62

The use of economic and ecologic combus-

tibles, the sweet warm of natural fire, the

sweet fragrance of the wood of our forests

are the qualities that make indispensable

wood fired cookers in every house.

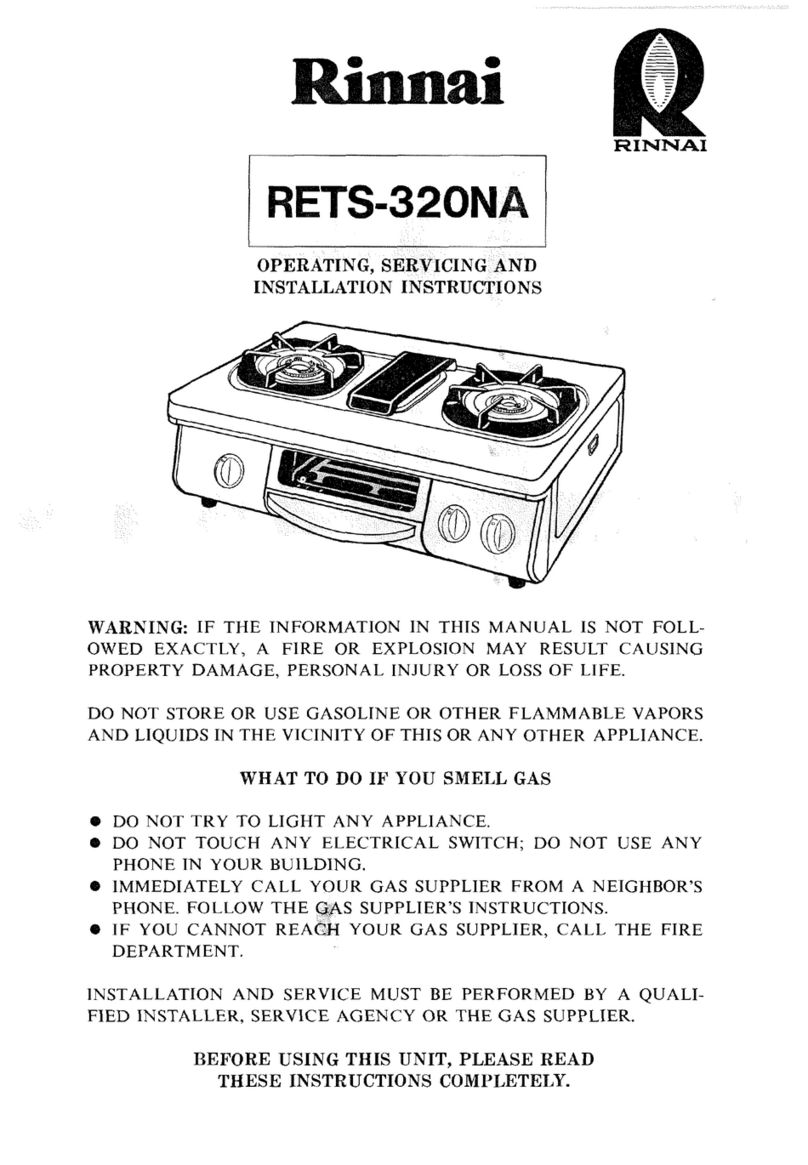

Your choice fell upon a Rizzoli cooker, result

of a tradition started in 1912 when Carlo

Rizzoli began the production of wood fired

cookers with the typical style of the valley in

the dolomites. Year after year Rizzoli con-

tinued to refine its cookers using even more

advanced technologies, but without losing

contact with the elegance, the beauty and

the functionality of the original product.

