Rizzoli M Series Quick start guide

M - MZ - ML RANGE

Operational Manual for USA/Canada

2

3

The use of economic and ecologic combustibles, the sweet warm of natural fire, the sweet fragrance of the

wood of our forests are the qualities that make indispensable wood fired cookers in every house.

Your choice fell upon a Rizzoli cooker, result of a tradition started in 1912 when Carlo Rizzoli began the

production of wood fired cookers with the typical style of the valley in the dolomites. Year after year Rizzoli

continued to refine its cookers using even more advanced technologies, but without losing contact with the

elegance, the beauty and the functionality of the original product.

1. INSTRUCTIONS

1.1 GENERAL INSTRUCTIONS

For the perfect working of Rizzoli cookers it is necessary the correct placing and connection to the chimney

and to the heating system if it is necessary. The installation normally ends when you light the cooker. It is

necessary to predispose a duly made chimney and well suited to the model you chose. Before the connection

of the cooker it is necessary to contact a local chimney sweeper. The installation usually ends with the lighting

of the cooker and the verify of the correct working.

It is necessary to use well dried and good quality wood: it is also necessary to sweep the chimney and the

cooker regularly.

We recommend to read carefully the instructions in this booklet before starting to use the cooker.

Keep this booklet because it could be useful in case of necessity. Talking about the working and the

installation of Rizzoli cookers, all the European/USA/Canadian laws, national and local laws and rules must

be respected.

1.2 SAFETY INSTRUCTIONS

• Respect all the safety distances during the installation of the device.

• The grids and the ventilation holes of the device must not be obstructed during the installation or the use

of the device.

• Extracting fans, if working in the same room where the device is installed, might cause problems when a

correct ventilation is not guaranteed.

• The installation must guarantee the possibility of access to clean the device, the flue outlet, the chimney

hood and for the maintenance of the hydraulic components.

• When using the cooker, some parts of the device may be very hot, keep attention not to lean and not to

touch by hand hot parts (frame, plate and doors).

• When you cook and generally when you use the cooker you must not wear flammable dresses.

• Keep more attention in presence of children.

• Do not place on the device flammable or explosive materials, in particular curtains or do not place near

flammable chemicals and aerosol cans.

• The fire door must always be closed except for lighting operations, fire feeding operations and during the

maintenance operations.

• Do not open the fire door when the cooker is working and in presence of flame.

• The loading of an excessive amount of wood may overheat the device and generate damages to things or

persons.

• Check regularly the gaskets, the carbon and ash residuals inside the cooker, the in the fume circuit and in

the chimney connection.

• Check regularly the fume-circuit and, the chimney connection and the chimney itself. At least every six

months of normal use contact an experienced technician for checking and cleaning the device.

• The plate must be cleaned regularly according to necessities after every use and make regularly the specific

maintenance.

• Before you go away for a long time, be sure that the fire is terminated.

4

• The first lightings of the cooker and the first seasonal lightings must be done with temperate fire in order

to prevent possible breakings of the internal parts.

• After a long period in which you do not use the cooker, check carefully that obstructions are not present

and that the cooker works regularly.

• Use only original or authorized spare parts.

• Do not make any unauthorized modification.

1.3 RECOMMENDED COMBUSTIBLES

Wood fired cookers are built to use wood for burning. We recommend to use good quality wood, dry,

seasoned and split.

Using good quality wood is warranty of good heating power and avoid the forming of carbon residuals and

soot. To avoid dissipation of energy and eventual deforming and damaging processes you must not use

excessive combustible (see paragraph 6.1).

Burning an excessive amount of wood can cause the sudden ignition of flammable gases, with the risk of

causing damage to things and people.

WARNING!

Painted part of the cooker could change colour if the temperatures in the

combustion chamber are too high. The causes could

be the excessive wood loading or the

use of not correct combustibles. This damage is not covered by warranty.

1.4 OTHER COMBUSTIBLES

The use of pre-compressed trunks and coal is not allowed, because the strong heating produced may damage

the internal refractors, the wood-carrying grill, the oven and in general all the parts directly exposed to fire.

Other combustibles and refuses, for example plastic, enamelled or treated wood or carton must not be

burned. Using this materials cause serious damage not only to your health and environment but also to wood

fired cooker and chimney. The cooker must not be used as incinerator. It is recommended to use only the

suggested combustibles and not liquid fuel.

1.5 PARTS OF COOKERS

Picture 1

1

Riser

7

Starting air regulation

13

Flame keeper

2

Frame

8

Plinth

14

Primary and secondary air

3

Side

9

Woodbox

regulation

4

Starting lever

10

Oven door

15

Plate

5

Fire door

11

Oven door glass

16

Disc or circles

6

Door opening lever

12

Oven thermometer

5

Picture 2

1

Riser

7

Starting air regulation

13

Flame keeper

2

Frame

8

Plinth

14

Primary and secondary air

3

Side

9

Woodbox

regulation

4

Starting lever

10

Oven door

15

Plate

5

Fire door

11

Oven door glass

16

Disc or circles

6

Door opening lever

12

Oven thermometer

1.6 ACCESSORIES

Together with the wood fired cookers Rizzoli you will find some accessories that simplify the installation, the

maintenance and the daily use of the device.

• Ash drawer

• Glove

• Poker

• Scraper

• Oil for the care of the plate

• Cleaning oil for the plate

•

Abrasive sponge

• Sponge for fire door cleaning

• Devices for the connection of the exhaust

-pipe

• Grill for the oven

• Baking

-pan

• Instruction booklet for us

e and maintenance

• Green booklet and warranty certificate

• Quality certificate of the refracto

ry bricks

6

2. INSTALLATION

2.1 GENERAL NOTES

Wood fired cookers are easy to install; anyway you must take some cares to avoid damages due to

unskillfulness. Before the installation, we recommend to verify the necessary space, the safety distances, the

correct predisposition of the chimney and the possibility to make the necessary connections.

Do not drag the cooker, move it keeping it lifted from the floor. The device must not be moved making effort

on the handrail or on the handles.

2.2 SAFETY DISTANCES

Be sure that the cookers that have to be framed has the minimum safety distances to flammable or high

temperature sensible materials, see table 2.2 (T). Rizzoli also produces spacer to reduce distances. If the

cooker is framed between not sensible to heating materials, it is necessary anyway to keep a minimum

distance of 0.08” - 0.12”(2 - 3 mm) to allow the dilatation of the materials when the temperature changes.

The device must be placed on a floor with enough load capacity. If the existing building does not satisfy this

condition, you must adopt different solutions (for example you can use a plate to distribute the load). In

case of floor made with flammable material, it is necessary to use a fireproof protection for the floor in

front of the fire door. The cover of the floor must extend for 18”(46 cm) minimum in the front part and 8”

(20.32 cm) minimum over the fire door on the sides. We suggest not to install furniture on the top of the

stove. Eventually, the resistance of the furniture to heat must be guaranteed, in this case you must respect

a minimum distance of 36”(91,44 cm) from the plate. In case you want to use an aspiring hood, it is

absolutely necessary that it is resistant to high temperatures. Rizzoli is specialized in the production of

aspiring hoods to be used together with the wood fired cookers. During the installation, you must be sure

not to obstruct the ventilation holes on the top: this to prevent the decadence of the isolating properties of

the device and, in general, of its correct working.

