Rittal DET-AC III Slave User manual

Faster – better – everywhere.

Montage-, Installations- und Bedienungsanleitung

Mounting, installation and operating instructions

Löschsystem DET

-

AC III Slave

DET-AC III Slave Extinguishing

System

DK 7338.321

Translation of the original operation manual

Rittal GmbH & Co. KG

Postfach 1662

D-35726 Herborn

Germany

Phone: +49(0)2772 505-0

Fax: +49(0)2772 505-2319

Internet: http://www.rittal.com

E-mail: [email protected]

Part number of the German original: 916006

© Rittal GmbH & Co. KG 2016

This manual contains important information on the safe and efficient assembly, installation, com-

missioning, and maintenance as well as on safe and efficient handling of the Extinguishing

system DET-AC III Slave (hereinafter referred as the "system"). This operating instruction is an

integral part of the system and must be kept in the immediate vicinity of the extinguishing zone

at all times. It is intended for the trained Authorized Distributor and the owner of the system

Ä

Chapter 2.8.1 „Qualifications” on page 15.

This operating instruction must have been carefully read before commencing any task. The pre-

requisite for safe operation of the system is compliance with the specified safety instructions

and procedural instructions. In addition to the information provided in this instruction, all local

accident prevention and general safety regulations applicable for the system’s area of imple-

mentation must also be complied with.

Document identification:

Document name ---

Language en_US

Document no. 100046741

DOC ID 100070578

Approval / modification no. ES16-014

Part no. 916007

Revision 03

Version 00

Edition 05-2016

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 2

Table of contents

1 General........................................................................................................................... 7

1.1 Overview....................................................................................................... 7

1.2 Abstract......................................................................................................... 7

1.3 Scope of delivery.......................................................................................... 8

1.4 Limitations of liability..................................................................................... 9

2 Safety............................................................................................................................ 10

2.1 Safety instructions and warnings................................................................ 10

2.2 Safety instructions in behavior guidelines................................................... 11

2.3 Intended use................................................................................................ 11

2.4 Misuse......................................................................................................... 11

2.5 Structural changes...................................................................................... 12

2.6 Basic dangers............................................................................................. 12

2.6.1 General dangers associated with fire extinguishing systems..................... 13

2.6.2 Dangers when the system is released........................................................ 13

2.7 Behavior in the event of a fire..................................................................... 14

2.7.1 Preventive steps......................................................................................... 14

2.7.2 Steps in the event of a fire.......................................................................... 14

2.8 Personnel requirements.............................................................................. 15

2.8.1 Qualifications.............................................................................................. 15

2.8.2 Unauthorized personnel.............................................................................. 16

2.8.3 Instruction................................................................................................... 16

2.9 Environmental protection............................................................................ 16

2.10 Owner's responsibility................................................................................. 17

2.10.1 Owner......................................................................................................... 17

2.10.2 Owner’s obligations..................................................................................... 17

2.11 Responsibility of the Authorized Distributor................................................ 18

2.11.1 Authorized Distributor................................................................................. 18

2.11.2 Obligations of the Authorized Distributor.................................................... 18

2.12 Safe operation............................................................................................. 19

2.13 Spare parts................................................................................................. 19

3 Structure, function and connections......................................................................... 20

3.1 Structure..................................................................................................... 20

Table of contents

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 3

3.2 Function...................................................................................................... 20

3.3 Connections................................................................................................ 22

3.3.1 Relay outputs.............................................................................................. 23

3.3.2 Door contact switch..................................................................................... 24

3.3.3 Interfaces to the Monitoring System CMC III / CMC‑TC............................. 24

3.3.4 Connection of external alarm device........................................................... 25

3.3.5 Manual call point connection....................................................................... 25

3.3.6 Power supply.............................................................................................. 25

3.3.7 USB port..................................................................................................... 26

3.3.8 Connection for networking.......................................................................... 26

4 Transport instructions................................................................................................ 27

4.1 Transport inspection.................................................................................... 27

4.2 Transport..................................................................................................... 28

4.3 Packaging................................................................................................... 28

5 Mounting and installation........................................................................................... 30

5.1 Operating conditions and installation requirements.................................... 30

5.2 Installation and commissioning................................................................... 31

5.2.1 Installation instructions................................................................................ 32

5.2.2 Installation steps and function test.............................................................. 33

5.2.3 Temperature indicator................................................................................. 35

5.2.4 Language setting for display and operation................................................ 35

5.2.5 Checking the failure and alarm function...................................................... 36

5.3 Installation and commissioning of additional electrical devices.................. 38

5.3.1 Potential-free contacts................................................................................ 39

5.3.2 Monitoring System CMC III / CMC‑TC........................................................ 40

5.3.3 Door contact / blocking............................................................................... 40

5.3.4 Combination of systems.............................................................................. 43

5.3.5 Manual call point......................................................................................... 47

6 Alarms and failures..................................................................................................... 48

7 Display and control elements..................................................................................... 50

8 Messages display........................................................................................................ 51

Table of contents

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 4

9 Maintenance program................................................................................................. 55

