iWISETM

Models:

RK815DTG3/RK815DTG3A

RK825DTG3/RK825DTG3A

Hauteur de montage et position selon la taille de la pièce :

Pour le RK815DTG3/RK815DTG3A

Hauteur de montage L - LONG C - COURT (SHORT)

Pour le RK825DTG3/RK825DTG3A

2.1m-2.7m (6'11"-8’10") 15m (50’) 6m (20’)

1.8m-2.0m (5'11"-6’7") 25m (82’) 8m (26’)

MIN MAX

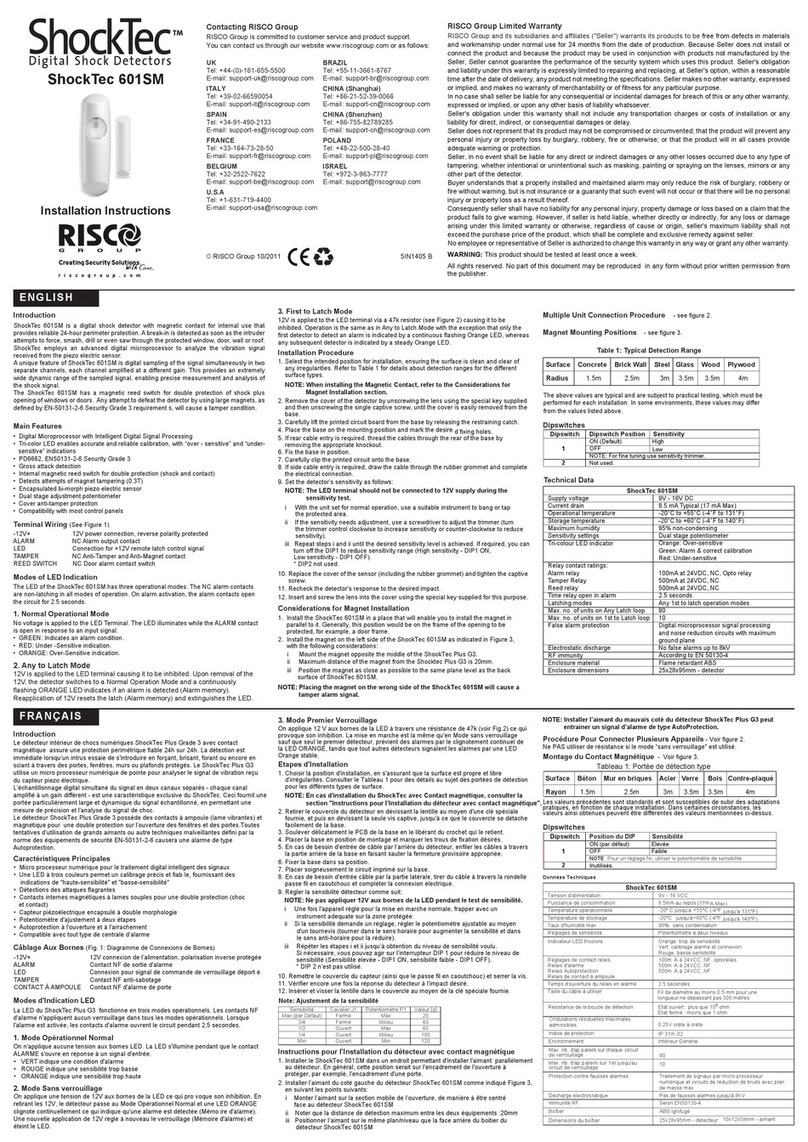

ENGLISH

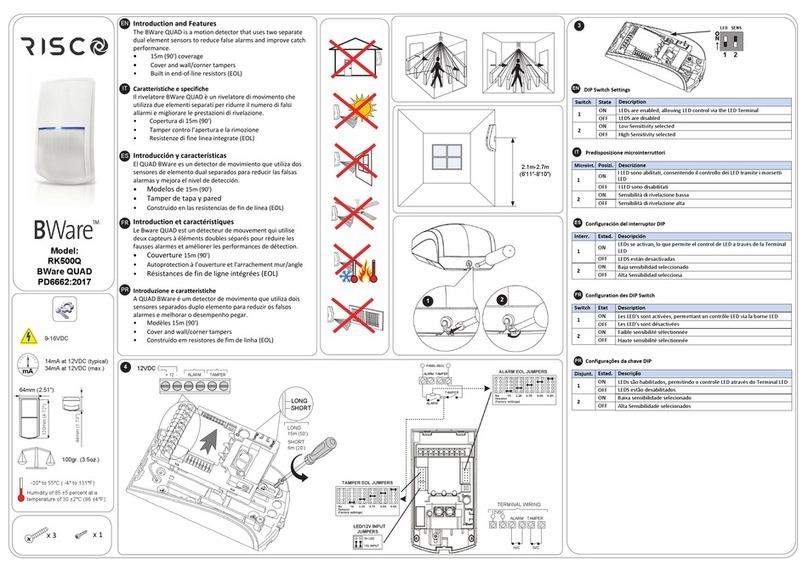

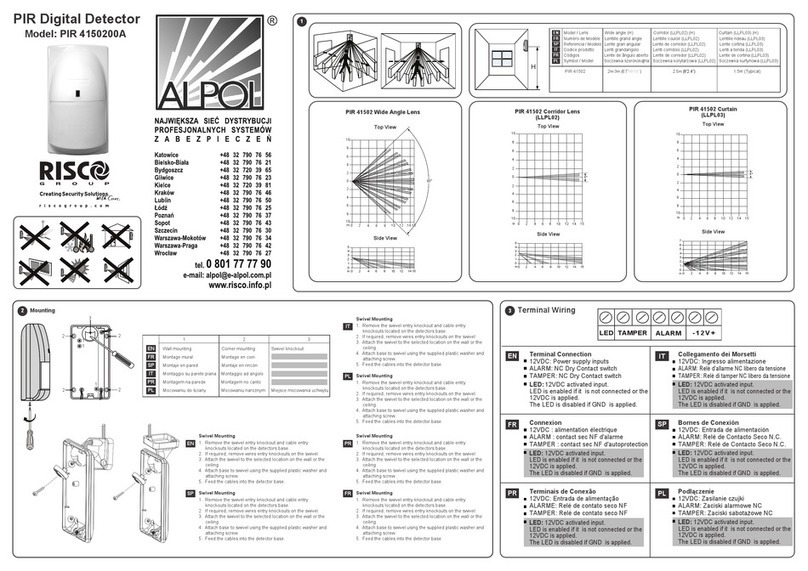

RK815DTG3/RK815DTG3A/RK825DTG3/RK825DTG3A detectors are available in 15m

and 25m models, and include built-in end-of-line (EOL) resistors to simplify installation.

Installation / Maintenance

1. Mounting - The iWISE

RK815DTG3/RK815DTG3A/RK825DTG3/RK825DTG3A

can be mounted

either on a flat surface or on a wall corner (corner mounting).

•Using a suitable tool, open the following knockouts on the detector’s base (see Figure 1).

Note: If a back tamper is to be used it is mandatory to screw the tamper back plate to the wall (or

wall corner).

2. To select the correct vertical adjustment position for wide angle lens, use the scale on the bottom

left hand side of the PCB as follows:

Mounting height and scale position based on room size:

For RK815DTG3/RK815DTG3A

Mounting Height L - LONG S - SHORT

2.1m-2.7m (6'11"-8’10") 15m (50’) 6m (20’)

For RK825DTG3/RK825DTG3A

1.8m-2.0m (5'11"-6’7") 25m (82’) 8m (26’)

Note: For Corridor installations, select position to 'LONG' and mount the detector at 2.5m/8’2” height.

3. Set jumpers (see Jumper Setting section).

IMPORTANT: On the face of the Microwave, you will find a colored dot, this represents the Microwave

channel. When installing two detectors in near locations, it is recommended that these dots (channels)

are not of the same color. Example: Two Red should be avoided

Note: Reset the detector after each change made to the settings.

4. Install the front cover back to its place (in a reverse sequence of the removal.

5. Perform a Walk test (see Walk Test section).

6.

Changing Lenses (see Figure 2).

Terminal Wiring (see Figure 5)

Terminal Description

- 12 + 12VDC Input

ALARM N.C. Relay

TAMPER N.C. Tamper switch

FAULT/AM Normally Closed Relay: The FAULT/AM relay opens in the following events:

• Detector is masked (Alarm relay is also opened)

• Self test failed

• Input voltage is lower than 8VDC

LED LED operation remote control

When an ”Activation Signal”** is applied to the LED input terminal, all LEDs will

be disabled.

LEDs are enabled if nothing is connected (unless LED jumper is OFF) or 0V/12V

is applied (according to the LED/SET Input Jumper position, 12V or 0V).