Picture 3 - Minimum safety distances when using suited spacers (wall and sides protector or non combustible materials) for the

installation into furniture.

7

2.3 CHIMNEY

Chimney has a main importance for a correct working. Wood fired cookers are built to insure the maximum

efficiency, anyway the performances of the cooker are deeply influenced by the chimney. If the chimney has

defects or does not match the building laws, it is not insured the correct working of the device. To build the

chimney you must use suitable materials, made to work with high temperatures and according to fireproof

laws: it is not important the kind of material, on condition that it is right and that the chimney is isolated.

Contact a specialized technician or a local chimney sweeper for any problem dealing with the chimney,

chimney hood and connection to cooker.

Picture 4 - Components of the chimney. A= cooker, B= conjunction, C= flue, D= chimney, E= reflow zone

2.4 DIMENSIONS AND CORRECT FORMS OF CHIMNEY

Picture 5 - Samples of correct and incorrect chimney connection.

8

Chimney must be dimensioned in a correct way according to the type of cooker it is connected with, minding

the environmental and general conditions of the place in which it is placed. The section of the chimney must

permit the flow of the fumes produced by the cooker without difficulties, but it must not be too big otherwise

the chimney will experience problems in heating itself and this may generate problems like weak draught

and condensation. In table 1 it is indicated the recommended diameter for the flue according to the model

of device and to the height of the chimney (H). The height of the chimney must be enough to insure the

draught necessary to the chosen model. Bigger is the height of the chimney, bigger is the draught; if the

chimney is lower than 4 metres, the correct working of the cooker is not insured. The chimney must not have

tortuous parts, horizontal parts or counterslope parts; the number of bends must be reduced to minimum.

In picture 5 you can see some examples of good and bad chimney connection.

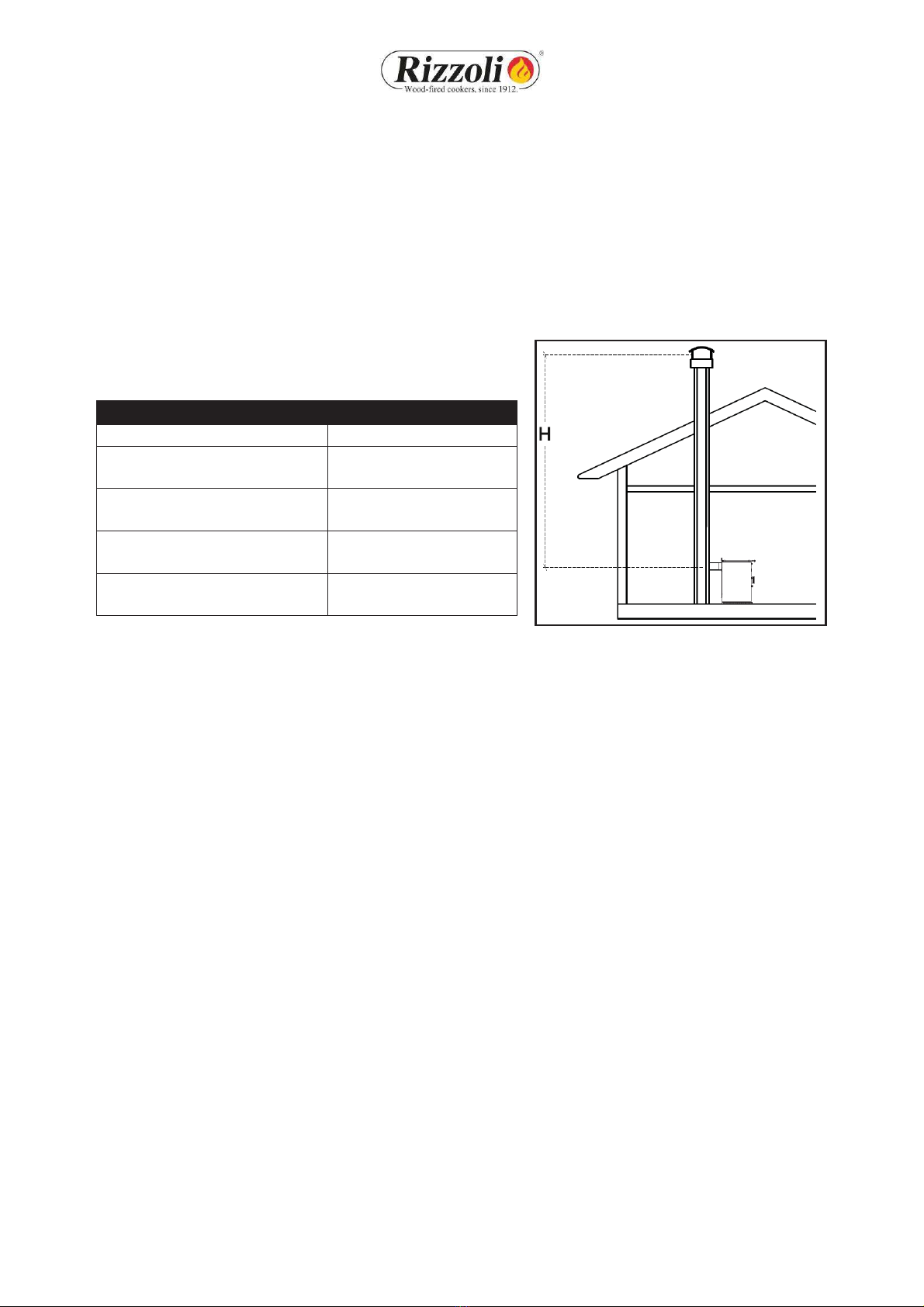

Table 1 - Indications for the dimension of the chimney according to its

height.

Model

M - MZ - ML RANGE

ø entrance

5,51” (140 mm)

ø flue

H < 13,2’(4 m )

Draught not guaranteed

ø flue

13,2’(4 m) < H < 19,7’(6 m)

7,09” (180 mm)

ø flue

H > 19,7’(6 m)

6,3” (160 mm)

Necessary

chimney draft

12 Pa

(0.0482 wc)

Picture 6 - H dimension for the sizing of the flue.

2.5 CHIMNEY FLUE

The flue must be well isolated and circular if possible. The flue must not have defects, narrowings or losses.

All the inspection doors must be closed and well sealed. The connection of other devices to the same chimney

is not allowed.

2.6 CHIMNEY POT

The chimney pot must have an exit section doubled than the one of the chimney, in order to make easier the

exit of the smoke. The chimney pot must be enough tall to lean out over the reflow zone generated by the

roof: if you are not sure about this contact experienced technicians. If you are in a windy place, it might be

necessary to install windproof devices.

The chimney should extend at least 3 feet above the roof surface it penetrates and 2 feet higher than any

roofline or other obstacle within a horizontal distance of 10 feet.

