CPC 1602 User manual

7

1602 MONTTOR Ar.[D COI{TROL

SYSllEM

P.N. 901-1602

DOCUMENT No.025-1602

December 1988

Data, drawings and othet material containd

h-erein are proprietary to computer Process

Controls, lnc. aN may not be reproducd

withaut the prior approval of Computer process

Controls.

Computer Process Controls, lnc.

,275 Kennestone Circle, Suhe 100

Marietta, GA 30066 (&4) 425-2724 cPc

Section/ParagraPh

1.0 1.L

L.2

l-. 3

1.4

l-. 5

L.6

2.4 2.L

2.2

2.3

2.4

2.5

2.6

2.7

2.8

3.0

3.1-

4.0 4.L

4.2

4.3

4.4

4.5

5.0 5.L

5.2

5.3

5.4

5.5

5.5

5.7

5.8

II'ABLE Of CONIENrB

GEIIERAIJ INFORITATION

Introduction

General DescriPtion

Operator Terminal

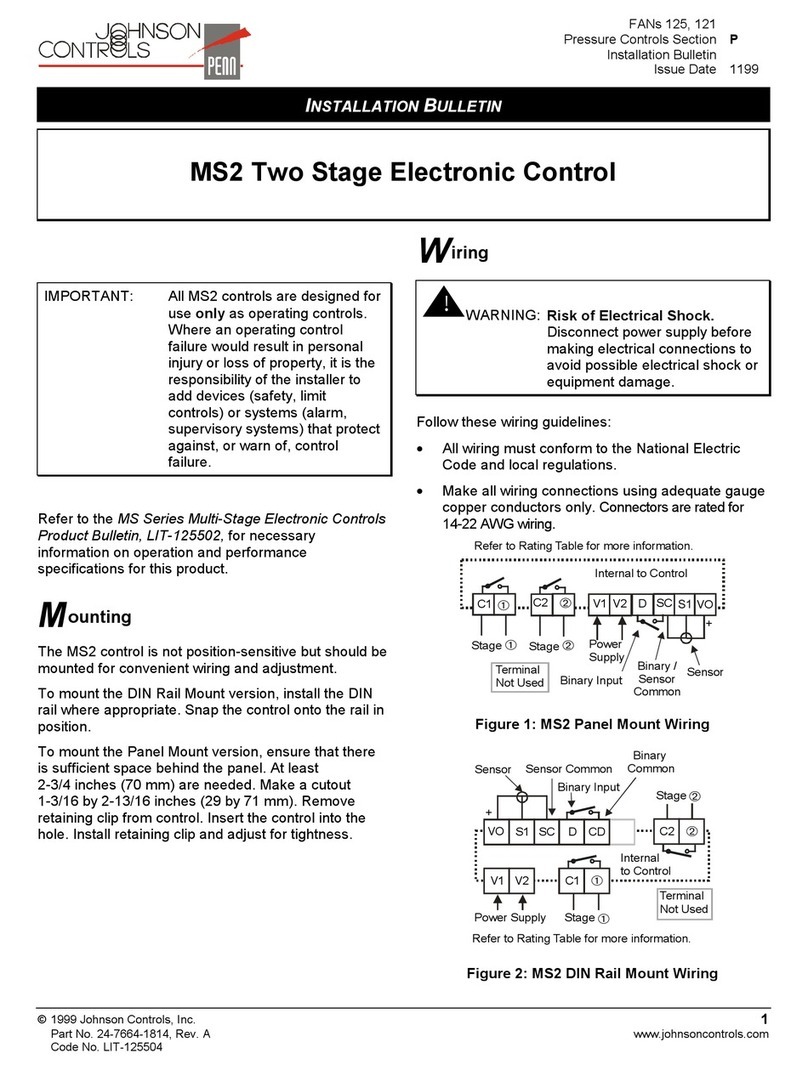

Wiring

optional EquiPment

Technical Characteristics

IXSTALLAEION

General

Pre-InstaIIation

Mounting

Field Wiring

operator Terminal Connection

Modem Connection and

Installation

Remote Communications Bus

Wiring

Expansion Enclosure

Installation

ETARTUP/CEECKOUT

Before Turning the Power On

DEECRIPTION OF OPERJArION

General

Control Functions

Monitor Functions

AIarms/Notices

ExPansion Network

PROGRJtr}IUING TEE L6O2

General

Menus

Passr+ords

Logging On to the 1642

Logging Off

Programm ingrlMon it o r i ng

Procedures

ExPert Mode

Programming EntrY

6.0 CONTROL STRATEGY GUIDE

6. l- General

6.2 Phase Loss

6.3 overrides

6.4 Digital InPut Overrides

6.5 Schedules -'-

6.6 Demand Limiting

6.7 DutY CYcIing

6.8 Analog Sensor Control

6.9 Defrost

5.10 fnverted OutPuts

6.l-L Logging

7.O TROUBLESEOOIIING

7.L General

8.0 PROGRNTI{ING FORI,IS

8.1 General

9.0 PART8 LIST

9.l- General

1O.O GLOSSARY OA TERUS

LTST OT ILLUSTRATIONS

Figure Title

2-1- Typical Wiring Methods

2-2 Setting Baud Rate on L6O2

2-3 Hayes Smartmodem Switch Settings

2-4 Typical Mounting Installation

5-l- L6O2 Menu Flowchart

9-1 Locati-on of L6Oz Circuit Boards

I,I8T OF TABLES

Table Tit1e

1-l- Technical Characteristics

2-1" Recommended Wire

5-l- operator Programming Guide

7-L Troubleshooting Guide

7-2 SYstem Alarms

7-3 Network Alarms

9-1 L6o2 Standard Parts List

g-2 L6O2 oPtional Parts List

l_L

PREFACE

].. GENERAL DESCRIPTTON. ThE CPC 1602 MONitOT ANd CONtTOI

iystem is a general purpose controf ly:!q+ designed to mj-nimize

energy usage in small ana meaium sized buildings. The L602 Monitor

and -Controt Unit (tfCU) may be expanded from 48 to 104 control and

nonitor points by connelting Lne L6O2 through a commu4ications

network to optioiral Expansion Board Enclosures . A 'variety of

control stratlgies and lnonitoring capabilities are available with

each L602 application.

2. CONTENTS. This manual consists of the following sections:

SECTION I

SECTION TI

SECTION III

SECTION IV

sEcrroN v

SECTION VI

SECTION VII

SECTION VIII

SECTION IX

SECTION X

3. USE OF THIS !,!ANUAL. This manual contains information

necessary to insta1l, operate, and maintain the Computer Process

Controls l-602 Monitor ana Control Unit (MCU). The table of

contents indicates sections, Pdragraphs, and titles to