9.1 Installing the maintenance program............................................................ 55

9.2 Homepage.................................................................................................. 56

9.3 Project......................................................................................................... 57

9.4 Event memory............................................................................................. 57

9.5 Firmware..................................................................................................... 58

9.6 Customer data............................................................................................ 58

9.6.1 General....................................................................................................... 58

9.6.2 Components................................................................................................ 59

9.6.3 Timeouts..................................................................................................... 59

9.6.4 Threshold values......................................................................................... 59

9.7 Operation.................................................................................................... 60

10 Repairs......................................................................................................................... 62

10.1 Regular checks by the owner...................................................................... 62

10.2 Inspection, maintenance and repairs by the Authorized Distributor............ 63

10.2.1 Checking for proper installation.................................................................. 66

10.2.2 Checking for external damage.................................................................... 66

10.2.3 Recording the WA No. / Part No. / F. No..................................................... 66

10.2.4 Recording the date of the current maintenance / inspection....................... 67

10.2.5 Recording the current version..................................................................... 67

10.2.6 Checking current fault messages, history since last maintenance............. 67

10.2.7 Checking the discharge nozzle for contamination...................................... 67

10.2.8 Checking the temperature indicator............................................................ 67

10.2.9 Checking the setting of date and time......................................................... 67

10.2.10 Checking the function of the door contact switch........................................ 68

10.2.11 Checking the blocking switch...................................................................... 68

10.2.12 Checking for proper connection of the transmission................................... 68

10.2.13 Checking whether shutdown occurs........................................................... 68

10.2.14 Reading out and transferring data.............................................................. 68

10.2.15 Checking the electrical connections............................................................ 68

10.2.16 Changing the battery "control card CPU3".................................................. 68

10.2.17 Checking the DIP switch on the control card CPU3.................................... 69

10.2.18 Checking the networking of the systems.................................................... 69

10.2.19 Checking for contamination in the housing................................................. 69

10.2.20 Checking loss monitoring............................................................................ 69

Table of contents

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 5

10.2.21 Checking the total weight............................................................................ 70

10.2.22 Changing the tank....................................................................................... 70

10.2.23 Concluding the inspection........................................................................... 70

10.3 Repairs after a release................................................................................ 71

10.3.1 Safety instructions for the tank change....................................................... 71

10.3.2 Removal...................................................................................................... 72

10.3.3 Disposal of the old tank and installation of a new tank............................... 74

10.4 Firmware update......................................................................................... 74

11 Spare parts, accessories, consumables and tools.................................................. 75

12 Technical data.............................................................................................................. 77

13 Index............................................................................................................................. 79

Appendix...................................................................................................................... 82