2.7 STOVE PIPES CONNECTION

The connection of the cooker to the flue must be as short as possible and must not have horizontal or not

much inclined parts. The counterslope parts are forbidden and must be absolutely avoided. Near the

conjunction, flammable materials must not be present. The conjunction must not go inside the flue. To

increase the safety of the conjunction, we suggest to install a washer on the wall being sure that the

connection between the washer and the chimney is walled and well sealed. Also all the connection must be

fixed and sealed. Connections through wall, ceiling and floor ( see Part 2 Installation instruction).

9

2.8 FLUE OUTLET POSITION

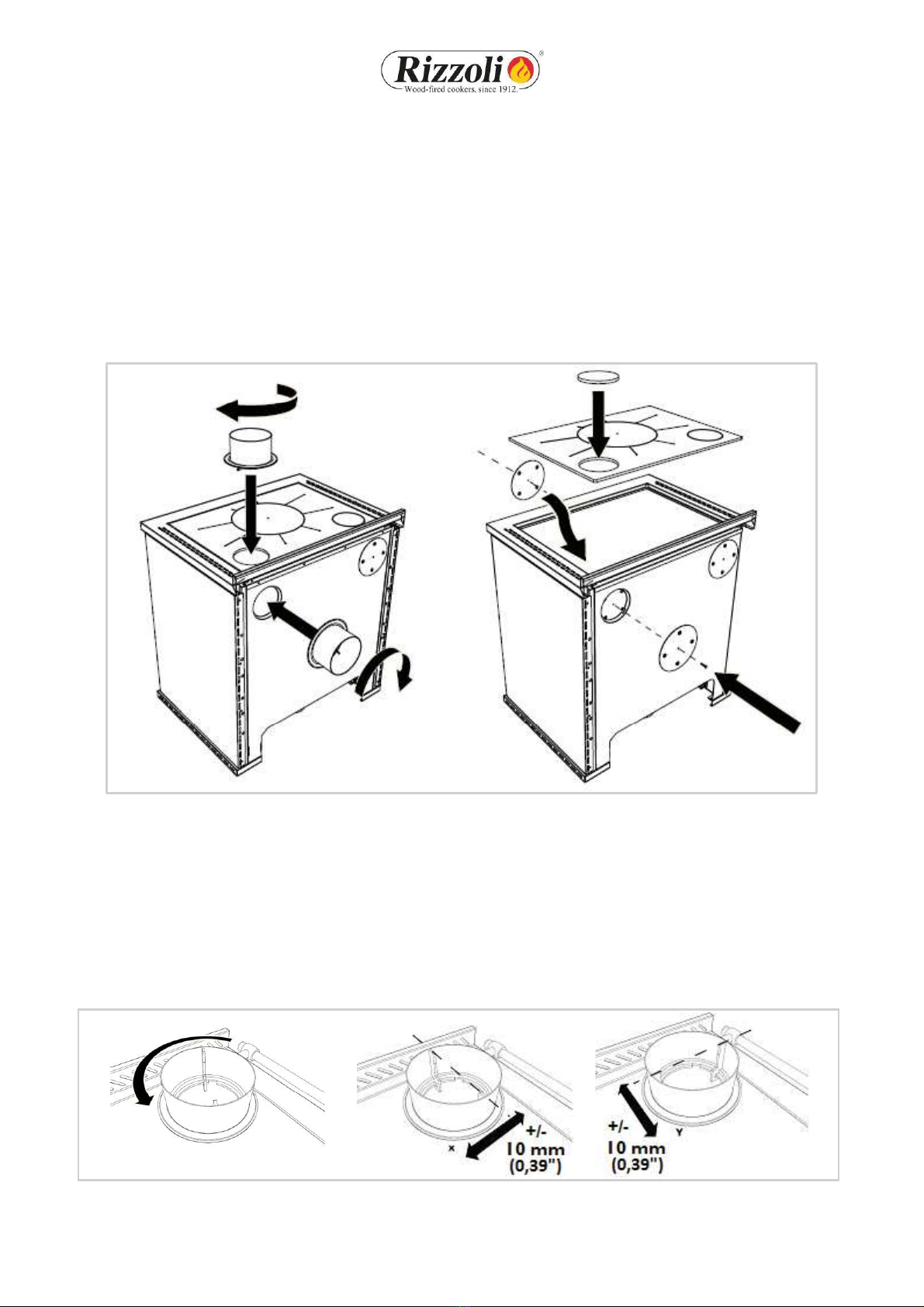

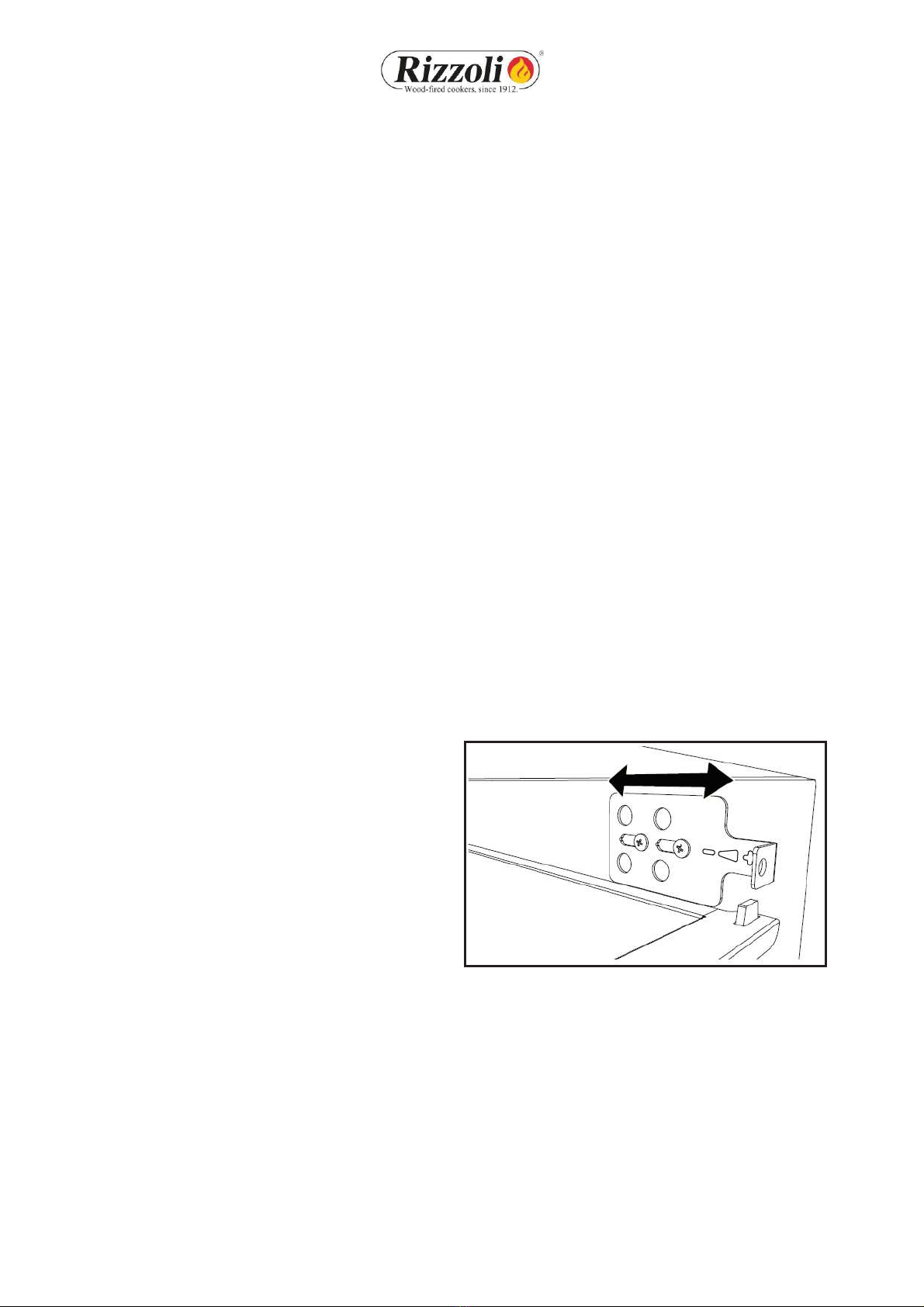

M-MZ-ML Range models are endowed with the predisposition of the flue outlet in the upper and rear parts,

