Rhein-Nadel Automation GmbH 2

VT-BA-FP15-EN_2018 / 13.11.2018 SJ

Table of Contents

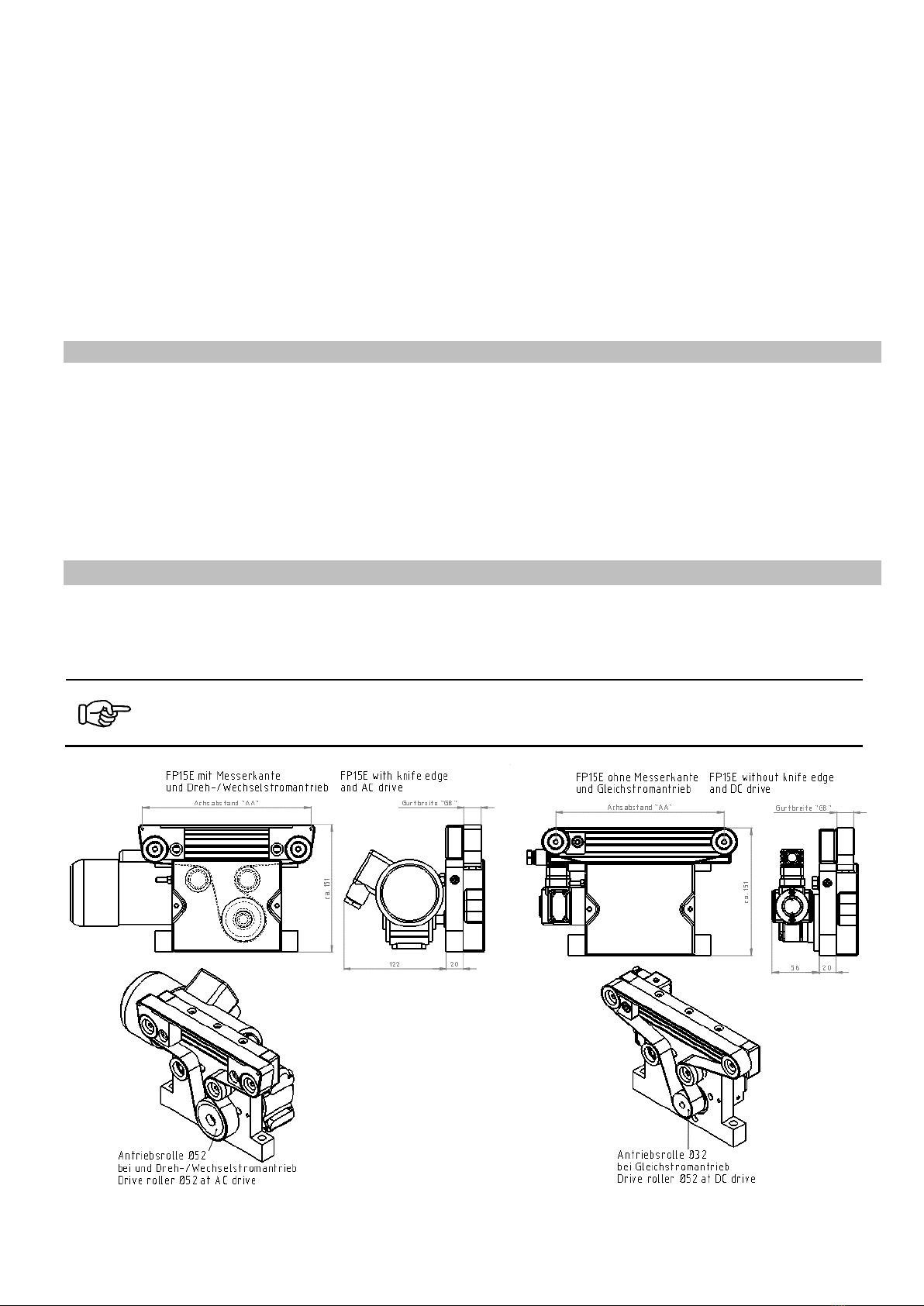

1. Technical data........................................................................................................................ 4

