RMS 1S20 User manual

1S20 User Guide

Arc Fault Monitor

relay monitoring systems pty ltd

Advanced Protection Devices

User Guide

Test Manual

1S20

User Guide

About This Manual

This User Guide covers all 1S20 relays manufactured from June 2005. Earlier relays do not

necessarily incorporate all the features described. Our policy of continuous may means that extra

features & functionality may have been added.

The 1S20 User Guide is designed as a generic document to describe the common operating

parameters for all relays built on this platform. Some relay applications are described but for specific

model information the individual “K” number Product / Test manuals should be consulted.

The copyright and other intellectual property rights in this document, and in any model or article produced

from it (and including any Registered or unregistered design rights) are the property of Relay Monitoring

Systems Pty Ltd. No part of this document shall be reproduced or modified or stored in another form, in any

data retrieval system, without the permission of Relay Monitoring Systems Pty Ltd, nor shall any model or

article be reproduced from this document without consent from Relay Monitoring Systems Pty Ltd.

While the information and guidance given in this document is believed to be correct, no liability shall be

accepted for any loss or damage caused by any error or omission, whether such error or omission is the

result of negligence or any other cause. Any and all such liability is disclaimed.

Contact Us

©Relay Monitoring Systems Pty Ltd 2001-2005

6 Anzed Court • Mulgrave 3170 • AUSTRALIA

Phone 61 3 9561 0266 • Fax 61 3 9561 0277

Email [email protected] • Web www.rmspl.com.au

To download a PDF version of this guide:

http://www.rmspl.com.au/userguide/1S20_user_guide.pdf

To download the model specific Test Manual:

http://www.rmspl.com.au/search.asp

How this guide is organised

This guide is divided into five parts:

Part 1 Overview

About this Manual

Contents

Test Manual

Part 2 Mechanical Configuration

Part 3 1S20 Arc Fault Monitor Technical Bulletin

1S30 Arc Fault Sensor Technical Bulletin

Part 4 Installation

Handling of Electronic Equipment

Safety

Unpacking

Mounting the 1S20 Arc Fault Monitor

Mounting the 1S30 Arc Fault Sensors

1S20 Configuration Switches

Equipment Connections

Operating Conditions

Part 5 Maintenance

Mechanical Inspection

Speed of Operation Performance Testing

Test Intervals

Defect Report Form

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1A54_Guide/Iss B/24/07/06

Part

1

Test Manual

This User Guide covers all 1S20 relay versions & describes the generic features & attributes

common across all versions.

Different relay versions are required to cater for varying customer requirements such as auxiliary

voltage range, I/O configuration, case style, relay functionality etc.

The product ordering code described in the Technical Bulletin is used to generate a unique

version of the relay specification & is called a type number. The type number takes the form

1S20Kxx where the Kxx is the “K” or version number.

Refer to: www.rmspl.com.au/handbook/PARTA3.pdf

for a complete description of the RMS “K” number system.

Each 1S20 version has a specific Test Manual which provides details on the unique attributes of

the relay. Each Test Manual includes the following information:

•Test Certificate

•Specific technical variations from the standard model if applicable

•Test & calibration record

•Wiring diagram

A Test Manual is provided with each relay shipped.

If you require a copy of the Test Manual for an RMS product the following options are available:

•Check the RMS web site at: www.rmspl.com.au/search.asp

•RMS CD catalogue select: List all Product/Test Manuals under Technical Library

•Contact RMS or a representative & request a hard copy or PDF by email.

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1A54_Guide/Iss B/24/07/06

Part

2

Mechanical Configuration

Great care has been taken to design a rugged, cost effective & flexible mechanical solution for

the 1S20 series Arc Fault Monitor. The ZA12 case MATRIX range provides a compact draw out

case solution with M4 screw terminals:

•1S20 surface mount type ZA12 plastic case suitable for surface or DIN rail mounting

•1S20 panel mount type ZA12 plastic case suitable for through hole panel mounting

•1S30 arc sensor Surface mounting plastic mousing

The 1S20 is configured in a ZA12 case & the following photographs depict the general mechanical

configuration.