Table of contents

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 6

1 General

1.1 Overview

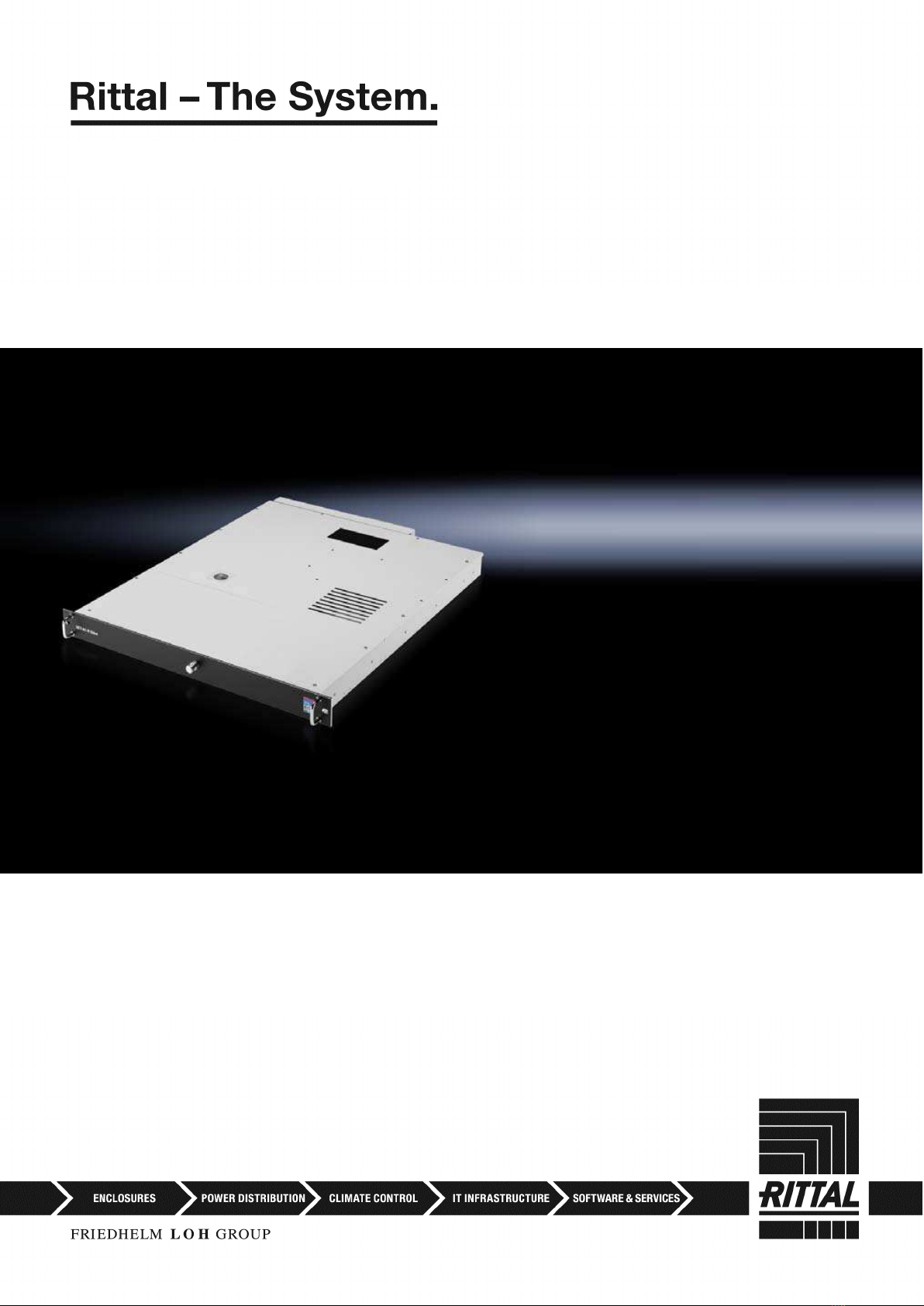

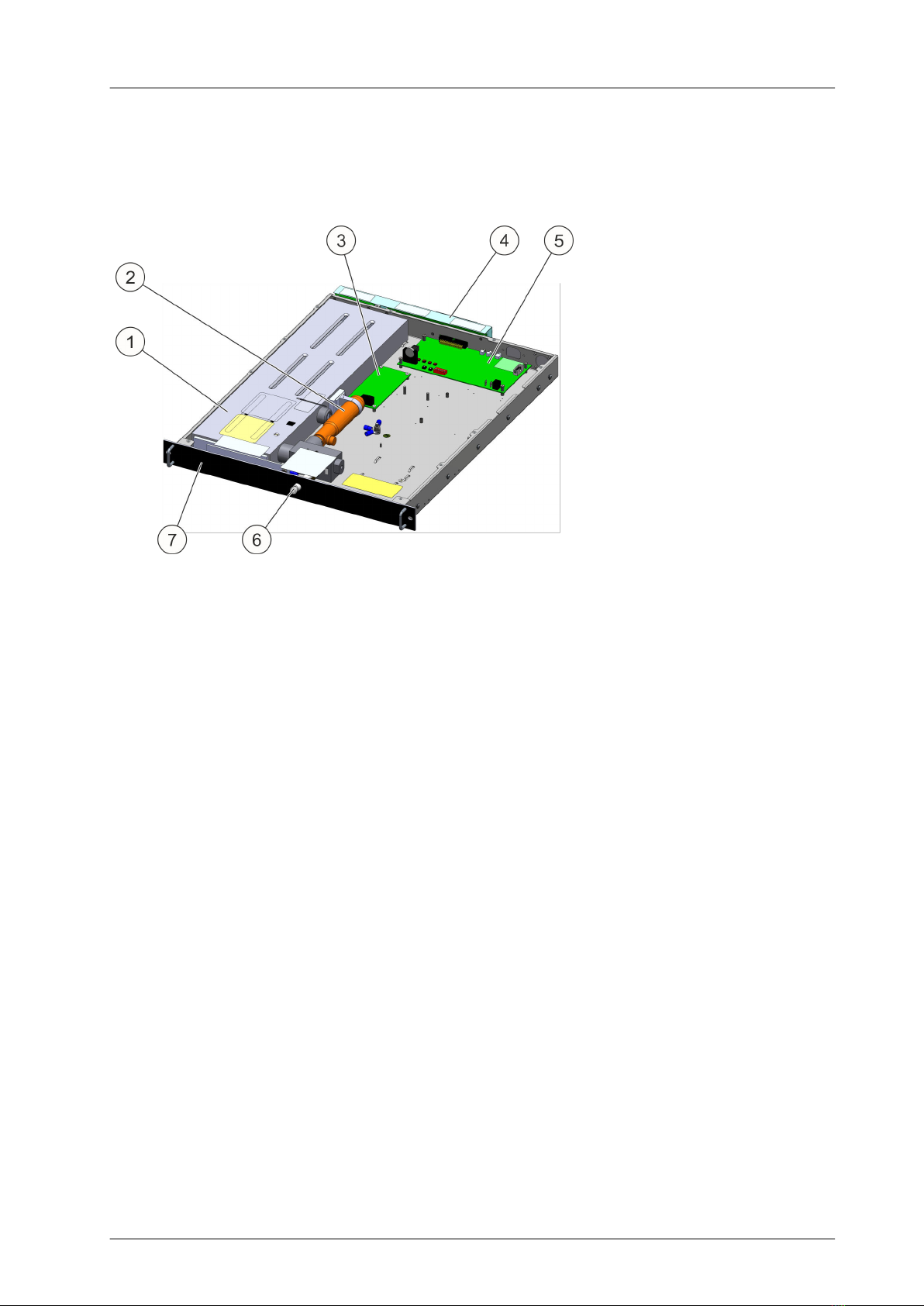

Fig. 1: Structure of the system

1 Tank (extinguishing agent container) with

fill level monitoring and release device

2 Propellant cartridge

3 Loss monitoring card

4 Connection strip (connection technology

card / network interface card

5 Control card CPU3

6 Discharge nozzle

7 Front panel

1.2 Abstract

The DET-AC III Slave Extinguishing system, which is intended for installation in

closed switch cabinet systems, is a compact unit that was developed to extinguish

fires. A superordinate system (active extinguishing system DET-AC III Master or

aspirating smoke detection system EFD III) is to be in place in order to activate this

unit.

NovecTM 1230 by 3MTM is used as the extinguishing agent which vaporizes at the

discharge nozzle and spreads evenly across the extinguishing zone. This extin-

guishes the fire by extracting heat energy from the flames.

Alarms and failures can be transmitted to a superordinate position (building control

system or permanently manned location) via potential-free contacts or via the Moni-

toring System CMC (a Rittal product).

The compact system with a space requirement of only one rack unit is intended for

installation in the upper third of the closed switch cabinet system to be protected.

General

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 7

1.3 Scope of delivery

Designation Piece Part number

Extinguishing system DET-AC III Slave 1 7338.321

CAN bus connecting cable (Master/Slave) 3) 1 907531

Cable power supply 3) 1 903228

Resistance 1.8 kΩ for manual call point 2) 1 675235

Resistance 1.8 kΩ for alarms 2) 1 675235

Terminating resistor 47R with rectifying diode 1N4007 for means

of alarm 2)

1 917751

Resistance 470 Ω 1/2 W for door contact 3) 1 675223

Terminating resistor 1K 3) 1 908119

Terminating resistor 22K 3) 1 906913

Fillister head screw M6x16 (to fasten the front panel in the 19"

cabinet) 3)

2 607284

Fillister head screw DIN 7985 M5x16 (fastening rear side rail) 3) 4 906928

Fillister head screw M4x6 similar to ISO 7380 (assembly side

rails) 3)

12 889264

Plate DET-AC III Slave 3) 1 916088

Left rail 3) 1 915914

Right rail 3) 1 915915

Operating instruction German 3) 1 916006

Operating instruction English 3) 1 916007

Safety data sheet 3MTM NovecTM 1230, German 3) 1 917711

Safety data sheet 3MTM NovecTM 1230, English 3) 1 917712

Safety data sheet DET-AC, German 3) 1 920329

Safety data sheet DET-AC, English 3) 1 920330

1) ... pre-assembled

2) ... assembled

3) ... enclosed

Accessories

● Suction pipe system (part number 7338.130)

● Access sensors (part number 7320.530)

General

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 8

