Rhein-Nadel Automation GmbH 2

VT-BA-FP120-EN_2020 / 02.03.2020 SJ

Table of Contents

1. Technical data........................................................................................................................4

1.1. Table...................................................................................................................................4

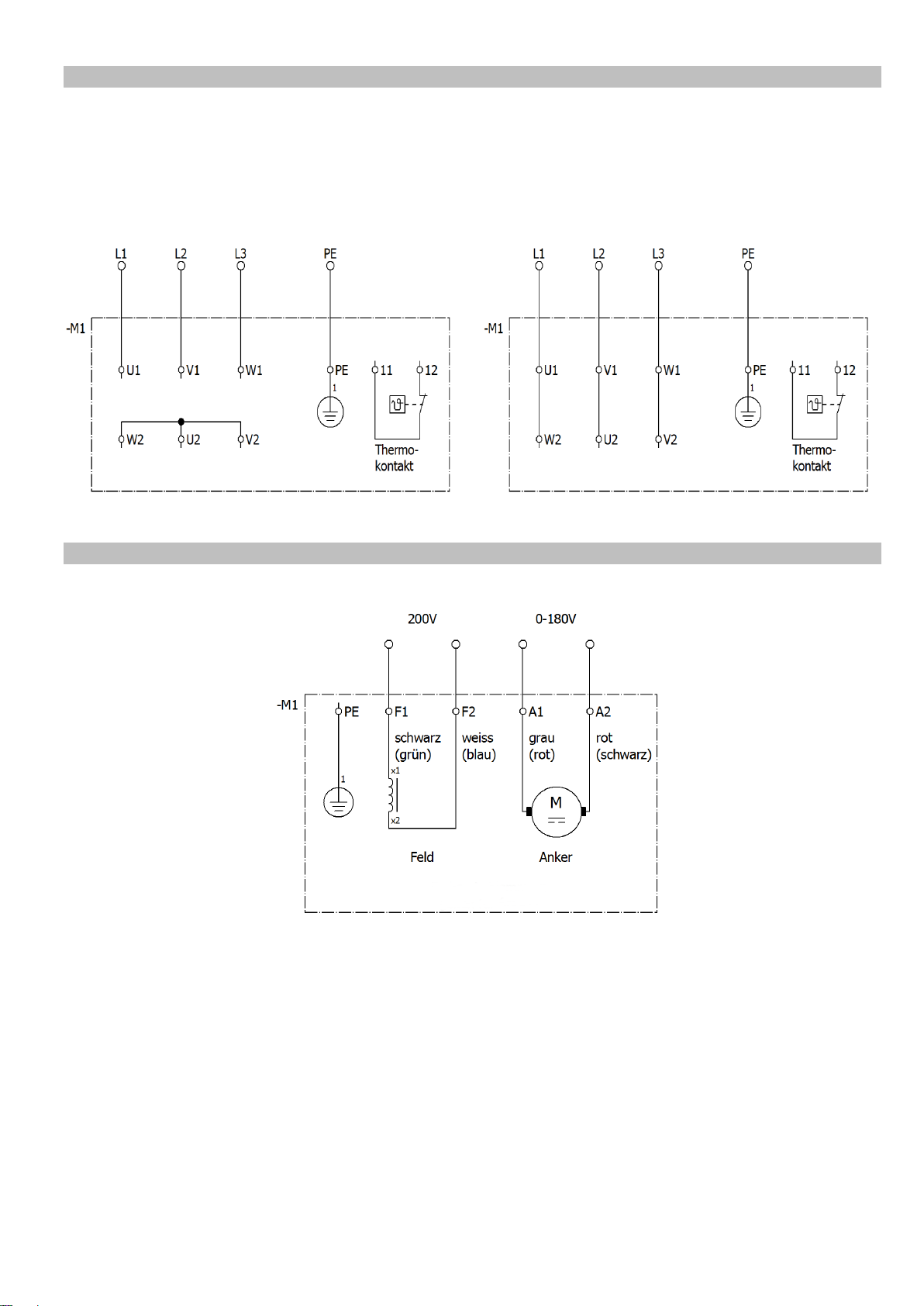

1.2. Motor connection diagrams.................................................................................................5

1.2.1. Constant-speed three-phase motor..............................................................................5

1.2.2. Constant-speed A.C. motor (with capacitor)................................................................. 5

1.2.3. Variable-speed three-phase motor...............................................................................6

1.2.4. D.C. motor....................................................................................................................6

2. Safety directives.....................................................................................................................7

2.1. Applicable directives and standards....................................................................................9

