RMG 503 User manual

Operation and Maintenance,

Spare Parts

Serving the Gas Industry - WORLDWIDE

Gas Pressure Regulator

RMG 503

503.20

edition 01/2003

valid for gas pressure regulator RMG 503 from serial no. 0207 31622

and integrated SAV system RMG 711 from serial no. 9706 19948

Contents

page

1. General matters 3

1.1 Safety notices 3

2. gas pressure regulator 4

2.1 Special operating notices 4

2.1.1 Commissioning 4

2.1.2 De-commissioning 4

2.2 Special maintenance notices 4

2.2.1 Screw tightening moments 4

2.2.2 Lubricants 4

2.3. Spare parts

2.3.1 Spare part drawings 5, 6

2.3.2 Spare parts list 7

3. Integrated SAV system RMG 711

3.1 Special operating notices 9

3.2 Special maintenance notices 9

3.2.1 Switch gear 9

3.2.2 Main valve 10

3.2.3 Screw tightening moments 10

3.2.4 Lubricants 10

3.3 Spare parts

3.3.1 Spare part drawings 11, 12, 13

3.3.2 Spare parts list 14, 15

3.3.3 Spare part drawings accessories 16

3.3.4 Spare parts list accessories 17

4. Parts for maintenance purposes 18

503.20 p.02

503.20 p.03

Safety indications are indicated by the following key words or symbols

indication used for:

For the gas pressure regulator with integrated SAV RMG 503 the detailed product information 503.00 is

available containing

technical data, designs and measurements as well as design descriptions and operating

notices

.

The pertinent subassemblies are described in separate operating and maintenance instructions:

regulator RMG 630/640 630.20

filter RMG 905 905.20

control unit K 10a / K 11a 672.20

control unit K 16 / K 17 / K 18 670.20

push button valve RMG 910a 910.20

push button valve RMG 913a 913.20

1. General matters

1.1 Safety notices

The RMG publication "General operating instructions for gas pressure regulators and safety devices" provides

information on installation, commissioning, and operation, and contains notices on fault removal.

For planning and maintenance of gas pressure regulators the relevant national regulations must be observed:

Germany: DVGW worksheets G 600, G 459/II, G 490/I, G 491 and G 495

The time intervals for maintenance works on the pressure reducer RMG 218 (D118aV) depend largely on the

operating conditions and the composition of the gas. Therefore, no fixed maintenance intervals are being

prescribed. It is recommended to keep to the maintenance cycles stated in the DVGW worksheet G 495.

During maintenance all components must be cleaned and thoroughly checked for safety. A visual

check is required even if irregularities were found during operation or functional checks.

The check must cover seals and membranes in particular as well as any guiding components. Damaged

components must be renewed.

The item numbers mentioned in the maintenance notices correspond to those in the spare part drawing and

spare parts list.

It is recommended to keep the parts marked "W" in the spare part drawings and spare part lists in stock for

maintenance purposes. These parts are listed on a separate sheet.

!Danger

!Caution

Note

danger to persons

danger to equipment and the environment

Important additional information

Open the startup valve.

The startup valve is used to achieve safe pressure compensation at the throttle

diaphragm.

2.1.1 Commissioning

Close outlet gate valve

Fully release the setpoint springs of the regulator RMG 630/640 in the regualting stage

and the load limiting stage (regulator RMG 630 only) by turning the setpoint adjustment

screw anti-clockwise.

Apply inlet pressure slowly.

The startup valve must always be closed again.

Adjust the setpoint value in the load limiting stage at the regulator RMG 630 to

approx. 10 bar above pa.

Adjust the output pressure in small steps by turning the setpoint adjustment screw

clockwise until the desired value has been reached. The load limiting pressure at the

RMG 630 will rise automatically.

2.1.2. De-commissioning

Turn the setpoint adjustment screw of the regulating stage anti-clockwise

Slowly close the outlet gate valve

2.2 Special maintenance notices

Due to the maintenance-friendly design the maintenance of the gas pressure regulator is principally limited

to checking the throttle diaphragm. This must be checked for wear and swelling and where necessary be renewed.

Prior to dismantling all gas supplied chambers must be depressurised.

The throttle diaphragm (306) must be inserted into the main valve body without

distortion.

Foam rings (314 and 319) from nominal width DN 80/150 are to be renewed with

every maintenance.

2.2.1 Screw tightening torques M

A

in Nm

screw

item no. 25/50 50/100 80/150 100/200

318 160 160 240 240

nominal width DN

components lubricants RMG part no.

all O rings and

diaphram tensioning bead silicon grease 00 027 081 (tube 0.1 kg)

all fastening screws

and pipe screw connections assembly grease 00 028 267

For designs with noise reduction

the correct position of the relief plates

(328) must be observed ->

The groove of the relief plates

must face upwards

503.20 p.04

2. Gas pressure regulator

2.1 Special operating notices

•

•

•

Caution

!

Note!