right or left. The choice of the side must be done when ordering the cooker. After the delivery, it is still

possible to change the position from right to left and from left to right but it is necessary to make some

variations inside the cooker in addition to the replacement of the flue connector. The variation must be done

by experienced technicians.

The use of the flue outlet upper or rear is free and can be chosen by the installer. Before connecting the

cooker, it is necessary to chose the correct outlet and to verify that the other outlets are closed, eventually

using the caps given as endowment of the cooker.

Picture 7 - Multiflue cooker, predisposition of the correct flue outlet.

2.9 CORRECT CONNECTION TO THE CHIMNEY

If the conduct of the chimney starts from a lower floor than the connection point of the device, it may be

necessary to close the conduct under the connection pipe with fireproof materials. If you have the chimney

behind or up, you have to use the connector with bayonet coupling. This must be inserted and turned so that

it can remain blocked. This connector has a tolerance of about 1 cm (0,39”) to make the installation easier.

The tolerance is available according to a single direction which depends on the orientation of the connector

(see picture 8).

Picture 8 - Tolerance for flue outlet on the top and back. The tolerance depends on the orientation of the connector.

10

The connection with the chimney must be always well fixed and sealed, it must not have narrowing and must

not decrease the usable section of the chimney (see picture 9). If near the cooker there is flammable material

or high temperatures sensible, the connection must be isolated and the safety distances must be strictly

observed.

Picture 9 - Examples of correct and incorrect connection of the chimney.

2.10 AIR INTAKE

The standard installation of the wood fired cooker considers that the comburent air is taken from the room

where the device is installed through the air intake of the device located in the plinth. In this case, in the

room must be always ensured the recycle of fresh air, in particular if the room is small and window and door

frames are hermetic. The correct flow of air in the room must be ensured also in presence of other

combustion based devices, aspiring hoods, chimneys and vent-holes. The air intake in the room must have a

minimum surface of 80 cm2. On demand, Rizzoli can give specific valves which can allow the automatic

opening of the air intake only when it is necessary for the correct working of the device in order to warrant

a maximum depression of 4 Pa in the place of installation. The wood fired cookers can also be connected so

that the comburent air comes directly from outside. In this way, for the device it is not necessary another air

intake in the room of installation. To make this it is necessary to prepare a conduct connected directly with

the external part of the house and make a direct connection with the air intake of the device. The air intake

of the cooker is located inside the woodbox in correspondence of the combustion chamber. For the

connection, we suggest to use a flexible pipe.

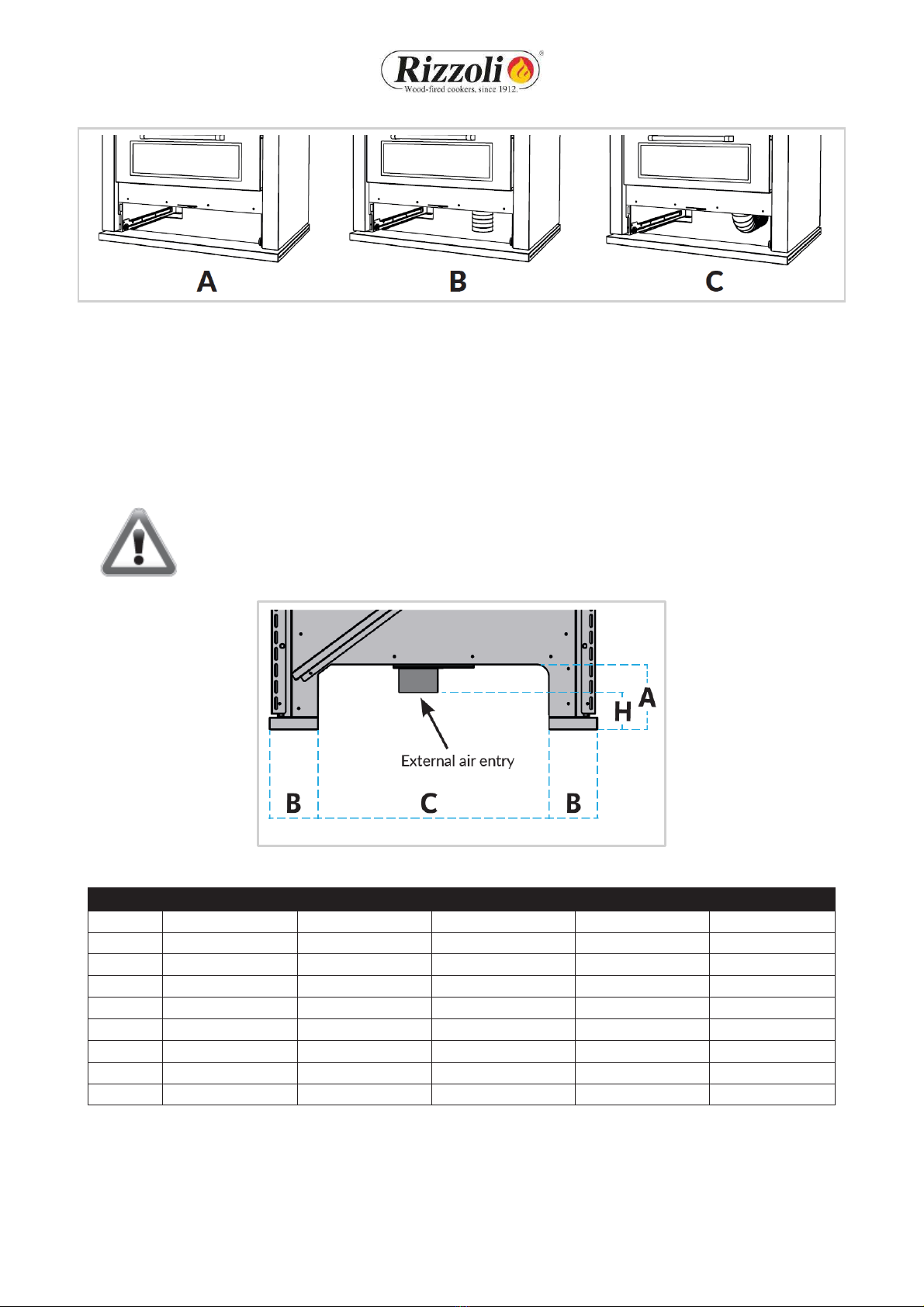

Picture 10 - Installation with air intake in the room of installation and installation with air intake directly connected to the wood

fired cooker.