1.1. Table................................................................................................................................... 4

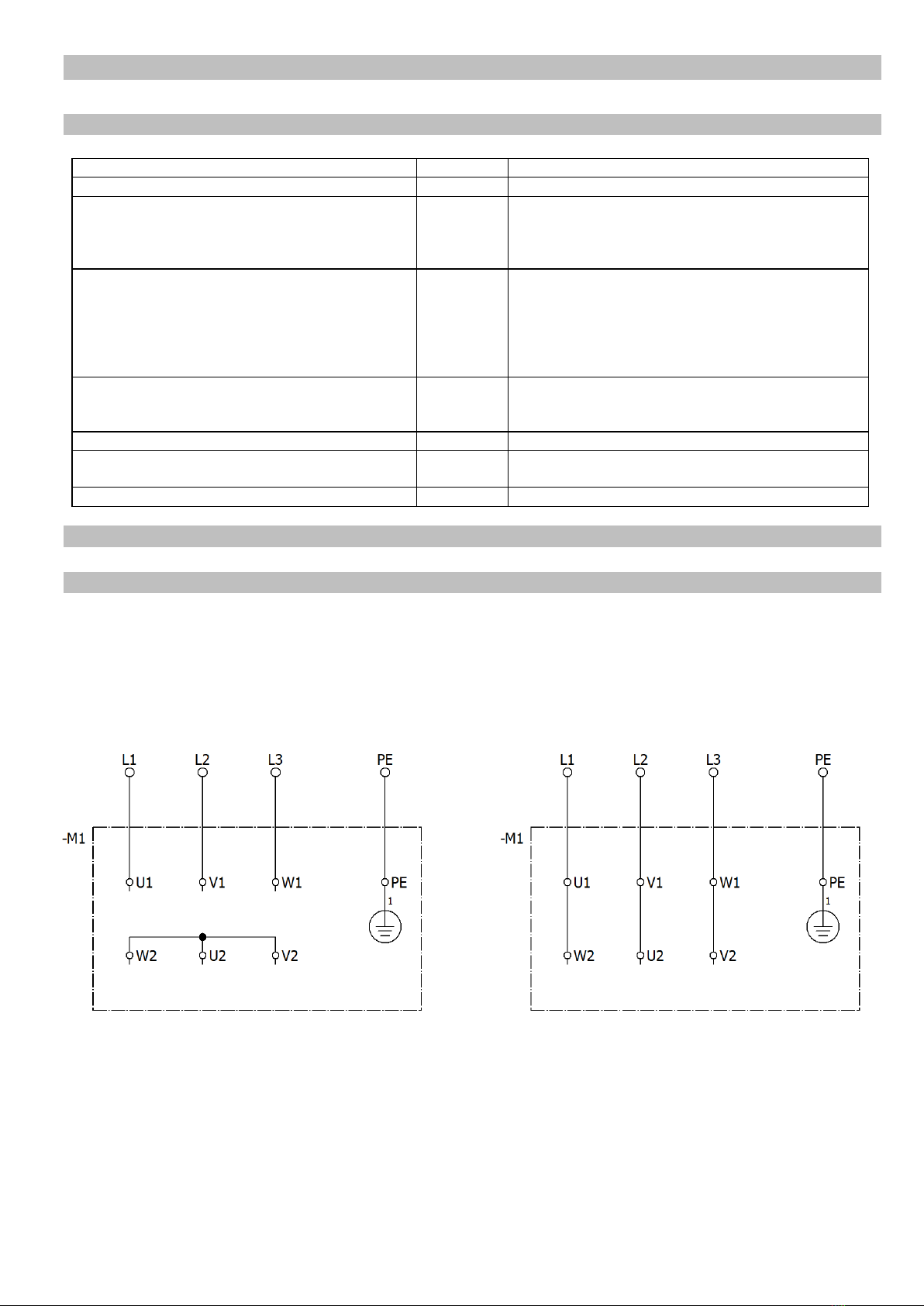