facilitate l0cation of information. Illustrations,

tables, and diagrams, when applicable, are placed

throughout the publication io supplement the text rnaterial. Lists

of iilustrationl and tables indicate the numbers and titles.

Abbreviations, phrases, and words are set forth in the text

exactly as they-appear on the eguipnent. A glossary in Sectj'on

X givls definitions- of certain terms unigue to this product and its

application.

General Information

Installation

Startup/Checkout

Description of OPeration

Programming the L602

Operator Function Guide

Troubleshooting

Programming Forms

Parts List

Glossary

STUDY TEI8 ITAITUAL CAREFULLY PRIOR TO

INSIALLING AIID OPERATING TETS sYsTEI'I

111

8ECTION I

GENERAI, INTORIII.ATION

1.1- GENERAL DESCRIPTION. The Computer Process Controls 1602

Monitor and Control Unit (MCU) is a stand alone unit that will

monitor 32 inputs and control 1b outputs (24VAC). fnputs L thru 16

are analog (sensor) inputs, and 17 thru 32 may be either digital

(dry contacts) or analog (sensor) as defined by the user.

with the addition of up to 2 CPC L6AI Expansion Boards (1-6 Analog

or Digital Inputs each) and up to 3 CPC 8RO Expansion Boards (8

Relayed Outputs each), the L6O2's total number of inputs is 64 and

outputs is 40. The l-6AI Expansion Board's inputs may be defined as

either analog or digit.a1. The l-6AI and 8RO Expansion Boards

communicate with the L6O2 on the itExpansion Communication Busrt

(ECB). The purpose of the ECB is to aIIow the Expansion Boards to

be mounted closer to the devices being monitored or controlled.

Since a single 2-conductor shielded-wire communication line runs

from the L6O2 to an Expansion Board, input and output wiring runs

will be shorter and less installation tirne will result.

Each ]-602 controller has connections for a itRemote Communications

Busrr (RCB). The purpose of the RCB is to alIow an operator to

monitor and program the L6O2 from a remote location using a modem

and telephone lines or from an on site terminal. The CPC

Intelligent Pressure Control and the Intelligent

Environmental Control may also be connected to the RCB.

Some of the

Inputs

Alarms

Schedules

Outputs

Overrides

Duty Cycle

Demand

Phase

Defrost

Logging

features of the CPC L6O2 MCU are:

Monitoring of temperature, pressure, dewpointretc.

and detecting digital input on/off states

Programmable alarm setpoints for all inputs

Conrol outputs by time, day, night set back, week and

holidays

Control outputs by phase Loss, manual overrides,

digital overrides, schedules, demand setpoints, and

duty cycling, and mutiple sensors

Manually turn outputs on or off

Automatically turn outputs on/off for a specific

amount of time or by sensor control

Set winter/summer demand targets (IffH) and try to

achieve them by shedding specific outputs

Automatically turn outputs off when phase loss

is detected

Automatically perform up to 6 scheduled defrost

per day. Defrost types can be hot gas, electric,

or off cycIe.