11

Picture 11 - Possible connections of the air intake of the cooker.

A= External air intake not connected, B= External air intake on the floor, C=External air intake on the wall.

To make the connection easier we suggest to make the external air intake on the floor in correspondence

with the internal part of the plinth, or on the wall through the rear part of the device (see table 2 and picture

12).

For ML Range wood fired cookers it is recommended to connect the external air intake to the floor but on

demand it is possible to have an optional item to make the connection to the wall.

Are also possible other solutions for the connection but they must be decided together with Rizzoli.

WARNING! Aspiring hoods or extracting air fans in the room may generate problems to

the device if there is not a suited air intake or in case of air intake sub-dimensioned.

Picture 12 - Rear sight of the plinth of the wood fired cooker and specifies for the connection with the air intake.

Dimensions

Models

A

B

C

H

ø

M 60

6,22” (158 mm)

4,64” (118 mm)

14,33”(364 mm)

4,72” (120 mm)

3,74” (95 mm)

M 70

6,22” (158 mm)

4,64” (118 mm)

18,27”(464 mm)

4,72” (120 mm)

3,74” (95 mm)

M 80

6,22” (158 mm)

4,64” (118 mm)

22,20”(564 mm)

4,72” (120 mm)

3,74” (95 mm)

MZ 60

5,51”(140 mm)

3,66”(93 mm)

16,30”(414 mm)

4,72” (120 mm)

3,74” (95 mm)

MZ 70

5,51”(140 mm)

3,66”(93 mm)

20,24” (514 mm)

4,72” (120 mm)

3,74” (95 mm)

MZ 80

5,51”(140 mm)

3,66”(93 mm)

24,17”(614 mm)

1,02” (26 mm)

3,74” (95 mm)

ML 60

--

--

--

1,02” (26 mm)

3,74” (95 mm)

ML 80

--

--

--

1,02” (26 mm)

3,74” (95 mm)

Table 2 - Dimensions for the connection of the external air intake.

12

WARNING! For the correct working of the device verify that the passage of comburent air

is not obstructed or, in case of connection with external air intake, that the air aspiration

grill is not obstructed.

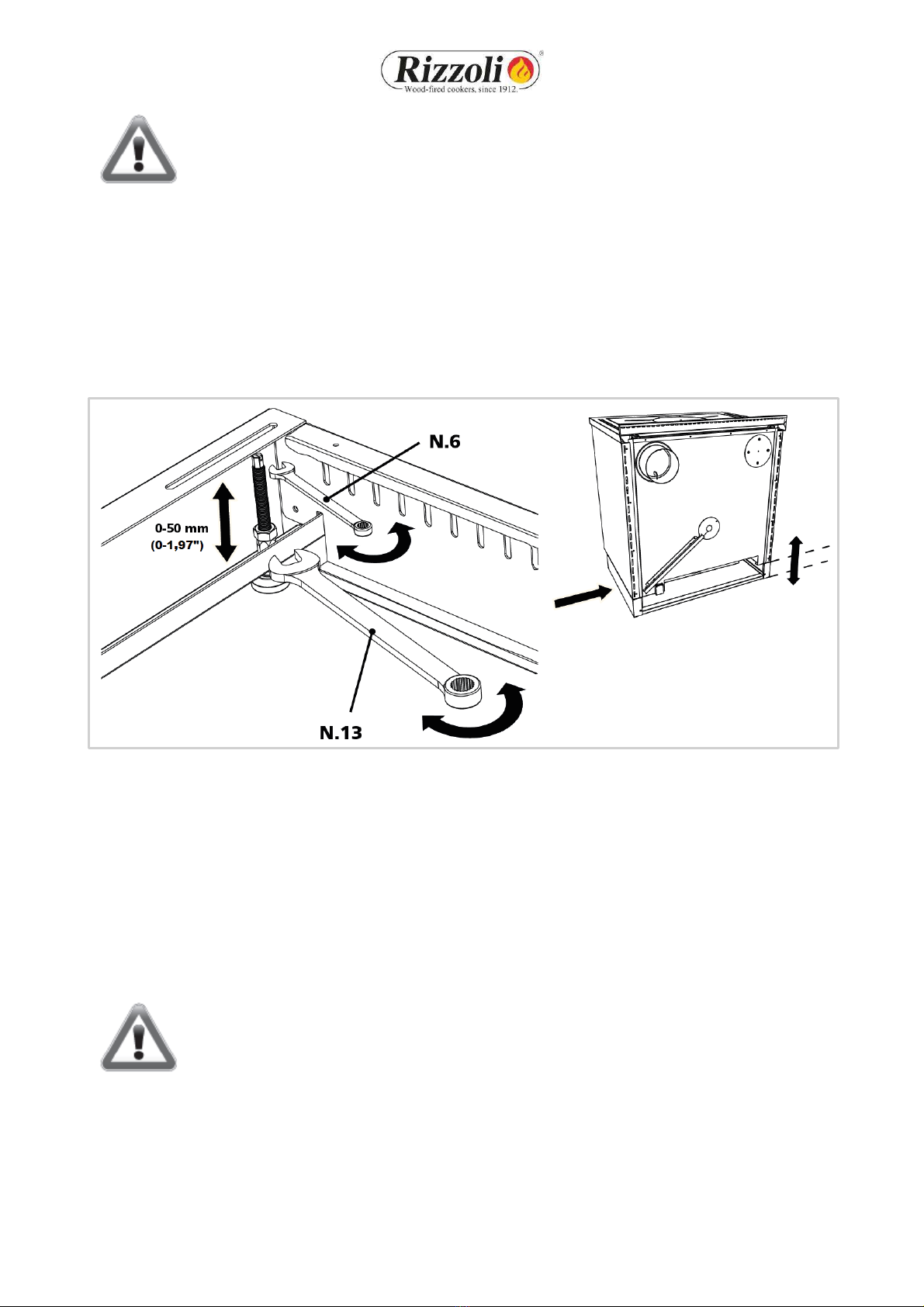

2.11 PLINTH REGULATION (MZ)

The plinth of MZ Range cookers can be regulated in order to match the space in which the cooker is inserted.

It is possible to adjust the level of the cooker by operating on the levelling pins that can be regulated in height.

To do this, it is necessary to remove the woodbox and regulate singularly each pin placed in the plinth near

the corners, so that the adjustment of the cooker is correct. For the regulation of the pins, use an hex key

n.6: once you have reached the desired height, fix the locknut with a n.13 key (see picture 13). The pins have

an excursion of 50 mm (1,97”).