•

•

•

Note!

•

•

•

2.2.2 Lubricants

•

•

•

!Danger

503.20 p.05

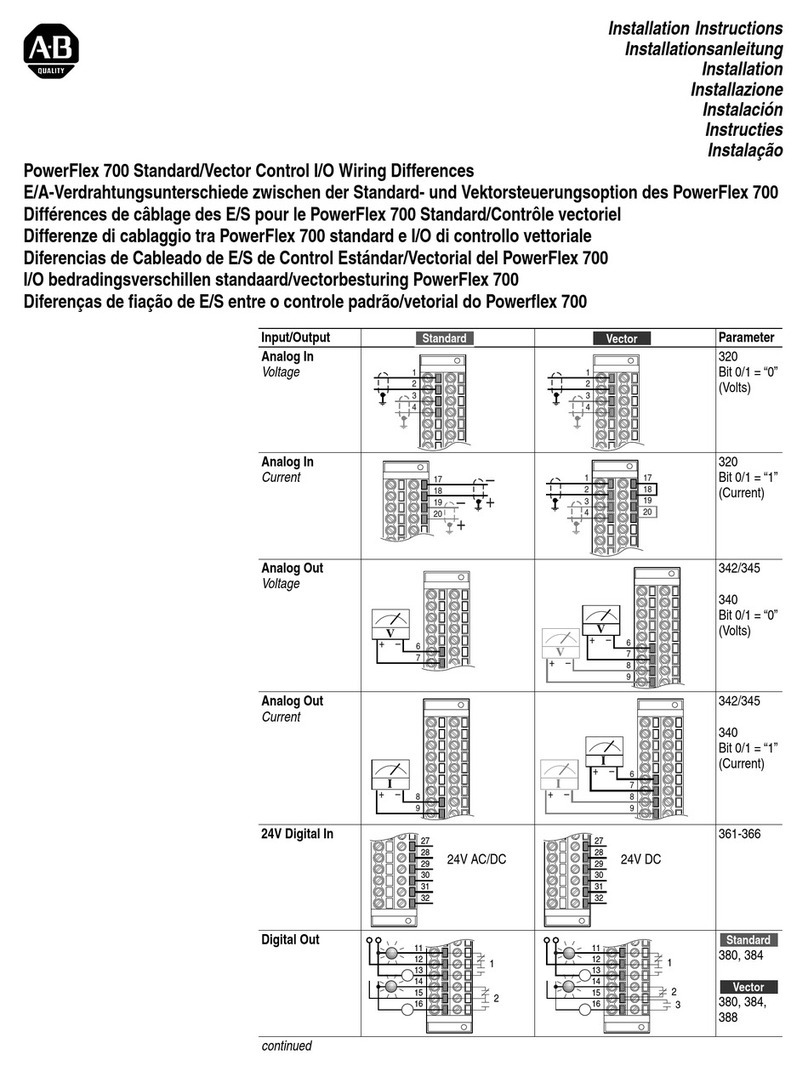

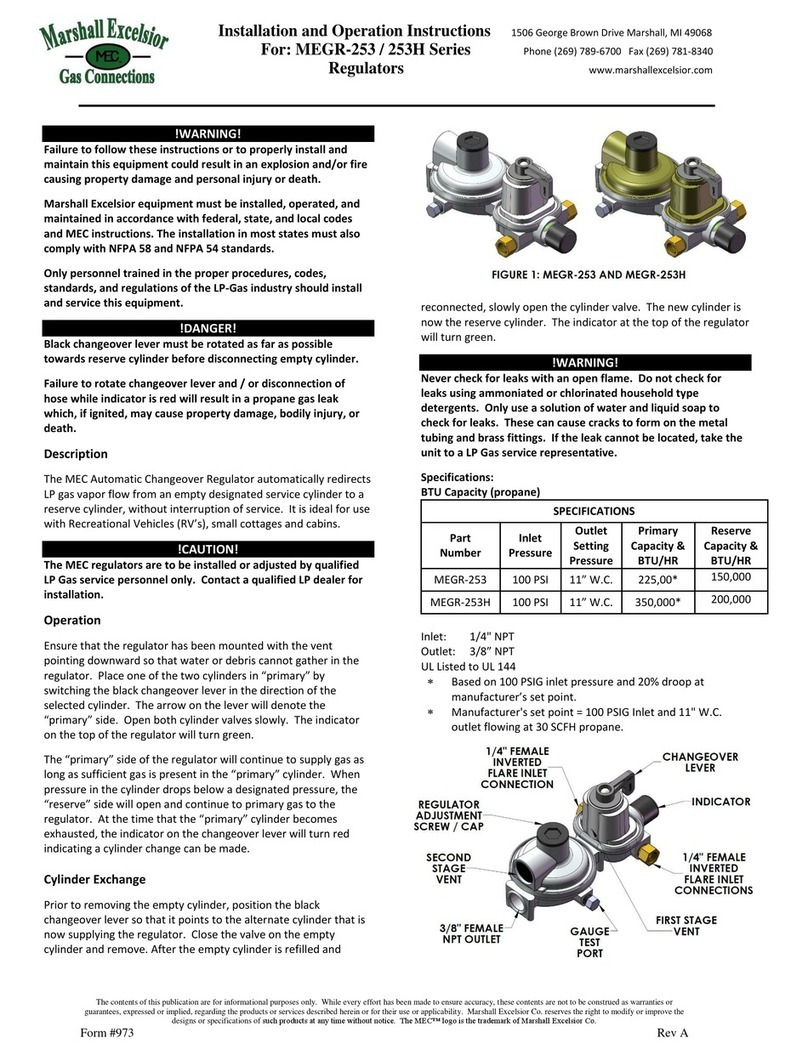

2.3.1 Spare part drawings

1

4

5

4

5

4

5

8

6

5

7

cross section A - B

GDR element

safety cut-off

unit (SAV)

AB

503.20 p.06

313

312

311

310

W

306

305

304

W 303

302

315

316

318

350

320

327

328

313

312

311

310

W 306

305

304

W 303

302

314

W

315

316

318

350

319 W

320

327

328

DN 25/50 and DN 50/100

DN 80/150 and DN 100/200

A

M

A

M

with noise reductionwithout noise reduction

M

Observe torques in table on page 4!

WParts should be kept in stock for maintenance.

A

item

no. description quant W material DN 25/50 DN 50/100 DN 80/150 DN 100/200

RMG stock no.

1 body, version "-":

1 PN 40 1 GS 10 024 470 10 024 520 10 024 620

1 PN 40 / ANSI 600 RF 1 GS 10 024 477 10 024 527 10 024 627

1 ANSI 300 RF 1 GS 10 024 473 10 024 523 10 024 623

1 ANSI 300 RF / ANSI 600 RF 1 GS 10 024 478 10 024 528 10 024 628

1 ANSI 300 RJ 1 GS 10 024 474 10 024 524 10 024 624

1 ANSI 600 RF 1 GS 10 024 475 10 024 525 10 024 625

1 ANSI 600 RJ 1 GS 10 024 476 10 024 526 10 024 626

1body, version "a"

1 PN 40 1 GS 10 027 670

1 PN 40 / ANSI 600 RF 1 GS 10 027 677