Battery backed up hourly, daiIy, override, analog and

digital inputs, unacknowledged and acknowledged

alarms, and runtimes for digital inputs and outputs.

t_. L

1,.3 OPERATOR TERMINAL. Computer Process controls offers a

variety of terminals to meet ttre customer's needs for both

Local -and remote applications. Computer Process Controls has

made every effort to make the L6O2 conpatible with most

data terminals and personal computers operating in t|I" -rrData

Terminalr mode. The comrnunication -is done using the industry

standard RS-232 and sent in ASCII format. We recommend the

ioifJri"g two types of terninals. One is a printing

terminal, the other a video teminal

PRINTING

VTDEO cPc P.N. 380-0707

cPc P.N. 380-0905

l-.3.L OPERATOR TERMINAL SET UP. Using the terminal

instructions, set the terminal up with the following parameters:

8 Data bits Per character

- No parity

- one stop bit

- Baud raLe to match modem and 1602 selection (300, L2OO, ot

2400). See Figure 2-2 for instructions for setting baud

rate on the L602.

L.3.2 REI.IOTE COMI,IUNICATIONS. If the terminal does not have a

built-in modem, connect an external modem, following the

modem and terrninal manufacturer's instructions. The modem must

be Hayes l-2OO Smartmodem for proper receiving of incoming ca1Is.

Hayes brand modems are used by CfC, Inc. since they have proven to

be dependable and almost immune to line noise. See rrOperator

ferminil Connectionsrr for direct connection (no modem) of the

operator terminal to the L6O2.

1.4 WIRING. AlI input/output wires are connected

terminal blocks supplied in the L6O2 enclosure. These

removed without dillonnecting the wires. See Section

details.

1.5 OPTIONAL EQUIPMENT. The L6O2 may be modified or enhanced

with the following optional equipnent (see I'Optional Parts List").

Contact CPC for aiy iaaitionat information for 1602 options.

a. 3OO or 1200 Baud telePhone modem

b. sensors for temperature, 0-100 Psig transducers, o-5oo

psig transducers, humidity sensors, dew point sensors,

refrigerant level sensors, and light level sensors.

Control relays

Expansion Boird Enclosures to increase the number of 1602

inputs and or outputs

alir:rn Receiver faLkages for off-site alarm receiving.

Addition of Intelligent Pressure Controls and Intelligent

Environmental Controls on the L6O2 communications bus.

Additional 1-602 MCU's for increased capability.

Orion Front End System Dat,a-Pak Software (P.N. 804-1650)

for IBM Personal Computers. Enables user to retrieve

Iogs, restore set points, bask up set points, and

organize information.

to the

may be

II for

d.

A

f.

9.

h.

L-2

l--6 TECHNICAL CHARACTERISTICS. Technical Characteristics of

the system are shown in Table L-1.

Table l--l-. Technical Characteristics

. _ -- -:l::::::::-T : - - - - - -- - ;|; -- - - - - - -

Microprocessor 8085A-8 bit '-'-

Communications RS-232 Interface for Remote Communication

Network. 3OO, l-200, or 24OO baud- Compati-

b1e with Hayes Smartmodem conmands-

RS-485 Interface for the Expansion Communi-

cation Network. l-200 ' 24OO, or 4800 baud.

Front Panel Display L.E.D. indicator for polrer, processor run,

transmit and receive data.

Field Outputs 24 VAC fused (pica fuse), 30 VA total

output for l-5 combined. Maximum 1,2 VA

each output.

Field Analog Inputs -l- to +7 VDC

Field Digital Inputs Dry contact inputs.

Phase Loss Input Dry contact closure to Input #lZ (Digital)

from phase monitor device. one millisecond

reaction time.

KWHR and KW Input Pu1se input to Input #:r (Digital) -

Power Supply 1,20 VAC, 1- amP.

Failure Protection -Norma11y Closed Outputs for fail on.

-Normally Open Outputs for fail off if de-

sired.

-Watchdog timer resets processor every 5

seconds in the event of a failure-

-Output board automatically turns on all

outputs when processor is stopped for one

minute. A1arm contacts close.

-When multiple outputs reguire turning on

simultaneously, 2-3 second staging occurs

-Non volatile memory saves set points, logs

and names.

-8RO and l-6AI Expansion Boards Failure Pro-

tection (explained in individual manuals)

Physical Dimensions -Lsrr wide X 24tt high X 5.5rr deep.

