SAFETY WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

UNPACKING OF PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

TOOLS REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

MOUNTING OF FAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

I BEAM & CEILING TRUSS MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

ATTACHMENT OF MOTOR BRACKET & SAFETY CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . .8

STABILIZATION CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

BLADE ATTACHMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

GUARDING THE FAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

MOTOR WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

CONTROL BOX WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

STOP CIRCUIT FOR MULTIPLE FANS (SCHNEIDER ELECTRIC) . . . . . . . . . . . . . . . . . . . .14

CONTROL BOX MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

LAMINATED BEAN KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

ANNUAL PLANNED MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

FAN NOISE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21-22

PARTS LIST – CEILING BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

PARTS LIST – LOWER BRACKET – MOTOR BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . .24

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

PARTS LIST – STABILIZATION CABLES-CONTROL BOXES . . . . . . . . . . . . . . . . . . . . . . . .26

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

PARTS LIST – LAMINATED BEAM KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

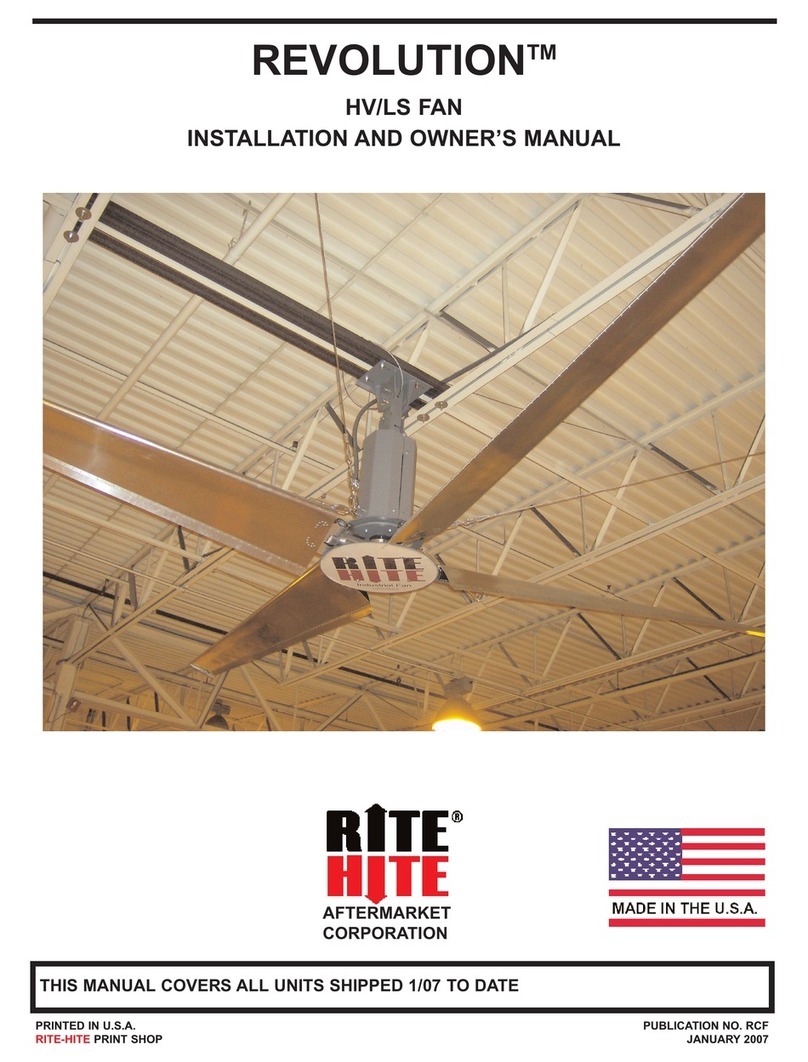

PRODUCT INTRODUCTION

Thank you for purchasing the Revolution SP Fan from RITE-HITE®.

IMPORTANT

Read and understand contents of this manual prior to installation or operation of this equipment.

For best results, have this product serviced by your authorized RITE-HITE®.

NOTICE TO USER

Your local RITE-HITE®Representative provides the Planned Maintenance Program (P.M.P.) which can be fitted to your

specific operation. Call your local representative or RITE-HITE®at 1-414-355-2600 or toll free at 1-800-456-0600.

The RITE-HITE®products in this manual are covered by one or more of the following U.S. patents: 4,560,315 (RE:

32,968); 4,634,334; 4,692,755; 4,744,121; 4,819,770; 4,843,373; 4,865,507; 4,920,598; 4,995,130; 5,040,258;

5,440,772; 5,442,825; 5,453,735;

37,570); 5,882,167; 5,964,572;

6,116,839; 6,190,109;

6,488,464; 6,497,067;

HITE®, LEVEL-RITE®, THINMANTM

, SAFE-T-LIP®, HYDRACHEK®, WHEEL-LOKTM

, DOK-

®

, DUAL-DOK®,SAFE-T-STRUT and SAFE-T-GATE ®are trademarks of

®

.

TM

,DOK-COMMANDER , JUMBOTM

®

5,111,546; 5,212,846; 5,271,183; 5,299,386; 5,311,628; 5,323,503; 5,375,965;

5,531,557; 5,546,623; 5,553,987; 5,582,498; 5,664,930; 5,702,223; 5,762,459 (RE:

6,010,297; 6,052,268; 6,065,172; 6,070,283; 6,074,157; 6,085,375; 6,092,970; 6,106,212;

6,220,809; 6,627,016; 6,238,163; 6,322,310; 6,311,352; 6,360,394; 6,368,043, 6,431,819;

6,499,169; 6,505,713; 6,524,053; 6,634,049; 6,654,976; 6,676,360; and pending U.S. and foreign patent

applications. RITE-

LOK

RITE-HITE