SET Remote SET/UNSET control

SET:If an ”Activation Signal”** is applied, anti-mask detection is disabled (for

Grade 2 configuration).

UNSET: If nothing is connected or 0V/12V is applied (according to the LED/SET

Input Jumper position, 12V or 0V) anti-mask detection is enabled (see also

“Green Line” and “Remote Self Test”

**Activation Signal-

If 12VDC is applied, and the LED/SET Input Jumper is on 12v position

- Or -

0V is applied and LED/SET Input Jumper is on 0V position

Jumper Settings

Jumper Function

SW1-2: ACT

ON

ACT Enabled

Important: Do not use ACT™ mode if you are expecting that there will be

moving objects outside the required protected area, a corridor for example.

OFF ACT Disabled.

SW1-1: LED Used to determine the operation of the detector’s LEDs

Used to determine if ACT mode is enabled or disabled

ON: LEDs are enabled, allowing LED control via the LED input terminal

OFF: LEDs are disabled

Walk Test

1. Two minutes after applying power (warm-up period), walk test the Detector over the entire protected

area to verify proper operation of the unit (see Figure 6).

2. The MW range can be adjusted by using the potentiometer located on the PCB. It is important to set

the potentiometer to the lowest possible setting that will still provide enough coverage for the inner

boundary protected area (see Figure 4).

MW range adjustment (Figure 4)

1 Over power A Detector

2 Under power B Corridor

3 Correct adjustment

Red On ALARM

Flashing Fault / Anti-Masking detection

Note: Anti Masking detection is operational in “Unset” mode only

(see Terminal Wiring section, SET terminal).

All LEDs Flashing At power-up, the LEDs will flash consecutively until the end of the

warm-up period (2-3 minutes). At the end of the warm-up period

the RED LED will continue to flash until the end of AM initiation.

(consecutively)

LEDs Display

LED State Description

Yellow On PIR detection

Flashing Trouble in PIR channel

Green On MW detection

Flashing Trouble in MW channel

Note: AM and Trouble indications continue until masking is removed or trouble is corrected.

Technical Specification

Electrical

Current consumption 16.8mA at 12VDC (Typical)

39.5mA at 12VDC (max.)

Voltage requirements 9 -16VDC***

Alarm contacts 24VDC, 0.1A

Tamper contacts 24VDC, 0.1A

FAULT/AM contacts 24VDC, 0.1A

Environmental

RF immunity According to EN50130-4

Operating temperature -10C to 55C (14F to 131F)

Storage temperature -20C to 60C (-4F to 140F)

Optical

Filtering White Light Protection

Physical

Size 127.6 x 64.2 x 46.6 mm (5 x 2.5 x 1.84 in.)