● Monitoring System CMC III

– CMC III Processing Unit (part number 7030.000), optional

– CMC III Compact Processing Unit (part number 7030.010), optional

● Depth-variable slide rails (part number 5501.480), optional

1.4 Limitations of liability

All specifications and information provided in this operating instruction have been

compiled in consideration of all applicable standards and regulations as well as the

state of the art. The manufacturer accepts no liability for the following damage:

● Failure to follow this operating instruction

● Failure to follow local provisions and any regulations regarding the maintenance

of fire extinguishing systems

● Operating the system in environmental and usage conditions other than the ones

for which the system has been designed

Ä

Chapter 12 „Technical data”

on page 77

● Use for other than the intended purpose

● Unauthorized technical changes

● Use of components not included in the system’s scope of delivery

● Non-compliance with maintenance intervals

● Non-performance of maintenance

● Maintenance errors due to non-compliance with current maintenance instruc-

tions / current maintenance notes of the manufacturer

● Damage for which a third party is to blame

● Intentional damage/manipulations

● Damage resulting from an unauthorized modification to the system

● Repairs not carried out according to regulations

● Actions that are not in the area of those described in this operating instruction

Use of the system must comply with local regulations, laws and standards. The

owner is responsible for the appropriate selection, intended use and compliance

with all standards, codes and ordinances.

The construction and use of the system described in this operating instruction are

only to be used for the purposes that are shown and described. The manufacturer or

private labeler provides no warranty or guarantee for uses not described in this

specification or for uses that do not comply with legal and local regulations.

Graphs or reports used in this operating instruction are for illustrative purposes only,

are not representative or descriptive of any specific design and can deviate from the

actual version of the system.

The manufacturer or private labeler and its representatives disclaim use of the

depictions, graphs and reports for any purpose other than illustration; any other

application or usage is solely the responsibility of the owner.

General

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 9

2 Safety

This section provides an overview of all important aspects that are essential for the

protection of personnel as well as safe and trouble-free operation. Additional task-

specific safety instructions will be provided in the sections that refer to the individual

life stages of the plant.

