Shimadzu RID-10A User manual

228

-

30179

DIFFERENTIAL REFRACTIVE DETECTOR

RID

-

1

OA

FOR

SHIMADZU

HIGH

-

PERFORMANCE

LIQUID

CHROMATOGRAPH

USER’S

MANUAL

Read the instruction manual thoroughly before you use the product. Keep

this

instruction

manual

with care

so

that you can use it any time you need it.

SHIMADZU

CORPORATION

CHROMATOGRAPHIC

&

SPECTROPHOTOMETRIC

INSTRUMENTS DIVISION

KYOTO,

3APAN

Copyright

0

Shimadzu Corporation

1995.

.

All rights are reserved, including those to reproduce

this

publication or

parts

thereof in any

form without permission in writing from Shimadzu Corporation.

Information in this publication is subject to change without notice and does not represent

a

commitment on the part of the vendor.

Any errors or omissions which may have occurred in this publication despite the utmost care

taken in its production will be corrected

as

soon

as

possible, but not necessarily immediately

upon detection.

Note that Shimadzu does not have any obligation concerning the effects resulting from the

application of the contentsof this manual.

MS, MS

-

DOS, Microsoft and Visual Basic are registerd trademarks, and Windows is

a

trademark of Microsoft Corporation

in

the USA.

IBM is

a

registerd trademark

of

InternationalBusiness Machines Corporationin the USA.

TrueType

is

a

registerd trademark of Apple Computer, Inc in the USA.

The

RID

-

1

OA

is the differential refractive index detector for the high

-

performance liquid

chromatograph.

In

orderto operate the unit safely, strictly observe the following points.

1.

Do

not

use

the unit for any purpose otherthan the above mentioned analysis.

2.

Follow the procedures described in the instructionmanual.

3.

Observe the warnings and cautions.

4.

Do

not disassemble

or

modify the unit without approval

from

Shimadzu. Failing to do

so

may lead to a dangerous situation or damage of the unit.

5.

For internal repair of the product, contactyour Shimadzu ServiceRepresentative.

6.

The pink

-

color pages and the meshed parts are for our service engineers, and are not

intended for our clients.

Do

not attempt installation of the instruments

as

serious damage

could result.

WARNING IN

THE

INSTRUCTIONMANUAL

This instructionstipulates the content of warnings as follows:

-1

Applied ina case that could result indeath or serious injury.

-1

Applied in a case that could result in slight injury or physical

damage.

-1

Applied for improvement of operating efficiency or help in

understanding.

I

For safety

of

operation,this unit is provided with

the

A

mark

at the portion where special

When operating the

parts

where

this

mark

is

indicated, exercise

special

caution

after

reading

cautions are required.

the

manual.

Replacement

of

fuses

This

unit uses the

following

fuse. Be sure to replace the fuse

of

same

type

and

capacity.

Rated voltage

:

100-24OV

Part

N

O

.

072

-

01652

-

23 250V 5AT

I

CAUTION

I

Do

not bend the optical cable forremote controlwith the radius

of

35mm

or less.

Bending it with the radius smaller than 35mm may damage the cable, whith may cause

malfunction

of

the

unit.

m

VAOS

I

AOX-022

VAOSI

A02

I

96-000ZE-822

26-0002€-822

VAOS

I

hpedea

A001

16-000Zf-822

a3NlOS

JaMOd

'ON

lred

8.

Solvent

not

usable

HFIPA

(Hexafluoroisopropyl alcohol) affects the materials used in the flow path and

deteriorate the strength of the material. In the worst case, pipe may explode and high

-

pressure solvent scatters.

As

it is very dangerous,never

use

HFIPA.

9.

Others

The equipment should not be exposed to direct sunlight or strong air currents.

It

is

also

recommended to install in

a

room where temperature fluctuation

is

small.

N

Liquid chromatography using flammable organic solvents as mobile phase requires proper care

against

fire,

explosion, etc. Pakcularly, among various possible accidents,those caused by static

electricity are difficult to anticipate, and tend to occur only with unexpected conditions which

often make countermeasuresinsufficient.

