Contents

Operating Manual PNOZ X2C

19918-EN-10 | 3

Introduction ............................................................................................................................4

Validity of documentation ..........................................................................................................4

Using the documentation ..........................................................................................................4

Definition of symbols .................................................................................................................4

Safety ......................................................................................................................................5

Intended use .............................................................................................................................5

Safety regulations .....................................................................................................................5

Safety assessment....................................................................................................................5

Use of qualified personnel.........................................................................................................6

Warranty and liability.................................................................................................................6

Disposal ....................................................................................................................................6

For your safety ..........................................................................................................................6

Unit features ...........................................................................................................................7

Safety features .......................................................................................................................7

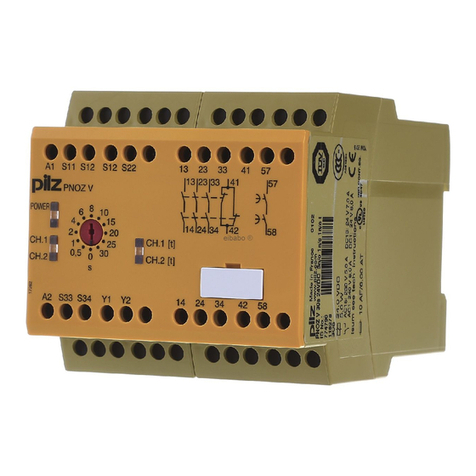

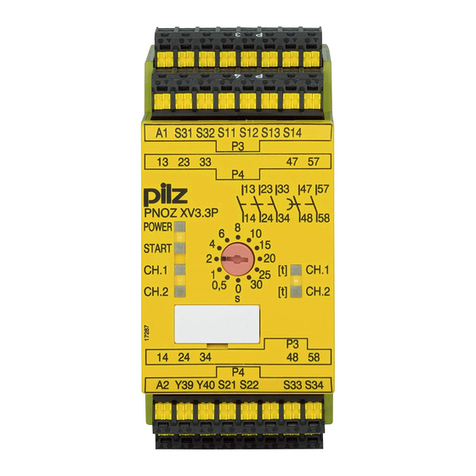

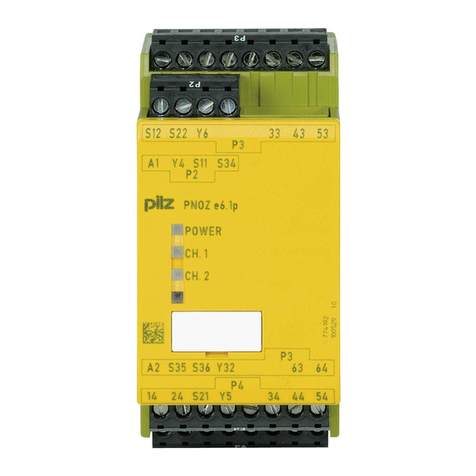

Block diagram/terminal configuration .................................................................................7

Function Description .............................................................................................................8

Operating modes.......................................................................................................................8

Timing diagram .........................................................................................................................8

Installation ..............................................................................................................................9

Wiring ......................................................................................................................................9

Preparing for operation .........................................................................................................10

Operation ................................................................................................................................11

Status indicators........................................................................................................................12

Faults – Interference ..............................................................................................................12

Dimensions in mm .................................................................................................................12

Technical details ....................................................................................................................13

Safety characteristic data..........................................................................................................16

Supplementary data ...............................................................................................................16

Service life graph ......................................................................................................................17

Order reference ......................................................................................................................17

EC declaration of conformity ................................................................................................17

UKCA-Declaration of Conformity .........................................................................................18