4. Making Adjustments to the Holder

A. Closer spring force should be as low as possible.

(Closer should arrive at lowest setting).

B. Turn OFF Power (using ON/OFF switch).

C. To set Hold Open:

1. Door should be in CLOSED position.

2. Raise or lower cam until the word “Pull”is dis-

played from the UNDERSIDE of the unit (Fig 4a).

3. Open door to desired Hold Open position.

4. Raise or lower cam and ROTATE until pocket of

cam is in position next to Roller A shown in Fig 4b

5. Release cam to re-engage teeth.

6. Turn ON power (using ON/OFF switch).

7. OPEN DOOR. Door should stay in Hold Open

position–if not, repeat Steps 3 and 4.

8. Pull door OUT of Hold Open–door should close

freely.

9. OPEN DOOR. If releasing force needs to be

increased, turn adjusting nut IN. If lesser holding

force is desired, turn nut OUT.

Trouble-Shooting Tips:

1. Turn ON power.

2. Can door swing far enough to engage hold open? Minimum opening is 85°.

3. Make sure closer is at lowest spring setting.

4. Put piece of metal against the magnet to make sure it is receiving current.

5. If not, double check wiring instructions.

6. If so, with door in closed position look up at holder mechanism. Word PULL should be visible, if

not, adjust cam.

7. Turn adjusting nut.

8. Check arm indexing.

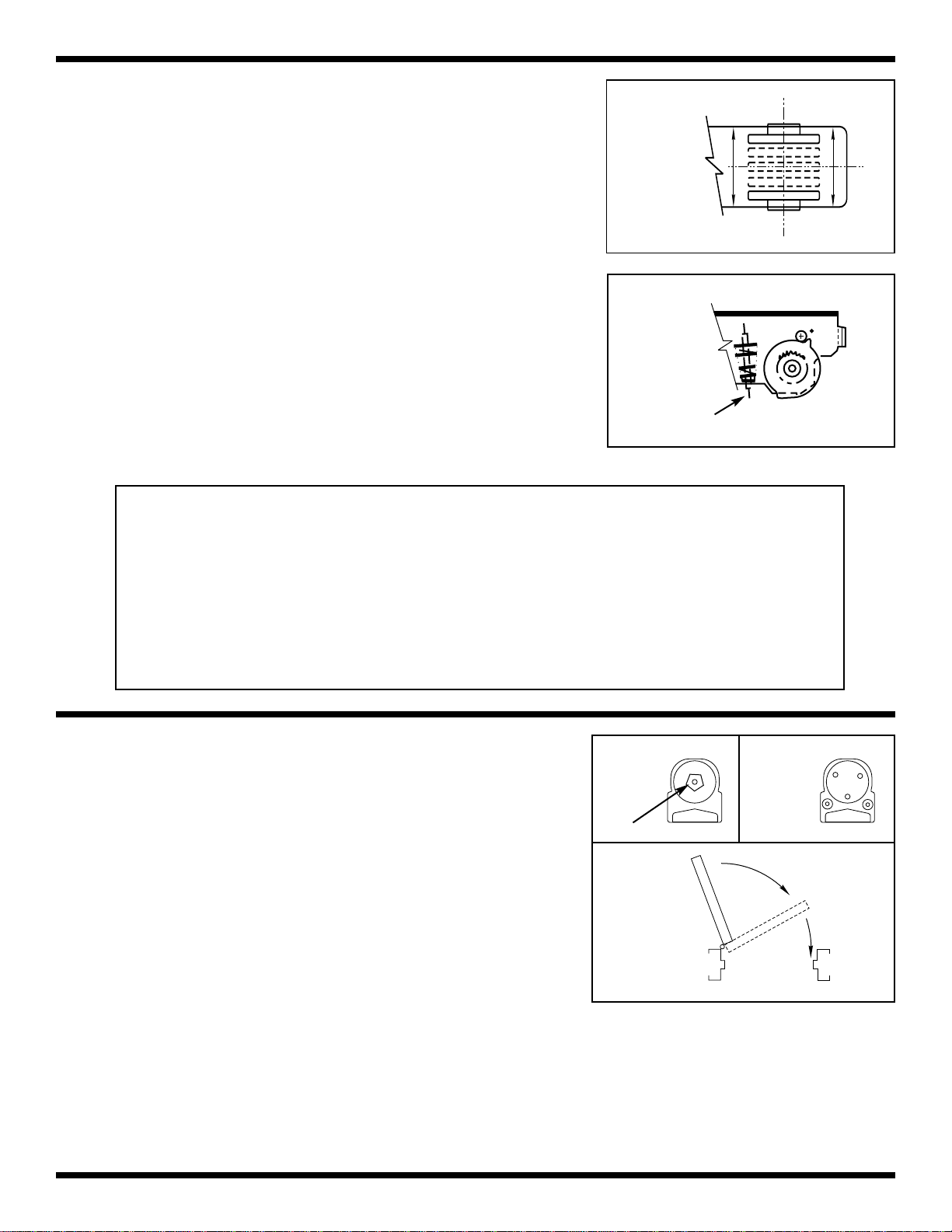

5. Closer Adjustments

A. Manually pull door out of Hold Open.

B. If closing force is too weak, turn adjusting nut on end of

closer (Fig 5a) clockwise.

C. Put door in Hold Open position.

D. If door does not stay in Hold Open, re-adjust closing

force until door latches but the force of the closer

does NOT pull door out of Hold Open.

E. Adjust closing speed. (Fig 5b)

F. Adjust latch speed. (This speed should be slightly

faster than closing speed.)

G. Attach covers to closer and holder with screws provided.

Page 4

ISFM0600