At a site where preparative liquid chromatography is practiced, a large amount of flammable

substances may be used. Therefore, once an accident happens, it could lead to tremendous

damage.

The mechanism of accident caused by static electrical discharge and preventive measures are

describedbelow. Take due care in safety measures in handling of equipment.

1.

Mechanism

of

Static ElectricalDischargeAccident (Example)

Accidents caused by static electricity take place through the following processes.

When liquid is fed at high speed through a small

-

diameter

tube like the pipe of a liquid chromatograph, static electrical

charge occurs by frictionbetween solid and liquid

as

shown in

Fig.

1.

Occurrence

of

Static

Electricity

1

$

-

Flowing liquid

A

Solid

body

A

:

Electric charge

movingwith

flowing liquid

B

:

Electric charge

being fixed

to

the

solid surface.

Fig.

1

Occurrence

of

Static Electricityby Friction betweenSolidand Liquid

Chargingand storage

of

static electricity

t

1

Energy release by

1

I

discharge

I

3.

Ignition

of

combustible

substances

f

When the charged liquid is collected in an insulated vessel,

the static charge accumulates gradually, and the voltage can

easily reach

a

few kilovolts.

If

some other conductive object

is

brought near the vessel,

electricity is discharged at a certain distance from the vessel

releasingheat energy.

If flammable gas of sufficient concentration exists nearby,

ignition iscaused by this energy.

If

air drv

\

Liquidisflowing at high

speed

througha

small

diametertube.

*Chargeiseasily accumulatedif

bubblesare includedinthe liquid.

Insulatedvessel

(likepolyethylene)

Spark discharge

-

””;”oyc

I

Ill

/

Inflammablegas isstored inthe

headspace

of

thevessel.

(\

n\

Inflammableorganic solvent is

charged

to

agreatextent.

e

-

-

-

-

Floorcovered

with

rubber, etc.,

providesunwantedinsulation.

Fig.

2

Conditionswhich may cause Accidents

2.

PreventiveMeasuresagainstAccidents

The principal preventive measure is the prevention of “charging and storage of static

electricity” among those items shown in “Mechanism

of

Static Electrical Discharge

Accident.” The preventive measures are shown below. It is recommended to exercise two

ormore measures simultaneously.

3K

Particularly when a large quantity of flammable solvent is held in a large vessel,

be

sure

to observethe preventivemeasures

1,2,

and

3.

Preventive measure

1.

Use metallic (conductive) waste liquid vessel which is well grounded.

This

releases the

charge of the waste liquid and vessel to ground.

The followingitems areavailable.

(1)

Grounding

wire

with clip P/N

228

-

21353

-

91

(2)

Metallic

18

liter can

P/N

038

-

00044

(3)

Metallic

4

litercan

P/N

038

-

00043

-

01

3K

+E

Be sure to ground the vessel properly. Disconnecting of grounding wire or poor

grounding defeatthe purpose of using

a

metallicvessel.

There are some metallic cans which have no conductivity

due

to

an

oxidized coating

or lacquer on their surface. Be

sure

to

confirm

the grounding

of

vessels by a tester

before application.

When a liquid with almost no conductivity (of 10-lOs/mor less) is discharged into the

vessel, it isnecessary to

mix

it with another liquid with some conductivity. (The other

liquid can be placed in the vessel

in

advance.)

%

Preventivemeasure

2.

Minimize the clearance

of

both inlet and outlet

of

vessel to prevent flame from entering the

vessel.

(1)

Cap with three holes for

18

liter and

4

liter cans

(P/N

228

-

21

354-91)

is available.

Connect clipto metallic

Minimizeclearance

by

attaching acap. groundthe metallicvessel.

Metallic

18

litter can

(A

platedcan is recommended.)

Static electricity

of

the liquid

is releasedvia vessel.

Fig.

3

Anti

-

Static Electricity Measuresfor Vessel

Preventivemeasure

3.