2.1 Safety instructions and warnings

Safety instructions and warnings are marked with symbols in this manual. The

safety instructions and warnings are always introduced by signal words that express

the extent of the hazard.

L DANGER

Indicates an imminent danger. This danger will result in death or serious injuries if it

is not avoided.

L WARNING

Indicates a potentially imminent danger. This danger could result in death or

serious injuries if it is not avoided.

L CAUTION

Indicates a potentially imminent danger. This danger could result in minor or mod-

erate injuries if it is not avoided.

NOTICE

Indicates a potentially harmful situation. This danger could result in property or

environmental damage if it is not avoided.

Additional markings

INFORMATION

This marking indicates useful tips and recommendations as well as information for

efficient and trouble-free operation.

In instructions, this marking begins with the symbol .

Safety

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 10

2.2 Safety instructions in behavior guidelines

Safety instruction can refer to specific, individual behavior guidelines. Such safety

guidelines (warning messages) are embedded in behavior guidelines so that they do

not interrupt the reading flow when executing the action. The signal words described

above are used.

Example:

1. Unscrew screw.

2. L CAUTION! Clamping danger on the cover!

Carefully close the cover.

3. Tighten screw.

2.3 Intended use

This system is designed exclusively for the intended use described here.

The system is designed exclusively to extinguish smoldering or developing fires in

closed 19" switch cabinet systems.

The system must only be operated using the extinguishing agent NovecTM 1230 by

3MTM.

The system must only be used in areas which personnel do not enter.

Typical applications for using the system is the protection of closed 19” switch cabi-

nets. This, for example, includes:

● IT, server and network technology

● Production controls

● Telecommunications equipment

● Power supply and control systems

The system may only be operated within the operating conditions specified in

Ä

Chapter 12 „Technical data” on page 77.

Intended use also includes compliance with all specifications regarding mounting,

installation, checking, inspection and maintenance, which are described in this oper-

ating instruction:

Ä

Chapter 5 „Mounting and installation” on page 30

Ä

Chapter 10 „Repairs” on page 62.

2.4 Misuse

Any use that extends beyond the intended use, or any other use of the system is

considered misuse.

Safety

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 11

L WARNING

Danger due to misuse!

Misuse of the system can lead to personal injury and property damage.

● No structural changes to the device to be protected or to the system may be

performed.

● Do not use the device to be protected in any way that is contrary to that which

was considered by the trained Authorized Distributor.

● Do not block the discharge nozzles.

The system must not be used for the following incendiaries:

● Chemicals that release oxygen.

● Mixtures containing oxidizing substances (e.g. sodium chlorate, sodium nitrate,

explosives, gunpowder).

● Chemicals capable of thermally decomposing autonomously (e.g. certain organic

peroxides).

● Reactive metals (e.g. sodium, potassium, magnesium, titanium or zirconium) and

reactive hybrids or metal amides.

The system must not be used under the following operating conditions:

● Hot surfaces above 500 °C (932 °F), which due to operational conditions have

been heated to temperatures in excess of the extinguishing agent’s decomposi-

tion temperature.

2.5 Structural changes

This system has been tested for the intended use. Consult an Authorized Distributor

if changes to the device are planned.

2.6 Basic dangers

The following section describes remaining risks that can arise from the system even

with intended use.

In order to reduce risks of personal injury and property damage and avoid dan-

gerous situations, the safety instructions listed here and the safety instructions in the

other sections of this operating instruction must be followed.

Safety

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 12

2.6.1 General dangers associated with fire extinguishing systems

L WARNING

Risk of injury from faulty release!

A faulty release of the system may cause injuries and property damage.

● Release the system via manual call points only in the event of a fire.

● Protect the manual call points in the extinguishing zone from inadvertent actua-

tion.

● Block the system before performing any work in the extinguishing zone gener-

ating heat and smoke.

2.6.2 Dangers when the system is released

L WARNING

Risk of injury from developing products of decomposition and fire smoke!

Fires generate decomposition products which may lead to chronic health impair-

ments if inhaled and if there is contact with the skin.

● Do not use the system if, in normal operation, surface temperatures in excess

of 500 °C (932 °F) are to be expected.

● Keep the extinguishing zone closed in the event of a fire, e.g. do not open any

of the switch or server cabinet doors.

● After a fire, the extinguishing zone is not to be opened by the safety officer until

the danger of re-ignition has subsided.

L WARNING

Risk of injury from shock!

The release of the system involves sudden noises from the discharged agent

which may surprise persons to the extent that they suffer shock.

● Inform all persons staying close to the extinguishing zone about the existence

of the system and the possibility of its sudden release.

● Make persons familiar with the procedures required in the event of an alarm, a

fire or release of the system.

L WARNING

Risk of injury from noise!

High noise levels due to acoustical alarms (e.g. signal horns) can cause hearing

damage.

● Stay out from the immediate vicinity of acoustic alarm equipment.

Safety

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 13

NOTICE

Property damage from cooling ambient air!