Front view of panel mount version

Note combined tri-colour LED & reset button

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1A54_Guide/Iss B/24/07/06

Front view of surface mount version

Note separate tri-colour LED, reset button, type number detail & retention screws

Rear view of 1S20 Arc Fault module Rear view of panel mount version terminal base

Note wiring diagram & configuration switches Note type number detail & retention screws

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1A54_Guide/Iss B/24/07/06

1S20 Arc Fault Monitor shown un-plugged from terminal base

Note gold PCB contacts

Internal view of panel mount version PCB Internal view of surface mount PCB

Note combined tri-colour LED & reset button Note separate tri colour LED & reset button

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1A54_Guide/Iss B/24/07/06

Part

3

Technical Bulletin

The detailed technical attributes, functional description & performance specifications for the 1S20

are described in the attached Technical Bulletin. For the most up to date version go to:

www.rmspl.com.au/handbook/1S20.htm

For any specific attributes of a particular version refer to the Test Manual for that type (K)

number.

The order of precedence for technical information is as follows:

•Test Manual

•Technical Bulletin

•User Guide

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1A54_Guide/Iss B/24/07/06

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S20/Issue R/28/02/2010 - 1/11

Features

Compact, economic design

Simple panel mounting for

retrofit applications

Two or three arc sensor inputs

Two high speed tripping duty

arc sense output contacts

Push button reset

Continuous arc sensor

supervision

Integrated self supervision

Fail alarm contact

20-60 & 36-150V DC auxiliary

versions

Introduction

Medium voltage switchgear is a key

element in the power supply chain.

Existing protection systems operate

effectively under most circumstances, but

they are too slow to handle arcing short

circuits.

Arcing faults can occur as a result of

insulation breakdown due to equipment

age & / or poor maintenance.

The degree of damage caused by arcing

depends principally on the duration of the

arc. If an arc lasts only 100ms, the

switchgear needs to be checked & the

insulation resistance measured before

power can be re-established. With a

200ms arc, the power supply will be

interrupted; the switchgear must be

checked; power is re-established only

after minor repairs. In the event of a

500ms arc the supply is interrupted, metal

parts of the switchgear are destroyed &

poisonous gases are emitted. A 1s arc

destroys most of the switchgear & may

cause a fire, injury to personnel & damage

to property.

The over-current caused by an arc is, due

to its resistance, lower than the over-

current caused by a “metallic” short circuit.

The over-current caused by the arc may

also be lower than the protection start

current when energising circuits or starting

large motors. The consequence of these

conditions is that a protection system

based solely on over-current detection

cannot effectively discriminate between

normal system currents & an arc fault

condition:

•For moderate arc fault currents the trip

time of the over-current IDMT stage will

be too slow;

•For very low arc fault currents the

instantaneous trip stage of a standard

over-current relay cannot be set low

enough.