Mounting Holes -7.Ottwide X 2l-.5[ (0.25trholes)

Weight -Approx. 42 1bs.

L-3

SECrION II

INSTALLAEION

2.L GENERAL. This section contains suggestions and factors

to consider during the pre-installation and installatiol phases

of the CpC :.602 systern. - Close adherence to the suggestions will

assure satisfactory performance from the eguipment

2.2 PRE-TNSTALLATION. Prior to receiving the L6o2 control

unit(s), the sensors and interface relays may !e installed- A11

wiring' should conform to National Electrical Codes (NEC) and all

1ocal codes.

2.2.L WIRING PROCEDURES. Table 2-L gives suggested wire

gauge and approved CPC part numbers. Shields are grounded olly

it the L6O2 control unit. For best results use only stranded

iyp" iff wire, #18 awg or smaller. Larger wires wiII not fit

properly into the terminal blocks of the L602.

2.2.2 UTILITY I.{ONITORING. If you will be monitoring KW and

KWHR usage, the L6O2 needs a DRY CONTACT pulse l1put. This can

be suppiiea by a pulse generating meter or combination current

transformers and watt houi transducer. Contact CPC or your Iocal

utility for more information. The pulse rate should be from a

form rrArr, two wire connection, 10 to l-00 watts/puIse. In

general, the lower this ratio (watts/pu1se) the better your

resolution will be.

2.2.3 SENSOR LOCATTON. In general, sensor location should be

consj-dered carefully. A misplaced sensor will cause poor

control, poor product integrily, and discomfort in building

ENViTONMENII. NOTN: SENSOR WIRES SHOULD NOT BE PULLED IN THE

SAIvIE CONDUIT AS HIGH VOLTAGE WIRING. CPC IS NOT RESPONSIBLE FOR

INACCURATE READINGS FROM INSTALI,ATIONS USING NON-SHIELDED SENSOR

CABLES.

a. Refrigerated Cases Install tenperature sensors in the

dischirge air stream where they may be checked and

serviced without disassembly of the case.

b. Walk In Coolers Install temperature sensor in the

center of the cooler in the air f10w from the coiIs.

c. Room temperature - Locate in a central area away from

external influences such as entrances ,or refrigerated

cases. If in a supennarket or retail storer w€ suggest a

location two/thirds of distance towards the front of the

building, near check out counters.

d. Dew Point - Locate away from refrigerated cases where

sufficient room air movement is present.

POWER INPUT. Power input is a dedicated, 120 VAC systern.

2.2.4

2-t

2.2.5 CONTROL OUTPUTS. Control outputs are 24 VAC. Outputs

are 0.0 vAc when a load is commanded roNn, 24.0 VAc when a load

is commanded rrOFFrt. Inverted loads operate just the opposite. (See

Section 6.9). A total of 20 field relays may be connected to each

L6O2 UCU. Do not connect more than six field relays to any one

L6OZ output. Use CPC Part Number 896-0004 for field relays.

Connect loads to the Normally Closed contacts (N.C..) for fail on

wiring for non inverted outputsr or to the Normally .Open contacts

(N.O.) for fail off wiring of inverted outputs. '---

NOTE: The 8Ro Expansion Board outputs may or may not supply

the 24 VAC (see the t'Optiona1 Parts Listtt). The 8Ro board

provides jumper selectable N.O. or N.C. contacts.

2.2.6 REUoTE CoI4MUNICATIoNS. If the unit is to be configured

for operation over a remote terminal, the telephone company must

be contacted to install a telephone line. They will reguire

the'following information:

a. Line Type - Voice Grade, Tone Dial

b. FCC Registration Number - BFJ9D9-58737-DME

c. Ringer Eguivalence: 0.4db

d. Termination to RJILC jack, or egual to modem specs.

2.3 IIIOUNTING. The L6O2 MCU is supplied with four mounting

holes for waII mounting. The unit should be mounted such that

the field wiring may be conveniently routed into the conduit

holes in the bottom of the enclosure. Because L2O VAC

independent power is reguired, proximity to a power source is

also desirable. See Table l--1 dimensions and Figure 2-4 for Typical

Mounting Installation.

2.4 FIELD WfRING. Table 2-L gives recommended wire

specifications for field connections. Figure 2-1 shows typical

wiring connections.

2.5 OPERATOR TERMfNAL CONNECTION. To connect an operator

loca1 terrninal to a L602 MCU use cable # 535-10L7 which includes

transmit data, receive data, and conmon. There is a connector on

the Field Input Board for this cable. See Figure 2-L. In addition,

a jumper wire needs to be in place between terminals #ZaA #ZOe.

