CAUTION Always disconnect, lock out, and tag out all

power sources before making electrical connections. Failure to

comply will result in injury or death to personnel and damage or

destruction of equipment.

Installation

Read and follow all instructions, notes, and cautions before

installing hardware components. Contact RJG, Inc. Customer

Support for any questions regarding installation.

CoPilot™ Hardware Installation Quick Start Guide—Hyrdaulic Machines

Refer to the CoPilot™ Hardware Installation and Setup Guide for more information—download online at https://www.rjginc.com.

All rights reserved. © RJG, Inc. 2018

STANDARD EQUIPMENT QTY

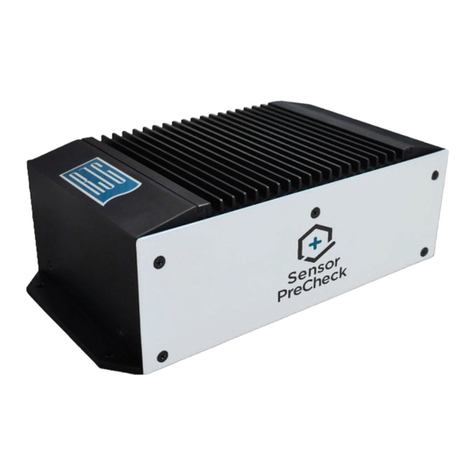

AP4.0—Application Processor 1

PS‑AP50W‑12V—AP4.0 Power Supply/

Cable 1

Touch Screen Computer 1

Touch Screen Cables—One HDMI,

One USB 2

LE‑R‑50—Lynx 50” Stroke/Velocity

Encoder 1

CE‑LX5‑4M‑F90—Lynx Four‑Meter

90°Cable 13

CE‑LX5‑2M—Lynx Two‑Meter Cable 12

CE‑LX5‑4M—Lynx Four‑Meter Cable 13

J‑LX1—Lynx Single Feed‑Through 1

ID7‑M‑SEQ—Lynx Sequence Module 1

C‑ID7‑M‑3M—Shielded Cable for

ID7‑M‑SEQ 11

OR2‑M—Lynx Relay Module OR

OA1‑M‑V—Lynx Analog Output Module 15

C‑OR2‑M‑3M—Shielded Cables for

OR2‑M 21,5

LS‑H‑1/4NPT‑3K—Lynx 3,000 lb.

Hydraulic Pressure Sensor 1

CE‑LX5‑2M—Lynx Two‑Meter Cable 1

J‑LX5—Lynx Five‑Port Junction Box 1

OPTIONAL EQUIPMENT QTY

L‑PX—Lynx Proximity Switch 11,4

1Item not shown.

2For standard installation; use of L‑PX requires a quantity of 3.

3For standard installation; use of L‑PX requires a quantity of 2.

4Only used if mold closed signal is not available from the ID7‑M‑SEQ sequence module.

5OA1‑M‑V used for control (V→P) if OR2‑M cannot be utilized.