Filtro Protezione contro le luci bianche

Fisiche

Dimensioni 127.6 mm x 64.2 mm x 46.6 mm

Peso 120 gr.

Installazione / Manutenzione

Installazione - Il rivelatore BWare DT può essere installato sia su di una

superficie piana che ad angolo.

1. Rimuovere il coperchio del rivelatore utilizzando un attrezzo appropriato

(come descritto nella Figura 1).

2. Utilizzando uno strumento appropriato aprire i fori a sfondare, di seguito

elencati, della base del contenitore come illustrato in Figura 2.

3. Per selezionare la posizione corretta della scheda elettronica con la lente

grandangolo montata, usare i riferimenti ( LONG / SHORT) situati nella

parte inferiore destra della scheda elettronica seguendo le indicazioni

della tabella di seguito illustrata:

4. Predisporre i ponticelli e i microinterruttori (Vedere la sezione relativa).

Nota: Ad ogni modifica delle predisposizioni/regolazioni, effettuare sempre

un reset del rivelatore rimuovendo e applicando tensione.

5. Rimontare il coperchio frontale e stringere la vite di blocco coperchio.

6. Effettuare una prova di copertura (Sezione Prova di movimento vedere

in basso).

Cablaggio Morsettiera (vedere Figura 5)

Morsetto Descrizione

- 12 + Ingresso di alimentazione 12V

ALARM Relé N.C.

TAMPER Interruttore N.C.

LED Controllo remoto dei LED e funzione GREEN LINE (con

microinterruttore SW1-3 in posizione ON)

Quando viene applicato un ”Segnale di Attivazione”** al

morsetto LED, tutti i LED vengono disabilitati e, se il

microinterruttore GREEN LINE è in ON, la sezione

microonda viene disabilitata.

I LED sono abilitati se al morsetto LED non è collegato

niente (a meno che il ponticello LED sia estratto).

**Per Segnale di attivazione si intende quanto segue-

- Viene applicata una tensione 12 Vcc e il ponticello LED Input è nella

posizione 12V (posizione di default)

- Viene applicato un riferimento di alimentazione 0V e il ponticello LED

Input è nella posizione 0V

Prova di movimento (Walk Test)

1. Due o tre minuti dopo aver alimentato il rivelatore (inizializzazione)

effettuare la prova di copertura dell’area da proteggere verificando la

risposta del rivelatore tramite l’accensione dei LED (vedere Figura 7).

2. La portata della microonda va regolata tramite l’apposito potenziometro

situato sulla scheda elettronica. Regolare il potenziometro della

microonda al minimo possibile riferito all’area da proteggere

(vedere Figura 5).

Il rivelatore BWare DT è un rivelatore di movimento che integra le tecnologie

più avanzate per le installazioni professionali. Questo rivelatore include

quella Anti-Cloak™ (ACT™) ed ha le resistenze di fine linea integrate nel

circuito per semplificarne al massino l'installazione.

Il rivelatore BWare DT utilizza la microonda in banda K la quale consente

una penetrazione ridotta attraverso i muri.

ITALIANO

Altezza di installazione e regolazione scheda elettronica in funzione

dell’areadi copertura:

Altezza di installazione L - LONG S - SHORT

2.1m-2.7m 15m 6m

J4- LED Usato per impostare la polarità dei comandi di attivazione

per gli ingressi LED.

Posizionato sul lato 12V richiede come

comando di attivazione una tensione

positiva. Fare riferimento alla sezione

relativa il Cablaggio Morsettiera,

morsetto LED.

Posizionato su 0V richiede come

comando di attivazione un riferimento

negativo di alimentazione 0V. Fare

riferimento alla sezione relativa il

Cablaggio Morsettiera, morsetto LED.

Microint./Pontic. Funzione

Predisposizione microinterruttori e ponticelli

Predisposizione microinterruttori e ponticelli

Microint./Pontic. Funzione

SW1-2: ACT Usato per abilitare o disabilitare la funzione ACT.

ACT abilitato

Importante: Non usare la funzione ACT™ se nel luogo di

installazione del rivelatore si prevede movimento di oggetti

al di fuori dell’area protetta come, ad esempio, il movimento

di persone in un corridoio attiguo.

ACT disabilitato.

SW1-1: LED Usato per abilitare o disabilitare il funzionamento dei LED.

ON

(Default) I LED sono abilitati ed è possibile anche controllarli via

comando remoto tramite l’ingresso LED.

OFF

ON

OFF

(Default)

I LED sono disabilitati. Non è possibile alcun controllo remoto.