This should have been factory installed, but check to insure the

jumper is in place. Connect the terminal as follows:

Local Terminal Cable # ]-eOZ

Data Terminal Transmit---) 535-1,0L7 {---

Data Terminal Receive ---) -------{--- connector on the

Data Tenhinal Common ---) t--- InpuL Board

See Figure 2-L for the location of the connections to the 1602

MCU. Before operating the terminal, folIow the instructions in

paragraph 1-. 3 . l-, SETUP.

2-2

Note that when using a netvork of CPC units, you may parallel

yorr operator terminai connections with the rrRemote communications

Busrr (RcB). This allows cornmunications with any device on the

network from any location on the RCB'

2.6 IITODEM CONNECTION AND INSTALI'ATION. USE CPCTS PATt NUMbET

370-03OO, 370-1200, of 370-2400 telephong_19dem. The tetephone

nodern i; suppfiea ,itn cable assernbly #SfS-fOfS, power supplyr dDd

telephone cb'nnecting wire. llount the telephone uodem near any

1602 IICU, preferaUiy device #f . Proximity to-the telephone jack

;;-- ""ppfi.a--bt the telephone company is also desirable. A L15

VAC -aupfex 'outlet is- required ior porrer to the modem's

transformer. Install as follows:

a. Mount the modem using the supplied bracket'

b. Connect the modem connector into the modem'

c. Connect the loose end of the modem cable #535-1015

to the L6O2.

Modem Wire No.

#2 Rx (Receive)

#a Tx (Transmit)

#z (shield)

#zo DTR

L6O2 Terminal No.

*zoz Tx (Transmit)

#203 Rx (Receive)

#zoL (shield)

#205 DTR

d. Plug in the modem power pack into a 9uplex outlet, and

into the power jack at the back of the modem

e. Plug the telephone wire into the back of the modem and

into the waII jack.

f . Set the Modem irplprr switches according to Figure 2-3

g. Turn on the power to the modem using the switch on the

back of the unit.

2.7 REI,IOTE COMMUNICATIONS BUS (RCB) WIRING. when you are

installing ,rritipt. MCU's, or connecting !h. 1602 to the

irrt"rrig"it presiure Controls or rntelligent Environmental control

for remote communications, each unit must be connected to the

RcB. This bus is a 3 conductor shielded cable (Belden #8771') '

rh; connection between L6o2 units is parallel, , or t'daisy chainrr

fashion on terminals *2OL, #2O2, and #2O3. When connecting to

interfigent pressure Controls and or Intelligent Environmental

Control, follow this table:

1602 Terminal No.

#zot (shield)

#2o2 (transmit)

#Zol (receive)

DO NOT INTERCONNECT EACH DEVICE ON THE REMOTE CO}'IMUNICATIONS BUS

UNTIL EACH DEVTCE HAS BEEN ASSIGNED A UNIQUE DEVICE NT'UBER' SEE

TABLE 5-1, SECTION 1O-3 FOR INSTRUCTIONS ON SETTING THE 1602

DEVICE NUMBERS. TO SET THE IPC AND IEC DEVICE NUIIIBERS ' SEE THE

IPC COMMUNICATIONS !.IANUAL AND THE IEC }TANUAL RESPECTIVELY '

IPC Terminal No.

#r

#z

#g

IEC Terrninal No. J1

#1 Green

#2 Red

#g B1ack

2-3

2.8 EXPANSION ENCLOSURE INSTALLATTON. rf the optional l"6AI and or

8RO Expansion Boards are used, refer to the rrExpansion Board

Enclosuie Manualrr for mounting details. A site close to the devices

being monitored or controlled can be chosen as long as 1-20VAC is

readily available to power the unit.

2.8.L EXPANSION COMMUNICATION BUS (ECB). The L6O2 needs.2 jumper

wires to be in place on the Field Inputs Board 'E- xpansion Bus

Terminal Block (see Figure 2-l) . If junpers have not =beeh factory

installed, connect one between terminals #2L2-#2L3, and one

between #2L4-f215. As with the Remote Communications Bus, the

Expansion Enclosures may also be connected in paraIle1 on the EcB.

The EcB wiring consists of a 2-conductor shielded-wire cable

(Belden #8451 22 gauge or #91,54 20 gauge for long runs) connected

between the 1,602 and the Expansion Board (l-6AI or 8RO) as follows:

l-602 MCU RS-485 Expansion Enclosure

Terminal Block RS-485 Bus Connector

2Og Ground (O V, shiled)

zLO Comm + (485 +, red)

zLL Comm - (485 -t black)

If you are utilizing one or more 8RO Boards (P.N. 801--3000) or L6AI

Boards (P.N. 8OL-3Ol-O), refer to the manuals that are supplied with

them, manual part numbers 025-3OOO and 025-301-O respectively.