Picture 13 - Regulation of the height of the cooker with hex key through the levelling pins

2.12 TELESCOPIC PLINTH REGULATION (MZ)

The wood fired cookers MZ Range have a special woodbox integrated with the plinth. In this case it is anyway

possible the regulation of the height of the plinth but not the regulation of the recess. The regulation of the

height of the plinth can be made in the same way as described in paragraph 2.11. After the regulation of the

pins, it is possible to regulate the sliding part of the plinth to cover the empty part: to do this, remove the 2

screws as picture 14 A and 14 B. Then, it is necessary to regulate also the height of the plinth integrated in

the woodbox. To do this, release the two screws on the woodbox, lower slowly the plinth then screw again

when the chosen height is reached (as in pictures 14 C and 14 D).

WARNING! For a correct installation it is necessary to keep about 10 mm (0,39”) between

the floor and the plinth of the woodbox.

13

Picture 14 - Regulation of the telescopic plinth.

2.13 DOOR OPENING VARIATION

M-MZ-ML Range cookers are predisposed with the rightwards fire door opening, if not indicated leftwards

at the order. It is possible to change the opening also after the installation. The operation must be done by

experienced people.

Picture 15 - Variation of the door opening direction.

2.14 FIRST LIGHTING

Before starting to use the cooker, remove the packaging materials in the oven and in the wood box, remove

the stickers and remove the plastic film in which is wrapped the plate and remove with a rag the most of the

oil on its surface. We suggest to make a first lighting of the device just to verify the correct installation. The

14

first lighting must be done with moderate fire, using little wood broken in small pieces. In the next lightings

you can progressively increase the load of combustible. During the first lightings some smell due to processing

residuals might happen. This phenomenon is normal, it requires the ventilation of the room and will

disappear quickly.

WARNING! During the first lightings of the cooker it is recommended to keep the oven

door open to allow the expulsion of eventual working residuals, otherwise the cooker

could suffer damages.

2.15 SETTLEMENTS

The refractory mortar used for the internal walling contains always a little moisture that is eliminated after

the first periods of use: so it is normal that the first times you light the cooker a little condensation is being

generated.

All the refractory materials inside the cooker experience a settlement process that may generate small

holes on the bricks, such holes do not preclude anyway the working of the cooker. Other settlements may

involve other parts of the cooker so during the heating and cooling phases you might hear light noises.

These symptoms do not absolutely preclude the use of the cooker and fading out till disappearance with

the constant use of the cooker.

3. USE

3.1 WORKING OF THE COOKER

During the operation, inside the cooker happens a combustive reaction of combustible (the wood inserted

in the combustion chamber) and burning (the oxygen present in the air of the room in which the cooker is

placed).

The wood fired cooker makes an intermittent combustion: after the lighting, the combustion goes on till the

exhaustion of the combustible but it can be maintained lighted by making another load of combustible and

so on.

The maintenance of the combustion in time is guaranteed by the correct working of the chimney, which

allows to evacuate the fumes and in the same time to feed the flame with comburent air. In this way, the

features of the chimney have a big influence on the correct working of the device.

The combustion of wood requests that the air flow inside the combustion chamber happens in different

points to obtain the maximum efficiency. In particular, it is present a primary air feeding that flows in the

lower part of the combustion chamber by the grill, and one or more secondary air feedings that flow in the

upper part of the combustion chamber.

The primary air is the main air and regulates the combustion speed.

The secondary air allows the post-combustion of the fumes, generating further heating, knocking down the

amount of harmful gas and so improving both the rendering and the impact on the environment.

Once started the combustion it cannot be interrupted in a safe way: it must be always faded out naturally

with the exhaustion of all the combustible inserted.

WARNING

!For a correct operati

on verify that the eventual external air intake in the room

and the air aspiration and ventilation grids are not obstructed.

15

3.2 STARTING

To allow an easier lighting of the cooker with cold

chimney, the M-MZ-ML Range wood fired cookers have

two devices useful for starting. The starting key is ruled

by a rod: extracting the rod, the key opens. This creates

a direct connection between the combustion chamber

and the chimney, in order to obtain an improved

draught. The regulation of starting primary air allows the

direct entrance of air from the room in which the cooker

is installed to the combustion chamber. When starting,

it is suggested to open both the devices that later shall

be closed when the fire will be started for the normal

working of the cooker. The cooker is designed to be used

with the starting regulations closed, using they in

different ways does not allow to the cooker to work at

its maximum and may cause damages.

To light the fire, you can use as combustible well dried

wood, broken thin, together with the products available

in commerce. The combustion might be difficult as far as

the chimney is cold. The necessary time depends on the

chimney and the weather conditions.

Picture 16 - Regulation of starting primary air.

Picture 17 - Starting key. With lever outside, the key is open and the starting is easier; with lever inside the key

is closed for the normal working.

WARNING!

All handles and regulators might get hot! Please use included glove!

WARNI

NG! It is

important that the wood starts to burn quickly. The lighting of a big amount

of wood in starting phase can cause an excessive production of smoke and a quick gas

emission with consequent damage to the stove.

3.3 AIR REGULATION

The air flow is ruled by an apposite valve ruled by a lever placed below the oven door. The valve is closed in

the left position, is open in the right position. The position of the valve rules the comburent air inflow: more

it is open, faster will be the combustion and bigger will be the power of the device. When the cooker is not

working the primary air must be closed, in order to limit the undesired air flow that may cause an anticipated

cooling of the device and the room. This operation is particularly important when the external air intake of

the cooker is directly connected. Generally, for the good working of the device, we suggest to follow the

indication for the regulation of air reported in table 3.