Do

not approach the vessel with charged objects including the human body.

Charging prevention measures for human body

a)

b) Grounding

of

human body

c) Make working floorconductive

Prevention of charging of shoes and clothes

Suitable products to be used for those measures a), b), and c) are available on the

market.

When persons who use no charge prevention measures approach dangerous sections,

they have to be grounded beforehand. (For example, they should contact grounded

metal by hand.)

%

Preventivemeasure

4.

Use pipes with inner diameter of

2mm

ormore for waste liquid line for large flow rates.

3%

Inclusion

of

bubbles in the

tube

may increase the amount of charging by ten times.

Check that there isno inclusion

of

air

via

tube

joints.

Preventivemeasure

5.

When it is impossibleto use a conductive vessel, use caution in the followingpoints.

a)

Set the vessel

so

that the pipe outlet will be placed below the liquid

level

in the

vessel. Or, dip a grounded metal (ex. pipe connected

to

the main body of device) in

the liquid.

This

method is not effective

for

liquid with small conductivity(10-I0s/m

or

less).

Use

a

vessel

of

the

smallest possible capacity to minimize the damage by

fire

if it

should occur.

Prevent the

room

from

being

dry.

Humidity of

65% or

more has charge prevention

effects.

+E

b)

c)

a

1ChapterlI

General

1.1

Outline

..........................................................................................................

1

-

2

1.2

Features

........................................................................................................

1

-

3

1.3 Principle

of

Measurement

.............................................................................

1

-

4

1.4 Row Schematic

............................................................................................

1

-

6

1

Chapter2

1

PartsList

2.1 Parts and Accessories

...................................................................................

2

-

2

-1

Component Locationand Function

3.1 Front View

....................................................................................................

3

-

2

3.2 Interior

of

Front Cover. Right Side

..............................................................

3

-

3

3.3 Rear View

.....................................................................................................

3

-

4

I

Chapter4

1

Installation

4.1 Basic Installation Requirements

...................................................................

4

-

2

4.2 Example

of

SystemLayout

..........................................................................

4

-

3

4.3 Stacking Modules

.........................................................................................

4

-

4

4.4 Electrical Connections

..................................................................................

4

-

5

4.6 Connecting the Recorder and Integrator

.......................................................

4

-

11

4.7

4.5 Plumbing Connections

..........................................

:

......................................

4

-

6

Connecting the Drain Tube

for

SolventLeakage

...........................................

4

-

13

1-1

Operation

5.1

Precautions

for

Operation

.............................................................................

5

-

2

5.2 Fundamentals

of

Operation

..........................................................................

5

-

3

5.3 Plumbing

of

the Flow Selection Block

.........................................................

5

-

13

5.4

5.5 Creating and ExecutingTie

Programs

.......................................................

5

-

16

Additional Functions (AUX

-

FUNC)

............................................................

5

-

21

1

ChaDter

6

I

InitialPerformanceTest

6.1

System PerformanceCheck

............................................................................

6

-

2

-1

Control from External Equipment

7.1 Connection with System Controller SCL

-

1OA

.............................................

7

-

2

7.2 Control

form

the SCL-IOA

...........................................................................

7

-

3

7.3 ConnectingExternal Input and Output Terminals

........................................

7

-

10

I

Chapter

8

1

Maintenance

8.1

Cleaning the Flow Lines

...............................................................................

8

-

2

8.2 Span Adjustment

..........................................................................................

8

-

3

8.3 Replacement

of

Fuse

....................................................................................

8

-

7

8.4 Periodical Cleaning

......................................................................................

8

-

8

1-1

PerformanceVerification

9.1 Component Validation

..................................................................................

9

-

2

9.1

.

1

Test Procedures

of

Stand

-

aloneUnit

......................................................

9

-

3

9.1.2 Test ProceduresControlled

from

the

SCL

-

1

OA

......................................

9

-

5

9.2 System Validation

.........................................................................................