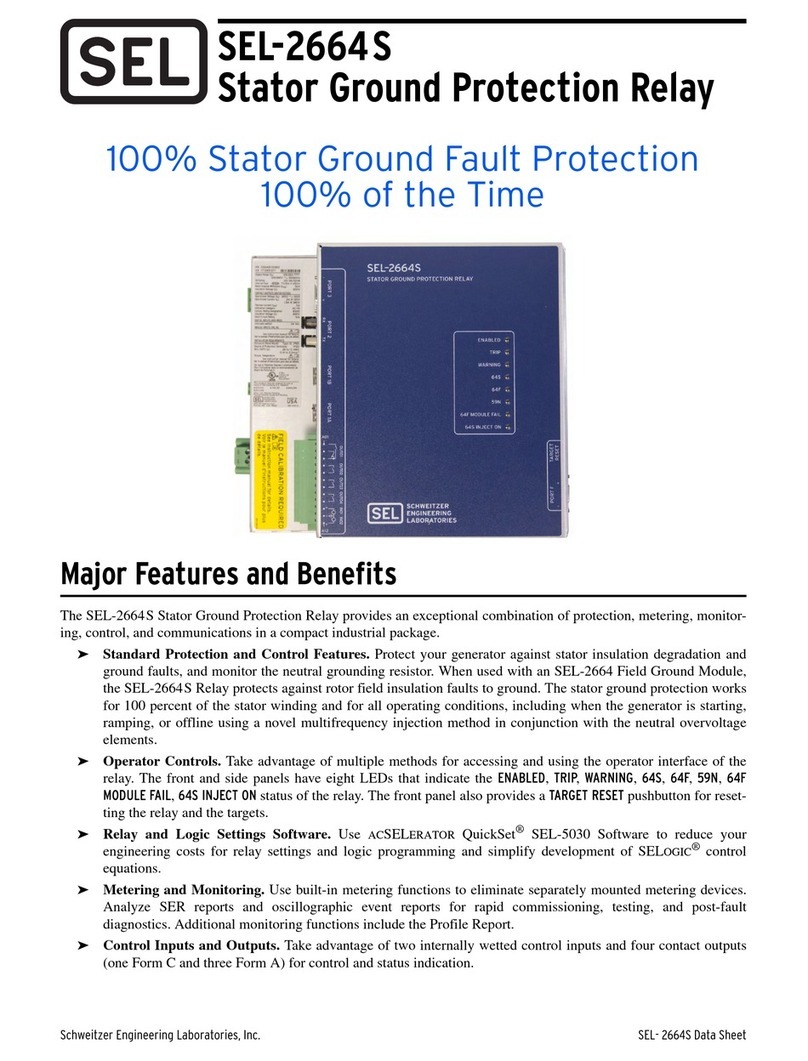

Technical Bulletin 1S20

Arc Fault Monitor Relay

1S30 Sensors - front & back 1S20 depicted in panel mount case configuration

ARC Fault Protection Made in Australia

Arc fault protection is a relatively new technique employed for the fast clearance of arcing

faults on BUS bars & within metal clad switchgear & associated cable boxes. The arc is

detected using an optical sensor & the signal input to a protection device which also

monitors the load current on the system. A trip signal can be achieved in less than 10ms

using arc detection only or within 15ms when using overcurrent check. This is considerably

faster than a traditional IDMT overcurrent relay & provides additional protection from the

onset of arcing faults with relatively low fault currents.

Arguably the greatest risk of arc fault damage exists at the CB cable termination & in the

CB chamber itself due to the slow clearance times of the IDMT feeder protection. The CB

cable termination is particularly at risk to ingress of moisture & rodent damage.

The problem of arc faults is most prevalent in older metal clad switchgear which already

has operational protection systems. The 1S20 Arc Fault Monitor has therefore been

designed for the following applications:

EXISTING SWITCHGEAR

Where a requirement exists to retrofit arc fault protection to metal clad switchgear utilizing

the existing overcurrent protection relay;

NEW SWITCHGEAR

Where a requirement exists to install arc fault protection to new switchgear for integration

with the customer preferred overcurrent feeder protection relay.

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S20/Issue R/28/02/2010 - 2/11

SWITCHGEAR ARC PROTECTION

Risk of arc fault damage exists at the CB cable termination & in

the CB chamber itself. The CB cable termination is particularly at

risk to ingress of moisture & rodent damage.

One, two or three arc sensors may be connected to the 1S20 Arc

Fault Monitors as depicted in the single line application diagrams

at right.

Figures 1 & 2 show the trip signals being used to trip the feeder

circuit breaker in the event of an arc fault occurring at any sensor

provided the overcurrent relay starter contact is picked up. In

these applications the overcurrent check stage is optional as the

consequence of a single feeder outage is less than the loss of an

entire BUS.

Figure 3 shows an application where a single 1S20 is applied for

the protection of the Cable box, CT chamber & CB chamber using

three sensors. In this configuration one arc trip output is used to

trip the feeder circuit breaker in the event of an arc fault in the

cable box / CT chamber. The second trip output is set for

independent operation to trip the BUS breaker (BUS overcurrent

check not shown), in the event of an arc fault in the CB chamber.

EXISTING SWITCHGEAR APPLICATIONS

The existing overcurrent relay protecting the feeder will normally

provide an independent output contact associated with the start

current setting of the relay. That is an output contact that will

close when a phase or earth fault current is detected above the

threshold which starts the internal relay timers. This starter

element should be set for instantaneous operation so that it will

pick up in the order of 15ms.

An Arc Fault Monitor relay 1S20 is installed on the switchgear

panel adjacent to the protection relay. The 1S20 is specifically

designed for simple retrofit to existing panels & requires only a

single 31mm mounting hole to be drilled. The 1S20 fits through

this hole, the designation label supplied with the unit positioned &

the retention shroud fitted. Refer Figure 12 & 13.

1S30 optical arc sensors are fitted in the cable termination box &

CT chamber as depicted in figure 2.

The overcurrent relay starter contact may optionally be wired in

series with the arc fault detection trip output contact as depicted

in figure 6. The resulting “AND” function trip output is wired to trip

the breaker in ~15ms in the event that an arc fault is detected

while the overcurrent start element is picked up.

The second arc trip & fail alarm contacts may be employed for

interface to a SCADA system for fault reporting.

NEW SWITCHGEAR APPLICATIONS

For new switchgear installations a modern numeric feeder

protection relay is likely to be employed which will have numerous

programming & configuration options.