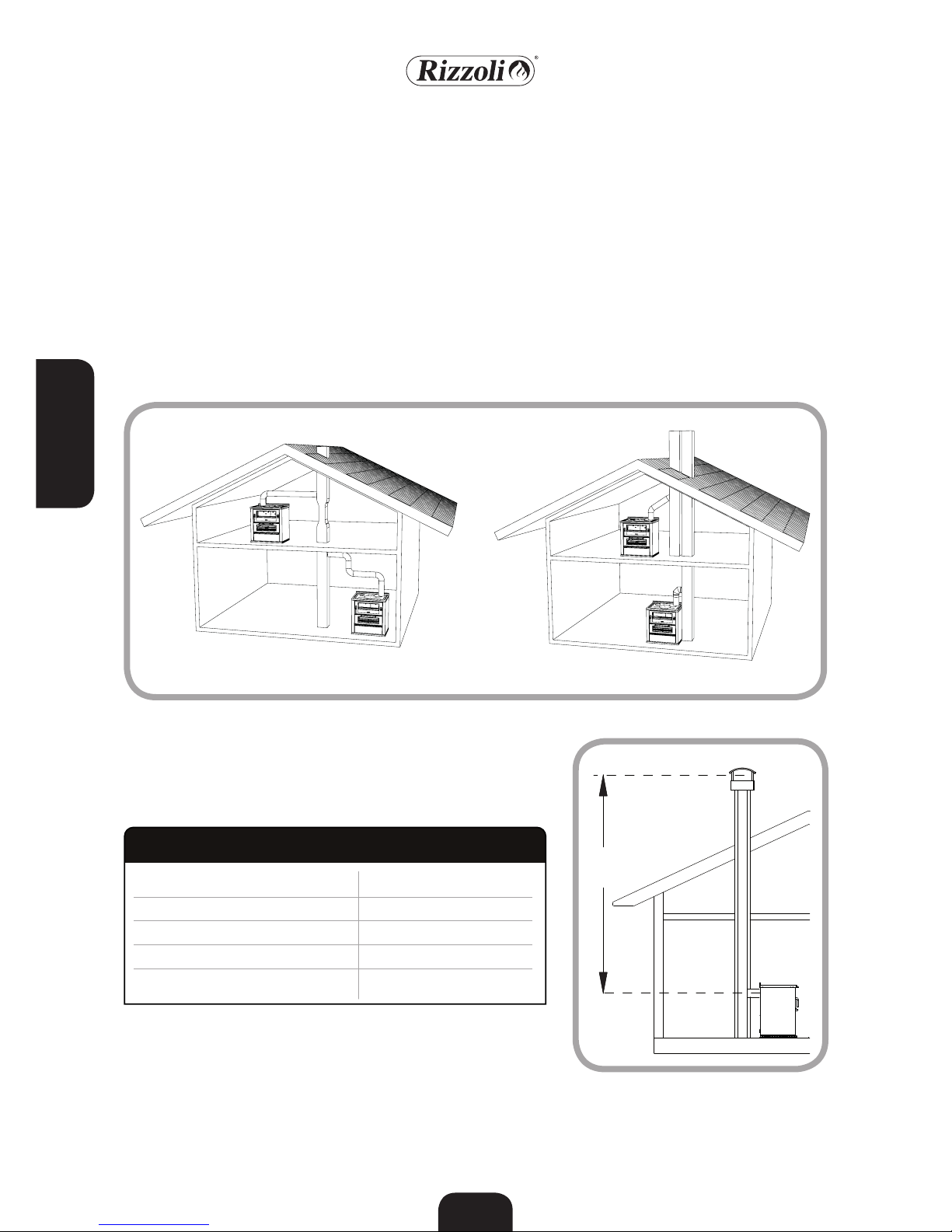

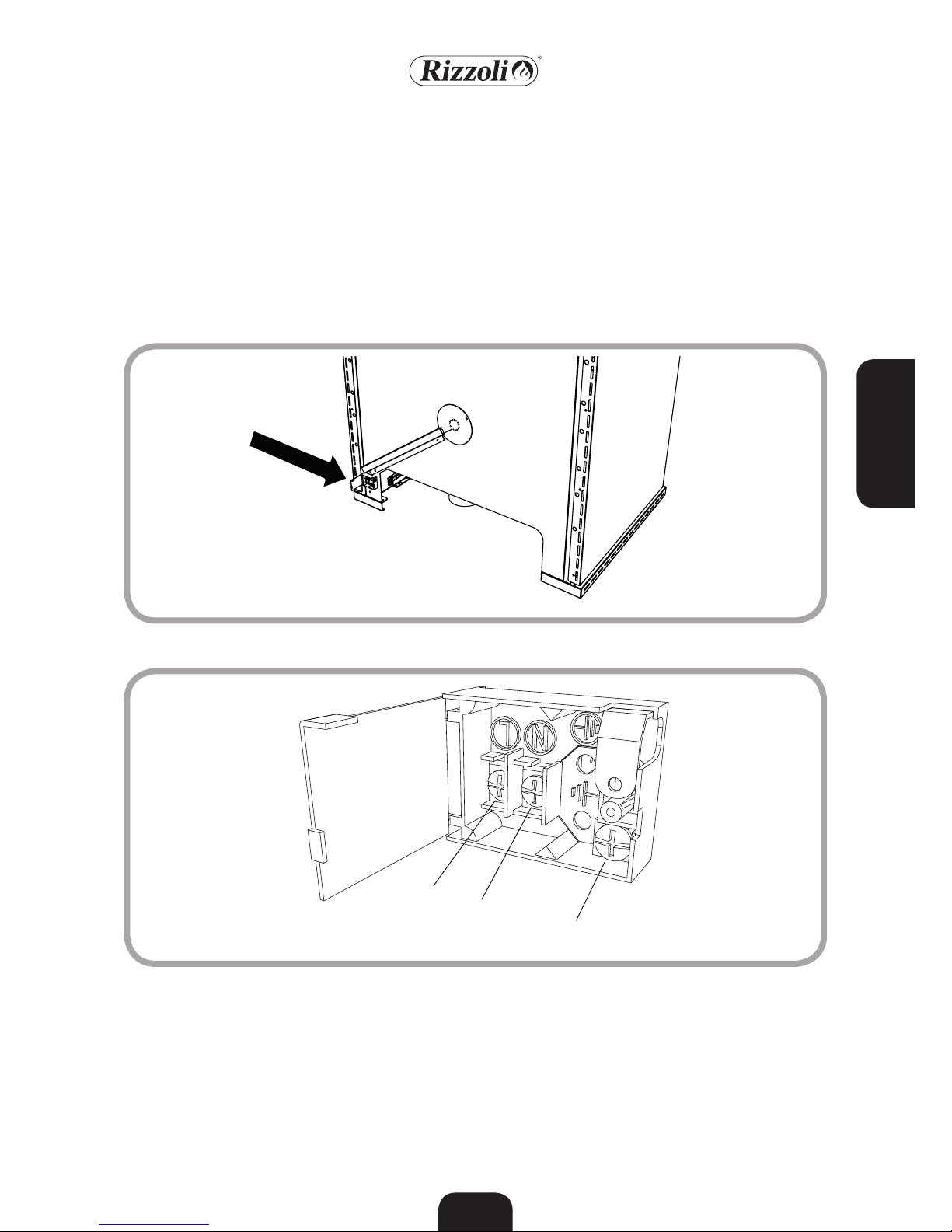

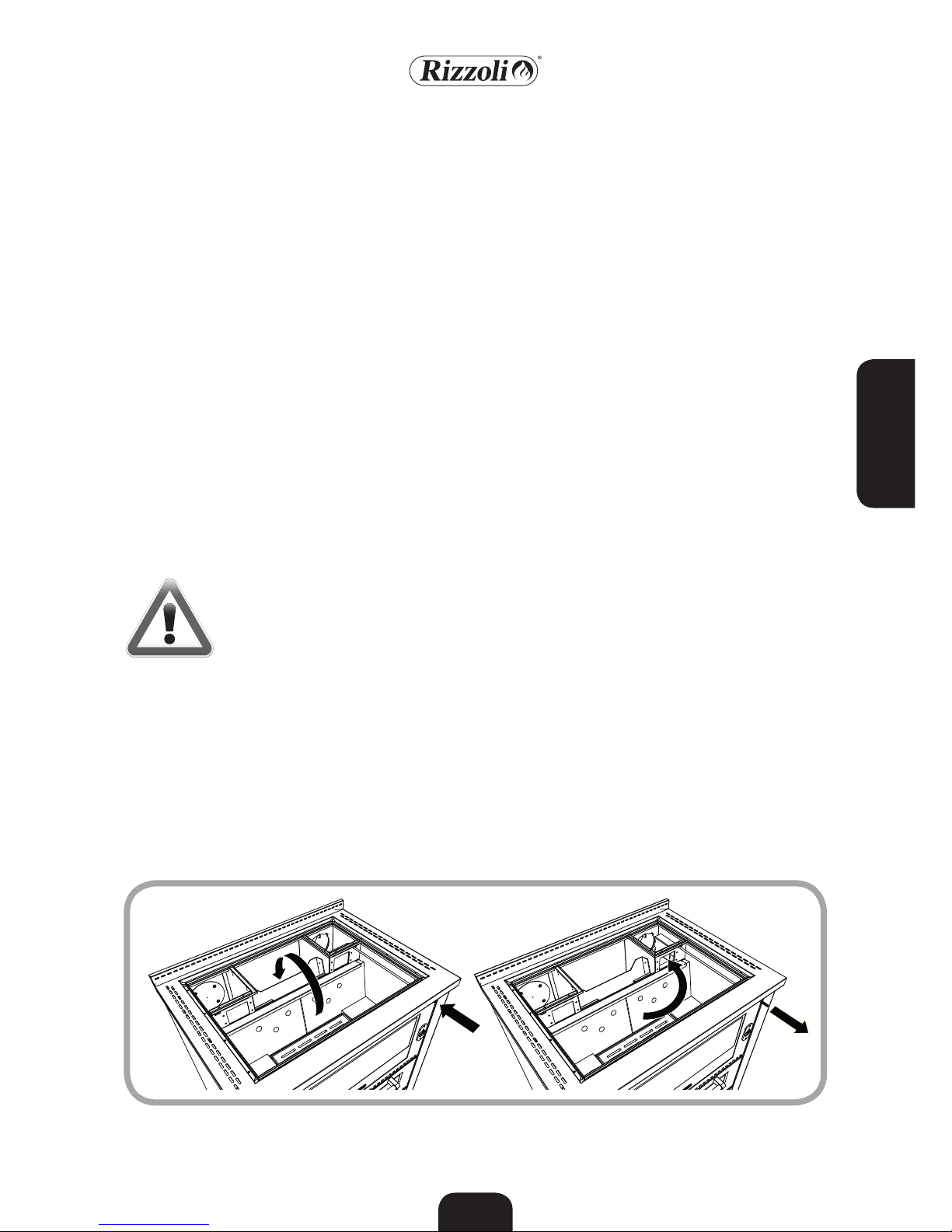

1. INSTRUCTIONS

For the perfect working of Rizzoli cookers it

is necessary the correct placing and connec-

tion to the chimney, to AC power and to the

heating system if it is necessary. The installa-

tion normally ends when you light the cook-

er. It is necessary to predispose a duly made

chimney and well suited to the model you

chose. Before the connection of the cook-

er it is necessary to contact a local chimney

sweeper. The installation usually ends with

the lighting of the cooker and the verify of

the correct working.

It is necessary to use well dried and good

quality wood: it is also necessary to sweep

the chimney and the cooker regularly.

We recommend to read carefully the in-

structions in this booklet before starting to

use the cooker. Keep this booklet because it

could be useful in case of necessity.

Talking about the working and the instal-

lation of Rizzoli cookers, all the European

laws, national and local laws and rules must

be respected.

