Rittal 3370.22 Series User manual

Assembly and operating instructions

Compact cooling unit

3370.22X 3370.52X

3370.32X 3370.62X

3370.37X 3370.72X

3370.42X

1194.42X 1194.55X

1194.62X 1194.72X

Contents

Page 2of 13 Rittal cooling unit assembly and operating instructions

EN

Contents

Contents.....................................................2

1Application...........................................3

2Technical data......................................3

3Assembly..............................................3

4Safety notes .........................................3

5Commencing operation and control

behavior......................................................3

5.1 Controller control....................................3

5.1.1 Operation of the controller......................3

5.1.2 Editable parameters...............................4

5.1.3 Parameter navigation.............................4

5.1.4 Setting the target temperature ...............5

5.1.5 Setting the temperature range ...............5

5.1.6 Controller display ...................................5

5.1.7 Display buttons.......................................5

5.1.8 Compressor: On / Off.............................6

5.2 Alarm parameters...................................6

5.3 Evaluating system messages.................6

5.4 Forced cooling........................................6

6Filter mats ............................................6

7Technical informations........................7

7.1.1 Operation of the cooling unit..................7

7.1.2 Condensate discharge ...........................7

8Handling instructions..........................7

8.1 Fitting the cooling unit ............................7

8.1.1 External mounting of the cooling unit.....8

8.1.2 Partial internal mounting of the cooling

unit (accessories not included)...............8

8.2 Electrical connection ..............................9

8.2.1 Connection data.....................................9

8.2.2 Overvoltage protection and power line

load ........................................................9

9Inspection and maintenance...............9

9.1 Compressed air cleaning .....................10

10 Storage and disposal.........................12

11 Scope of supply and guarantee........12

1 Application

Rittal cooling unit assembly and operating instructions page 3of 13

1Application

Enclosure cooling units are designed and built to

dissipate heat from enclosures by cooling the air

inside the enclosure and protecting temperature

sensitive components.

2Technical data

See nameplate

3Assembly

The standard wall-mounted unit is suitable for exter-

nal mounting. Cut out the sections and drill accord-

ing to the drawing.

Cut the enclosed seals to the required length and

attach to the unit. Screw tapped pins into the blind

nuts on the rear of the unit. The unit is then to be

secured using washers and nuts

4Safety notes

The following safety notices are to be observed in

their entirety for the correct use of the equipment:

To prevent the enclosure with the cooling unit

fitted tipping over, it is essential that this be

bolted to the floor.

A roller door is to be used to ensure problem

free opening and closing of the enclosure door.

A transportable enclosure with built-in cooling

unit may only be produced if an additional

transport anchorage to support the cooling unit

is used.

Prior to mounting, ensure that:

the site for the enclosure, and hence the ar-

rangement to the cooling unit, is selected so as

to ensure good ventilation;

the location is free from excessive dirt and mois-

ture,

the cutout for air extraction is located in the

upper area of the enclosure;

the mains connection ratings, as stated on the

rating plate. are available:

the ambient temperature does not exceed

+50°C;

The packaging shows no signs of damage.

Traces of oil on damaged packaging are an in-

dication of refrigerant loss and of leakage in the

unit system. Any damage to the packaging may

be the cause of subsequent malfunctions:

the enclosure is sealed on an sides

Condensation will occur if the enclosure is leaky;

the separation of the units from one another and

from the wall should not be less than 200mm;

air inlet and outlet are not obstructed on the

inside of the enclosure;

units are only fitted horizontally in the specified

position Max. deviation from the true horizontal:

2°

condensate drainage is provided

electrical connection and repair are carried out

only by authorized personnel

Use only original replacement parts and acces-

sories.

Losses from the components installed in the

enclosure must not exceed the specific refrige-

ration capacity of the cooling unit itself;

The customer may not modify the cooling unit in

any way.

5Commencing operation and

control behavior

Following the completion of mounting and a waiting

period of approximately 30 minutes (to allow oil to

collect in the compressor in order to ensure lubrica-

tion and cooling).

5.1 Controller control

Figure 1: Controller

After electrical connection the internal fan turns on

and circulates the enclosure air. This helps assure

even temperature distribution within the enclosure.