1 ANSI 300 RF 1 GS 10 027 673

1 ANSI 300 RF / ANSI 600 RF 1 GS 10 027 678

1 ANSI 300 RJ 1 GS 10 027 674

1 ANSI 600 RF 1 GS 10 027 675

1 ANSI 600 RJ 1 GS 10 027 676

4 screw plug 3 St 00 026 175 00 026 175 00 026 175 00 026 175

5sealing ring 6 LM 00 018 842 00 018 842

5 sealing ring 5 LM 00 018 842 00 018 842

6 connecting piece 1 St 00 030 074 00 030 074 00 030 111 00 030 111

7 connecting piece 1 St 00 030 111 00 030 111 00 030 023 00 030 023

8 connecting piece 1 St 00 030 074 00 030 074 00 030 074 00 030 074

503.20 p.07

2.3.2. spare parts list

WParts should be kept in stock for maintenance purposes

material identifications

St ... steel LM ... light alloy SSt ... foam

NSt ... rustproof steel Ms ... brass K ... plastic

FSt ... spring steel Cu ... copper KG ... rubbery plastic

NFSt ... rustproof spring steel Bz ... bronze KGT ... rubbery plastic with coating

GS ... steel cast GLM ... light alloy cast KV ... rubber-like plastic material (NBR)

GGG ... steel cast with spheroidal graphite GMs ... brass cast KT ... special plastic (NBR)

GZn ... zink cast AlBz ... aluminium bronze PGL ... plexiglass

GBz ... bronze cast

503.20 p.08

item

no. description quant W material DN 25/50 DN 50/100 DN 80/150 DN 100/200

RMG stock no.

