IMR01K01-E1

TEMPERATURE CONTROLLER

SA201 INSTRUCTION MANUAL

IMR01K01-E1

Thank you for purchasing the RKC instrument. In order to

achieve maximum performance and ensure proper operation

of your new instrument, carefully read all the instructions in

this manual. Please place this manual in a convenient

location for easy reference.

All Rights Reserved, Copyright 2001, RKC INSTRUMENT INC.

!"

This is a Class A instrument. In a domestic environment,

this instrument may cause radio interference, in which case

the user may be required to take adequate measures.

!"

This instrument is protected from electric shock by

reinforced insulation. Provide reinforced insulation between

the wire for the input signal and the wires for instrument

power supply, source of power and loads.

!"

Be sure to provide an appropriate surge control circuit

respectively for the following:

- If input/output or signal lines within the building are

longer than 30 meters.

- If input/output or signal lines leave the building,

regardless the length.

!"

This instrument is designed for installation in an enclosed

instrumentation panel. All high-voltage connections such

as power supply terminals must be enclosed in the

instrumentation panel to avoid electric shock by operating

personnel.

!"

All precautions described in this manual should be taken to

avoid damage to the instrument or equipment.

!"

All wiring must be in accordance with local codes and

regulations.

!"

To prevent instrument damage or failure, protect the power

line and the input/output lines from high currents with a

protection device such as fuse, circuit breaker, etc.

!"

Prevent metal fragments or lead wire scraps from falling

inside instrument case to avoid electric shock, fire or

malfunction.

!"

Tighten each terminal screw to the specified torque found

in the manual to avoid electric shock, fire or malfunction.

!"

For proper operation of this instrument, provide adequate

ventilation for heat dispensation.

!"

Do not connect wires to unused terminals as this will

interfere with proper operation of the instrument.

!"

Turn off the power supply before cleaning the instrument.

!"

Do not use a volatile solvent such as paint thinner to clean

the instrument. Deformation or discoloration will occur. Use

a soft, dry cloth to remove stains from the instrument.

!"

To avoid damage to instrument display, do not rub with an

abrasive material or push front panel with a hard object.

NOTICE

!"

This manual assumes that the reader has a fundamental

knowledge of the principles of electricity, process control,

computer technology and communications.

!"

The figures, diagrams and numeric values used in this

manual are only for purpose of illustration.

!"

RKC is not responsible for any damage or injury that is

caused as a result of using this instrument, instrument

failure or indirect damage.

!"

Periodic maintenance is required for safe and proper

operation of this instrument. Some components have a

limited service life, or characteristics that change over time.

!"

Every effort has been made to ensure accuracy of all

information contained herein. RKC makes no warranty

expressed or implied, with respect to the accuracy of the

information. The information in this manual is subject to

change without prior notice.

!"

No portion of this document may be reprinted, modified,

copied, transmitted, digitized, stored, processed or

retrieved through any mechanical, electronic, optical or

other means without prior written approval from RKC.

SYMBOLS

:This mark indicates precautions that must be

taken if there is danger of electric shock, fire, etc.,

which could result in loss of life or injury.

:This mark indicates that if these precautions and

operating procedures are not taken, damage to

the instrument may result.

:This mark indicates that all precautions should be

taken for safe usage.

:This mark indicates important information on

installation, handling and operating procedures.

:This mark indicates supplemental information on

installation, handling and operating procedures.

:This mark indicates where additional information

may be located.