The condenser fan and compressor are controlled

by the controller. The minimum time is 3 minutes to

restart the compressor after it has switched off. The

switching difference is 5 K. To avoid short switching

cycles and hence the danger of inadequate or only

partial cooling in some sections of the enclosure,

The switching difference should be set to be only as

low as necessary. For economic reasons (energy

saving), the nominal value of the internal enclosure

temperature Ti should also be set to be only as low

as necessary.

5.1.1Operation of the controller

The display terminal H1 consists of a 3 position 7-

segment display which indicates the internal enclo-

sure temperature in °C as well as any fault codes.

The actual enclosure internal temperature is con-

stantly displayed on H1. When a system message is

generated, this alternates in the display with the

current internal enclosure temperature.

5 Commencing operation and control behavior

page 4of 13 Rittal cooling unit assembly and operating instructions

5.1.2Editable parameters

Param.

Type

Display

screen

Parameter

Min.

value

Max.

value

Factory

setting

Description

F

PS

Password

0

99

22

Protection code for modifying the configu-

ration parameters (default=22). The value

of the password can be customized from

the supervisor

S

St

Setpoint

r1

r2

35

:r1 minimum value and r2 maximum

value of the set point. Parameter St de-

termines the desired temperature to be

maintained inside the cabinet or cold

room (set point).

F

rd

Regulation diffe-

rential

0

+19

5

Value that is added to (or subtracted

from, i

set point.

rd= low values:

more precise temperature control;

high compressor On/Off switching

frequency in the event of minimum.

Temperature deviations (with the risk

of causing damage).

rd= high values:

less precise temperature control;

low compressor On/Off switching

frequency in the event of minimum

temperature deviations.

Important: the compressor can also be

safeguarded using the parameters that

limit the number of activations/hour and

the minimum off time

C

r1

Setpoint min.

value

20

r2

30

r1 & r2 :set the range of temperatures

for setting the set point.

C

r2

Setpoint max.

value

r1

50

45

C

cc

Continuous cycle

period

0

15

1 (hours)

?

C

A0

Alarm and fan

differential

-20

+20

2

See chapter 5.2

F

AH

Alarm maximum

temp.

-50

+99

10

See chapter 5.2

C

Ad1

Delay for high and

low temp. alarm

0

199

30

Delay for high temperature alarm when

power on just before. When alarm condi-

tion is achieved but power on just before ,

the timer start to count for a specify value

(Ad1). Only the time elapsed, alarm relay

can be active

5.1.3Parameter navigation

The operating parameters, modifiable using the key-

pad, are divided into two types: frequent (type F) and

configuration (type C). Access to the latter is pro-

tected by password (default= 22) to prevent acciden-

tal or un-authorized modifications.

Accessing the type F parameters:

Press the SET button for more than 3 s (if there

are active alarms, mute the buzzer), the display

use the UP and DOWN buttons to scroll the pa-

rameters. The LED corresponding to the catego-

ry of parameters will be on (see parameters list)

press SET to display the value associated with

the parameter increase or decrease the value us-

ing the UP or DOWN button respectively;

press SET to temporarily save the new value and

display the parameter again; repeat the proce-

dure for any other parameters that need to be

modified;

press the SET button for more than 3 s to per-

manently save the parameters and exit the pa-

rameter setting procedure.

Accessing the type C parameters:

Press the SET button for more than 3 s (if there

are active alarms, mute the buzzer), the display

5 Commencing operation and control behavior

Rittal cooling unit assembly and operating instructions page 5of 13

press the SET button to access the password

setting; use the UP and DOWN buttons to scroll

access the parameters);

press the SET button to confirm the password ;

use the UP and DOWN buttons to scroll the pa-

rameters. The LED corresponding to the catego-

ry of parameters will be on (see Below Table);

press SET to display the value associated with

the parameter increase or decrease the value us-

ing the UP or DOWN button respectively;

press SET to temporarily save the new value and

display the parameter again;

repeat the procedure for any other parameters

that need to be modified;

press the SET button for more than 3 s to per-

manently save the parameters and exit the pa-

rameter setting procedure.

Accessing the type S parameters:

press SET for 1 s, the set value will start flashing;

increase or decrease the value using UP or

DOWN;

press SET to confirm the new value.

5.1.4Setting the target temperature

The temperature is preset at the factory to 35℃.

press SET for 1 s, the set value will start flashing;

increase or decrease the value using UP or

DOWN;

press SET to confirm the new value.