16

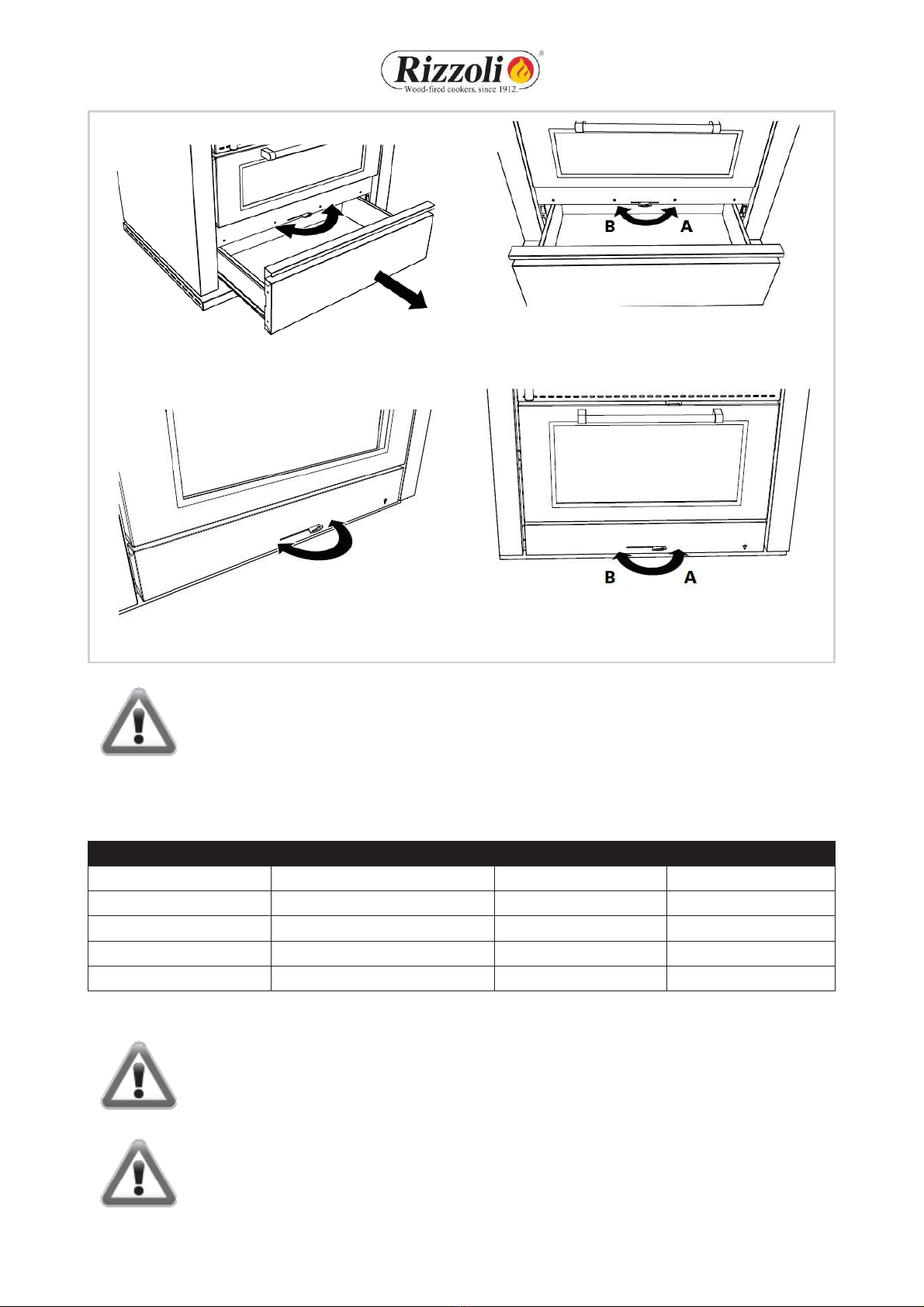

Picture 18 - Regulation of the air intake lever (M-

MZ Range).

Picture 19 - The valve is open in correspondence of the

position marked by letter “A”, while

is closed in the position

marked with letter “B” (M-MZ Range).

Picture 20 - Regulation of the air intake lever (ML Range).

Picture 21 - The valve is open in correspondence of the

position marked by letter “A”, while

is closed in the position

marked with letter “B” (ML Range).

WARNING!

All handles and regulators might get hot! Please use included glove!

The open position is indicated when the device is working. It allows the entrance of the combustive air

necessary to feed the flame. The cooker cannot work with the lever in closed position.

Condition

Air regulation

Starting air

Starting key

Starting

Open

Open

Open

Fast cooking

Open

Closed

Closed

Slow cooking

Half open

Closed

Closed

Fast heating

Open

Closed

Closed

Slow heating

Open at minimum

Closed

Closed

Table 3 - Cooker regulations in the different use conditions.

WARNING

!When

loading wood, consider a gap of few millimetres between wood and

glass, in order to avoid overheating of the glass that could cause breakings.

WARNING!

Do not open the fire door during combustion, as otherwise smoke may escape.

The

cooker is designed to be used with the closed fire door.

17

3.4 PLATE COOKING

The radiant plate is designed to allow a fast and simple cooking. The hotter part is situated in correspondence

with the hotplate, this is the best part for placing a pot which must get warm quickly. The external parts of

the plate are better to keep foods warm. To obtain the maximum cooking speed you have to use broken and

thin wood and make the regulations as described in the previous chapters. The plate must not be overheated

and made red hot because in such way the device may experience damages without having no advantage for

the cooking of foods.

3.5 OVEN COOKING

The internal temperature of the oven depends on the combustion speed and on the amount of combustible

used. In particular, working on the lever of the air intake and so on the speed combustion, you can obtain a

more steady combustion in order to avoid sudden changes in temperature inside the oven. If you want to

heat the oven starting from the device, we suggest to increase the temperature with bright fire and then to

decrease the speed combustion to keep the temperature steady. The cookers are endowed with fire door

with glass and thermometer that makes easier the temperature controlling operations; the temperature

indicated by the thermometer is approximate ad is useful only for the cooking of foods. If you want to brown

the meals, you should keep them in the upper part of the oven: instead, if you want to cook in a steadier way

you should keep the meals in the centre. When you do not use the oven, we suggest to keep the oven’s door

slightly open in order to let the heat go outside the cooker: an overheating can damage the cooker.

For example, to cook the spineless person biscuits in a correct way, it is necessary the pre-heating of the oven

at a temperature indicated on the thermometer of 150°C (302°F), keeping it in temperature by adding more

or less 1 Kg (2,2 lbs)of wood for every charge as the reaching of the coals. Once the temperature becomes

stable, insert the baking-pan with the biscuits in the central position in the oven for 10 minutes, then extract

the baking-pan, rotate it and reinsert it again in the central position for other 5 minutes. In the end, remove

the baking-pan from the oven and leave cool the biscuits.

3.6 STEAM EXCESS VALVE

Cooking meals sometimes may generate a steam

excess inside the oven. For this reason on M-MZ-

ML Range models there is a valve that allow to

eject the steam in excess. The valve is placed inside

the oven on the lateral side towards external and

when necessary it shall be regulated to open the air

intakes. To avoid possible burns, it is

recommended to regulate the valve only before

the lighting of the cooker.

Picture 22 - Steam excess valve.

3.7 HEATING

Wood fired cookers may be used also to heat the ambient in which they are installed. The heating comes

from the plate and from the front of the cooker. So the heating is effective just in the ambient in which the

cooker is inserted and in particular near the cooker itself.

Also for the heating of an ambient you have to start the cooker with bright flame without using too much

woo d as long as a bed of cinders is created: at this point you can put more load of combustible inside the

combustion chamber. For a bigger autonomy of the cooker we suggest to use wood cut in big pieces, hard if

possible (ash-tree, beech, hornbeam and others) and to make the regulations as described for the slow

heating.