Weight

*** Power to be supplied by 5A max. power source using safety approved wires,

with a min Gauge of 20AWG.

120 gr. (4.2 oz.)

FRANÇAIS

Les détecteurs RK815DTG3/RK825DTG3 sont les tout derniers modèles de détecteurs de mouvement

conçus pour les établissements professionnels. Ils intègrent deux technologies de pointe: Anti-masque

et Anti-Cloak™ (ACT™) Anti-camouflage, qui répondent aux nouvelles directives de protection de

l'environnement. .

Disponibles en modèles 15m et 25m, les détecteurs RK815DTG3/RK825DTG3 comprennent des

résistances de Fin de ligne (EOL = end-of-line) intégrées qui facilitent l'installation.

Installation

1. Montage – RK815DTG3/RK825DTG3 peut être installé soit sur une surface plane soit en coin

(gauche ou droit).

•

A l’aide d’un outil adequat, ouvrez les pastilles pr

é-

perc

ée

s correspondantes sur la báse du d

tecteur (cf. Figure 1).

Remarque: En cas d'utilisation d'une autoprotection arrière, il est impératif de fixer la plaque de cette

dernière en la vissant au mur (ou à l'angle du mur).

2. Pour définir le bon réglage vertical, positionnez l'appareil en LENTILLE GRAND ANGLE. Servez-vous

de l'échelle figurant sur le côté inférieur gauche de la carte PCB (cf. Figure 6) comme suit :

3. Réglez les cavaliers (cf. § Réglage des cavaliers).

Remarque: Il est conseillé de réinitialiser le détecteur après chaque modification apportée au réglage.

4. Replacez le couvercle frontal (en inversant pour cela l'ordre des étapes de la procédure de retrait).

5. Exécutez un test de passage (cf. §Test de passage).

6. Changement des lentilles (cf. Figure 2).

Câblage des Terminaux (cf. Figure 5)

Terminal Description

- 12 + Entrée 12VCC

ALARM Relais N.F., 24VCC, 0,1A

TAMPER Relais N.F., 24VCC, 0,1A

FAULT / AM Sortie normalement fermée : La sortie FAULT/AM s'ouvre dans les cas

suivants :

• Détection ou neutralisation d'un masquage,

• Echec du test automatique,

• Tension d'entrée inférieure à 8VCC.

LED Contrôle à distance des indicateurs LED

Lorsqu'un ”Signal d'Activation”** est appliqué à l'entrée LED du bloc des

terminaux ou bornes de connexion, les indicateurs LED se désactivent

(cf. aussi l'entrée Test automatique dans le tableau consacré au Réglage

des cavaliers).

Les voyants LED sont activés si rien n'est relié (sauf si le cavalier LED

est éteint (OFF).

SET Contrôle à distance de la mise en Service (SET) / mise en Inactivité du

système (UNSET).

SET (mise en service): Si un ”Signal d'Activation”** est appliqué, la

détection de masquage est désactivé (en configuration de catégorie 2).

UNSET (mise en inactivité) : Si aucune connexion n'est appliquée ou

que la Terre (GND/12V) est reliée (selon la position du Cavalier d'entrée

LED/SET, à 12V ou 0V), la détection de masquage est activée (cf.

également les entrées “Green Line” et “Test automatique à distance”

dans le tableau consacré au Réglage des cavaliers).

**Signal d'Activation-

Si une tension de 12VCC est appliquée et que le Cavalier d'entrée LED/SET est en position 12V

-Ou-

Si la Terre (GND) est reliée, le Cavalier d'entrée LED/SET est en position 0V.

Réglage des cavaliers

Cavalier Fonction

SW1-1: LED Définit le fonctionnement des indicateurs LED du détecteur.

Marche (ON) L'activation des indicateurs LED dépend du paramétrage du contrôle à distance

de leur fonctionnement (cf. § Câblage des Terminaux, borne de connexion LED).

SW1-4: Self

Test Used to test detection technologies.

(Local Self Test): If there is no alarm detection in the PIR channel for a period

of one 1 hour, the detector will self-test. If the local self test fails, the FAULT/A

M

Relay will activate.

ON

Arrêt (OFF) Les indicateurs LED sont désactivés.

Définit si le mode ACT est activé ou non

SW1-4:

Test

automatique

Permet de tester la capacité de détection des canaux IRP et HF.

(Test automatique local): si aucune détection n'est décelée pendant une période

d'une heure, le détecteur exécute un test automatique. En cas d'échec du test

automatique local, le relais FAULT/AM est activé.

SW1-3: Green Line

RK815DTG3/RK815DTG3A/RK825DTG3/RK825DTG3A, concept qui permet aux détecteurs

de respecter les directives environnementales en évitant les émissions excessives.

Cette caractéristique permet en effet de désactiver le canal HF (hyperfréquence) lorsque

le système d'alarme est inactivé (“UNSET”), neutralisant ainsi tout excès d’émission

d’hyperfréquences’ pendant que les locaux sont occupés.

Marche (ON)

"Green Line" activée: Pour désactiver le module HF pendant les périodes

d'inactivité du système (UNSET), les indicateurs LED doivent aussi être

désactivés à distance.

Arrêt (OFF) Green Line désactivé (OFF): le canal HF est constamment activé.

SW1-2: ACT

Marche (ON) ACT activé.

Important ! N'utilisez pas le mode ACT™ dans une zone en dehors de laquelle

le passage d'objets en mouvement vous paraît logique et attendu, un couloir par

exemple.

Arrêt (OFF)

(Défaut) ACT désactivé.