SW1-4: Self Non applicabile in questa versione.

Test

SW1-3: Green Line

BWare DT include la funzione Green Line che evita emissioni radio superflue

nell’ambiente. Questa funzione disabilita il canale a microonda (MW) quando

il sistema di sicurezza è disinserito.

La funzione Green Line è abilitata: Per disabilitare la sezione

microonda (MW) a sistema DISINSERITO va applicato un

comando di attivazione al morsetto LED (0V o 12V in funzione

della polarità configurata tramite il ponticello LED/SET INPUT).

Anche i LED verranno in questo caso disabilitati. La sezione

microonda viene disabilitata in questo modo solo se al morsetto

SET non viene applicata alcuna tensione.

Nota: Quando la funzione Green Line è attiva (Microonda

spenta), il rivelatore si attiva usando la sola sezione ad

infrarossi (PIR).

La funzione Green Line è disabilitata. La sezione a

microonda (MW) è sempre accesa.

ON

OFF

(Default)

Ponticelli Per

resistenze EOL

I ponticelli J1 e J2 permettono la selezione dei valori resistivi

da assegnare ai circuiti di Tamper e di Allarme (1K, 2.2K,

4.7K, 5.6K, 6.8K) in funzione della centrale d’allarme

utilizzata (vedere la Figura 4 in basso).

Seguire lo schema di collegamento dei morsetti illustrato in

Figura 4 quando si vuole collegare il sensore ad una centrale

d’allarme usando il doppio bilanciamento resistivo (DEOL).

J1 - Alarm EOL

J2 - Tamper EOL

(Default)

Contains FCC ID UXS-IPM165F

BWare RK515DTGL FCC Compliance Section:

FCC Part 15 Note:

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment to an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician.

FCC Warning:

The manufacturer is not responsible for any radio or TV interference caused by

unauthorized modifications to this equipment. Such modifications could void the

user's authority to operate the equipment.

Lorsqu'un ”Signal d'Activation”** est appliqué à l'entrée

LED du bloc des terminaux ou bornes de connexion, les

indicateurs LED se désactivent (cf. aussi l'entrée Test

automatique dans le tableau consacré au Réglagedes

cavaliers).

Les voyants LED sont activés si rien n'est relié (sauf si le

cavalier LED est éteint (OFF).

**Signal d'Activation-

Si une tension de 12VCC est appliquée et que le Cavalier d'entrée LED

est en position 12V (Défaut de position)

-Ou-

Si la Terre (GND) est reliée, le Cavalier d'entrée LED est en position 0V.

SW1-3: Green Line

Le BWare DT intègre la fonction Green Line, qui suit les recommandations

environnementales. Cette fonction désactive le canal hyper fréquence quand le

système d’alarme est désarmé, pour éliminer le surplus d’émissions HF quand

les locaux sont occupés.

Marche (ON) La fonction Green Line est activée : Pour désactiver le module

HF pendant le désarmement, les LEDs doivent aussi être

désactivées par le terminal de connexion LED.

Note : Quand le Green Line est activé (HF désactivé), le

détecteur sera toujours actif (IRP seul).

Arrêt (OFF)

(Défaut) Green Line désactivé (OFF): le canal HF est constamment activé.

Réglage des cavaliers

Cavalier Fonction

SW1-1: LED Définit le fonctionnement des indicateurs LED du détecteur.

Marche (ON)

(Défaut)

L'activation des indicateurs LED dépend du paramétrage du

contrôle à distance de leur fonctionnement (cf. § Câblage des

Terminaux, borne de connexion LED).

Arrêt (OFF) Les indicateurs LED sont désactivés.

SW1-2: ACT Définit si le mode ACT est activé ou non

Marche (ON) ACT activé.

Important ! N'utilisez pas le mode ACT™ dans une zone en

dehors de laquelle le passage d'objets en mouvement vous

paraît logique et attendu, un couloir par exemple.

Arrêt (OFF)

(Défaut) ACT désactivé.

Les cavaliers J1 et J2 permettent de sélectionner les

résistances EOL (fin de ligne) d'Autoprotection, Alarme et

FAULT (1K, 2,2K, 4,7K, 5,6K, 6 et 8K) en fonction

de la centrale (cf. Figure 4 ci-dessous).

Suivez les indications du diagramme de connexion du bloc

des terminaux de la Figure 4 pour relier le détecteur à une

zone EOL Double (DEOL).