The discharged extinguishing agent extracts heat from the ambient air contained in

the extinguishing zone. This cools down the extinguishing zone by as much as

20 °C (36 °F) when fighting a fire.

● Do not mount components that are sensitive to cold and varying temperatures

in the immediate vicinity of the discharge nozzle.

NOTICE

Property damage from falling and flying objects!

The discharge velocity of the extinguishing agent may cause unsecured objects to

tip over or become airborne.

● Do not place any loose objects into the outflow area of the discharge nozzle.

2.7 Behavior in the event of a fire

2.7.1 Preventive steps

● Always be prepared for fires and accidents!

● Keep first-aid equipment (first-aid kit, blankets, etc.) and substitute extinguishing

agents (e.g. fire extinguisher) in proper working order and readily available.

● Familiarize personnel with accident prevention, first aid and rescue equipment as

well as options for releasing the system manually.

● Keep access paths clear for rescue vehicles.

2.7.2 Steps in the event of a fire

L WARNING

Risk of death due to fire!

Severe fire smoke may develop when a fire erupts and while the fire is being extin-

guished. Fire smoke development may result in severe airway damage or death.

● Keep the extinguishing zone closed in the event of a fire, e.g. do not open any

of the switch or server cabinet doors.

● After a fire, do not have the extinguishing zone opened by the safety officer

until the danger of re-ignition has subsided.

● Shut down all consumers of the power supply that are in the cabinet.

Take the following steps when a fire erupts:

● Initiate first-aid measures if necessary.

● Alert any endangered persons in the adjoining areas.

Safety

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 14

● Notify the fire department and/or emergency medical services.

● Notify the person in charge at the system's location.

2.8 Personnel requirements

2.8.1 Qualifications

The different tasks described throughout this manual require different qualifications

and skills from the persons entrusted with these tasks.

L WARNING

Risk from insufficiently qualified personnel!

Insufficiently qualified personnel is incapable of assessing the risk involved in han-

dling the system and may cause severe or fatal injuries to themselves or others.

● Allow only qualified personnel to perform the work.

All work must be limited to personnel that can be expected to complete the work in a

reliable manner. Persons whose ability to respond is impaired, for example, by

drugs, alcohol or medication are not permitted.

Definition of the qualifications:

Authorized Distributor

The Authorized Distributor has verifiably undergone training provided by the manu-

facturer during which the company was made familiar with the knowledge and pro-

cedures necessary to install, commission and service the system in a safe manner.

Person in charge of the system

The person in charge of the system has verifiably been given instructions by the

company that installed the system as to the specifics of the tasks entrusted to

him/her and all possible dangers that may arise from improper conduct. The person

in charge of the system has been appointed by the owner as the person who is

responsible for the correct and proper completion of the work and inspections per-

formed on the system.

Qualified electrician

The qualified electrician is capable of performing work on electrical systems and

independently detecting and avoiding any possible risks due to his/her long years of

expertise and experience and his/her familiarity with all applicable standards and

regulations.

A qualified electrician must also provide proof of his/her professional qualification

that confirms his/her capacity to perform work on electrical systems.

Safety

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 15

The qualified electrician must comply with the provisions of all applicable legal regu-

lations regarding accident prevention.

2.8.2 Unauthorized personnel

L WARNING

Risk of injury due to unauthorized personnel!

Unauthorized personnel who do not meet the requirements described herein are

not familiar with the risks involved in releasing and/or blocking the system. This

creates a risk of injury.

● Keep unauthorized personnel away from the system.

● Make sure that a person in charge of the system is available who has the

knowledge necessary to handle the system properly.

2.8.3 Instruction

The Authorized Distributor must instruct the owner’s person in charge of the system

in the handling of the system and subsequently hand over the operating instruction

to this person. For better traceability an instruction report must be drawn up with at

least the following contents:

● Date of the instruction

● Name of the person being instructed

● Content of the instruction

● Name of the instructor

● Signatures of the instructed person and the instructor

● Part number and serial number of the system.

2.9 Environmental protection

NOTICE

Danger to the environment due to incorrect handling of materials that can

harm the environment!

In case of incorrect handling of materials that can harm the environment, especially

improper disposal, there can be significant damage to the environment.

● Always observe the notes below about the handling of materials that can harm

the environment and their disposal.

● If materials that can harm the environment accidentally escape into the envi-

ronment, take suitable measures immediately. In case of doubt, inform the

responsible authority about the damage and ask what suitable measures to

take might be.

Safety

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 16

Extinguishing agent NovecTM 1230

The extinguishing agent has been classified as slightly reactive to water. It must be

disposed of in accordance with all applicable local waste disposal regulations.

Observe the safety data sheet provided by the extinguishing agent’s manufacturer

3MTM. The photolytic half-life of the extinguishing agent is 3 – 5 days. The global

warming potential (GWP) value is 1, while the value of the ozone decomposition

potential (ODP) is 0.

2.10 Owner's responsibility

2.10.1 Owner

The owner is the person or entity that operates the system himself/itself for commer-

cial or economic purposes, or who transfers the device to a third person for use/

application, and who bears the legal responsibility for protecting the user, personnel,

or third parties.