(Défaut)

(Défaut)

(Default)

(Default)

(Default)

Marche (ON)

SW1-3: Green Line

The RK815DTG3/RK815DTG3A/RK825DTG3/RK825DTG3A includes a Green Line feature

that follows environmental guidelines by avoiding surplus emission. This feature disables the

MW channel when the alarm system is “Unset”, thus eliminating surplus MW emission

while the premises is occupied.

ON Green Line feature is enabled: To deactivate the MW module in “UNSET”

period, the LEDs must also be remotely disabled by the LED terminal.

Note: When ‘Green Line’ is on (Microwave off), the detector will still activate

(PIR only)

OFF Green Line feature in disabled: MW is constantly in use.

(Remote Self Test): Remote Self Test is activated when the SET terminal is

switched from SET to UNSET mode. For remote self test pass, the Alarm Relay

will activate for 5 seconds.

If the remote self test fails, the FAULT/A

M Relay

will activate.

OFF

(Default)

J4 - LED/SET

INPUT Used to determine the polarity of the external input.

See Terminal Wiring section, LED and SET Terminals

See Terminal Wiring section, LED and SET Terminals

J1 - Alarm EOL

J2 - Tamper EOL

J3 - FAULT/AM EOL

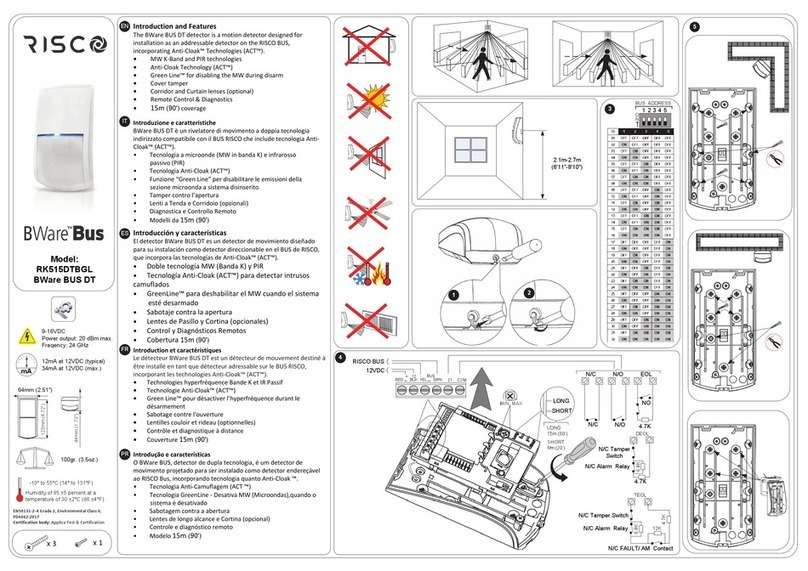

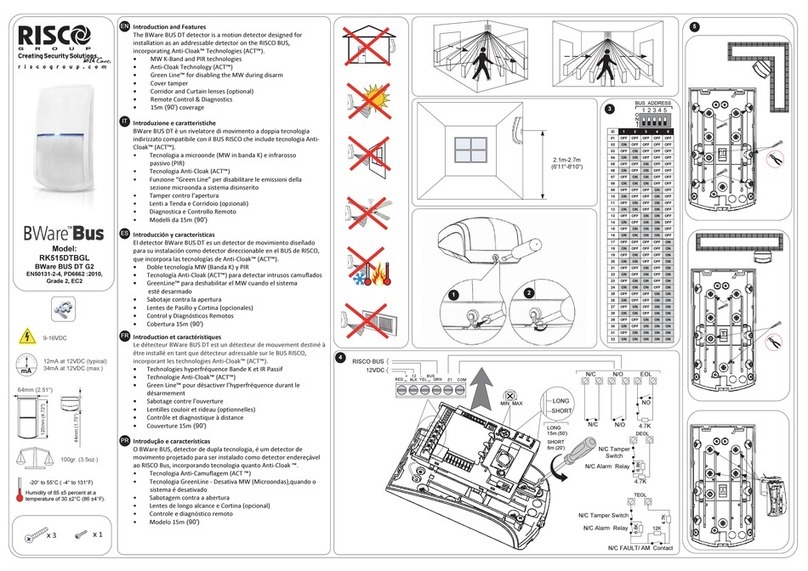

Jumpers J1 and J2 allow the selection of Tamper and Alarm resistance

(1K, 2.2K, 4.7K, 5.6K, 6.8K) according to the control panel (see Figure 3) .

Jumper J3 allows the selection of 12K for Fault/Anti-Mask.

Follow the terminal block connection diagram in Figure 3 when

connecting the detector to a Double/Triple End Of Line (DEOL/TEOL)

Zone.

Important: After applying power to the detector, close the cover within 2 minutes as after this

period AM initialization will start.

Remarque: Pour les installations en couloir, sélectionnez la position 'LONG' et appliquez l'option de

montage à hauteur de 2,5m/8’2”.

Les cavaliers J1, J2 et J3 permettent de sélectionner les résistances EOL

(fin de ligne) d'Autoprotection, Alarme et FAULT/AM (1K, 2,2K, 4,7K, 5,6K,

6,8K et 12K) en fonction de la centrale (cf. Figure 3 ci-dessous).

Suivez les indications du diagramme de connexion du bloc des terminaux

de la Figure 3 pour relier le détecteur à une zone EOL Double/Triple

(DEOL/TEOL).

Cavaliers TEOL

J1 - Alarm EOL

J2 - Tamper EOL

J3 - FAULT / AM EOL

Installatie / Onderhoud

1. Montage - De RK815DTG3/RK825DTG3 kan op een vlakke oppervlakte worden gemonteerd, of op

een muurhoek (hoekmontage)

• Met een passend gereedschap opent u de volgende uitwerpers op de basis van de detector (zie

Afbeelding 1).