9

-

9

9.2.1 Test Procedure

of

IsocraticLC System

..................................................

9

-

9

1-1

Troubleshooting

10.1

10.2 Symptoms.Causes and Remedies

................................................................

10

-

2

List

of

Error

Messages

..................................................................................

10

-

4

-1

Specifications

...............................................................................

11

.

1

RID-1

OA

Specifications 11

-

2

[-I

ReplacementParts

12.1 Consumables

and

Repair

Parts

.....................................................................

12

-

2

12.2 Optional

Parts

...............................................................................................

12

-

4

rChapterl31

Reference

13.1 SolventCharacteristics

.................................................................................

13

-

2

.

Chapter

1

General

1.1

Outline

.....................................................................................................

1

-

2

1.2

Features

...................................................................................................

1

-

3

1.3

Principle

of

Measurement

.......................................................................

1

-

4

1.4

Flow

Schematic

.......................................................................................

1

-

6

1

-

1

RID

-

1OA

-

RID-1OA

is

the

differential refractive index detector for the high

performance liquid chromatogaph developed as

a

module

of

the

LC

-

1

OA

series.

The

RID

-

10A

improves analysis productivity and convenience

of

use like a

UV

detector. Its shortened stabilization time, the fact that

it covers various applications from high sensitivity analysis to

sampling analysis preparation

and

more,

RID-1OA

is much

improved in convenience than conventional models.

Only handling instructions for

RID

-

1

OA

and related accessories

are

described

in

this

instruction manual.

For

handling instructions of

other components,please refer to the pertinent instruction manual.

1

-

2

-

RID

-

1OA

1.

Excellent

stability

Stabilizationtime after turning on the power has been shortened to

reduce the waiting time for

start

of

analysis. Excellent stability has

been realized by employing the dual temperature control structure

of

the optical system and by improving the thermal design.

-

0

r

t

By adaptingthe originalfour

-

partitionedphotodiode,

this

equipment

now covers the wide dynamic range of various applications from

high

sensitiveanalysisto large scalepreparation of high concentration

samples.

2.

Various

applications

3.

Safety measure

4.

Correspondingto the

LC-1OA

series

The standard model is equipped with

a

leak sensor which enables

automatic performance

of

operations such

as

stopping the pump in

the early stage of organicsolvent leakage.

This

equipment is designed forthe

LC

-

1

OA

series to have excellent

operability

as

a

component of the total system, including control

from the

SCL-1OA

and

data

processingin the

CLASS

workstation,

etc.