302 flow divider 1 LM 10 011 137 10 011 137 10 011 237 10 011 237

303 o-ring 1 W KG 00 020 508 00 020 508 00 021 184 00 021 184

304 insert 1 St 10 023 551 10 023 551 10 023 631 10 023 631

305 slotted valve part 1 LM 10 023 550 10 023 550 10 023 630 10 023 630

306 diaphragm 1 W KG 10 011 140 10 011 140 10 011 240 10 011 240

310 connecting piece 1 St 00 030 023 00 030 023 00 030 023 00 030 023

311 spring 1 NFSt 10 011 149 10 011 149 10 011 249 10 011 249

312 diaphragm cover 1 St 10 021 590 10 021 620 10 021 653 10 021 685

313 pan head screw 1 St 00 010 021 00 010 021 00 010 003 00 010 003

314 foam disc 1 W SSt 10 023 593 10 023 633

315 pan head screw 1 St 00 008 176 00 008 176 00 010 393 00 010 393

316 diaphragm plate 1 LM 10 011 138 10 011 138 10 011 238 10 011 238

318 pan head screw 10 St 00 010 555 00 010 555

318 pan head screw 24 St 00 010 601 00 010 601

319 foam disc 1 W SSt 10 023 592 10 023 632

320 pan head screw 4 St 00 010 361 00 010 361 00 010 097 00 010 097

327 locking washer 4 St 00 014 118 00 014 118 00 014 123 00 014 123

328 release plate 1 LM 10 023 510 10 023 510 10 023 589 10 023 589

350 locking washer 10 St 00 014 116 00 014 116

350 locking washer 24 St 00 014 139 00 014 139 00 014 139 00 014 139

3.1 Special operating notices

opening the safety shut-off valve (SAV)

To open the SAV main valve insert handle (712) into the corresponding bore of the disk (734) and turn.

503.20 p.09

•

3. Integrated SAV system RMG 711

With control units K 10a or K 11a the SAV main valve can only be opened

if the control units have first been engaged.

To engage the control units K 10a and K 11a screw off lid, turn upside-down, and screw lid on to the

switching rod inside the control unit. Then pull the switch rod upward to the stop (see also 672.20).

The control units K 10a and K 11a are fitted with an underpressure shut-off device.

They can only be engaged if the pressure at the measuring point corresponds to the

operating pressure.

•

Test switching of the control units K 10a and K 11a

Test switching must only take place if the control units K 10a

and K 11a have been fitted to the switch casing (710), otherwise mechanical damage

could result.

3.2 Special maintenance notices

3.2.1 switch gear

Prior to removing the switch bearing (707) the pressure piece (768) must be removed from

the switch casing (710).

Please note during assembly of the switch bearing:

- an angled double edge of the switch bearing must point towards the pressure piece (768).

(see 3.3.1 SAV system cross section A-A)

- the sliding ring (721) must be positioned below the switch bearing.

•

•

Caution

!

Note!

Note!

503.20 p.10

•

3.2.2 Main valve

valve flap (753)

To visually check the o-ring of the valve flap (754) remove cover (747) and open SAV (engage).

When inserting a new lubricated o-ring (774) into the groove of the valve flap (753) the

o-ring should initially be pressed into the groove at 3 - 4 points spaced equally along the diameter.

Only then should the o-ring be pressed in completely.

After separating the valve flap from the valve flap lever (750) the locking nut (752) must be

tightened with the correct torque and must further be secured using the splint (773).

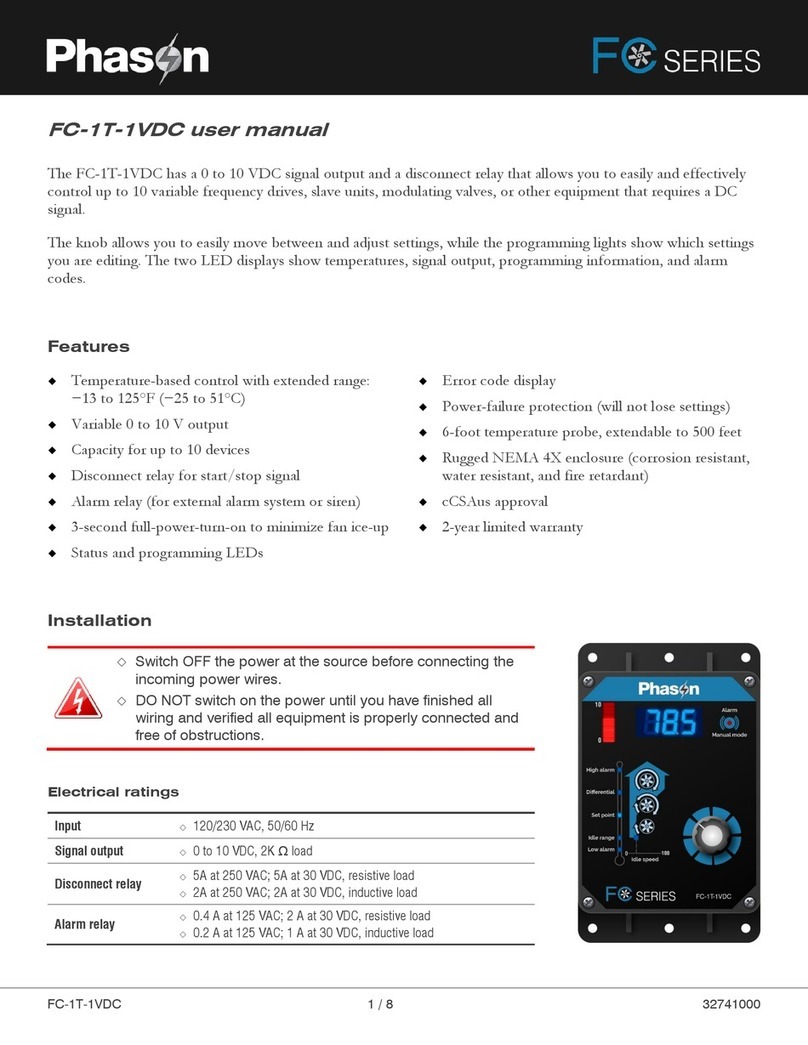

closing springs (731)

2 grooves for receiving the closing springs are forned into the spring casing (733). The grooves

are required for the different reception of the closing springs in the desings

"right hand operation"

or

"left hand operation"

.