Opmerking: Als een achterstamper wordt gebruikt, is het verplicht om de achterplaat van de stamper

op de muur (of muurhoek) vast te schroeven

2. Om voor de brede hoeklens de juiste verticale afstelpositie te selecteren, gebruikt u de schaal op de

linker onderkant van de PCB. U doet dit als volgt:

Montagehoogte en schaalpositie op basis van kamergrootte:

Voor RK815DTG3/RK815DTG3A

Montagehoogte L - LANG C - KORT

2.1m-2.7m 15m 6m

Voor RK825DTG3/RK825DTG3A

1.8m-2.0m 25m 8m

Opmerking: Voor installaties in een hal selecteert u de positie naar 'LANG' en monteert u de detector

op een hoogte van 2,5 m/8'2".

3. Jumpers instellen (zie sectie Jumperinstellingen).

Opmerking: Stel na elke wijziging aan de instellingen, de detector opnieuw in.

4. Installeer het voorste lid terug op zijn plaats (in omgekeerde volgorde van de verwijdering).

5. Voer een looptest uit (zie sectie Looptest).

6. Lenzen wisselen (zie. Afbeelding 2).

Bedrading terminal (zie Afbeelding 5)

Terminal Beschrijving

- 12 + 12 VDC-ingang

ALARME N.C.-relais

TAMPER N.C. Sabotageschakelaar

FAULT/AM Normaal gesloten relais: De relais STORING/AM wordt bij de volgende

gebeurtenissen geopend:

• Detectorbewaking wordt ingeschakeld (Relais alarm wordt ook geopend)

• Zelf-test is mislukt

• Ingangspanning is lager dan 8VDC

LED LED-werking afstandsbediening

Als op de LED van de ingangterminal een "Activeringsignaal"** wordt toegepast,

worden alle LED's uitgeschakeld. LED's worden ingeschakeld als niks is

aangesloten (tenzij LED-jumper op UIT is ingesteld) of 0V/12V wordt toegepast

(volgens de LED/INSTELLING positie van de ingangjumper, 12 V of 0 V).

SET Externe besturing INSTELLEN/NIET INSTELLEN

INSTELLEN: als een "activeringsignaal"** wordt toegepast, wordt de anti-

maskeringdetectie uitgeschakeld (voor configuratie Klasse 2).

NIET INSTELLEN: Als niks is aangesloten of als 0 V/12 V wordt toegepast

(volgens de LED/INSTELLING

Als 12 VDC wordt toegepast en de ingangjumper LED/INSTELLEN is op de positie 12V

-Of-

0 V wordt toegepast en ingangjumper LED/INSTELLEN is op positie 0 V

**Activeringsignaal-

Jumperinstellingen

Jumper Functie

SW1-2: ACT Gebruikt om vast te stellen of de ACT-modus is in- of uitgeschakeld.

AAN ACT ingeschakeld

Belangrijk: Niet de ACT™-modus gebruiken als u verwacht dat er buiten het

beschermde gebied (zoals bijvoorbeeld een hal, bewegende objecten zijn.

UIT ACT uitgeschakeld.

(Standaard)

(Standaard)

SW1-1: LED Gebruikt om de werking van de LED's van de detector vast te stellen.

AAN LED's worden ingeschakeld zodat via de ingangsterminal van de LED,

LED-besturing mogelijk is.

UIT LED's worden uitgeschakeld

SW1-4: Zelf

Test Gebruikt om detectietechnologieën te testen.

(Lokale zelftest): als in het PIR-kanaal gedurende 1 uur geen alarmdetectie

plaatsvindt, voert de detector een zelftest uit. Als de lokale zelftest mislukt,

wordt de STORING/AM-relais actief.

(Externe zelftest): de externe zelftest wordt geactiveerd als de terminal

INSTELLEN van de modus INSTELLEN naar NIET INSTELLEN schakelt.

Opdat de externe zelftest slaagt, zal de alarm-relais gedurende 5 seconden

actief zijn. Als de externe zelftest mislukt, wordt de STORING/AM-relais actief.

SW1-3: Groene lijn

De

RK815DTG3/RK815DTG3A/RK825DTG3/RK825DTG3A

bevat de functie Groene lijn

die milieurichtlijnen volgt door een overschot uitstraling te vermijden. Deze functie schakelt het

MW-kanaal uit als het alarmsysteem op "Niet instellen" is ingesteld en dus de overmatige

MW-uitstraling wordt verwijderd terwijl het gebied bezet is.

AAN

Functie Groene lijn is ingeschakeld: om de MW-module in de periode "NIET

INSTELLEN" te deactiveren, moeten ook de LED's van een afstand door de

LED-terminal worden uitgeschakeld.

Opmerking: Als 'Groene lijn' aan is (microgolf uit), is de detector nog steeds

actief (alleen PIR).

UIT

AAN

UIT

Functie Groene lijn is uitgeschakeld: MW is constant in gebruik.

Jumpers J1 en J2 maken de selectie mogelijk voor sabotage- en

alarmweerstand (1K, 2.2K, 4.7K, 5.6K, 6.8K) volgens het bedieningspaneel

(zie Afbeelding 3). Met jumper J3 is de selectie mogelijk van 12K voor

Storing/Anti-maskering.

Volg het aansluitingsschema van het aansluitblok in Afbeelding 3 als u de

detector op een twee-/drievoudige zone aan het einde van de lijn

(DEOL/TEOL) aansluit.

(Standaard)

(Standaard)

J1 - Alarm EOL

J2 - Sabotage EOL

J3 - STORING/

AM EOL

Looptest

Belangrijk: Na voeding naar de detector toe te passen, sluit u het lid binnen 2 minuten. Na deze

periode start namelijk de AM-initialisatie.