1

-

3

RID

-

1OA

-

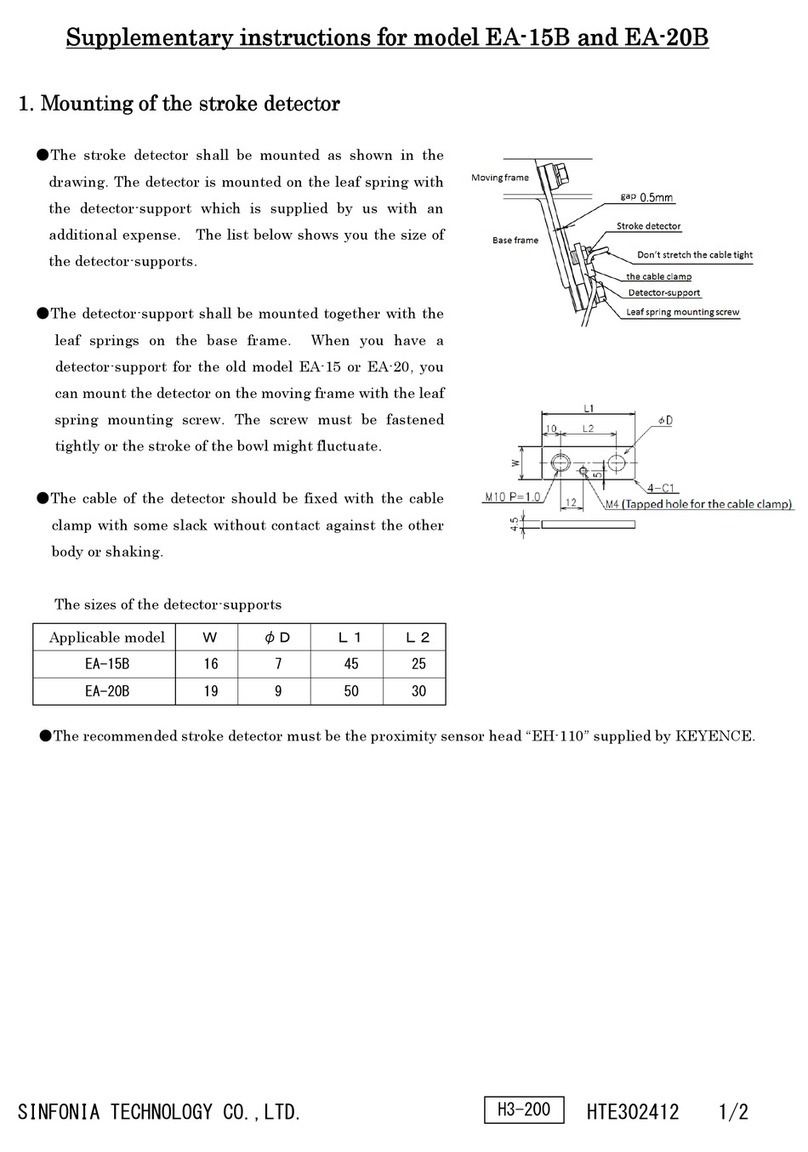

The optical system of this unit is shown in following illustration.

The light radiated from the lamp passes through the lens slit and

through the cell in the form of parallel rays, which is then reflected

by

the

mirror and passed through the cell

to

form an image of the

slit

on

the photodiode.

The

flow

cell consists of the sample side and the reference side.

When

the refractive index

in

the sample side cell varies,

the

image

of the slit moves horizontally.

W

lamp

#

When refractiveindex

I

When refractiveindex

,

in the

flow

cell

vanes,

Samole

/

<\-&

~&zf

the

slit

moves.