5.1.5Setting the temperature range

Press the SET button for more than 3 s (if there

are active alarms, mute the buzzer), the display

press the SET button to access the password

setting; use the UP and DOWN buttons to scroll

access the parameters);

press the SET button to confirm the password;

use the UP and DOWN buttons to scroll the pa-

rameters.

press SET to display the value associated with

the parameter increase or decrease the value us-

ing the UP or DOWN button respectively;

press SET to temporarily save the new value and

display the parameter again;

repeat the procedure for any other parameters

that need to be modified;

press the SET button for more than 3 s to per-

manently save the parameters and exit the pa-

rameter setting procedure.

Notice!

It is not allowed to change the value for

authorization

5.1.6Controller display

Figure 2: Controller display

function

Normal operation

Start up

no.

on

off

flash

1

compressor

on

off

call

on

2

digits

two digits with sign and decimal

point, -99 to 99(*).

Notice!

The parameters that feature three digit

values can be set from the supervisor.

---

5.1.7Display buttons

Figure 3: Display buttons

no.

Normal operation

Start up/ reset

Pressing the button alone

1

more than 3 s: switch the

compressor ON/OFF

-

2

1 sec: displays/sets

the set point

more than 3 sec.: ac-

cesses the parameter

setting menu (enter

password 22)

mutes the audible

alarm (buzzer)

-

pressed

together (2

and 3) acti-

vate parame-

ter reset pro-

cedure

Start up/ reset to factory setting parameters

Disconnect power supply

Reconnect power supply while holding but-

tons 2 and 3

After a few seconds the unit will restart with

factory setting parameters

5 Commencing operation and control behavior

Page 6 of 13 Rittal cooling unit assembly and operating instructions

5.1.8Compressor: On / Off

Switching the compressor ON: press UP for more

than 3 s (when pressing the button, the display

shows ON).

Switching the compressor OFF: press UP for more

than 3 s. The d

In OFF status, the following functions are disabled (if

featured by the model):

compressor control

duty setting

continuous cycle

5.2 Alarm parameters

A0: Alarm temperature differential

This represents the differential used to activate the

high temperature alarm

r-

mines the actual activation of the temperature alarm.

) defines the

nature of alarm relative):

A0 0 AH expressed as absolutes

A0 > 0 AH expressed relative to the set point

Figure 4: High temperature alarm

AH: High temperature alarm

AH setting: 10 degrees is the factory setting (-50 to

99 is the lower and upper limit ). Other Factory set-

tings: Setpoint (ST) = 35°C; A0 = 2°C.

For example: If the internal temperature of the cabi-

net is Ti = 46°C, ST (35°C)+ AH (10°C) = 45°C ,

so 46°C > 45°C the display will show AH-alarm. As

long as Ti is more than 43°C the display will show

AH-alarm, because ST (35°C)+ AH (10°C) - A0 (2°C)

= 43°C. If the temperature Ti will fall to 42°C the

alarm AH will no longer be shown in the display. As

long as the temperature inside of the cabinet will not

rise over 45°C again there will be no AH-alarm dis-

played.

Temperature alarm output

Logo and buzzer on display: The information

buzzer.

The over temperature message may also be

polled via a contact on the connection clamp of

the cooling unit (system message relay with

changeover contact, see connection diagrams).

--Terminal “1”C (connection of the supply voltage

to the fault signal relay)

--Terminal “2”NO (normally open) .

Notice!

Delay for high temperature alarm when

power ON: When alarm condition is

achieved but power is ON, the timer

start to count for a specify value (Ad1).

Alarm relay becomes active when this

time is elapsed.

Notice!

The u

Notice!

The contacts of the relays are normally

open (NO). If the alarm occurs the con-

tacts close (NC).

5.3 Evaluating system messages

Display

screen

Buzzer

Alarm

relay

System

message

Measures

E0

Active

Not

active

Ambient

temperature

probe bro-

ken

Check sen-

sor cable

and replace

if necessary

HI

Active

Active

High tem-

perature

alarm

Check cool-

ing capaci-

ty/check unit

5.4 Forced cooling

The continuous cycle is used to maintain refrigeration

forced cooling mode active in the cabinet or cold

room, regardless of the temperature inside the unit.

This may be useful for rapidly bringing the tempera-

ture below the set point value.