The basic concept is the same as for the existing switchgear

application described above except that the additional features &

flexibility of modern feeder protection relay allows improved

system integration.

This may be achieved by using the second arc trip output contact

to interface to a programmable status input on the feeder

protection relay. Depending on the model of protection relay

being used this input may be programmed to provide an alarm

message on the HMI, time stamped event record available via its

communications link.

Where this level of system integration is employed the 1S20 does

not need to be mounted on the front panel as the alarm

indications are available on the feeder relay. Remote reset of the

1S20 LED is achieved by momentary interruption of the power

supply using a SCADA controlled series contact. The DIN rail

mounting option is a convenient alternative in this situation.

Switchgear Applications

Figure 1:

Single arc sensor - Cable box only

(Optional overcurrent check stage depicted)

1S30

1S20

50/51

Figure 2:

Two arc sensors - Cable box & CT chamber

(Optional overcurrent check stage depicted)

1S30

1S30

1S20

50/51

Figure 3:

Two arc sensors - Cable box & CT chamber

Independent trip to CB

(Optional overcurrent check stage depicted)

1S20

1S30

1S30

1S30

50/51

Trip BUS CB(s)

1S20

1S30

1S30

1S30

50/51

Trip BUS CB(s)

One arc sensor - CB chamber

Independent trip to BUS breaker

(BUS overcurrent check stage not shown)

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S20/Issue R/28/02/2010 - 3/11

COMBINED BUS BAR & SWITCHGEAR ARC PROTECTION

Figure 4 shows an application where a single 1S20 is applied for

the protection of the Cable box & CT chamber plus the CB

chamber & BUS chamber using three sensors.

In this configuration one arc trip output is used to trip the feeder

circuit breaker in the event of an arc fault in the cable box / CT

chamber. The second trip output is set for independent operation

to trip the BUS breaker (BUS overcurrent check stage not

shown), in the event of an arc fault in the CB chamber or BUS

chamber.

Figure 4:

One arc sensor - Cable box / CT chamber

Independent trip to CB

Two arc sensors - CB chamber & BUS chamber

Independent trip to BUS breaker

(BUS overcurrent check stage not shown)

BUS Bar Applications

BUS BAR ARC PROTECTION

Figure 5 depicts how the 1S20 may also be applied for the

protection of bus bars. The number of sensors in the bus

chamber is dictated by the switchgear design and the length of

switchboard.

In most indoor metal clad switchgear the bus bar chamber is a

continuous chamber between panels only broken into segregated

sections at a bus section breaker & as such the strategic

placement of one or two arc sensors in each bus bar chamber run

is normally adequate.

Some indoor metal clad switchgear may segregate the bus

chamber of each panel from the next via insulated bus chamber

side barriers per panel, if this is the case then each bus chamber

per panel would need to be monitored by at least one arc sensor.

1S20

1S30

1S30

1S30

50/51

Trip BUS CB(s)

1S20

1S30

1S30

1S30

50/51

Trip BUS CB(s)

In large enclosures the arc sensors should be placed at

approximately 5m intervals.

1S20

1S30 1S30

50/51

50/51 50/51

Figure 5:

One, two or three arc sensors located in the BUS chamber

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S20/Issue R/28/02/2010 - 4/11

OPERATION INDICATOR

A single tri colour LED is integrated into the front panel reset push

button to provide the following status indications:

Solid red for 2s followed by:

Alternate red & green until reset.

Green solid

Orange flashing

Orange solid

Alternate orange & red.

System healthy

1S30 Arc Sensor 2 or 3 service

1S30 Arc Sensor 1 service

1S30 Arc Sensor continuous pick up

Flash green 3 times1S30 Power up test OK

Arc fault trip

ARC SENSOR CIRCUIT SUPERVISION

The 1S30 Arc Sensor is the heart of the system & supervision of

circuit continuity is critical for correct operation. To monitor the

integrity of the wiring between the 1S30 arc sensor & 1S20 Arc

Monitor, a continuous 2mA supervision current flows between the

units. The 1S20 alarm contact will drop out after a 1s time delay if

it fails to detect this current.

Where a fault is detected on the Arc Sensor 1 circuit the front

panel LED will give a solid orange indication.

Where a fault is detected on Arc Sensor 2 or 3 circuits the front

panel LED will give a flashing orange indication.

Where a fault is detected on Arc Sensor 1 & 2 or 1& 3 circuits the

front panel LED will give a solid orange indication.