Dhotodiode

This

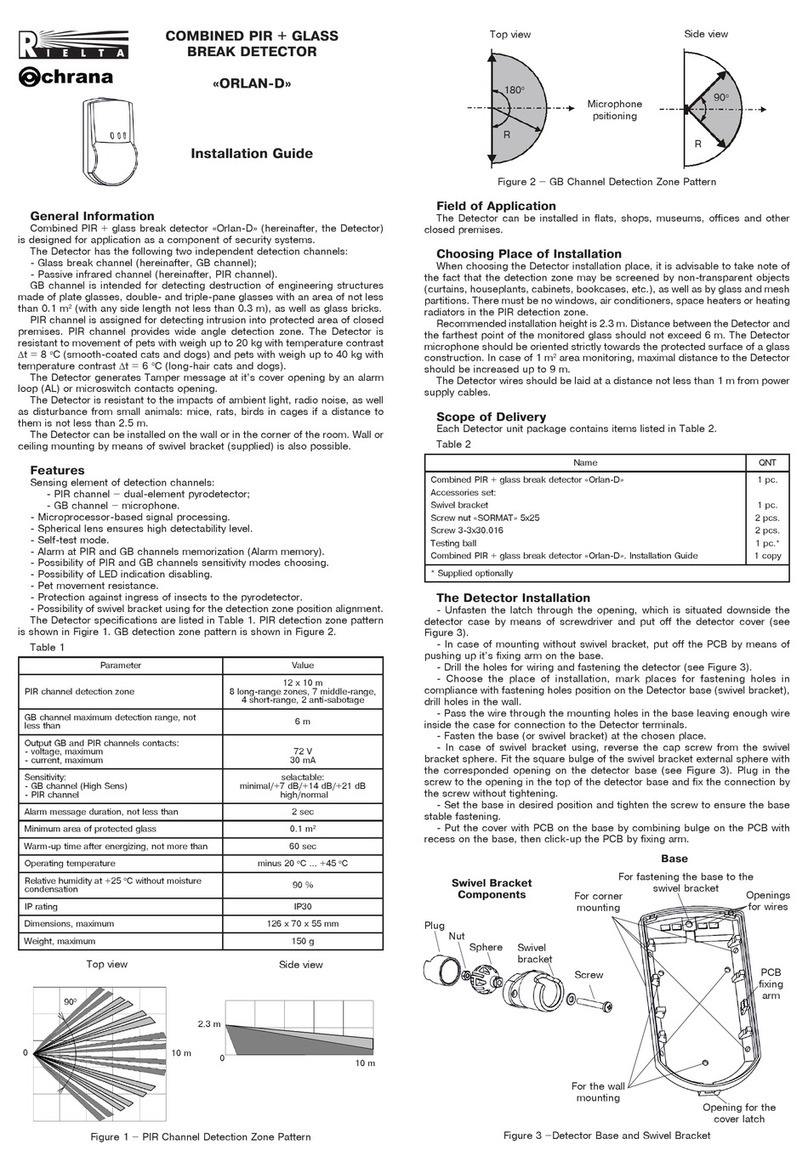

unit has a photodiodepartitioned in four

as

shown in the figure

below. When selecting a piece of photodiode to use among these

four, the unit is able to provide measurements for both analytical

and preparativework.

In

modes

P

and

L

In

mode

A

1

A

signal is processed

dividedinto up and down.

regarding

it

as

two

regarding

it

as

two

elements

A

signal is processed

divided into right and left.

Signal processing

in

mode

A

A

signal

is

processed using the right and left portions of the

photodiode

as

individual elements. Data processing is performed as

a two

-

partitionedphotodiode divided into right and left.

When the refractive index in the

cell

varies,

the

balanceof the incident

light intensity into right and leftparts

of

the photodiode changes. The

change

in

the right/left balance

is

converted into refractive index and

then can

be

recorded.

1

-

4

-

RID-1OA

1.3

Principle

of

Measurement

A

-

B

RIx

TOTAL

Signal processingin mode

P

-

E

a,

Signal processing is performed using the upper and lower parts of

L

Q

the photodiode

as

individual elements. Sincethe boundary between

the upper and lower parts

is

slanted against a horizontal line, when

an

image of the slit moves horizontally, the balance of the light

intensity

in

the upper/lower parts

of

the diodechanges.

This

change

in balance is converted intorefractiveindex. The change

of

the bal

-

ance against the variation

of

the

refractive index is one

-

twentieth

that

of

mode

A.

In

mode

A,

when the slit image goes beyond the

center line, measurement becomes impossiblebecause the balance

value stops varying, while in mode

P,

measurement is possible

under

these

conditions enabling measurement of a sample with high

concentration.

A

-

B

TQTU

Signal processing in mode

L

(An optional

flow

selection

block

isnecessary)

Signal processing is performed

as

the same

as

in mode

P,

using

each

of

the upper and lower parts of the diode

as

individual ele

-

ments. However, since the reference side with less flow line resis

-

tance is used

as

the sample cell, the image moves in the reverse

direction

of

that

of

mode

P.

Thus polarity is turned over

before

the

changein balance

is

convertedinto a refi-active index.

B

-

A

TOTAL

w.