To activate or deactivate the continuous cycle from

the keypad, Press UP+DOWN for more than 3 s, the

hes,

pause).

The unit starts the forced cooling mode at least after

the minimum compressor off time ( 3 min.). The

forced cooling mode is activated after the start for 1 h.

After this time the unit starts normal operation.

6Filter mats

The stainless steel filter mat available as an acces-

sory is coarse and filters large dust particles or fluff

from the air. Subject to the suction of the blower be-

ing high enough, fine dust is blown through the filter

mat and the external circuit of the unit. This does not

affect the unit's operation.

5 Commencing operation and control behavior

Rittal cooling unit assembly and operating instructions page 7of 13

Figure 5: Replacement of the filter mat

7Technical informations

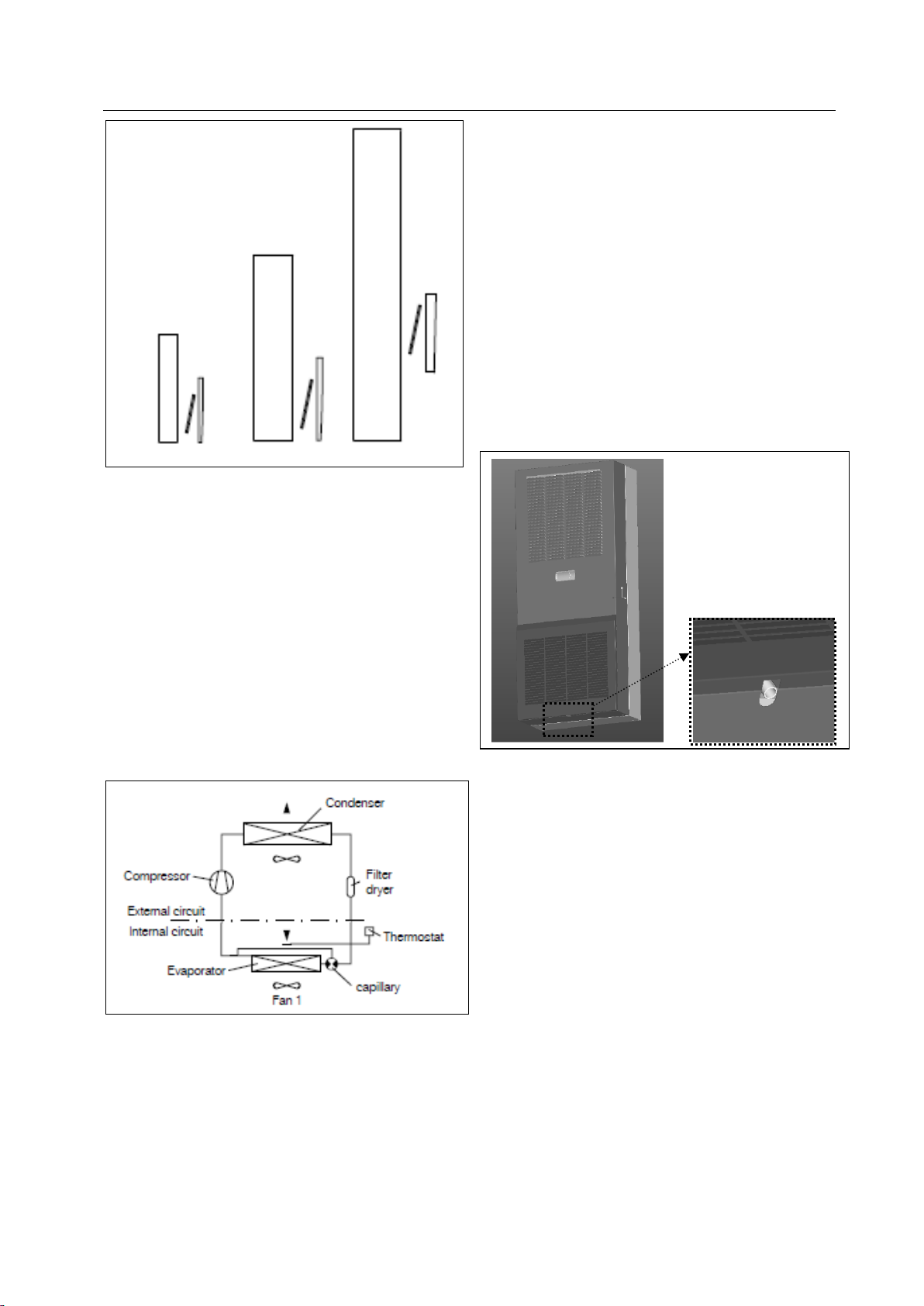

The cooling unit (compressor refrigeration unit) con-

sists of four main components: the coolant compres-

sor, evaporator, condenser, and the capillary, which

are connected by suitable Pipe-work. This circuit is

filled with a readily boiling substance, the refrigerant.