When inserting the closing springs, they should intially be placed into the spring casing (733).

The correct orientation of the springs as shown in figure 1 and 2 should be observed.

The closing springs are properly pre-tensioned when all 4 fastening screws (732) can be fitted to the

casing (approx. half a turn of the spring casing). The valve flap must be in the "closed" position.

•

•

•

figure 2 closing spring inserting position for

"left hand" operation

figure 1 closing spring inserting position for

"right hand" operation

Torque MAin Nm

DN Schrauben-Pos.-Nr.

708 732 745 752 800

3.2.3 Screw tightening moments

MA

3.2.4 Lubricants

25/50 8 8 40 8 -

50/100 8 8 75 12 -

80/150 20 20 160 40 10

100/200 20 20 160 40 10

components lubricants RMG part no.

manual actuator thread (767) assembly paste 00 027 091

all o-rings, sliding sleeves,

sliding faces and switch elements silicone grease 00 027 081 (tube 0.1 kg)

all fastening screws

and pipe screw connections assembly grease 00 028 267

503.20 p.11

711

710

709

708

736

735

734

733

712

732

709

731

730

726

W

727 W

729

728

727 W

726

W

725

724

723

722

721

720

719

717

716

715

707

706

705

703

702

A

A

767

766

768

766

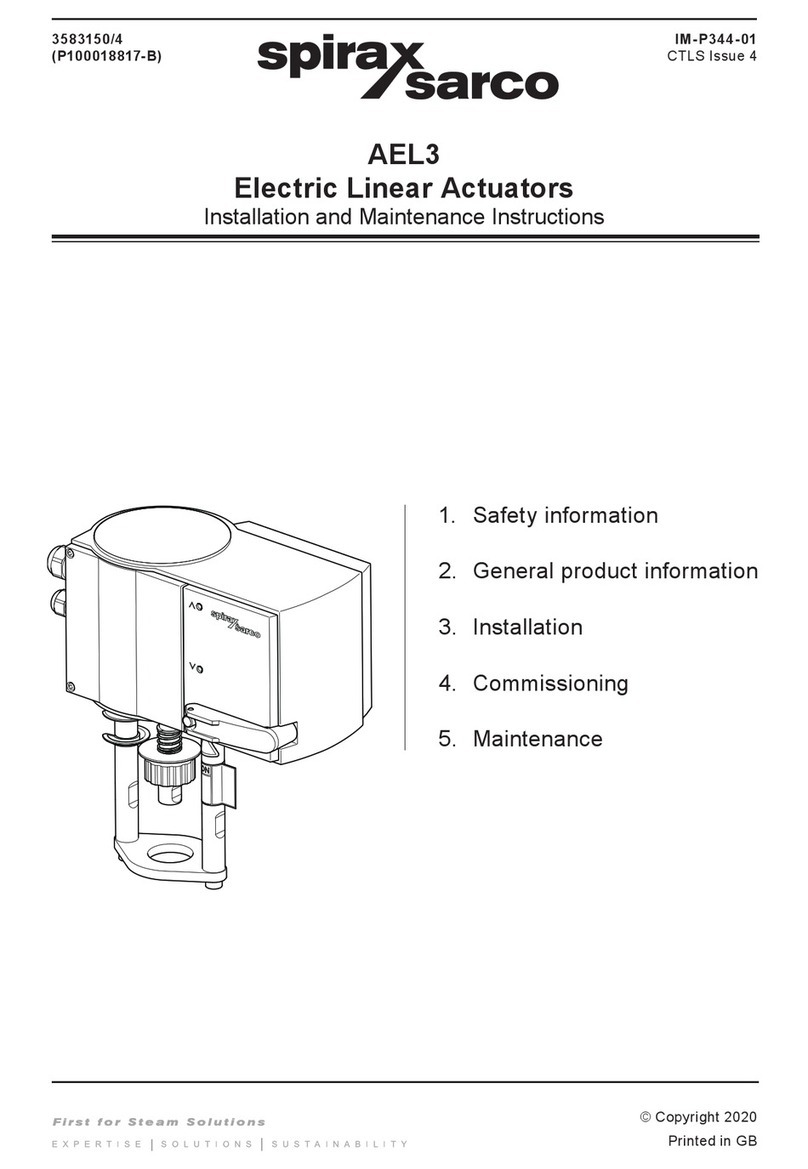

3.3.1. Spare part drawings

A

M

A

M

M

Observe torques in table on page 10!

