DFAWLC-044 - Installation Manual

Digital Fully Automatic Water Level Controller With Low/High

Voltage, Over Load, Dry Run protection and Timer - Tank Only

Digital Fully automatic water level controller will switch ON the motor when the water level in

the tank becomes low and will switch OFF the motor once the tank becomes full. This controller also has

the Voltage/Current /Dry Run Protection along with Timer function where it can be used as a cyclic

timer.

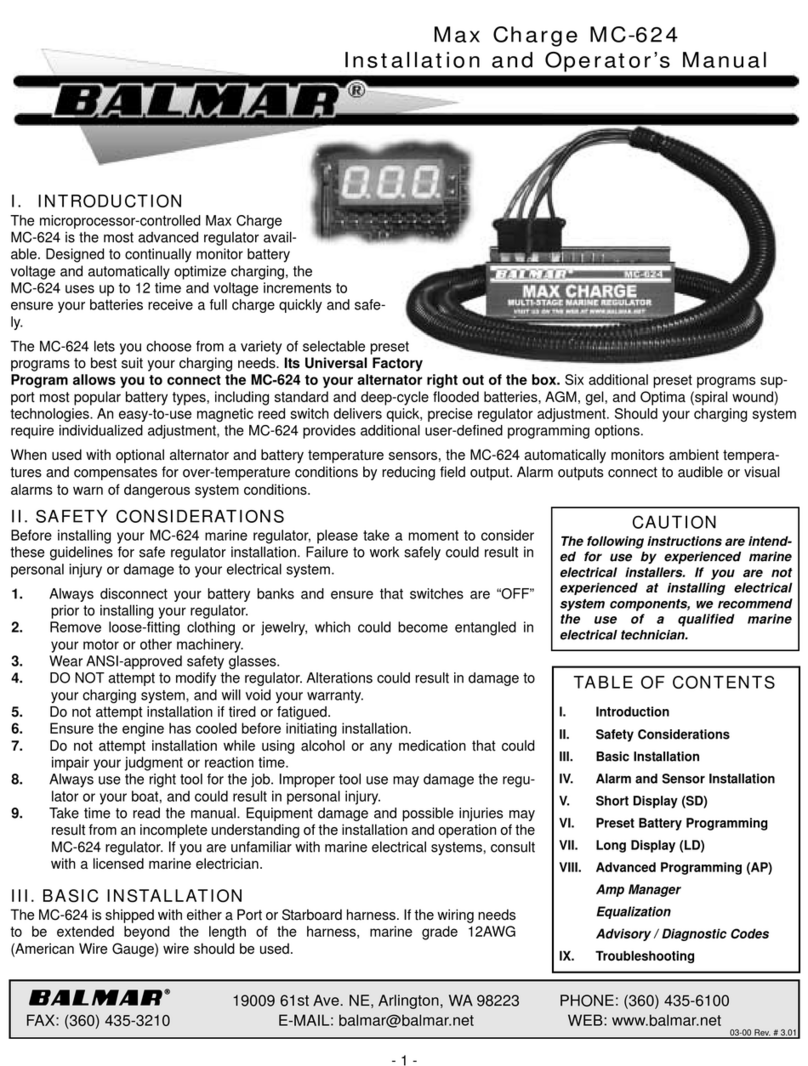

Picture1

Operating procedure:

Switch ON the controller with the help of the black button provided on the left side. Power ON

LED indication lights up.

Using the input keys (SET key, NEXT key and INC key), program the device as per your choice.

(Methods of programming the device is shared at the end for your reference).

Auto mode operation: In AUTO mode, motor will automatically switch ON when the water level

in the tank is low and automatically switch OFF when the tank becomes full.

Depending upon the water level in the tank, the level indication LED is ON.

When all the tank LED indication is OFF, the motor gets switched ON automatically. The motor

ON LED indication is ON. The tank starts filling and the corresponding LEDs starts lighting up.

When the T4 (higher level) LED indication goes ON, motor gets switched OFF. Motor ON LED

indication goes OFF.

Manual Mode: Helps to switch ON the motor manually. In this mode, the motor will be

constantly running. By changing it to AUTO mode, the above mentioned auto operation occurs.

This controller unit has a semi-automatic function (Manual ON and Auto OFF function). Just

keep the controller in MANUAL mode for the motor to get switched ON and then change it to

AUTO mode for Automatic OFF.

Dry Run Operation: When the motor is in ON condition, it checks the water flow in the inline

pipe of the tank. If there is no water flow for 1 minute, it switches OFF the motor preventing it

from Dry Run. Dry Run LED indication will be ON. This function occurs every one hour by default.

This reset time can be adjusted in Dry Run Time and the methods are explained below under

separate section.

Operation of L/H Voltage, O/U Load and Trip time: Motor will be in ON condition for the set

values. In any condition, the values goes low or high with set values, motor trips and will be OFF.

Based on the Trip time set, motor gets off. If any of these setting are not needed or To Disable

Operations –Set the Values as 0.

Timer Operation: This controller can be also used as a cyclic timer. ON time and OFF time can

be set as per below methods of programming and the motor will be ON for the set time and will

be OFF for the set time and the cycle repeats. In case if the tank is full, while the motor is ON, the

controller immediately switch off the motor and the display shows the voltage. Again motor

starts when tank is low.

The product is password protected and can be changed if required using the below methods.