1. Twee minuten na het toepassen van voeding (opwarmingsperiode), voert u over het hele beschermde

gebied van de detector de looptest uit om goede werking van de eenheid te verifiëren (zie Afbeelding 6).

2. Het MW-bereik kan worden afgesteld door de potentiometer op de PCB te gebruiken. Het is belangrijk

dat de potentiometer op de laagst mogelijke instelling wordt ingesteld om het binnenste beschermde

grensgebied voldoende dekking te bieden (zie Afbeelding 4).

Jumper Functie

J4 - LED/

INSTELLEN

INGANG

Gebruikt om de polariteit van de externe ingang vast te stellen.

Zie de sectie Bedrading terminal, terminals LED en INSTELLEN

Zie de sectie Bedrading terminal, terminals LED en INSTELLEN

MIN MAX

Afstelling MW-bereik (zie Afbeelding 4)

1 Overspanning

2 Onderspanning

3 Juiste afstelling

A Detector

B Hal

Groen Aan MW-detectie

Knipperen Storing in MW-kanaal

Rood Aan ALARM

Knipperen Storings-/anti-maskeringsdetectie

Opmerking: Anti-maskeringsdetectie is alleen in de

modus "Niet instellen" werkzaam (zie sectie Bedrading

terminal, terminal INSTELLEN).

Alle LED's Knipperen Opwarmingsperiode (2-3 minuten). Aan het einde

van de opwarmingsperiode gaat de RODE LED door

met knipperen tot het einde van de AM-initiatie.

(achtereenvolgende)

Opmerking: AM- en Storingsindicaties gaan door totdat de maskering wordt verwijderd of de

storing wordt gecorrigeerd.

Technische specificaties

Elektrisch

Stroomverbruik 16.8mA bij 12VDC (typisch)

39.5mA bij 12VDC (max.)

Spanningsvereisten 9 -16VDC

Alarmcontacten 24VDC, 0,1A

Sabotagecontactencontacten 24VDC, 0,1A

STORING/AM-contacten 24VDC, 0,1A

Omgeving

RF-immuniteit Volgens EN50130-4

Bedrijfstemperatuur -10C tot 55C

Opslagtemperatuur -20C tot 60C

Optisch

Filtrering Wit licht-bescherming

Fysiek

Grootte 127,6 x 64,2 x 46,6 mm

Gewicht 120 gr.

Display LED's

LED Status Beschrijving

Geel Aan PIR-detectie

Knipperen Storing in PIR-kanaal

MIN MAX

Test de passage

1. Deux minutes après avoir réalisé la mise sous tension (séquence d'échauffement), effectuez un

test de passage pour vérifier l'efficacité du détecteur sur la totalité de la zone à protéger.

2. Assurez-vous d'avoir bien réinstallé le couvercle frontal avant de mettre le détecteur sous tension

(cf. Figure 6).

3. Le potentiomètre situé sur la carte PCB permet de régler la portée de détection hyperfréquence. Il

est important de régler le potentiomètre sur le niveau le plus bas possible qui fournira cependant

une couverture suffisante sur la totalité de la zone à protéger.

Réglage de la portée HF (cf. Figure 4)

1 Trop puissant

2 Pas assez puissant

3 Réglage correct

A Détecteur

B Couloir

Affichage LED

LED Position Signification

Jaune Allumée (ON) Détection IRP

Clignotante Panne de canal IRP

Verte Allumée (ON) Détection HF (hyperfréquence)

Clignotante Panne de canal HF

Rouge Allumée (ON) Indique une ALARME

Clignotante Détection d'Erreur /Anti-masque

Remarque: La détection Anti-masque est opérationnelle

en mode “UNSET” (Inactivité du système) seulement (cf.

§ Câblage des Terminaux, terminal de mise en service

(SET).

Toutes

diodes LED Clignotante Lors de la mise sous tension, les diodes LED clignotent de

manière ininterrompue, l'une après l'autre, jusqu'à la fin de

la séquence d'échauffement (2 à 3 minutes). A la fin de ce

laps de temps, le voyant LED ROUGE continue à clignoter

jusqu'à la fin du lancement de l'AM (pour mettre un terme

au clignotement, fermez le couvercle).

(l'une après

l'autre)

Remarque: Les indications AM et Panne persistent jusqu'à élimination de la cause du masquage

ou réparation de la panne.

Spécifications techniques

Consommation électrique 16.8 mA à 12VCC (en utilisation typique)

39.5 mA à 12VCC (max. avec tous les voyants

LED allumés)

Tension requise 9 -16VCC

Contacts d'alarme 24VCC, 0,1A

Temps minimal de changement d’état: 2.2 seconds

Contacts d'autoprotection 24VCC, 0,1A

Contacts FAULT/AM 24VCC, 0,1A

Rétsistance de la boucle de Détection: Etat ouvert: plus que 108

Etat fermé: moins que 1 ohm

Ondulations résiduelles maximales

admissibles: 0.25 créte à créte

Taille du càble à utiliser: Fil de diamétre au moins 0.5 mm pour une

longueur ne dépassant pas 300 métres

Optiques

Filtrage Protection anti-lumière blanche

Physiques

Dimensions 127.6 x 64.2 x 46.6 mm (5 x2.5 x 1.84 in.)

Poids 120g

Environnementales

Immunité RF Selon EN50130-4

Température de fonctionnement De -20ºC à 55ºC (-4ºF à 131ºF)

Température de stockage De -20ºC à 60ºC (-4ºF à 140ºF)

Indice de protection: IP 31/IK 02

Electriques

Important : Après la mise sous tension du détecteur, fermer le couvercle dans les 2 minutes

pour que la période d’initialisation AM (Anti-Masque) démarre.