WParts should be kept in stock for maintenance.

A

cross section A - A

503.20 p.12

750

754 W

747

745

746

A

M

A

M

745 746

lid design

DN 50/100 to DN 100/20 up to 09/96

safety cut-off unit

DN 25/50 to DN 100/200 version "-"

safety cut-off unit

DN 80/150 version "a"

774

775

753

774

801

774 750

774 750 729 800

773 752 803 802 748

W

A

M

DN 80/150 and DN 100/200 design from 06/97

DN 50/100 design from 01/99

DN 80/150 und DN 100/200

design from 01/2000

DN 25/50,

DN 50/100 design up to 1/99

773 752 747 748 746 745

W

A

M

W

754 753 774 750 729 800

A

M

M

Observe torques in table on page 10!

WParts should be kept in stock for maintenance.

A

503.20 p.13

812

811

810

813/814

810

813/814

815

DN 80/150 and 100/200

with push button valve RMG 910a

DN 25/ 50 and DN 50/100

with push button valve RMG 913a

item

no.!description!quant.!W!material!DN 25/50!DN 50/100!DN 100/200!DN 80/150

"a"

RMG stock no.

702 plug 1 K 00 026 550 00 026 550 00 026 550 00 026 550

703 disk 4 St 00 008 281 00 008 281 00 014 106 00 014 106

705 switch casing cover 1 LM 10 022 323 10 022 323 10 022 423 10 022 423

706 feather key 1 St 00 026 255 00 026 255 00 026 240 00 026 240

707 switch bearing 1 NSt 10 022 327 10 022 327 10 024 632 10 024 632

708 pan head screw 4 St 00 010 120 00 010 120 00 010 379 00 010 379

709 safety washer 8 FSt 00 014 111 00 014 111 00 014 112 00 014 112

710 switch casing, complete 1 GLM/K 10 022 326 10 022 326 10 022 426 10 022 426

711 bearing bush 1 Ms 10 022 318 10 022 318 10 024 638 10 027 688

712 handle, complete 1 NSt/K/KG 10 024 536 10 024 536 10 024 636 10 024 636

715 hexagonal screw 4 St 00 010 083 00 010 083 00 003 873 00 003 873

716 pan head screw 1 St 00 008 177 00 008 177 00 008 177 00 008 177

717 disk 1 LM 10 001 186 10 001 186 10 001 386 10 001 386

719 switch pin 2 St 00 027 646 00 027 646 00 027 301 00 027 301

720 arresting sleeve, complete 1 NSt/SF 10 022 332 10 022 332 10 022 432 10 022 432

721 sliding ring 1 KT 00 021 140 00 021 140 00 021 112 00 021 112

722 guiding sleeve 1 NSt 10 022 330 10 022 330 10 022 430 10 022 430

723 safety washer 3 FSt 00 014 118 00 014 118 00 014 111 00 014 111

724 pan head screw 3 St 00 010 561 00 010 561 00 010 150 00 010 150

725 retainer ring 1 FSt 00 019 110 00 019 110 00 019 112 00 019 112

726 o-ring 2 W KG 00 020 227 00 020 227 00 020 235 00 020 235

727 o-ring 2 W KG 00 021 142 00 021 142 00 020 607 00 020 607

728 valve flap shaft 1 NSt 10 022 317 10 022 317 10 024 637 10 027 687

729 feather key 1 St 00 026 256 00 026 256 10 024 646 10 024 646

730 bearing bush 1 Ms 10 022 319 10 022 319 10 022 369 10 022 369

731 spiral band spring 3 NSt 10 022 336 10 022 336

731 spiral band spring 4 NSt 10 022 436 10 022 436

732 pan head screw 4 St 00 010 549 00 010 549 00 010 428 00 010 428

733 spring casing, complete 1 GLM/K 10 024 535 10 024 535 10 024 635 10 024 635

734 disk, complete 1 LM/St 10 024 540 10 024 540 10 024 640 10 024 640

735 disk 1 St 00 014 082 00 014 082 00 014 137 00 014 137

736 pan head screw 1 St 00 010 618 00 010 618 00 008 177 00 008 177

745 pan head screw M10x30 10 St 00 010 400

745 pan head screw M12x60 12 St 00 010 625

745 up to autumn 1996 M12x70 12 St 00 010 594

745 pan head screw M16x80 12 St 00 010 626

745 up to autumn 1996 M 16x110 12 St 00 010 543

745 pan head screw M16x65 18 St 00 010 669

746 safety washer 12 FSt 00 014 114 00 014 116

746 safety washer 18 FSt 00 014 116

746 safety washer 10 FSt 00 014 113

503.20 p.14

3.3.2 spare parts list

!item

no.!description!quant.!W!material!DN 25/50!DN 50/100!DN 100/200!DN 80/150

"a"

RMG stock no.