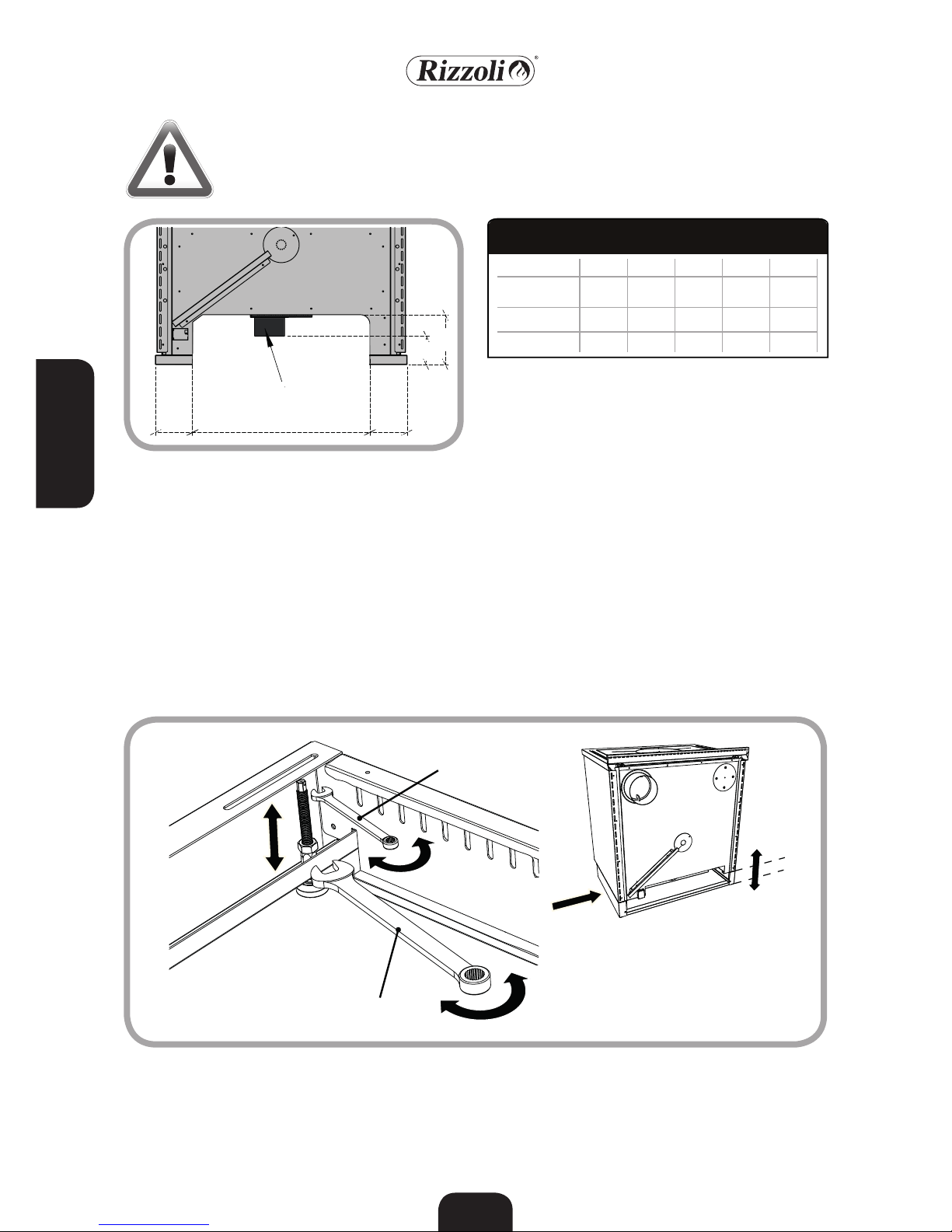

• Respect all the safety distances during the

installation of the cooker.

• The grids and the ventilation holes must

not be obstructed when you use the device.

• When using the cooker, some parts of the

device may be very hot, keep attention not

to lean and not to touch by hand hot parts

(frame, plate and doors).

• When you cook and generally when you

use the cooker you must not wear inflam-

mable dresses. • Keep more attention in

presence of children.

• Do not lean to the cooker inflammable or

explosive materials, in particular curtains

or very close to it, inflammable flacons and

aerosol bombs.

• The fire door must always be closed except

for lighting operations, fire feeding opera-

tions and during the maintenance opera-

tions.