1. PRODUCT CHECK

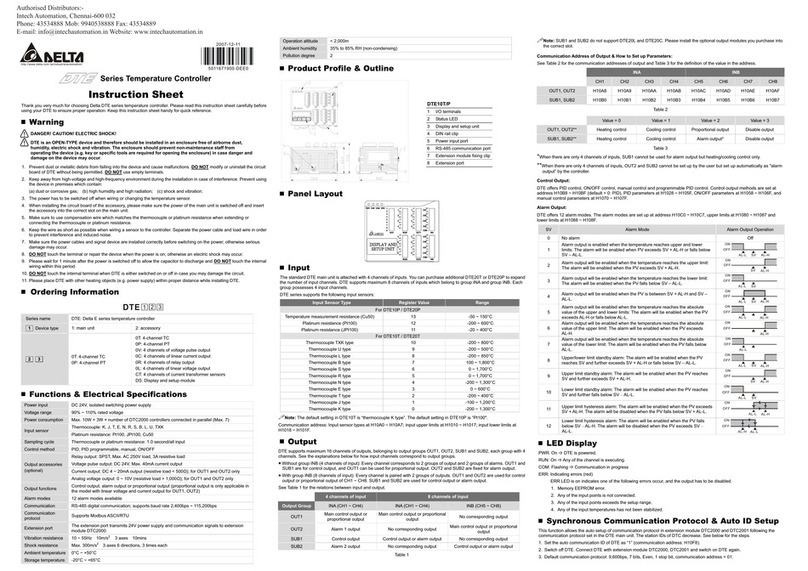

(1) Control action

F: PID action with autotuning (Reverse action)

D: PID action with autotuning (Direct action)

W: Heat/cool PID action with autotuning (Water cooling)

A: Heat/cool PID action with autotuning (Air cooling)

(2) Input type/Range code: See 9. INPUT RANGE TABLE

(3) Output 1 (control output or alarm output)

M: Relay contact output V: Voltage pulse output

(4) Output 2 (control output or alarm output)

N: No output M: Relay contact output

V: Voltage pulse output

(5) Power supply voltage

3: 24 V AC/DC 4: 100 to 240 V AC

(6) Alarm 1 [ALM1] and (7) Alarm 2 [ALM2]

N: No alarm A: Deviation high alarm

B: Deviation low alarm C: Deviation high/low alarm

D: Band alarm E: Deviation high alarm *1

F: Deviation low alarm *1 G: Deviation high/low alarm *1

H: Process high alarm J: Process low alarm

K: Process high alarm *1 L: Process low alarm *1

R: Control loop break alarm *2 V: SV high alarm

W: SV low alarm

(8) Option function

N: No function D: Contact input (RUN/STOP, STEP)

5: RS-485 (RKC communication) 6: RS-485 (Modbus)

(9) Waterproof/dustproof

N: No waterproof/dustproof 1: Waterproof/dustproof

(10) Case color

N: Off-white A: Off-black

(11) Output assignment code

No symbol: Standard output

03: PID action+ALM1

[OUT1: Control output OUT2: ALM1 output *3 ]

04: PID action+ALM1, ALM2

[OUT1: Control output OUT2: AND output of ALM1 and ALM2 *4]

05: PID action+ALM1, ALM2

[OUT1: Control output OUT2: OR output of ALM1 and ALM2 *3]

06: PID action+ALM1, ALM2

[OUT1: Control output OUT2: AND output of ALM1 and ALM2 *3]

07: PID action+ALM1, ALM2 or ALM1 only

[OUT1: Control output OUT2: No output (The alarm state can be

checked via communication or by lamp lighting) ]

08: PID action+ALM1, ALM2

[OUT1: Control output OUT2: ALM1 output *4

(ALM2 can be checked via communication or by lamp lighting) ]

09: ALM1+ALM2

[OUT1: ALM1 output *4 OUT2: ALM2 output

*4 ]

10: ALM1+ALM2

[OUT1: ALM1 output *4 OUT2: ALM2 output

*3 ]

11: ALM1+ALM2

[OUT1: ALM1 output *3 OUT2: ALM2 output

*3 ]

*1With hold action *2LBA can be selected for only ALM1.