2-4

8Ll.

E0la

or>

qP.

trtr

4,.-

V)

-d

<[ m. r I I llNo.E

(t llr-..o

AI t tclorr.

,,rL.l 1lr _._

AI\ALOG OR DIGITAL

I nput Conne ct i ons

Digital or Analog

As Def ined Thru

The Program Fr"ssE c

Trrarducrr

rlr

rl+

* EE

a \;

- EE

z

No.l,l l-No.2-.

oJ"_ail., rVr

I RY1 n= d i Out put

'tl-lf'-.4 -' Connect i ons

TYP I CAL

F I GURtr WIRI}{G

iao+E@r

ooooooo

d:iiiia m7

202

203

201

205

Temper at r:re Swit ctres Local Bu

CoNe ct lou

F ] ELD I hTPUT BOARD

r r N-n ; s-oEo-l f6i;-;-;-o-;= re I flEoEilTEEl

lsBBSSBgBl ls;;e;;;; I l;;;lo.-.* I

fO o eji o o o-1 l- o 6-oii o o o'1 f6! o 0-6 o o 6-l

E@r6eoi

NNNNNOO

oogloaoo

oooo

HNG

trtr[trtrtrtrtr

trtrTtrtrtrtrtr AI arm

Out put s

F I ELD OUTFUT BOARD

|-Erj-=rE=Eglf EETRj-EET-SImFs--:"-eE-EE]

I ;6;iiiiomm I I roo s':6r)e,reo I I iaom m(rJo? o(J I

looooooool looooooool looooooool

iCqaE{$@a'O

oooooooo

o066s666

2-1

2--5

This card is

( See FIocat ed 2 nd

igure 9-1 up from bottom.

Page 9-3)

E

[]

E

[:]

[]

E

E

E

L]

E

E

[]

E

L]

t_l

E

t:]

E

^ 1 2345678

J.ffi

BAUD SELECT SWI T CI{ES

.-1 ,

E

a)

t\

l

tq

u

DIGITAL I/O CARD

P.N. 537-1650

TO SET BAUD RATE:

1. Turn power of f .

Z. Remove Digital l/O card from holder.

3 . SeL swi t ches per t he t ab le be I ow.

4. Replace board. ldake sure it is seated.

5. Turn power back on.

IrioTE :

S1{I TCFIES

5 TO I

ARE NOT

USED SETT

F] NG BATID RATE

I GITRE 2-2

BAI]D RATES RS-232

REMOTE BUS RS-485

EXPANS I ON BUS

34

N/A N/A

00

10

01,

11

--> r 2

00

10

01

l.{/A N/A

11

SWITCH NO.

300

1200

2-400

480 0

9600

24

4 r z z4s6lBs

tffi <- DIP S\{ITCIIES

SWITCH NO.

T

o

(,

a

L)

4

5

6

7

B

o

.J

10

POSITION

DOWN

UP

DO\YN

DOWN

UP

lJP

IJP

DOI{N

lJP

TIP

NOTES :

o

o

1EOO BAUD MODEM SHOIYN

3OO BAUD HAS ONLY 8 SWITC}IES

POSITIONS 1 THROUGH B ARE

I DEI\M I CAL TO 12OO BAIJD MODEM

TO OBTAIN ACCESS TO SWITC}MS

REMOVE MODEM FRONT COVER

HAYES S}VIARTMODEM

S1{I TCH SETT I NGS

FIGI-IRE 2_3

z-7

RELAYO

BOX

EXPANS _

I ON BOX

MOL]-NT I NG BOARD

TYPICAL INSTALLATIONT

F I GTIRE 2--4

Z-B

Table 2-1-. RECOI'{I'IENDED WIRE

Terminal Numbers Function Recommended Wire

LOl- to L32 Inputs L to 16 (Analog) Belden #8762

Odd nuurbers are Common, #22-2 Shielded

Even numbers are Signal.

connect all shields to

chassis ground or any

conmon.

2OL Terninal/Modern conmon Belden #8772

2o2 Transmit to Terninal/ #22-3 Shielded

Modem.

2o3 Receive from Terminal/

Modem.

2O4 +5 VDC not used. Not used

2o5 Communications Data Not used.

Terminal Ready.

206 Communicatj-ons Clear To Jumper wire.

Send - Connect to #ZOe.

2O7 Common.

2o8 +L2 vDc to Pressure Belden #e772

Transducers and #206. #22-3 Shielded

2Og Expansion Bus Common. Belden #8451 #ZZ-

2 shielded-wire

z1-o Expansion Bus Transmit.

zLL Expansion Bus Receive.