Operation

ARC SENSOR FUNCTION

The 1S30 is an optical sensor that responds to the flash of light

emitted during the incidence of an arcing fault. Onset of the light

flash & detection by the 1S30 occurs in a few ms.

When an arc is detected, the resistance presented by the 1S30

drops to a level where the current flow increases to approximately

20mA. This increased current flow is instantaneously detected by

the 1S20 & its trip output contacts closed. Refer to the 1S30

Technical Bulletin for further details.

ARC FAULT TRIPPING USING CURRENT CHECK

Fast operation of a tripping scheme usually results in reduced

system security. The arc detection method can however, combine

the 1S20 optical detection technique with a traditional overcurrent

method to maximize system security particularly for BUS bar

protection schemes. Both conditions must coexist for the trip

condition to be met as depicted in figure 6.

Type:1S20K1 [C] Vx: 48V DC

Serial No : 126578

1S20 Arc F ault Monitor

ARC FAULT TRIP INITIATE

CB

A

RC FAUL

T

MONITORSENSOR

OVER-CURRENT RELA

Y

3 Pole OC + EF

RESET / TEST

System F unctioning

Arc Faul t Trip

System Service

DC Fail

GREEN:

RED:

ORANGE:

DARK:

Figure 6:

Key components required to implement an Arc Fault Protection

scheme with an overcurrent check stage

to enhance system security

The application examples in figures 1 to 5 utilize this concept for

enhanced system security in that both the 1S20 AND the OC 50

starter contact must be picked up for a CB trip signal to be

initiated. As the arc fault trip contact picks up considerably faster

than the overcurrent relay starter element, the CB trip time will be

dictated by the overcurrent relay performance.

LOW CURRENT ARCING FAULTS

Arcing faults can occur at low current levels & it is possible for the

over-current starter element to be set above this level. To avoid

this problem & obtain very fast clearance (<10ms), of an arc fault,

the 1S20 arc fault trip contact may be wired directly to the breaker

operate coil. It should be noted that this method may lead to

reduced system security.

ARC DETECTION RESET TIME (Effect of multiple arc trips)

A delay of 2s is required to reset the 1S20 after an initial arc

sensor trip. Subsequent arc detection will cause the trip output

contacts to re-operate & reset the time delays described under

Configuration Switch Settings.

INDEPENDENT TRIP OUTPUT CONTACTS

The 1S20 may be set using configuration switch 3 for both trip

output contacts to pick up when an arc is detected by any sensor

input. Alternatively arc sensor 1 can be linked to trip contact 1 &

arc sensor 2 (& 3 if fitted), to trip contact 2. This function may be

applied where an arc fault detected in the cable box is directed to

trip the feeder circuit breaker while an arc fault in the BUS

chamber is to be directed to trip the BUS.

ARC SENSOR CONTINUOSLY PICKED UP

High ambient light levels may cause a 1S30 to be continuously

picked up. This condition could occur for example if the CB cable

box cover was left open in very high ambient light level

conditions. A non arc fault over-current pick up would then result

in an arc fault trip operation.

To avoid possible mal operation due to this condition, the 1S20 is

designed to automatically disable the arc fault tripping function if

the 1S30 sensor is picked up for >10s. The 1S20 alarm contact

will be set & the front LED flash alternate orange & red until the

ambient light level problem is corrected. The 1S20 will then

perform an arc sensor test function & automatically reset.

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S20/Issue R/28/02/2010 - 5/11

Figure 7: 1S20 rear view showing configuration switches

Configuration

CONFIGURATION SWITCH

The configuration switches are accessible to the user by first

unplugging the electronic module from the terminal base as

shown in Figure 7.

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

1: ARC SENSOR 2

2: LATCHING TRIP LED

3: INDEPENDENT ARC TRIP

4: LATCHING TRIP CONTACTS

5: ARC SENSOR 3

CONFIGURATION SWITCH SETTINGS

The internal wiring label identifies the position of the following

switch functions:

Switch 1: Arc sensor 2

ON - Arc Sensor 2 fitted

OFF - Arc Sensor 2 not fitted

Switch 2: Arc fault trip indication LED reset

ON - Latching until manually reset

OFF - Automatic self reset (Extinguish) after 4 hours

Will also reset contacts set for latching function

Switch 3: Independent arc trip output contacts

ON - Arc Sensor 1 activates trip output contact 1 &

Arc sensor 2 or 3 activates trip output contact 2

OFF - Arc Sensor 1, 2 or 3 activate both trip outputs

Switch 4: Arc fault trip output contact reset

ON - Latching – Reset with trip LED

OFF - Self reset after 2s

Switch 5: Arc sensor 3

ON - Arc Sensor 3 fitted

OFF - Arc Sensor 3 not fitted

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S20/Issue R/28/02/2010 - 6/11

Wiring Diagrams

2

1

3

4

5

6

8

9

12

11

10

Figure 8: 1S20 Socket Terminal Layout viewed from the front when un-plugged from the main housing

Note: * Always wire Arc Sensor 1. Arc Sensors 2 & 3 are optional.