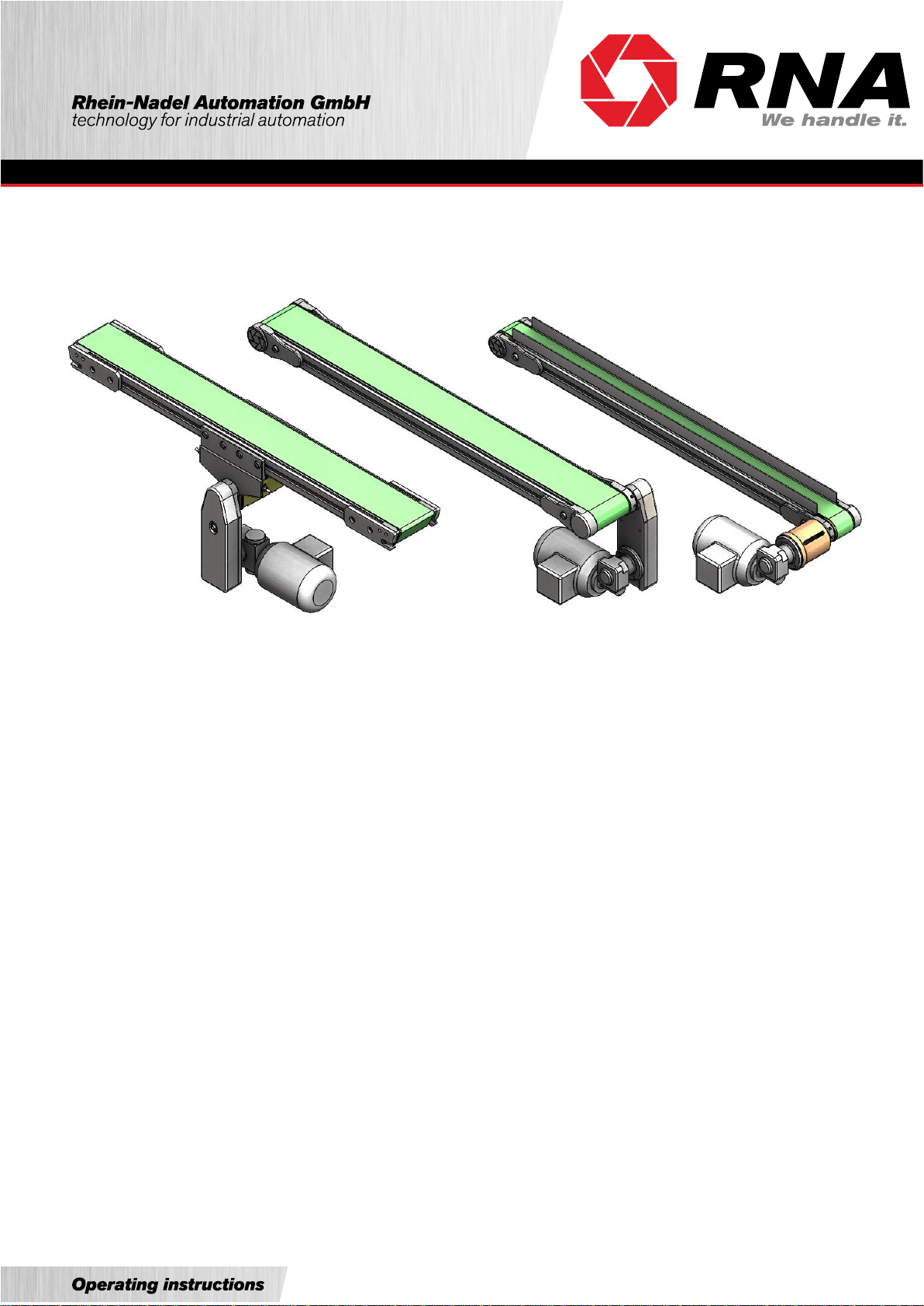

3. Design and functional description of belt conveyors ..............................................................9

4. Shipment and installation.....................................................................................................11

4.1. Shipment...........................................................................................................................11

4.2. Installation.........................................................................................................................11

4.2.1. One-piece belt feeders...............................................................................................11

4.2.2. Installation of multi-segment belt feeders...................................................................11

4.2.3. Installation on RNA supports......................................................................................13

4.2.4. Drive system (belt conveyors without RNA control units)...........................................14

4.2.5. Preliminary adjustment of belt tracking.......................................................................14

5. Commissioning.....................................................................................................................15

5.1. Adjustment of belt return station .......................................................................................15

5.2. Adjusting the center drive station......................................................................................16

5.3. Adjusting at the head drive station (reserved only for exceptional situations)...................16

5.4. Changing the sense of rotation.........................................................................................16

6. Belt replacement..................................................................................................................17

6.1. Replacing a belt with head drive station............................................................................17

6.2. Replacing a belt with center drive station..........................................................................17

7. Maintenance.........................................................................................................................18

7.1. Belt....................................................................................................................................18

7.2. Motor.................................................................................................................................18

7.3. Gearbox............................................................................................................................18

7.4. Chain drive system ...........................................................................................................19

7.5. Return, drive and supporting rollers..................................................................................19

7.6. Environmental effects .......................................................................................................19

8. Spare parts and customer service........................................................................................19