2L2 +5 VDC. Connect JumPer

Wire to #2L3. JumPer Wire

I

n3 Data Terminal Ready. Connect Jumper Wire

Jumper wire to #ztz.

2L4 Clear to Send. Connect

Jumper Wire to #2L5. JumPer Wire

I

21,5 Common. Connect Jumper Jumper Wi-re

Wire to *2L4.

2t6 +L2 VDC. (not used)

2-9

Table 2-1" Continued. Recommended Wi-re

Terminal Numbers Function Recommended Wi-re

301- to 332 Inputs L7 to 32 (Digital) #zz-z Twisted

or (Field selectable as Pair. (Digita1)

additional Analog InPuts) 'o'r

Odd numbers are conmon. Beldeir' #8762

Even numbers are signal #22-2 Shielded

(i.e. #goL and #3o2 are (Analog)

D.r. #tt or A.I. # tzl

NOTE: FOR DIGTTAL TNPUTS

USE DRY CONTACTS ONLY! !

4Ol- 4 VAC Not used.

4O2,4O3 Pulse Output Alarm for Belden #8762

Pulse input dialers. #22-2 Shielded.

4O4 24 VAC Not used.

405 24 vAc Not used'

406, 4O7 Latched Alarm fn compliance

1 Amp max. with loca1 and

N. E. C.

408 24 VAc Not Used'

5Ol--532 24 VAC Control Outputs #22-2 Twisted

Odd numbers are 24 VAC Pair.

Even numbers are conmon

(i.e., sOL is OutPut #f

24 VAC. 502 is OutPut

#f Common. )

TB1-1 l"2O VAC In comPliance

with local codes

TB1-2 Neutral and N.E.C.

TB1-3 Ground

NOTE: UNIT TTUST BE GROUNDED! ! ! ! !

2-LO

SECTION III

sTARrgP/CEECKOUT

3.1 BEFORE TURNING THE POWER ON.

oD, you must do the following: Prior to turning the Power

3.L.l- DISCONNECT OUTPUTS. Disconnect the outputs by removing

the terrninal blocks along the bottom edge of the field output

board. This will insure that the control relays remain in their

normal (fai1 safe) position during the startup procedure.

3.1.2 SET THE ANAIOG INPUT (1,-16) SWITCHES. See Figure 2'].'

The switches should be rtuprr for temperature sensor inputs . and dorsn

for other type sensors. Set the switches in the rruprr position f9.

any spares. 'it any of the Input Terminals L7 thru 32 are to be

pr-ograirmea for use as analog inputs refer to Table 5-1

IAEM-ITfUHCTION l-0.10 for program instructions. Note: Inputs L7 thru

32, where used as analog, ilay be used for temperature sensors

oniy. Check with CpC for any other analog use of these.

3.1.3 RECHECK WIRING. Recheck the wiring at the 1602 unit.

Make sure jumpers are installed between terminals #ZOO-ZOe, and

betrteen terminals #2L2-#2t3 and #2L4-#215.

3.]-.4 DISCONNECT THE EXPANSTON COMMUNICATION BUS. REMOVE thE IOWET

terminal bloek on right side of the field inputs board that

connects the L6o2 to the Expansion communication Bus.

3.1.5 CONNECT YOUR OPERATOR TERMINAL. Connect your data terrninal

using instructions in Section 1.3.1- and in Section 2.5. Insure that

the baud rate is selected properly on the terminal and the L6O2

controller(s). See Figure 2-2.

3.1.6 TURN ON THE POWER. Turn on the power switch located in

the j.602 unit. It should illuminate; if not, check incoming power.

When powered up, the indicator lights on the unit door should be as

follows:

a. +L2, -L2, +5 lights should be illuminated.

b. Running light should be blinking on and off.

c. Transmit and Receive lights should be off.

If you have any problems, see Section VII, Troubleshooting, for

more information.

3-1

SECTION IV

DESCRIPIION OF OPERATION

4.L GENERAL. The CPC ]-602 Ii{CU is designed to be a total

Monitoring and Control System. Through it's simplicity of

operatj-on, it. is designed to meet the needs of the most demanding

application. The L6O2 has a variety of control fun9tions built

iirto it,s software. Each output can be controlled by eight

separate control strategies or by any combination of the eight

or all eight together. The nineth item below, defrost, works

independently of the first 8 strategies only when an actual defrost

is in progress. When a defrost schedule is idle, waiting for the

next defrost time, the outputs operate under the control of the

first 8 strategies. The output control strategies are as follows:

1. Phase Loss protection

2. Fixed or Timed Overrides ON or OFF.

3. Up to 2 Digital Input Overrides on each Output. Overrides

can be either ON or OFF.