J1 - Alarm EOL

J2 - Tamper EOL

Toutes

diodes LED Clignotante

l'une après

l'autre

Lors de la mise sous tension, les diodes LED

clignotent de manière ininterrompue, l'une après

l'autre, jusqu'à la fin de la séquence

d'échauffement (2 à 3 minutes).

Affichage LED

LED Position Signification

Jaune Allumée (ON) Détection IRP

Clignotante Panne de canal IRP

Verte Allumée (ON) Détection HF (hyperfréquence)

Clignotante Panne de canal HF

Bleu Allumée (ON) Indique une ALARME

Rétsistance de la boucle de Etat ouvert: plus que 108

Détection: Etat fermé: moins que 1 ohm

Ondulations résiduelles maximales 0.25 créte à créte

admissibles:

Taille du càble à utiliser: Fil de diamétre au moins 0.5 mm pour une

longueur ne dépassant pas 300 métres

Filtrage Protection anti-lumière blanche

Dimensions 127.6 x 64.2 x 46.6 mm (5 x2.5 x 1.84 in.)

Poids 120g

Immunité RF Selon EN50130-4

Température de fonctionnement De -20ºC à 55ºC (-4ºF à 131ºF)

Température de stockage De -20ºC à 60ºC (-4ºF à 140ºF)

Indice de protection: IP 31/IK 02

Spécifications techniques

Consommation électrique 14.8 mA à 12VCC (en utilisation typique)

39.5 mA à 12VCC (max. avec tous les

voyants LED allumés)

Tension requise 9 -16VCC

Contacts d'alarme 24VCC, 0,1A

Temps minimal de changement 2.2 seconds

d’état:

Contacts d'autoprotection 24VCC, 0,1A

Electriques

Test de passage

1. Deux minutes après avoir réalisé la mise sous tension (séquence

d'échauffement), effectuez un test de passage pour vérifier l'efficacité

du détecteur sur la totalité de la zone à protéger.

2. Assurez-vous d'avoir bien réinstallé le couvercle frontal avant de mettre

le détecteur sous tension (cf. Figure 7).

3. Le potentiomètre situé sur la carte PCB permet de régler la portée de

détection hyperfréquence. Il est important de régler le potentiomètre

sur le niveau le plus bas possible qui fournira cependant une couverture

suffisante sur la totalité de la zone à protéger (cf. Figure 5).

J4 - Entrée

LED Détermine la polarité de l'entrée externe LED.

Cf. § Câblage de Terminal, borne de

connexion LED (Mise en service). Cf. § Câblage de Terminal, borne de

connexion LED (Mise en service).

SW1-4: Test Non applicable dans cette version.

automatique

Câblage des Terminaux (cf. Figure 5)

Terminal Description

- 12 + Entrée 12VCC

ALARM Relais N.F., 24VCC, 0,1A

TAMPER Relais N.F., 24VCC, 0,1A

LED Contrôle à distance des indicateurs LED

Hauteur de montage L - LONG C - COURT (SHORT)

2.1m-2.7m (6'11"-8’10") 15m (50’) 6m (20’)

Hauteur de montage et position selon la taille de la pièce :

4. Réglez les cavaliers (cf. § Réglage des cavaliers).

Remarque: Il est conseillé de réinitialiser le détecteur après chaque

modification apportée au réglage.

5. Replacez le couvercle frontal (en inversant pour cela l'ordre des

étapes de la procédure de retrait).

6. Exécutez un test de passage (cf. §Test de passage ci-dessous).

FRANÇAIS

Le détecteur BWare DT est le dernier détecteur de mouvements pour

les installations professionnelles, et intègre les technologie

Anti-Camouflage (ACT™) ainsi que des résistances de fin de ligne

(EOL) pour simplifier l’installation.

Le détecteur utilise un module Hyper Fréquence en bande K, qui

permet une réduction de la pénétration à travers les murs.

Installation

Montage - l’BWare DT peut être installé soit sur une surface plane soit

en coin (gauche ou droit).

1. Retirer le détecteur de couvercle frontal a l’aide d'un outil adequat

(décrit son la Figure 1).

2. A l’aide d’un outil adequat, ouvrez les pastilles pré-percées

correspon dantes sur la báse du d tecteur (cf.Figure 2).

3. Pour définir le bon réglage vertical, positionnez l'appareil en

LENTILLE GRAND ANGLE.

Servez-vous de l'échelle figurant sur le côté inférieur droit de la carte

PCB de couvercle (cf. Figure 7) comme suit :

(Défaut)

Environnementales

Optiques

Physiques