747 lid 1 St 10 022 311 10 024 541 10 024 641 10 027 681

748 o-ring 1 W KG 00 020 247 00 020 427 00 020 573 00 021 361

750 valve flap lever 1 St 10 022 263 10 022 313 10 024 633 10 024 633

752 securing nut 1 St 00 013 199 00 013 200 00 013 202 00 013 202

753 valve plate, complete 1 Ms/NSt/St 10 022 262 10 022 312 10 022 407 10 022 407

754 o-ring 1 W KG 00 020 236 00 020 458 00 020 313 00 020 313

766 screw plug 2 St 00 026 175 00 026 175 00 026 175 00 026 175

767 manual release, complete 1 Al/FSt/NSt 10 022 340 10 022 340 10 022 440 10 022 440

768 pin with spring, complete 1 Ms/NSt 10 022 391 10 022 391 10 022 391 10 022 391

773 pin 1 St 00 015 000 00 015 000 00 015 007 00 015 007

774 O-Ring 1 KG 00 020 282 00 021 334 00 021 287 00 021 287

775 Druckfeder 1 FSt 10 018 394

800 hexagonal screw 2 St 10 024 648 10 024 648

801 grooved dowel pin 2 St 00 017 200 00 017 200 00 017 200

802 sealing ring 1 LM 00 018 694 00 018 694 00 018 694

803 screw plug 1 St 00 010 381 00 010 381 00 010 381

810 push button valve 1 10 005 200 10 005 200 89 100 210 89 100 210

811 screw connection 1 St 00 031 817 00 031 817

812 connecting piece 1 St 00 030 622 00 030 622

813 union nut 3 St 00 030 803 00 030 803

813 union nut 1 St 00 030 803 00 030 803

814 cutting ring 3 St 00 030 903 00 030 903

814 cutting ring 1 St 00 030 903 00 030 903

815 screw connection 1 St 00 031 207 00 031 207

503.20 p.15

503.20 p.16

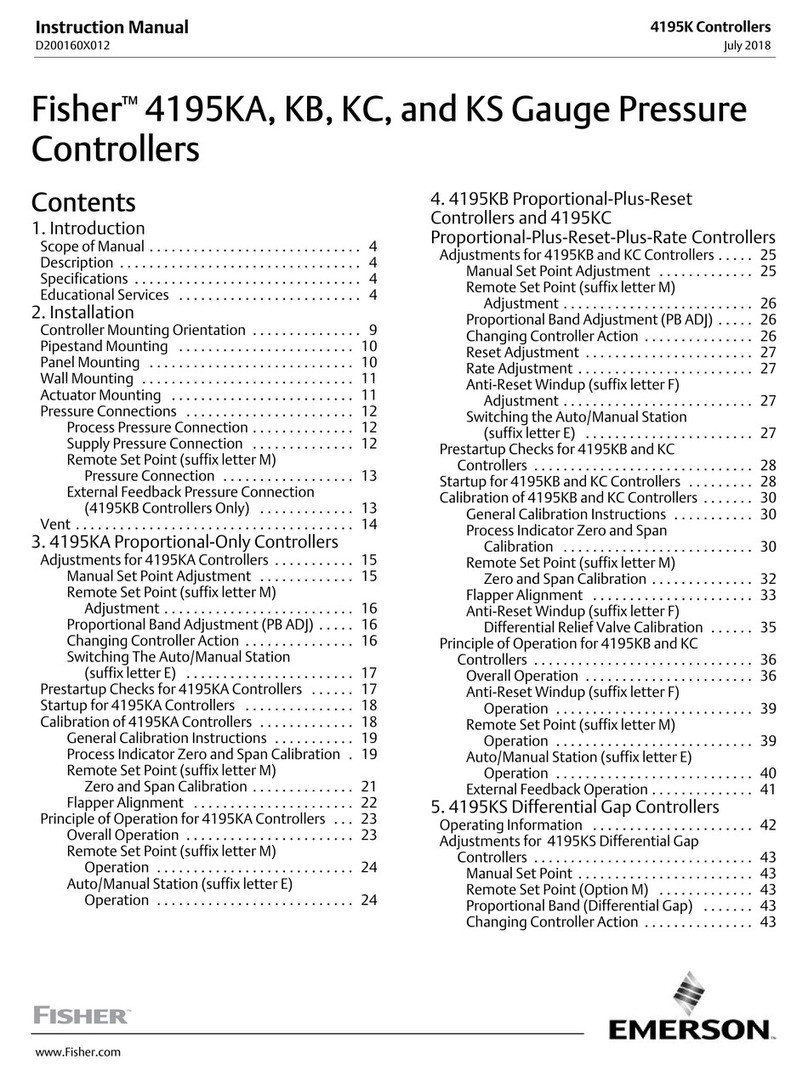

3.3.3 Spare part drawing accessories

1012

1013

1000

1001

1002

1003

1004

1005

1006

1007

1008

1009

1010

1011

1014

1015

1017

1016

1020

1021

1022

electromagnet actuation during power supply electromagnet actuation during power failure

electrical indicator for "CLOSED" position

503.20 p.17

item

no. designation quant. W material part no.