18

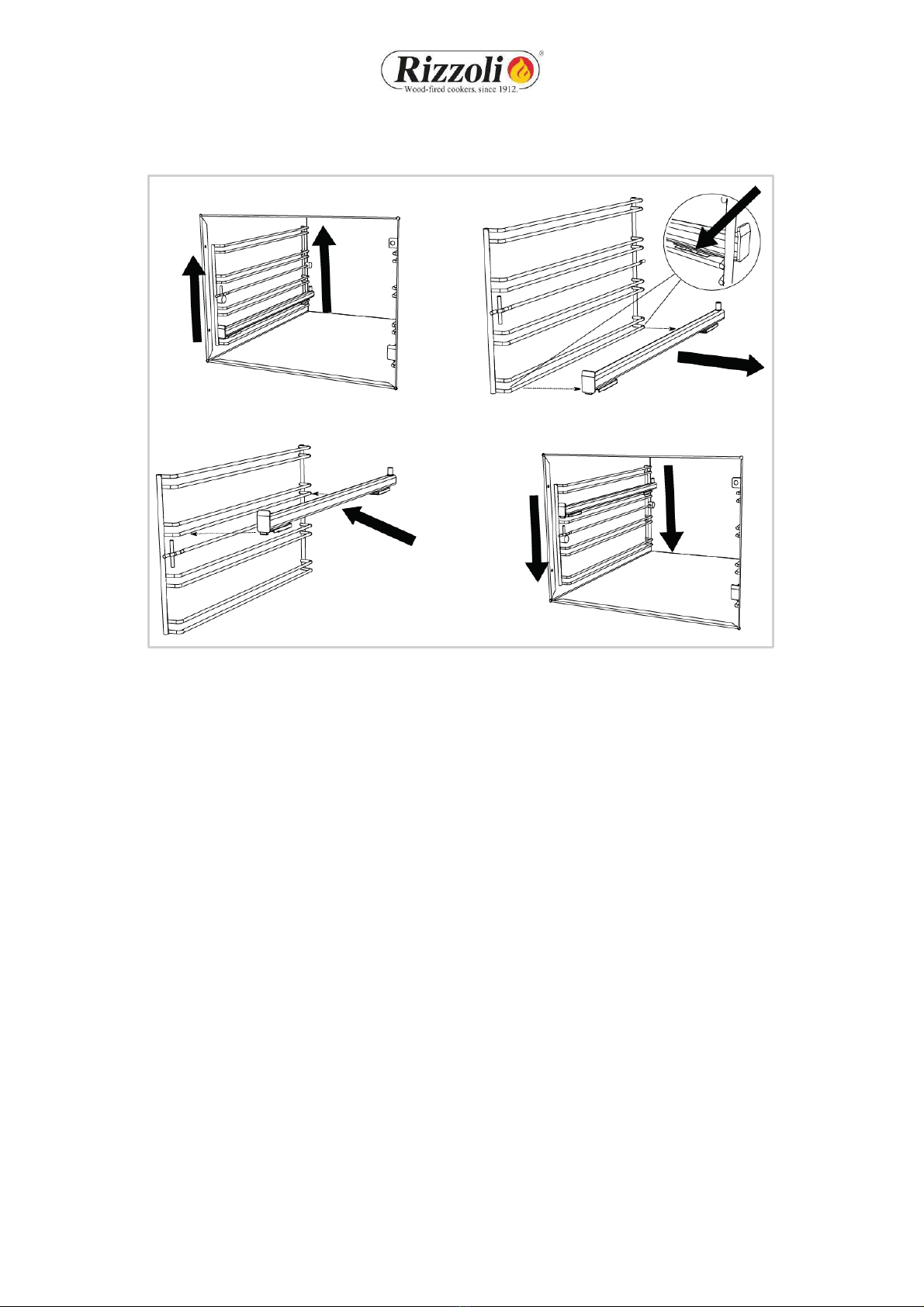

3.8 TELESCOPIC PULLOUT FOR BAKING PAN

Picture 23 - Instructions for the variation of the position of the telescopic pullout.

All the wood fired cookers have a telescopic pullout for endowed baking pan system. In this way, it is possible

to extract the baking pan without the necessity to sustain it, ensuring a better practicality. The telescopic

pullout is placed in a single position inside the oven, in the upper position. Only on ML cookers this can be

modified and moved to the lowest position or in the positions middle superior and superior. The process to

modify the position of the telescopic pullout is indicated in picture 23. Anyway, on all the cookers it is possible

to insert the baking pan without the telescopic pullout.

3.9 WOOD BOX (M - MZ)

The wood box has a slide scroll system that allows an assisted closure. When pushing the box, it will close

automatically.

For cleaning and for other reasons it could be necessary to remove the wood box. To make this you have just

to extract the box as the end of its track, then lift it softly and at the same time extract it again. To set the

box to the initial position, repeat the same operations inverted.

19

3.10 FIRE DOOR PROTECTION (OPTIONAL)

On M-MZ-ML Range cookers it is possible to have

on demand a steel protection which could be

placed on the fire door. This protection is

designed to shield the door when the cooking

operations require the continuous presence of

the user in front of the cooker or in presence of

children. In the other situations the use of the

protection depends on your discretion. The

placing operations must always be done with cold

cooker opening the fire door and placing the

protection on the door by joint.

Picture 24 –Fire door protection.

3.11 PLATE COVER (OPTIONAL)

On every cooker it is possible to use a stainless steel plate cover, made to cover the plate in the periods in

which the cooker is not used. In this way you obtain an uniform desktop. The plate cover must be used with

cold cooker. Before placing it, be sure that is not present humidity, that the plate is clean and that all the

necessary maintenance is done.

20

4. MAINTENANCE

4.1 CLEANING

The device works better if all its parts are without combustion residuals, a clean device will be less exposed

to problems due to wear. Cleaning frequency depends on how much and how the device is used, as well as

combustible quality.

WARNING! All these operations must be done with cold cooker.

4.2 CLEANING THE VISIBLE PARTS

Stainless steel parts have to be cleaned cold with neutral detersives or with a specific solution for stainless

steel in case of hard to remove dirt. Do not use at all abrasive sponges that may scratch the surface. Dry with

a soft rag, following the glazing wise.

In particular situations, after the installation or with the cooking of meals, an oxidised superficial stratus may

be generated, in particular on the inox stainless steel frame. Also in these situations, an accurate cleaning

will restore the state of the product as it was new. On request Rizzoli gives specific products to clean stainless

steel. For enamelled or painted parts, do not use abrasive or aggressive solution and in case of stains pour

some oil and wait while it absorbs the halo, then clean with a soft rag. It is also recommended to avoid the

use of solvents or denatured alcohol on painted parts.

4.3 GRILL CLEANING

Every time you use the cooker you have to clean the wood carrying grill before, at least you have to clean the

more rough deposits: the holes of the grill should not be obstructed. To make this you can use the poker

given together with the cooker. If the grill is not well cleaned, the flame could not be well feed and so you

could experience an irregular combustion. If the grill is being removed, it must be placed in its housing with

the flat part turned upwards.

4.4 ASH BOX

Every time you use the device you have to check the ash box located under the combustion chamber. When

the box is full, you have to empty it. If you do not empty it, the ash accumulates itself and makes the cleaning

more difficult. In case of excessive cinders the flame could not be well fed and you could experience an

irregular combustion.

4.5 OVEN CLEANING

The oven must be cleaned with apposite products available in commerce, to make this operation easier you

can remove the oven door. To make this you have to open the oven door and raise the tongues located on

the door’s hinges. Now, you can unhook the door from the cooker closing it softly and lifting the lower part

of the door. To hook again the door to the cooker, make the same operations reversed. Also the grids on the

sides could be removed to make the cleaning more simple.

Other manuals for M Series

1

This manual suits for next models

10

Table of contents

Other Rizzoli Cooker manuals

Popular Cooker manuals by other brands

Brandt

Brandt KV368WE1 operating instructions

Falcon

Falcon 90 Induction U109988 - 02 User guide & installation & service instructions

Tricity Bendix

Tricity Bendix U30352 SE558 user manual

Smeg

Smeg FS67MFX instruction manual

Indesit

Indesit KD3E1/G Instructions for installation and use

Bosch

Bosch HKN31 0 Series user manual