The R134a (CH2FCF3) refrigerant is free from chlo-

rine. It has an ozone destroying potential (ODP) of 0

and is therefore environmentally friendly. A filter

dryer which is integrated in the hermetically sealed

cooling circuit, provides effective protection against

moisture, acid, dirt particles, and foreign bodies with-

in the cooling circuit.

7.1.1Operation of the cooling unit

Figure 6: Operation of the cooling unit

The compressor takes the gaseous refrigerant from

the evaporator and compresses it to a higher pres-

sure in the condenser. During this process the tem-

perature of the refrigerant rises above the ambient

temperature and heat can be dissipated to the envi-

ronment via the surface of the condenser. Then the

refrigerant is liquefied and, by means of a thermos-

tatically controlled capillary, returned to the evapora-

tor, where it evaporates at low pressure. The heat

required for complete evaporation is drawn from the

enclosure interior causing it to cool down. The cool-

ing cycle is thus completed, the aforementioned

process of the heat transfer starts afresh.

7.1.2Condensate discharge

A drain pipe fitted to the evaporator divider panel

ensures that any condensate which may form on the

evaporator (at high air humidity, low temperatures

inside the enclosure) is drained away from the bot-

tom of the unit. For this purpose, a length of hose

should be fitted to the condensate pipe connection

piece. The condensate must be able to run off freely.

If the condensate is to be drained off over a greater

distance, then care must be taken that the hose is

free from kinks and a check for correct drainage

made.

8Handling instructions

8.1 Fitting the cooling unit

The enclosure cooling unit may optionally be exter-

nally mounted on the enclosure (1) or partially inter-

nally mounted (2).

8 Handling instructions

Page 8 of 13 Rittal cooling unit assembly and operating instructions

Figure 7: Installation method

To this end, cut the side panel or door of the enclo-

sure, as per the Manu included with the supply, and

drill the relevant holes.

Notice!

For mounting the units SK 3370724 in

the TS side panel or rear panel, we

recommend the use of enclosure panel

fasteners TS 8800.071 (see RITTAL

Catalogue).

8.1.1External mounting of the cooling

unit

Cut the supplied sealing tape to the correct

length and stick it carefully along the back of the

unit so that no gaps are left at the joints.

Figure 8: Applying the self-adhesive tape

Screw the supplied grub screws into the blind

nuts on the rear of the unit.

Secure the unit using the supplied washers and

nuts.

Figure 9: Securing the unit (all compact units except 3370220)

8.1.2Partial internal mounting of the

cooling unit (accessories not in-

cluded)

Fix the 4 mounting bars on the air conditioner by

using screws.

Figure 10: Fixing mounting bars

Cut the supplied sealing tape to the correct

length and stick it carefully along the inside of the

rear enclosure half so that no gaps are left at the

connection points.

Figure 11: Sticking sealing tape

Mount the front enclosure tray using the washers

and nuts.