2.10.2 Owner’s obligations

● It is the owner's responsibility to ensure that the system complies with the local

provisions and regulations applying to the operation of extinguishing systems

using the extinguishing agent NovecTM 1230 and verify the system's operability.

In this regard, the following particularly applies:

– The owner must comply with the applicable regulations as well as all addi-

tional local regulations applying to the operation of the system.

– The owner must always observe the inspection intervals specified in this

operating instruction.

– The owner must perform these inspections and operate the system following

the procedural instructions described throughout this operating instruction.

– The owner must document the results of the inspections in the report log.

– The owner must report any detected defects and/or damage to the Author-

ized Distributor, which he/she is not authorized to rectify independently.

– The owner must document all shutdowns and failures the system experi-

ences in the report log of the system.

● The "Occupational Safety and Health Act" of 1970 specifies that a safe work-

place must be provided at all times for execution of tasks. To this end, the owner

must ensure that the system is inspected and operated in accordance with all

applicable commercial, industrial, local, federal and state laws, standards and

regulations.

● The owner must ensure that the personnel performing the work have the qualifi-

cations necessary to complete the task.

● The owner must ensure that all employees who handle the system have read

and understood this operating instruction. In addition, the owner must train per-

sonnel and inform them of dangers at regular intervals.

● The owner must ensure that all employees working in the extinguishing zone of

the system have been informed of the existence of the system and know the

risks involved and the steps necessary to handle the system (e.g. behavior in the

event of a fire or inadvertent release).

Safety

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 17

● The owner must appoint a person in charge of the system, who will be instructed

by the Authorized Distributor about how to safely perform tasks and checks at

the owner’s site of operation. The owner will confirm in the documentation of the

Authorized Distributor that these instructions have been given.

● The owner must confirm to the Authorized Distributor that the system's function

and mode of operation have been understood and the system was ready for

operation when accepted by the owner.

● The owner must ensure the availability of substitute extinguishing agents suit-

able for fire fighting in case the system is taken out of operation/disassembled.

2.11 Responsibility of the Authorized Distributor

2.11.1 Authorized Distributor

The Authorized Distributor is the entity that installs the system, commissions the

system, and can perform the service on the system.

2.11.2 Obligations of the Authorized Distributor

● The Authorized Distributor must ensure that the extinguishing system complies

with the provisions and regulations applicable for installation of extinguishing

systems in enclosed equipment and that the system has been correctly chosen

for the protection of this equipment (correct nominal fill, density given, ...). In this

regard, the following particularly applies:

– The Authorized Distributor must comply with the applicable local regulations,

and consider these regulations in the selection of the system.

– The Authorized Distributor must take the current state of the technology into

consideration at all times.

● The "Occupational Safety and Health Act" of 1970 specifies that a safe work-

place must be provided at all times for execution of tasks. To this end, the

Authorized Distributor must ensure that the system is erected, installed, and

maintained in accordance with all applicable commercial, industrial, local, federal

and state laws, standards and regulations.

● The Authorized Distributor must label the system and affix all necessary informa-

tion where it is permanently visible.

● The Authorized Distributor must ensure that the personnel performing the tasks

have the qualifications necessary for execution of the tasks.

● The Authorized Distributor must instruct a responsible person appointed by the

owner in the safe execution of the tasks and inspections that must be executed

by the owner, and document execution of this instruction.

● The Authorized Distributor must document the actual status of the system at the

time of transfer and inform the owner’s responsible person of the actual status.

Safety

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 18

2.12 Safe operation

The system described here was manufactured in accordance with state-of-the-art

technology and recognized safety rules and exhibits a high degree of operational

safety.

Nevertheless, improper or non-intended use / application of this system can cause

impairments to the system or to other assets.

The system must only be used in a fully functional, undamaged state.

The information provided in this operating instruction regarding installation, opera-

tion and maintenance of the system is intended to aid proper, safe and failure-free

operation. As regulations in this regard can deviate from each other due to world-

wide use, the applicable national regulations and laws at the site of operation are to

be observed in so far as they contradict the information provided in this operating

instruction. As a general rule, the following information in particular is to be

observed / adhered to:

● National safety and accident prevention regulations.

● National standards and laws; in particular those concerning hazard detection

systems.

● National assembly and construction regulations.

● Generally recognized rules of technology.

● This operating instruction and the warnings and safety instructions contained

within it.

● Parameters and technical data of this system.

If it can be assumed that safe operation is no longer possible (e.g. in the event of

damage), the system is to be taken out of service immediately and secured against

accidental commissioning.

2.13 Spare parts

Only original spare parts may be used

Ä

Chapter 11 „Spare parts, accessories, con-

sumables and tools” on page 75.