1S20 application dia

g

ram - Circuits shown in de-ener

g

ised condition

12

8

10

9

9 or 11

5

1

3

11

6

2

4

Vx

+

+

Fail

alarm

Arc 1

(Must be wired)

Arc 3 Arc 2

Arc fault trip alarm signal to

protection relay status input for comms.

I>start

Control

Protection

1S20

50/51

Overcurrent

relay

Arcfault

relay

I>

CBAux Switch Trip Coil

52

T

52 - a

Figure 9: 1S20 Wiring application diagram

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S20/Issue R/28/02/2010 - 7/11

MOUNTING OPIONS

The 1S20 is available in two versions:

1. A surface mount version which has a separate reset button &

LED indicator on the front panel. The advantage of this

version is the lower cost & where front panel space in limited.

2. A panel mount version which has a combined reset button &

LED indication. The advantage of this version is that it can be

either panel or surface mounted.

SURFACE MOUNT VERSION

This version is suitable for location in the rear of a cubicle. It may

be surface mounted as shown in figures 10 & 17. It may also be

DIN rail mounting when the optional 290407157 DIN Rail

Mounting Kit is fitted. Refer figures 11, 18 & 19.

Figure 10: 1S20 surface mount version front panel

SERIAL NO. &

RATING LABEL

ON MODULE SIDE

FOR PANEL

MOUNT VERSION

REMOVE FOR

REAR CABLE

ENTRY OPTION

REMOVE FOR

TWO M4 OR 4BA

MOUNTING SCREWS

TOP & BOTTOM REAR

TERMINAL BLOCK

RETAINING SCREWS

SLIDE OUT CABLE

ENTRY POINTS

3 ON ONE SIDE

1 AT EACH END

1S20K2 (CAB)

AUX:36-1 50V DC S/N:123456

Figure 11: Surface mount version side view

Mounting Options

PANEL MOUNT VERSION

This version is suitable for mounting on the front panel of a

cubicle or door. This is achieved using a 31mm diameter hole in

the panel adjacent to the protection relay as depicted in figures

12, 13 & 14.

This version may also be surface mounted by reversing the

terminal block retaining screws. It may also be DIN rail mounting

when the optional 290407157 DIN Rail Mounting Kit is fitted.

Refer figures 15, 16 & 19.

Figure 12: 1S20 through hole panel mount version

Use double sided tape supplied

Top & bottom positions

RELAY PANEL

3mm THICK

MAXIMIUM

FRONT PANEL

LABEL

(Supplied with module)

SLIDE OUT CABLE

ENTRY POINTS

3 ON ONE SIDE

1 AT EACH END

TOP & BOTTOM REAR

TERMINAL BLOCK

RETAINING SCREWS

THESE MAY BE

UNSCREWED &

REVERSED TO FIT

FROM THE FRONT OF

THE 1S20 MODULE TO

ALLOW SURFACE

MOUNTING

RETENTION

SHROUD

1S20 Arc Fault Monitor

RESET / TEST

System Functi oning

Arc Fault Trip

Sensor 1 Serv ice

Sensor 2 or 3 Servi ce

Continuou s Sensor P/U

DC Supply Fail

GREEN:

RED:

ORANGE S OLID:

ORANGE FLASH:

ORANGE / RED:

NONE :

Figure 13: Panel mount version side view

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S20/Issue R/28/02/2010 - 8/11

Panel Mount Version

Figure 14: Panel mounting cut out detail

Figure 15: Surface mounting detail

Figure 16: DIN rail mounting detail

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S20/Issue R/28/02/2010 - 9/11

Surface Mount Version

Figure 17: Surface mounting detail

Figure 18: DIN rail mounting detail

DIN RAIL

MOUNTING KIT

901-500-040

Iss A (20/11/09)

Figure 19: DIN rail clip fitting detail – Specify DIN Rail Mounting Kit P/N 290407157

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S20/Issue R/28/02/2010 - 10/11

AUXILIARY SUPPLY BURDEN (At 110V DC)

Monitoring mode: Less than 4W

Arc fault detected: Less than 10W for 2s

AUXILIARY SUPPLY

20 - 60V DC

3

6 – 150V DC

OPERATE TIME

Arc fault trip contacts guaranteed to pick up in less than 10ms

including bounce. Typical operate time is 7ms.