4. Schedule Control

5. Night Setback Schedule Control

6. Demand Limiting

7. Duty Cycling

8. Sensor Control (ternperature, pressure, dew point, etc. )

9. Scheduled Defrost Control.

4.2 CoNrROL FUNCTIONS. Each output of the 1602 is controlled

by the following eontrol strategies as listed in sequence of

priority of their control.

4.2.L PHASE LOSS. rnput #lZ (Digital) may be used as an input

from a phase monitor, CPC P.N. 23L-O258. If poor power is detected,

Input #lZ closes and all loads assigned to phase loss are turned

off. See Control Strategy Guide, Page 6-L, for more information.

4.2.2 OVERRfDE. Each output may be overridden from the

operator terminal. The override can force an output ON or OFF for

a timed period or until manually removed by the operator. Each

override is stored in an Override Log. See Control Strategy

Guide, Page 6-L, for more information.

4.2.3 DIGITAL INPUT OVERRIDE. One or two digital inputs may be

assigned to each output and set to force the output ON or OFF when

the digital input closes. Digital fnput Override #f has a

higher priority than Digital Input Override #2. See Control

Strategy Guide, Page 6-2, for more information.

4.2.4 SCHEDULE. Each output may be assigned to one of 12

schedules, each having 24 different events. (i.e., ON at 8:00 a.m.

is an event). Six types may be set for events (WK for Sun.-Sat.,

Holiday L, Holiday 2, Holiday 3, MF for Mon.-Fri., or each day may

be set separately) . See Control Strategy Guide, Page 6-2, for more

information. 4-L

A.2.5 NIGHT SET BACK. Each output nay be assigned a Night Set Back

Schedule (same definition as Section a.2.4 SCHEDULE) and setpoint

values to revert to when under control of this schedule. See

Control Strategy Guide , Page 6-2, for more information.

4.2.5 DEIIIAND LIMITING. Each output may be designated for

demand shedding. Outputs are shed by priority, maximum shed. time,

and minimum oi tirne.- In addition, an analog sensor.input limit

may override an output set for shedding. Winter and Summer

taigets may be selected for Demand control. See Control

stritegy GuidE, Page 6-3, for more information.

4.2.6 DUTY CYCLING. Each output nay be set for Duty Cycling.

An ON time from 0 to 240 minutes and an OFF time from 0 to 24O

minutes may be set. Alsor 8D analog sensor input limit .Tay

override an output for Duty Cycling. See Control Strategy Guide,

Page 6-4, for more information.

4.2.7 ANALOG SENSOR CONTROL. Each output may be assigned up to

four sensors for control using average, minimum, or maximum values.

Day eut-on, cut-off, On delay, Off deIay, and night set back cut-

on and cut-off may be set. The night set back schedule is

determined by one of the L2 regular schedules. See Control

Strategy Guide, Section 5.8, for more info:mation.

4.2.8 SCHEDULED DEFROST CONTROL. The defrost control can provide up

to G scheduled defrosts per day. The defrost types available are

hot 9as, electric, and ott cylte ?11 3 allowing ternination by

time, temperature, and or aigita:. input. See Control Function

Guide, Seclion 6.9, for more information.

4.3 UONITORING F"UNCTIONS. A number of monitoring functions are

standard with each 1502 MCU to assist the operator in determining

problems at the site under eontrol and to improve maintenance.

foonitoring functions such as, List Definitions and Set Points, List

Status, iresent Analog and Digital Inputs, Logging Data, and AIl

Alarns and Notices, are just a few of the standard functions.

4.3.L ANALOG SENSOR READINGS. Current readings of all Analog

Inputs can be monitored. Also I a single Analog Input cal be

moi:itored continuously. When the unit is monitoring a single

input, the L6O2 will update the value of that input on the screen

evLry S seconds. Currenl status displays the follo*ring information

for ltt Ana}og inputs or continuously for a single input:

This Week

High Low Last Week

High Low

Present TodaY YesterdaY

# Name Val-ue High Low High Low

4.3.2 DfGITAL STATUS LISTINGS. Current status of all Digital

inputs can be monitored. This listing shows Current on/off status,

On time, Accumulated Events, Last Olt duration, Last OFF duration,

And ON & oFr' Delay Timer times remaining.

4-2

Table of contents

Popular Control System manuals by other brands

Roger

Roger B73/LTM Instruction and warnings for the installer

Autopilot

Autopilot PPC10 Installation and user guide

BPC

BPC DUPLEX 250 Easy Use, maintenance and installation manual

OOOZNEST

OOOZNEST WorkBee CNC Mechanical Assembly Instructions

Rise

Rise VIGILANT 500 installation manual

Johnson Controls

Johnson Controls MS2 Installation Bulletin