Safety

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 19

3 Structure, function and connections

3.1 Structure

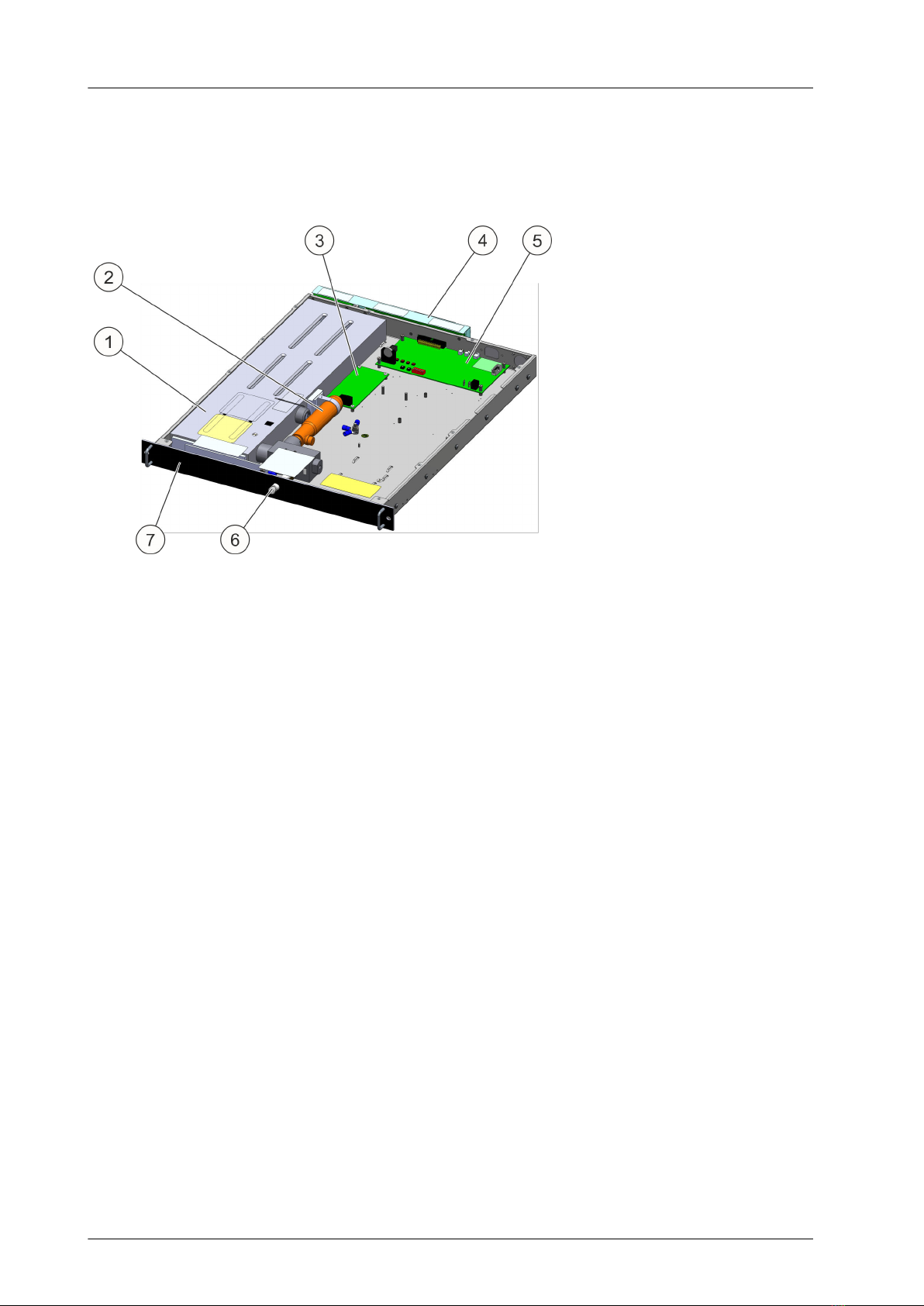

Fig. 2: Structure of the system

1 Tank (extinguishing agent container) with

fill level monitoring and release device

2 Propellant cartridge

3 Loss monitoring card

4 Connection strip (connection technology

card / network interface card

5 Control card CPU3

6 Discharge nozzle

7 Front panel

3.2 Function

In the event of a release, the system is triggered by a superordinate system (Active

extinguishing system DET-AC III Master or aspirating smoke detection system

EFD III). The release device is triggered electrically whereby the propellant cartridge

(Fig. 2 /2) is opened and the foaming agent flows into the tank (Fig. 2 /1). The relay

output „Extinguishing” is triggered. The foaming agent forces the extinguishing

agent to the discharge nozzle (Fig. 2 /6). At the nozzle, the extinguishing agent

vaporizes and develops the concentration necessary for extinction in the switch cab-

inet to be protected.

The fill level monitoring, which is integrated in the tank, reports an extinguishing

agent loss to the electronic evaluation unit of the superordinate system, which then

shows a failure (extinguishing agent loss) on the display. The relay output „Common

failure” is triggered.

The power supply for the system is ensured by means of the superordinate system.

The operation and display of the current state of the system is by means of the

superordinate system.

Structure, function and connections

Operating Instructions / DET-AC III Slave / 916007 / 05-2016 / en_US 20

This manual suits for next models

1

Table of contents