*3De-energized *4Energized

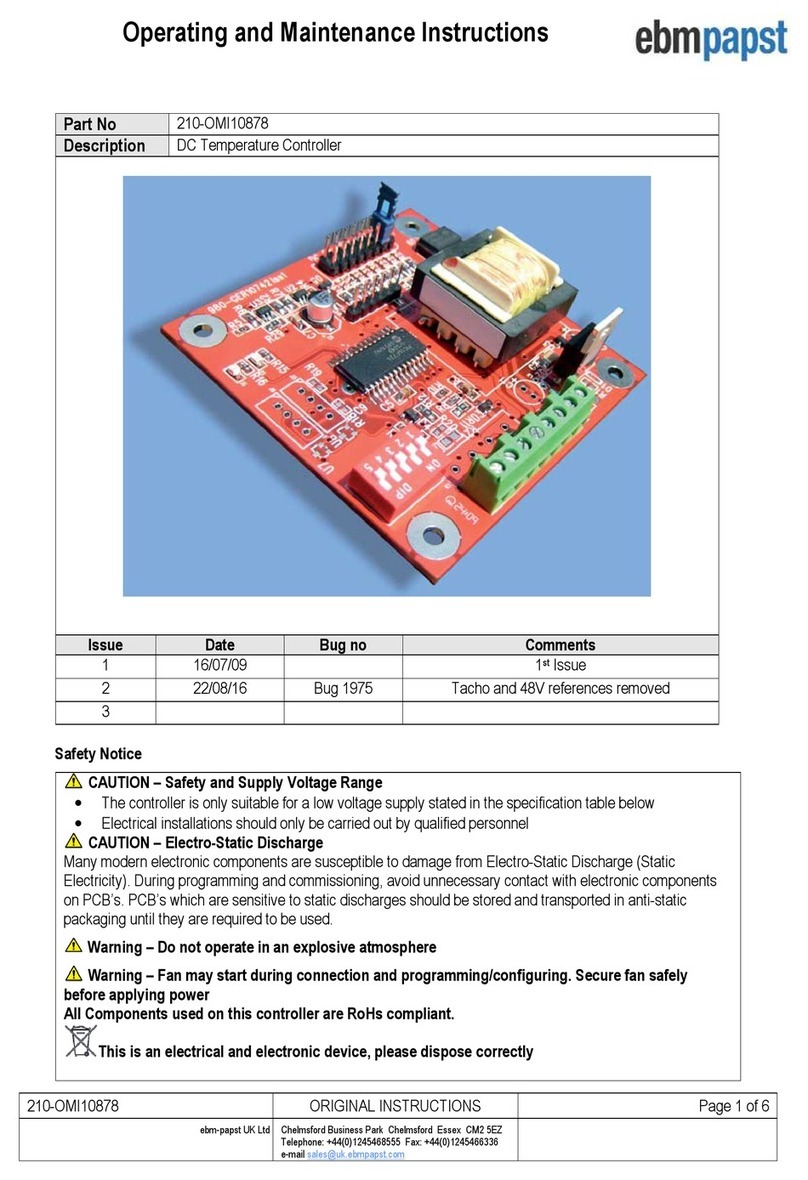

2. MOUNTING

2.1 Installation Environment

(1) This instrument is intended to be used under the following

environmental conditions. (IEC61010-1)

[OVERVOLTAGE CATEGORY II, POLLUTION DEGREE 2]

(2) Avoid the following when selecting the mounting location.

!"

Ambient temperature of less than 0 °C or more than 50 °C.

!"

Ambient humidity of less than 45 % or more than 85 % RH.

!"

Rapid changes in ambient temperature which may cause

condensation.

!"

Corrosive or inflammable gases.

!"

Direct vibration or shock to the mainframe.

!"

Water, oil, chemicals, vapor or steam splashes.

!"

Excessive dust, salt or iron particles.

!"

Excessive induction noise, static electricity, magnetic fields or noise.

!"

Direct air flow from an air conditioner.

!"

Exposure to direct sunlight.

!"

Excessive heat accumulation.