8 Handling instructions

Page 9 of 13 Rittal cooling unit assembly and operating instructions

Figure 12: Mounting cooling units

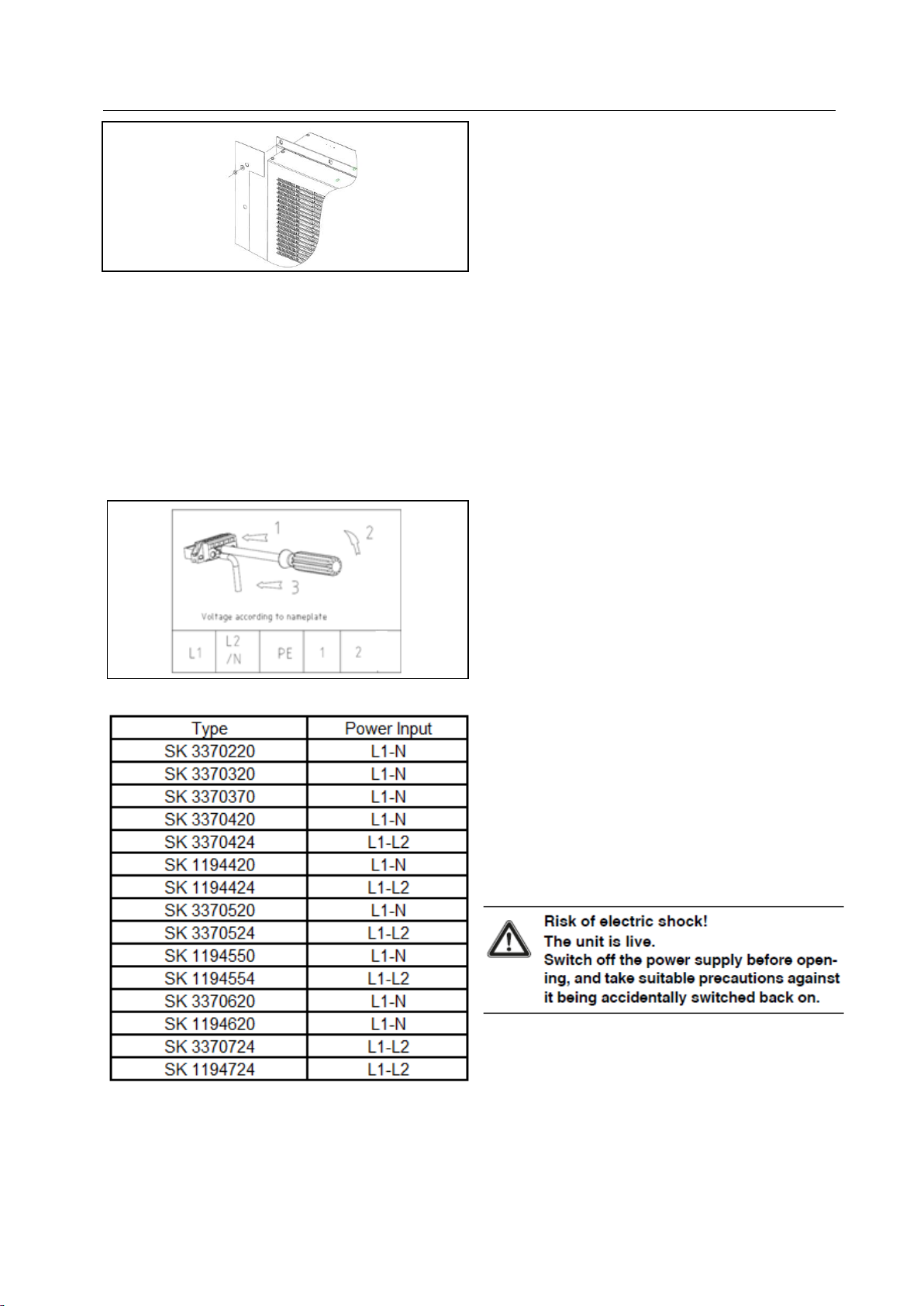

8.2 Electrical connection

When performing electrical installation, shall comply

with national and local institute There are existing

regulations and provisions of the local power supply

bureau. Electrical safety. Installed by qualified elec-

trician, electrician must comply with the current stan-

dards and regulations. Connect the power supply

cable according to the power supply tension as

shown on the name plate by following the instruc-

tions below:

Figure 13: Electrical connection

8.2.1Connection data

The connected voltage and frequency must cor-

respond to the values stated on the rating plate

The cooling unit must be connected to the mains

via an all-pin isolating device, which ensures at

least 3 mm contact opening when switched off

No additional temperature control may be con-

nected upstream of the unit at the supply end

Install the pre-fuse specified on the rating plate to

protect the cable and equipment from short-

circuits

The mains connection must ensure low-noise

8.2.2Overvoltage protection and power

line load

The unit does not have its own overvoltage pro-

tection. Measures must be taken by the operator

at the supply end to ensure effective lightning

and overvoltage protection. The mains voltage

must not exceed a tolerance of ±10%.