NEDERLANDS

De detectors

RK815DTG3/RK815DTG3A/RK825DTG3/RK825DTG3A

zijn de ultieme

bewegingsdetectors voor professionele installaties die met de Anti-maskering- en ). Hierbij

Anti-Cloak™-technologieën samenwerken (ACT™ stellen zij zich in op nieuwe

omgevingsvriendelijke richtlijnen.

RK815DTG3/RK815DTG3A/RK825DTG3/RK825DTG3A-detectors zijn beschikbaar in modellen

van 15 m en 25 m, en bevatten ingebouwde eind-van-lijn-weerstand (EOL) om de installatie

te vereenvoudigen.

Cavalier Fonction

J4 - Entrée

LED/SET Détermine la polarité de l'entrée externe.

Cf. § Câblage des Terminaux, bornes de connexion LED et SET (Mise en

service).

Cf. § Câblage des Terminaux, bornes de connexion LED et SET (Mise en

service).

RK815DTG3/RK815DTG3A/RK825DTG3/RK825DTG3A detectors are the ultimate motion detectors

for professional installations, incorporating both Anti-Mask and Anti-Cloak™ Technologies (ACT™),

adhering to new environmentally friendly guidelines.

(Test automatique à distance): le test automatique à distance s'active lorsque le

terminal de réglage (SET) passe du mode de mise en service (SET) à celui

d'inactivité du système (UNSET).

Si le test automatique à distance réussit, le relais d'alarme s'active pendant 5

secondes. Si le test automatique à distance échoue, c'est le relais FAULT/AM

qui s'active.

(Défaut)

Arrêt (OFF)

© RISCO Group 08/2022 5IN2634 D

EN50131-1 Grade 3*

EN50131-2-4 Grade 3*

EN50131-6 Type C

EN50130-5 Class II

EN50130-4

Certification Body: Applica Test & Certification

* Grade 2 when installed with swivel

RK815DTG3/RK825DTG3 applicable countries (European version):

AT BE CY CZ DK

EE FI FR DE GR

HU IE IT LV LT

PT

LU MT NL PL

SE SL ES SK GB

BG RO TR CH NO

RK815DTG3/RK825DTG3 applicable countries (German Version):

AT, CZ, SL, DE, TR, RU, EE

U.S. Patent Number:

This product is protected under Patent No. US 7,126,476 B2. Other patents pending.

UK Tel: 44-(0)-161-655-5500

ITALY Tel: +39-02-66590054

SPAIN Tel: +34-91-490-2133

FRANCE Tel: +33-164-73-28-50

Standard Limited Product Warranty (“Limited Warranty”)

RISCO Ltd. (“RISCO") guarantee RISCO’s hardware products (“Products”) to be free from defects in materials and workmanship when used and stored under normal

conditions and in accordance with the instructions for use supplied by RISCO, for a period of (i) 24 months from the date of delivery of the Product

(the “Warranty Period”). This Limited Warranty covers the Product only within the country where the Product was originally purchased and only covers Products

purchased as new.

Contact with customers only. This Limited Warranty is solely for the benefit of customers who purchased the Products directly from RISCO or from an authorized

distributor of RISCO. RISCO does not warrant the Product to consumers and nothing in this Warranty obligates RISCO to accept Product returns directly from end users

who purchased the Products for their own use from RISCO’s customer or from any installer of RISCO, or otherwise provide warranty or other services to any such

end user directly. RISCO’s authorized distributor or installer shall handle all interactions with its end users in connection with this Limited Warranty. RISCO’s authorized

distributor or installer shall make no warranties, representations, guarantees or statements to its end users or other third parties that suggest that RISCO has any

warranty or service obligation to, or any contractual privy with, any recipient of a Product.

Remedies. In the event that a material defect in a Product is discovered and reported to RISCO during the Warranty Period, RISCO shall accept return of the defective

Product in accordance with the below RMA procedure and, at its option, either (i) repair or have repaired the defective Product, or (ii) provide a replacement product to

the customer.

Return Material Authorization. In the event that you need to return your Product for repair or replacement, RISCO will provide you with a Return Merchandise

Authorization Number (RMA#) as well as return instructions. Do not return your Product without prior approval from RISCO. Any Product returned without a valid,

unique RMA# will be refused and returned to the sender at the sender’s expense. The returned Product must be accompanied with a detailed description of the defect

discovered (“Defect Description”) and must otherwise follow RISCO’s then-current RMA procedure published in RISCO’s website at www.riscogroup.com in connection

with any such return. If RISCO determines in its reasonable discretion that any Product returned by customer conforms to the applicable warranty

(“Non-Defective Product”), RISCO will notify the customer of such determination and will return the applicable Product to customer at customer’s expense. In addition,

RISCO may propose and assess customer a charge for testing and examination of Non-Defective Product.

Entire Liability. The repair or replacement of Products in accordance with this Limited Warranty shall be RISCO’s entire liability and customer’s sole and exclusive

remedy in case a material defect in a Product is discovered and reported as required herein. RISCO’s obligation and this Limited Warranty are contingent upon the

full payment by customer for such Product and upon a proven weekly testing and examination of the Product functionality.