2.2 Dimensions

2.3 Mounting Procedures

1. Prepare the panel cutout as specified in 2.2 Dimensions.

2. Insert the instrument through the panel cutout.

3. Insert the mounting bracket into the mounting groove of

the instrument. (Fig.1)

4. Push the mounting bracket forward with a blade screwdriver

until the bracket is firmly secured to the panel. (Fig.2)

5. The other mounting bracket should be installed the same way described in 3and 4.

!"

When the instrument is individually mounted, always secure with two mounting brackets either top and bottom or right and left.

!"

In addition, the mounting assembly also include two screws which can be used with the brackets to secure the instrument to the panel.

See Fig. 3.

!"

The waterproof/dustproof option on the front of the instrument conforms to IP66 when mounted on the panel. For effective

waterproof/dustproof, the gasket must be securely placed between instrument and panel without any gap. If gasket is damaged, please

contact RKC sales office or the agent.

#Close Mounting

Secure the mounting brackets in the positions as shown in Fig.4 and

Fig.5.

3. WIRING

!"

For thermocouple input, use the appropriate compensation wire.

!"

For RTD input, use low resistance lead wire with no difference in resistance between the three lead wires.

!"

To avoid noise induction, keep input signal wire away from instrument power line, load lines and power lines of other electric equipment.

!"

If there is electrical noise in the vicinity of the instrument that could affect operation, use a noise filter.

- Shorten the distance between the twisted power supply wire pitches to achieve the most effective noise reduction.

- Always install the noise filter on a grounded panel. Minimize the wiring distance between the noise filter output and the instrument power supply

terminals to achieve the most effective noise reduction.

- Do not connect fuses or switches to the noise filter output wiring as this will reduce the effectiveness of the noise filter.

!"

About four seconds are required as preparation time for contact output every time the instrument is turned on. Use a delay relay when the

output line is used for an external interlock circuit.

!"

Power supply wiring must be twisted and have a low voltage drop.

!"

For an instrument with 24 V power supply, supply power from a SELV circuit.

!"

This instrument is not furnished with a power supply switch or fuse. Therefore, if a fuse or power supply switch is required, install close to

the instrument. [Recommended fuse rating: Rated voltage 250 V, Rated current 1 A Fuse type: Time-lag fuse]

!"

For the current input specification, a resistor of 250 Ω(±0.02 % ±10 ppm, 0.25 W or more) must be connected between the input terminals.

If this resistor is installed, close vertical mounting is not possible. This resistor must be provided by the customer.

!"

The input and output terminals for the voltage pulse output are not isolated. Always use an isolating type SSR. If the grounded type sensor

is used, do not ground output wiring. Do not connect any output wires to the terminals with any other output wires.

3.1 Restrictions on Wiring

Always use recommended solderless terminal lugs or equal.

Screw size: M3 ×6 (With 5.8 ×5.8 square washer)

Recommended tightening torque: 0.4 N・m (4 kgf・cm)

Applicable wire: Solid/twisted wire of 2 mm2

4 mm

φ3.2 MIN

φ5.9 MAX

6 mm

"

!"

An external protection device must be installed if failure

of this instrument could result in damage to the

instrument, equipment or injury to personnel.

!"

All wiring must be completed before power is turned on

to prevent electric shock, fire or damage to instrument

and equipment.

!"

This instrument must be used in accordance with the

specifications to prevent fire or damage to instrument

and equipment.

!"

This instrument is not intended for use in locations

subject to flammable or explosive gases.

!"

Do not touch high-voltage connections such as power

supply terminals, etc. to avoid electric shock.

!"

RKC is not responsible if this instrument is repaired,

modified or disassembled by other than factory-approved

personnel. Malfunction can occur and warranty is void

under these conditions.

WARNING

!