1000 switch rod, optionally for:

1000 RMG 711 DN 25 and DN 50 1 NSt 10 022 568

1000 RMG 503 DN 25/50 and DN50/100 1 NSt 10 022 568

1000 RMG 530 DN 50/100 1 NSt 10 022 568

1000 RMG 711 DN 80 and DN 100 1 NSt 10 022 573

1000 RMG 503 and RMG 530 DN 80/150 and DN 100/200 1 NSt 10 022 573

1000 RMG 711 DN 150 1 NSt 10 022 578

1001 threaded bolt 1 St 00 008 486

1002 connection flange 1 LM 10 022 582

1003 guiding screw 1 NSt 10 001 811

1004 pressure spring 1 SF 10 001 183

1005 hexagonal nut 1 St 00 003 020

1006 adjustment nut 1 Ms 10 001 864

1007 bushing 1 LM 10 022 584

1008 O ring 1 KG 00 020 327

1009 magnet 1 00 024 436

1010 threaded bolt 4 NSt 10 022 585

1011 cover 1 LM 10 022 583

1012 packing ring 1 LM 00 018 706

1013 screw plug 1 St 00 026 523

1014 locking washer 4 SF 00 014 113

1015 hexagonal nut 4 St 00 005 692

1016 pressure spring 1 SF 00 028 067

1017 screw plug 1 Ms 10 022 586

1020 proximity switch 1 00 024 160

1021 cable box 1 00 024 099

1022 relay, optional:

1022 for 1 proximity switch (230V AC) 1 00 024 402

1022 for 2 proximity swirtches (230V AC) 1 00 024 403

3.3.4 Spare part list accessories

item

no. description quant. DN 25/50 DN 50/100 DN 100/200 DN 80/150

"a"

RMG part no.

303 o-ring 1 00 020 508 00 020 508 00 021 184 00 021 184

306 diaphragm 1 10 011 140 10 011 140 10 011 240 10 011 240

314 foam ring 1 10 023 593 10 023 633

319 foam ring 1 10 023 592 10 023 632

726 o-ring 2 00 020 227 00 020 227 00 020 235 00 020 235

727 o-ring 2 00 021 142 00 021 142 00 020 607 00 020 607

748 o-ring 1 00 020 247 00 020 427 00 020 573 00 021 361

754 o-ring 1 00 020 236 00 020 458 00 020 313 00 020 313

503.20 p.18

4. Parts for maintenance

503.20 p.19

The RMG Group of Companies on the internet: http://www.rmg.de

We supply you with products

for gas pressure regulation:

We reserve the right for technical changes

Serving the Gas Industry - WORLDWIDE

The other RMG Companies:

Bryan Donkin RMG Gas Controls Ltd.

Enterprise Drive, Holmewood, Chesterfield S42 5UZ, England

Telephone (++44) 1246 501-501 • Fax (++44) 1246 501-500

gas pressure regulating equipment, below ground gas control modules

RMG REGEL +MESSTECHNIK GMBH

Osterholzstrasse 45, D-34123 Kassel, Germany

Telephone (++49) 561 5007-0 • Fax (++49) 561 5007-107

gas pressure regulators and safety devices

RMG-GASELAN Regel + Meßtechnik GmbH

Julius-Pintsch-Ring 3, D-15517 Fürstenwalde, Germany

Telephone (++49) 3361 356-60 • Fax (++49) 3361 356-836

gas pressure regulating equipment, displacement meters, complete stations

RMG Messtechnik GmbH

Otto-Hahn-Strasse 5, D-35510 Butzbach, Germany

Telephone (++49) 6033 897-0 • Fax (++49) 6033 897-130

turbine meters, vortex meters, correctors, flow computers, odorizers

WÄGA Wärme-Gastechnik GmbH

Osterholzstrasse 45, D-34123 Kassel, Germany

Telephone (++49) 561 5007-0 • Fax (++49) 561 5007-207

design and assembly of gas pressure regulating and metering stations

Bryan Donkin RMG Co. of Canada Ltd.

50 Clarke Street South, Woodstock, Ontario N4S 7Y5, Canada

Telephone (++1) 519 5398531 • Fax (++1) 519 5373339

domestic regulators and safety devices

Karl Wieser GmbH

Anzinger Strasse 14, D-85560 Ebersberg, Germany

Telephone (++49) 8092 2097-0 • Fax (++49) 8092 2097-10

Heinrich-Lanz-Strasse 9, D-67259 Beindersheim/Pfalz, Germany

Telephone (++49) 6233 3762-0 • Fax (++49) 6233 3762-40

data logging, monitor systems, danger alarm systems

Betriebsstelle Beindersheim

This manual suits for next models

1

Table of contents

Other RMG Controllers manuals