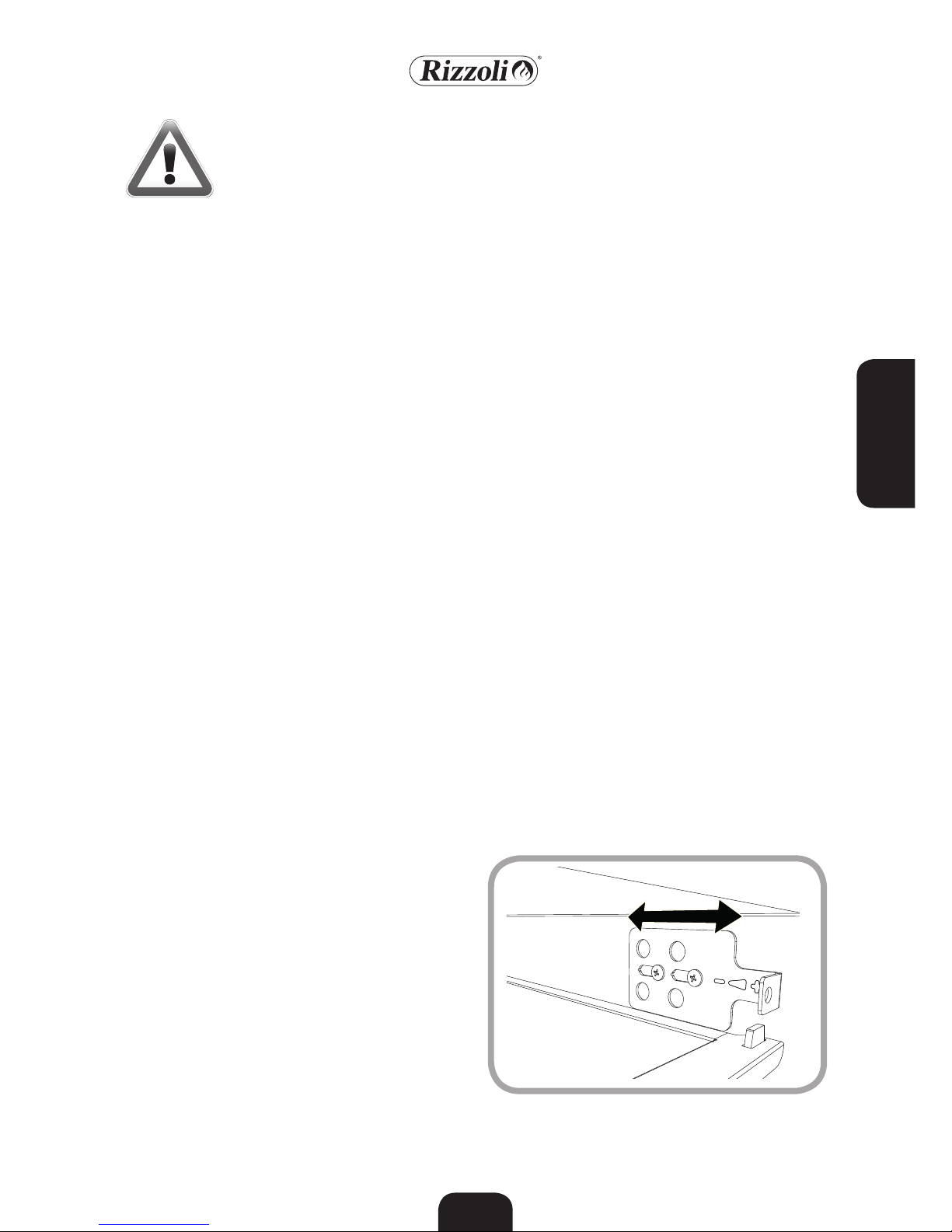

• Check regularly the fume-circuit and, the

chimney connection and the chimney it-

self. At least every six months of normal

use contact an experienced technician for

checking and cleaning of the wood fired

cooker.