SA201□□□□-□□-□*□□-□□/□/□□/

□□□□-□□-□*□□-□□/□/□□/□□□□-□□-□*□□-□□/□/□□/

□□□□-□□-□*□□-□□/□/□□/Y

(1) (2) (3)(4) (5) (6)(7) (8)(9) (10) (11)

CAUTION

L2

45 +0.6

0

22.225 +0.3

0

+0.6

0

45

25 L1

22.2 +0.3

0

Panel cutout

Close vertical mountingClose horizontal mounting

Individual mounting

+0.6

0

L1 = 48 ×n-3

n: number of units (2≤n≤6)

+0.3

0

L2 = 24 ×n-1.8

n: number of units (2≤n≤6)

NO: Normally Open

Communication

Option terminals

Input terminals

Power supply terminals

T/R(A) T/R(B)

SG

RS-485

11

10 12

Contact input

OUT1 terminals

Relay contact

OUT1

NO

4

3OUT1

3

+

4

−

Voltage pulse

OUT2 terminals

Relay contact Voltage pulse

Thermocouple (TC)

RTD

0 to 5 V DC , 0 to 10 V DC,

1 to 5 V DC

Voltage input

Current input

0 to 20 mA DC,

4 to 20 mA DC

100-

240 V

AC

LN

2

1

24 V

AC

LN

2

1

+−

24 V

DC

2

1

11

10 12

8

79

5

46

2

13

Outputs (OUT1, OUT2):

Relay contact output:

240 V AC, 2 A (Resistive load) 1a contact,

Electrical life 300,000 times or more (Rated load)

Voltage pulse output:

Input/output terminals are not isolated.

0/12 V DC (Load resistance 600 Ωor more)

Contact input (option):

Dry contact input

At open 500 kΩor more

At close 10 Ωor less

Power supply voltage:

85 to 264 V AC (Power supply voltage range),

50/60 Hz, Rating: 100 to 240 V AC

21.6 to 26.4 V AC (Power supply voltage range),

50/60 Hz, Rating: 24 V AC

21.6 to 26.4 V DC (Power supply voltage range)

Rating: 24 V DC

Power consumption:

4 VA max.(at 100 V AC) 7 VA max.(at 240 V AC)

4 VA max.(at 24 V AC) 100 mA max.(at 24 V DC)

100 mA max.(at 24 V DC)

-

+TC

9

8

IN

+−

9

8

A BB

RTD

9

8

7

+−

9

8

12

11

10

NO

NO

DI2

DI1

OUT2

NO

6

5OUT2

5

+

6

−

12V 12V

3.2 Terminal Configuration

Recommended dimension:

Fig.5Fig.4

Mounting brackets: 2

Mounting screws: 2

Instruction Manual (IMR01K01-E1) : 1

Accessories

CAUTION

WARNING

CAUTION

!

•If the SA201s have waterproof/dustproof options, protection will

be compromised and not meet IP66 by close mounting.

•Two SA201s cannot be inserted into a panel cutout of 48×48 mm.

If multiple instruments are vertically

closely mounted, it is necessary to

bend the terminal lugs when they are

connected to the lower terminals.

Always connect external wires starting from the

lower terminals (No.1 to 6). Disconnect the wires

starting from the upper terminals (No.7 to 12).

When multiple instruments are vertically closely

mounted, do not connect two or more solderless

terminal lugs to one terminal.

Fig.3

Fig.1 Fig.2

When using the

mounting screws,

only turn one full

revolution after the

screw touches the

panel.

Installation Conditions:

The display can not be seen from the outside of the

visual field range. The visual field range of SA201 is

40 degrees to the upper side, and 30 degrees to the

lower side from the center of the display vertically.

63.6

44.8

48

24

9.2

40.8

14.5

8

*2

*1

1

8.2 100

22

(Unit: mm)

*1 Rubber (option) *2 Terminal cover (option) Weight 110 g

For mounting of the SA201, panel thickness must be between 1 to 10 mm.

When mounting multiple SA201s close together, the panel strength should

be checked to ensure proper support.

Recommended solderless terminals:

Circular terminal with isolation

(M3 screw, width 5.5 mm, hole diameter 3.2 mm)