A

1

-

5

RID

-

1OA

-

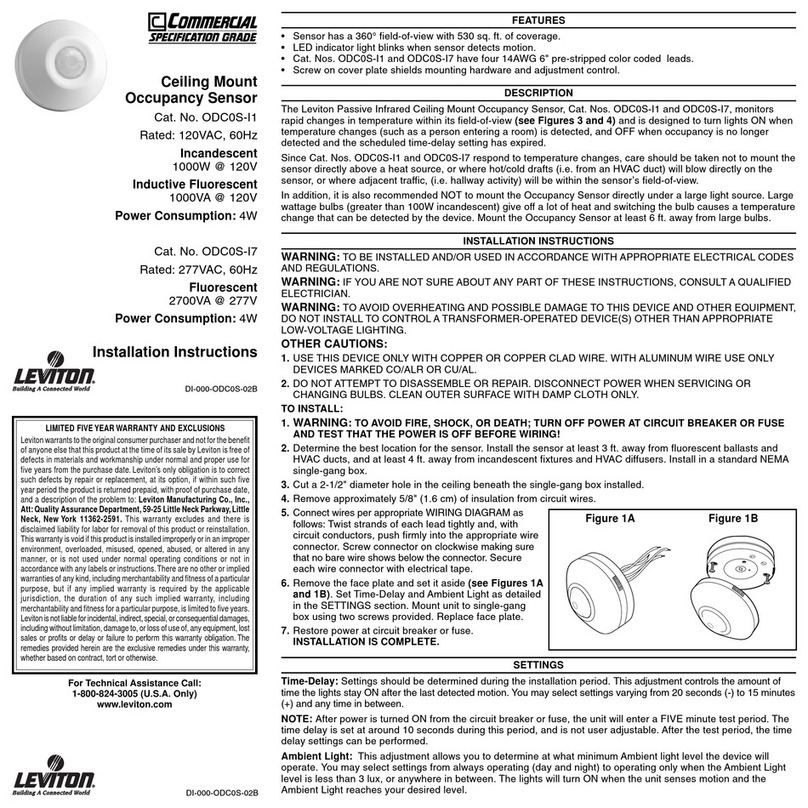

The diagram showsflow lines

in

the RID-10A.

At

R

flow

OFF

When the

R

flow switch is

OFT,

the solenoid valve is open at side

A.

The solvent passing through the samplecell flows into the outlet

port, not into thereference cell.

At

R

flow

ON

When the

R

flow switch

is

ON,

the solenoid valve is open at side

B.

The solvent passing through the sample cell flows into the outlet

port afterpassing through the reference cell. This

is

used to fill the

sample cell and the reference cell with solvent of equal refractive

index before starting the measurement.

R

flow

ON

Q

!

Outlet

port

Inlet

port

Tubing

volume (At

R

flow

OFF)

Inlet port to flow cell

63.5

pL

Flow cell volume

9pL

Flow cell to cell outlet port

280.2

pL

S:

Sample

R:

Reference

1

-

6

-

RID

-

1OA

Chapter

2

Parts List

c

v)

3

2.1

Parts

and

Accessories

..............................................................................

2

-

2

1

CONTENTS

1

2

-

1

RID-1OA

-

1

[Caution]

Part

Name

Signalcable

When connecting the flow line and performing maintenance, be

sure

to use the

parts

described on this page or

“1

2.1,

Consumable

and Repair

Parts

”.

Normal

function

of

the system

is

not

,guaranteed

when

other

parts

are

used.

Parts

No.

Quantity

228

-

25089

-

92

1

This equipment consists of the following components. Upon

unpacking, confirm that all

parts

listed below

are

included

in

your

shipment.

0

RID

-

IOA

Main Body

Powersupply cord

(

120V)

(220-240V)

Opticalcable

0

StandardAccessories

071

-

608

14

-

01

1

071

-

60814

-

06

070

-

92025

-

5

1

1

sus

tubing

Teflontubing

228-22310-00 lm

228-22305-00

50

crn

228

-

18495

-

03 2m

Remote

cable

I

228

-

28253

-

91

I

1

Lockingplate

Instruction

manual

SC

Coil

ASSY

(220-24OV)

Syringe

Syringe adapter

228-15672-91

Coupling 1.6C

228-16004-03

Male nut PEEK

228

-

18565

228

-

1875

1

1

228

-

30178

1

228-34050-9

1

1

Drain tubino

kit

I

228-18495-03

I

1

I

2

-

2

-

RID

-

1OA

-

Table of contents

Other Shimadzu Security Sensor manuals