In accordance with IEC 61 000-3-11, the unit is

intended solely for use at sites with a continuous

current-carrying capacity (incoming mains power

supply) of more than 100 A per phase and with a

supply voltage of 400/230 V. If necessary, the

electricity supply company must be consulted to

ensure that the continuous current-carrying ca-

pacity at the point of connection to the public grid

is sufficient for connection of such a unit.

The fans and compressors in single- and three-

phase units are intrinsically safe (thermal winding

protection). This also applies to transformer ver-

sions, types 3370.420, 3370.520, 3370.724 and

to special-voltage units which are likewise

equipped with a transformer.

Install the slow pre-fuse specified on the rating

plate (miniature circuit-breaker with appropriate

characteristic or gG

standard type slow fuse, circuit-breaker for plant

or transformer protection) to protect the cable

and equipment from short-circuits. Select a suit-

able circuit-breaker in accordance with the infor-

mation specified on the rating plate: Set it to the

minimum specified value. This will achieve the

best short-circuit protection for cables and

equipment. Example: Specified setting range 6.3

10 A; set to 6.3 A.

9Inspection and maintenance

The cooling circle is designed in the form of a main-

tenance-free, hermetically sealed system. The cool-

ing unit is filled with the required quantity of refrige-

rant at the factory, checked for leaks, and subjected

to a functional test run.

The installed maintenance-free fans are mounted on

ball bearings, protected against moisture and dust.

The life expectancy is at least 30,000 operating

hours. The cooling unit is thus largely maintenance-

9 Inspection and maintenance

Rittal cooling unit assembly and operating instructions page 10 of 13

free. All that may be required from time to time is to

clean the components of the external air circuit using

a vacuum cleaner or compressed air if they become

visibly dirty. Any stubborn, oily stains may be re-

moved using a non-flammable detergent, such as

degreaser. Maintenance interval: 2,000 operating

hours. Depending on the level of contamination in the

ambient air, the maintenance interval may be re-

duced to suit the air pollution intensity.

Notice!

Caution!

Risk of fire!

Never use flammable liquids for

cleaning.

Sequence of maintenance measures:

Check the level of dirt.

Filter soiling? Replace the filter if necessary.

Cooling membranes soiled? Clean if necessary.

Activate test mode; cooling function OK?

Check noise generation of compressor and fans.

Sequence of maintenance measures:

-Check the level of dirt.

-Filter soiling? Replace the filter if necessary.

-Cooling membranes soiled? Clean if necessary..

-Check noise generation of compressor and fans.

9.1 Compressed air cleaning

Figure 14: Break power

Figure 15: Twist off the screw on the top of the cover

Figure 16: Twist off the screw on the bottom of the cover

Figure 17: Open the cover

Figure 18: Disconnect the plug of the display

9 Inspection and maintenance

Page 11 of 13 Rittal cooling unit assembly and operating instructions

Figure 19: Twist off the screw of the outside fan(1)

Figure 20: Twist off the screw of the outside fan(2)

Figure 21: Remove the outside fan

Figure 22: Disconnect the plug of the outside fan(1)

Figure 23: Disconnect the plug of the outside fan(2)

Figure 24: Clean the heat pipe and compressor

chamber using compressed air

9 Inspection and maintenance

Rittal cooling unit assembly and operating instructions page 12 of 13

Figure 25: Clean the heat exchanger using

compressed air

10 Storage and disposal

Store the cooling unit in the appropriate position

for transport.

The closed cooling cycle contains refrigerant and

oil, which must be properly disposed of for the

protection of the environment. Facilities for dis-

posal are available at the Rittal plant.

Please contact us for advice.

11 Scope of supply and guaran-

tee

1 cooling unit, ready for connection

1 sealing tape

1 set of mounting and operating instructions

Guarantee:

This unit is covered by a 1-year guarantee from

the date of supply, subject to correct usage(see

also Safety notices under heading 4.). Within this

period, the returned unit will be repaired in the

factory or replaced free of charge. The cooling

unit is to be used for the cooling of enclosures

only. If it is connected or handled improperly the

manufac

this case we are not liable for any damage

caused.

RITTAL GmbH & Co. KG

Postfach 1662 ·D-35726 Herborn

Phone + 49(0)2772 505-0 ·Fax + 49(0)2772 505-2319

This manual suits for next models

10

Table of contents

Other Rittal Cooling Box manuals