CRO trace showing nominal operation time of the trip contacts at

7ms. First contact touch at 6.25ms and fully closed by 7.25ms.

Operation in <10ms is considered acceptable as current check

relay operate time is ~15ms.

ARC SENSOR INPUTS

Two or three independent arc sensor inputs type 1S30 or similar.

Figure 20: 1S30 Arc Fault Sensor (Refer 1S30 Technical Bulletin)

MINIMUM ARC DURATION

The minimum arc “flash” duration required to guarantee operation

of the output contacts is 1.25ms.

TRIP CONTACT RESET TIME

Once operated the trip output contacts reset as per the

configuration switch 4 setting.

MANUAL RESET

Press front button or interrupt power supply to reset LED’s.

Technical Data

OUTPUT CONTACTS

Arc fault trip contacts: 2 N/O

Fail alarm: 1 N/C for the power supply / CPU fail

Normally picked up & drops out to

signal an alarm condition.

OUTPUT CONTACT RATINGS IEC60255-0-2

Carry continuously 5A AC or DC

0.5s 20A AC or DCMake & carry

L/R ≤40ms & V ≤300V 0.2s 30A AC or DC

AC resistive

AC inductive

1,250VA

250VA @ PF ≤0.4

DC resistive 75W

Break capacity

I ≤5A & V ≤300V

30W @ L/R ≤40ms

DC inductive 50W @ L/R ≤10ms

Minimum number of operations 106at maximum load

Minimum recommended load 0.5W limit 10mA / 5V

TRANSIENT OVERVOLTAGE IEC60255-5

Between all terminals & earth 5kV 1.2/50us 0.5J

Between independent circuits without

amage or flashoverd

5kV 1.2/50us 0.5J

INSULATION COORDINATION IEC60255-5

Between all terminals & earth 2.0kV RMS for 1 minute

Between independent circuits 2.0kV RMS for 1 minute

Across normally open contacts 1.0kV RMS for 1 minute

AUXILIARY SUPPLY IEC60255-11

Allowable breaks / dips in supply

Collapse to zero from nominal voltage ≤20ms

HIGH FREQUENCY DISTURBANCE IEC60255-22-1 CLASS III

2.5kV 1MHz common mode

1

.0kV 1MHz differential mode No mal operation

ELECTROSTATIC DISCHARGE IEC60255-22-2 CLASS III

6

kV contact discharge No mal operation

RADIO FREQUENCY INTERFERENCE IEC60255-22-3

10V/m, 80 TO 1,000MHz No mal operation

FAST TRANSIENT IEC60255-22-4

4kV, 5/50ns, 100KHz repetitive No mal operation

CONDUCTED RFI IEC60255-22-6

10V, 0.15 to 80MHz No mal operation

TEMPERATURE RANGE IEC68-2-1/2

Operating: -5 to +55oC

Storage: -25 to +75oC

HUMIDITY IEC68-2-78

40 oC & 95% RH non condensing

CASE

ZA12 flush or DIN rail mount type

12 M4 screw terminals

Plug in module to facilitate easy wiring & fast changeover

AC AUXILIARY SUPPLIES (PS5R-A24 MODULE)

The Idec PS5R DIN rail mount power supply is suitable for

providing the 24V DC auxiliary supplied required for operating the

S20 Arc Fault Monitor from an AC auxiliary.1

Vx input: 85 to 264V AC

Power output: 7.5W continuous

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S20/Issue R/28/02/2010 - 11/11

CONFIGURATION CODE (Optional specification)

The configuration code can be set in the field by withdrawing the

relay module & following the instructions on the side plate label.