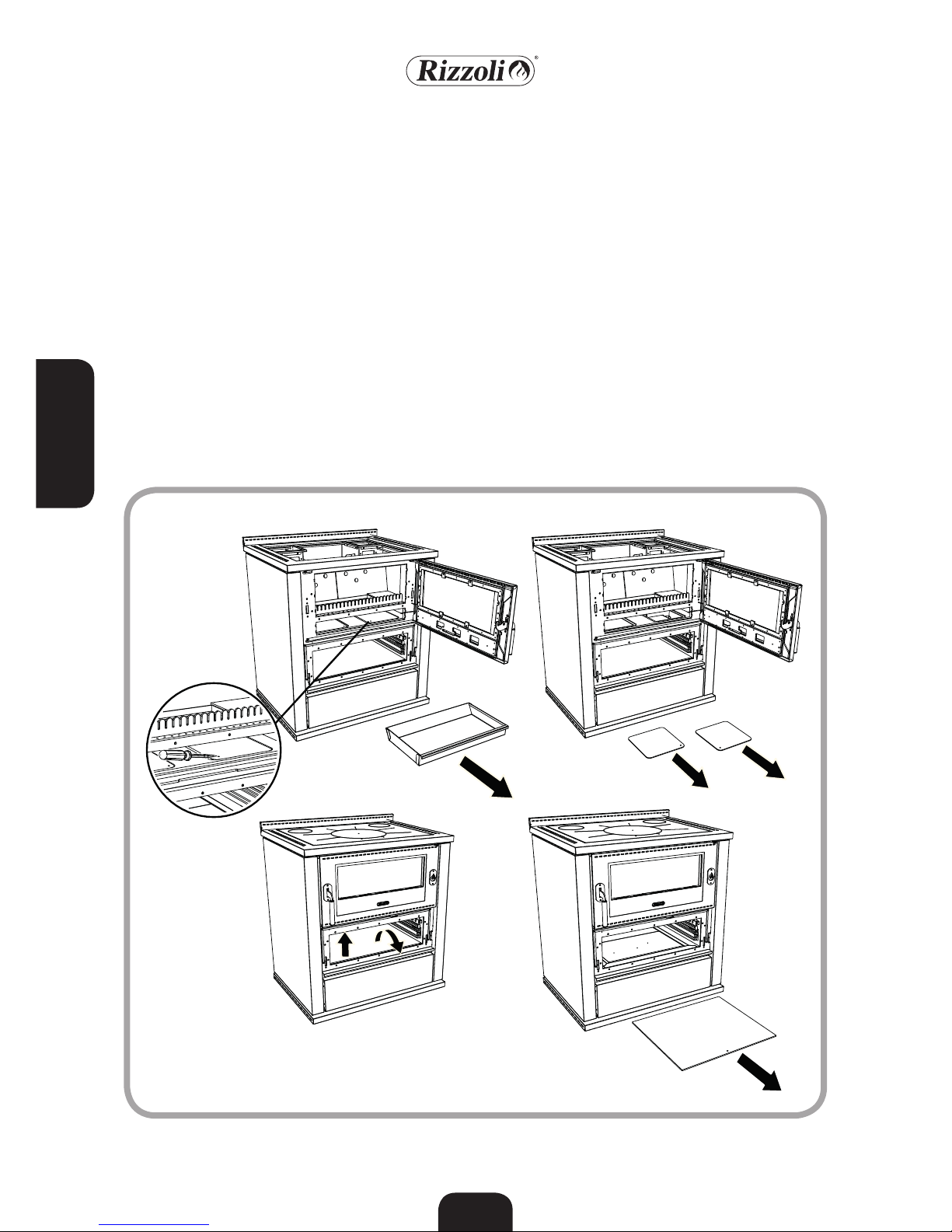

• The plate must be cleaned regularly ac-

cording to necessities after every use and

make regularly the specific maintenance.

• Before you go away for a long time, be

sure that the fire is terminated.

• The first lightings of the cooker and the

first seasonal lightings must be done with

temperate fire in order to prevent possible

breakings of the internal parts.

• After a long period in which you do not use

the cooker, check carefully that obstruc-

tions are not present and that the cooker

works regularly.

• Use only original or authorized spare parts.

• Do not make any unauthorized modifica-

tion.

1.1 GENERAL INSTRUCTIONS

1.2 SAFETY INSTRUCTIONS