Limitations. This Limited Warranty is the only warranty made by RISCO with respect to the Products. The warranty is not transferable to any third party. To the

maximum extent permitted by applicable law, this Limited Warranty shall not apply and will be void if: (i) the conditions set forth above are not met (including, but not

limited to, full payment by customer for the Product and a proven weekly testing and examination of the Product functionality); (ii) if the Products or any part or

component thereof: (a) have been subjected to improper operation or installation; (b) have been subject to neglect, abuse, willful damage, abnormal working conditions,

failure to follow RISCO’s instructions (whether oral or in writing); (c) have been misused, altered, modified or repaired without RISCO’s written approval or combined with,

or installed on products, or equipment of the customer or of any third party; (d) have been damaged by any factor beyond RISCO’s reasonable control such as, but not

limited to, power failure, electric power surges, or unsuitable third party components and the interaction of software therewith or (e) any failure or delay in the

performance of the Product attributable to any means of communication provided by any third party service provider, including, but not limited to, GSM interruptions,

lack of or internet outage and/or telephony failure. BATTERIES ARE EXPLICITLY EXCLUDED FROM THE WARRANTY AND RISCO SHALL NOT BE HELD

RESPONSIBLE OR LIABLE IN RELATION THERETO, AND THE ONLY WARRANTY APPLICABLE THERETO, IF ANY, IS THE BATTERY MANUFACTURER'S

WARRANTY. RISCO does not install or integrate the Product in the end user’s security system and is therefore not responsible for and cannot guarantee the

performance of the end user’s security system which uses the Product or which the Product is a component of.

This Limited Warranty applies only to Products manufactured by or for RISCO. Further, this Limited Warranty does not apply to any software (including operating system)

added to or provided with the Products or any third-party software, even if packaged or sold with the RISCO Product. Manufacturers, suppliers, or third parties other than

RISCO may provide their own warranties, but RISCO, to the extent permitted by law and except as otherwise specifically set forth herein, provides its Products “AS IS”.

Software and applications distributed or made available by RISCO in conjunction with the Product (with or without the RISCO brand), including, but not limited to system

software, as well as P2P services or any other service made available by RISCO in relation to the Product, are not covered under this Limited Warranty. Refer to the

Terms of Service at: www.riscocloud.com/warranty for details of your rights and obligations with respect to the use of such applications,

software or any service. RISCO does not represent that the Product may not be compromised or circumvented; that the Product will prevent any personal injury or

property loss by burglary, robbery, fire or otherwise, or that the Product will in all cases provide adequate warning or protection. A properly installed and maintained alarm

may only reduce the risk of a burglary, robbery or fire without warning, but it is not insurance or a guarantee that such will not occur or will not cause or lead to personal

injury or property loss. CONSEQUENTLY, RISCO SHALL HAVE NO LIABILITY FOR ANY PERSONAL INJURY, PROPERTY DAMAGE OR OTHER LOSS BASED ON

ANY CLAIM AT ALL INCLUDING A CLAIM THAT THE PRODUCT FAILED TO GIVE WARNING.

EXCEPT FOR THE WARRANTIES SET FORTH HEREIN, RISCO AND ITS LICENSORS HEREBY DISCLAIM ALL EXPRESS, IMPLIED OR STATUTORY,

REPRESENTATIONS, WARRANTIES, GUARANTEES, AND CONDITIONS WITH REGARD TO THE PRODUCTS, INCLUDING BUT NOT LIMITED TO ANY

REPRESENTATIONS, WARRANTIES, GUARANTEES, AND CONDITIONS OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, TITLE AND

WARRANTIES AGAINST HIDDEN OR LATENT DEFECTS, TO THE EXTENT PERMITTED BY LAW. WITHOUT LIMITING THE GENERALITY OF THE FOREGOING,

RISCO AND ITS LICENSORS DO NOT REPRESENT OR WARRANT THAT: (I) THE OPERATION OR USE OF THE PRODUCT WILL BE TIMELY, SECURE,

UNINTERRUPTED OR ERROR-FREE; (ii) THAT ANY FILES, CONTENT OR INFORMATION OF ANY KIND THAT MAY BE ACCESSED THROUGH THE PRODUCT

SHALL REMAIN SECURED OR NON DAMAGED. CUSTOMER ACKNOWLEDGES THAT NEITHER RISCO NOR ITS LICENSORS CONTROL THE TRANSFER OF

DATA OVER COMMUNICATIONS FACILITIES, INCLUDING THE INTERNET, GSM OR OTHER MEANS OF COMMUNICATIONS AND THAT RISCO’S PRODUCTS,

MAY BE SUBJECT TO LIMITATIONS, DELAYS, AND OTHER PROBLEMS INHERENT IN THE USE OF SUCH MEANS OF COMMUNICATIONS. RISCO IS NOT

RESPONSIBLE FOR ANY DELAYS, DELIVERY FAILURES, OR OTHER DAMAGE RESULTING FROM SUCH PROBLEMS. RISCO WARRANTS THAT ITS

PRODUCTS DO NOT, TO THE BEST OF ITS KNOWLEDGE, INFRINGE UPON ANY PATENT, COPYRIGHT, TRADEMARK, TRADE SECRET OR OTHER

INTELLECTUAL PROPERTY RIGHT IN ANY EVENT RISCO SHALL NOT BE LIABLE FOR ANY AMOUNTS REPRESENTING LOST REVENUES OR PROFITS,

PUNITIVE DAMAGES, OR FOR ANY OTHER INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, EVEN IF THEY WERE FORESEEABLE OR

RISCO HAS BEEN INFORMED OF THEIR POTENTIAL.

BELGIUM Tel: +32-2522-7622

CHINA (Shanghai)

Tel: +86-21-52-39-0066

ISRAEL Tel: +972-3-963-7777

RISCO Group Contacting Info

RISCO Group is committed to customer service and product support. You can contact

us through our website (www.riscogroup.com) or at the following telephone and

fax numbers:

UKCA and CE RED Compliance Statement:

Hereby, RISCO Group declares that this equipment is in compliance with the essential

requirements of the UKCA Radio Equipment Regulations 2017 and CE Directive 2014/53/EU.

For the UKCA and CE Declaration of Conformity please refer to our website:

www.riscogroup.com

Frequency

Power output 10.587Ghz

14dBm Max.

Fréquence

Puissance de sortie

10.587Ghz

14dBm Max.

Frequentie

Vermogen 10.587Ghz

14dBm Max.

iWI