The configuration code may be specified at time of order so that

the relay will be shipped from the factory pre-set to meet

customer requirements. e.g. CONFIG-01011

If a configuration code is not specified the factory default will be

set as indicated below. i.e. CONFIG-11111

Configuration

Switches

Specify factory

Configuration 1 2 3 4 5

CONFIG -

1 ARC SENSOR 2

1 ON Arc sensor 2 fitted (Default)

0

OFF Arc sensor 2 not fitted

2 ARC FAULT TRIP INDICATION RESET

1 ON Latched until manually reset (Default)

0 OFF Auto reset after 4 hours

3 INDEPENDENT ARC TRIP OUTPUTS

1 ON Arc sensor 1 operates trip output 1

Arc sensor 2 operates trip output 2 (Default)

0 OFF Arc Sensor 1 or 2 operate both trip outputs

4 TRIP OUTPUT CONTACT RESET

1 ON Latching – Resets with trip LED (Default)

0

OFF Self reset after 2s

5 ARC SENSOR 3

1 ON Arc sensor 3 fitted (Default)

0 OFF Arc sensor 3 not fitted

Ordering Information

Generate the required ordering code as follows: e.g. 1S20-CAB

1 2 3

1S20 Arc Fault Monitor Relay

1 AUXILIARY SUPPLY RANGE

A 20 - 60V DC

C

36 - 150V DC

2 MOUNTING

A Panel mount or surface mount *

B Surface mount only *

3 SENSORS

A Two arc sensor inputs (Default)

B Three arc sensor inputs

Note: * Where DIN rail mounting is required specify DIN Rail

Mounting Kit P/N 290407157

PS5R POWER SUPPLY MODULE

Use the PS5R-A24 DIN rail mount module to power a single 1S20

from an 85-164V AC auxiliary source.

1S30 ARC FAULT SENSOR

Refer to the 1S30 Technical Bulletin for ordering information on the

Arc Sensor.

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S30/Issue G/18/07/11 - 1/5

Features

Compact rugged design

One or two optical detectors

High speed arc detection

Heavy duty 6m termination

cable

Optional 20m & screened

cables

Simple flush panel mounting

outside or inside switchgear

compartment

Integrated sensor circuit

supervision

Very low sensitivity to ambient

light levels to avoid nuisance

tripping even in direct sunlight

Sealed module for harsh

environments

Optional metal reinforced

mounting shield

Application

Arc fault protection is a relatively new

technique employed for the fast clearance

of arcing faults on BUS bars & within

metal clad switchgear & associated cable

boxes. The arc is detected using an

optical sensor & the signal input to a

protection device which also monitors the

load current on the system. A trip signal

can be achieved in less than 10ms using

arc detection.

RMS manufactures a protection class arc

fault optical sensor & monitoring system

suitable for both low & medium voltage

switchgear and BUS bar applications.

1S20 3 sensor, 2 zone Arc Fault Monitor

1S25 8 sensor, 4 zone Arc Fault Monitor

1S26 1S25 with integrated current check

1S30 Optical Arc Fault Sensor

While the high intensity flash caused by an

electrical arc will be reflected within the

metal clad switchgear, it is recommended

that one or more sensors be mounted in

each enclosed switchgear compartment.

For BUS bar protection applications

multiple sensors are required to achieve

adequate coverage along the length of the

BUS. A sensor version with two optical

detectors “looking” in opposite directions is

available for this purpose (Refer figure 3

for generic layout).

Technical Bulletin 1S30

Optical Arc Fault Sensor

1S30 Arc Fault Sensors

Through panel mounting detector Front panel view of dual detector

View depicted at left version depicted at right

Description

Made in Australia

The 1S30 is an optical sensor that responds to the flash of light emitted during the

incidence of an arcing fault. Onset of the light flash & detection by the 1S30 occurs in a few

ms.

Each arc fault sensor consists of one or two silicon PIN photo diode light detectors

mounted on a circuit board together with the associated detection circuit (Figures 1 & 2).

The detector monitors a wide space angle. A broad spectral response in the visible region

is provided as depicted in figure 5.

Sensitivity of the arc sensor has been set to a low level to reduce the possibility of mal

operation under high ambient lighting conditions. This is made possible due the high

intensity of light emitted under arc fault conditions. Additional security can be incorporated

by way of a current check stage as described in the 1S20 Arc Fault Monitor Technical

Bulletin.

In stand by mode the 1S30 sensor presents a high resistance to the 12V DC control signal

provided by the 1S20, 1S25 or 1S26 Arc Fault Monitors. This allows a small circulating

current to flow for continuous supervision of the 1S30 connection circuit. When an arc is

detected, the resistance presented by the 1S30 drops to a level where the current flow

increases to approximately 20mA. This increased current flow is instantaneously detected

by the Arc Fault Monitor & its trip output contacts closed. Refer to the 1S20 Arc Fault

Monitor Technical Bulletin for further details.

This manual suits for next models

1

Table of contents