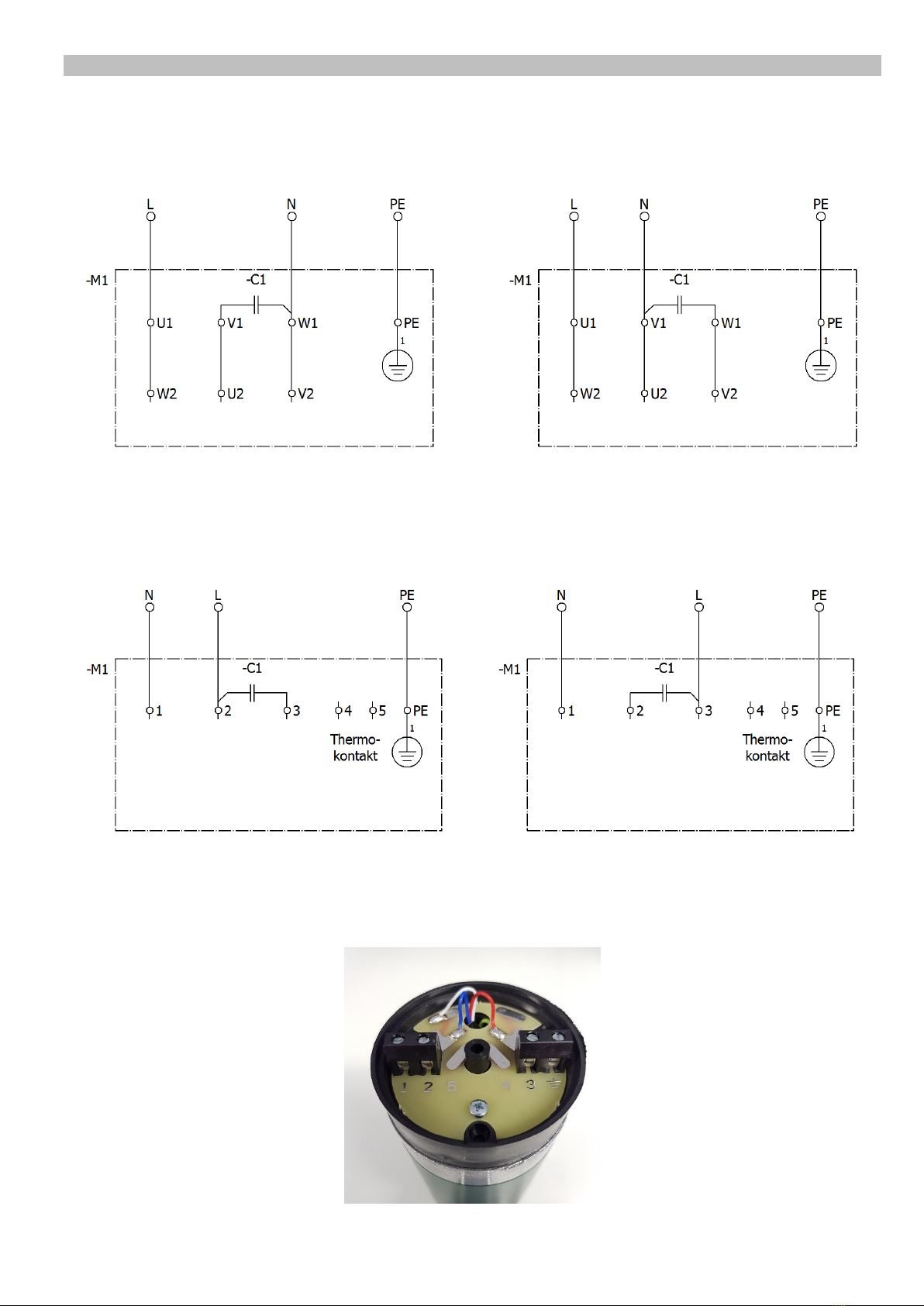

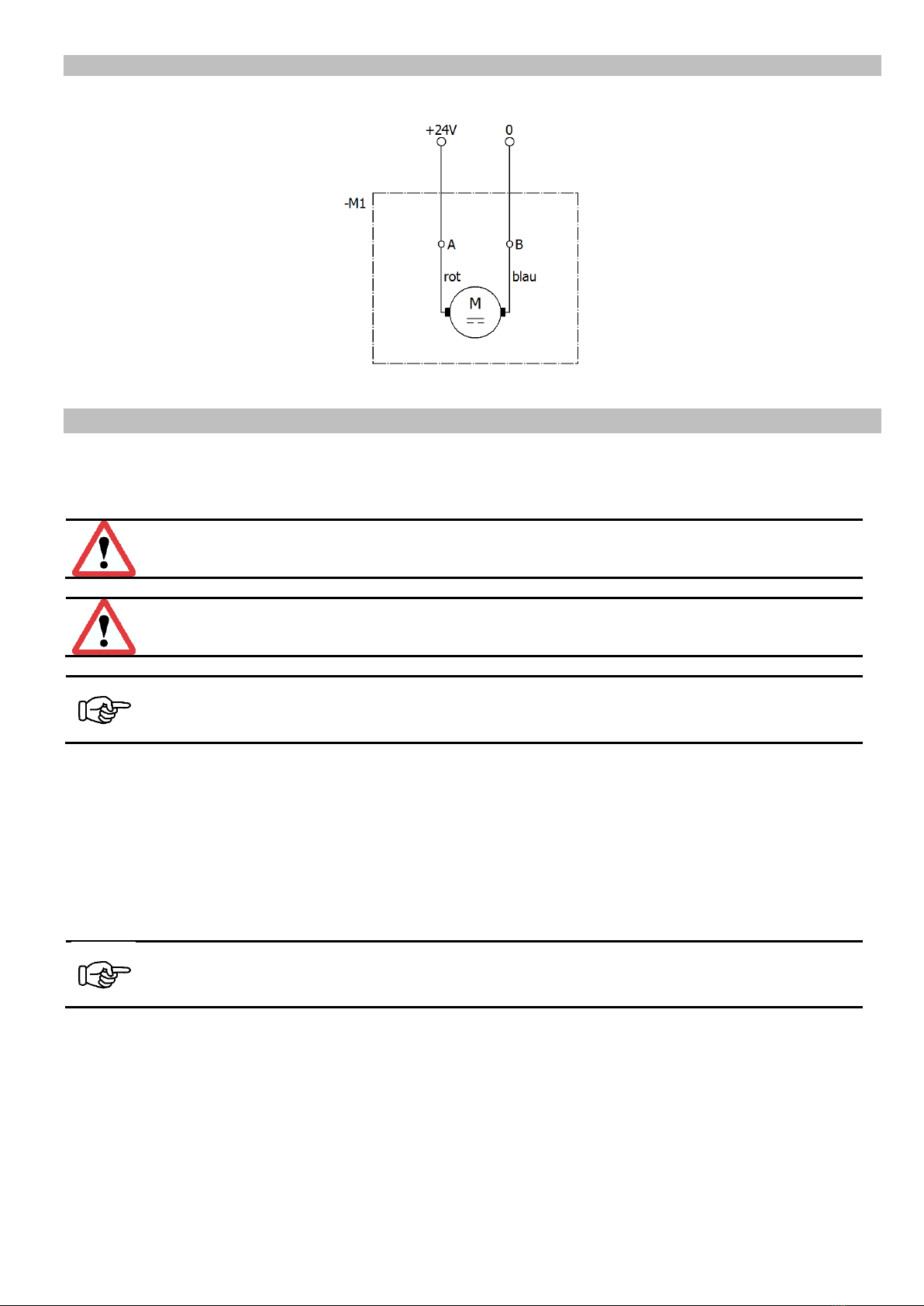

1.2. Motor connection diagrams................................................................................................. 4

1.2.1. Dunker / Rotek three-phase motor ............................................................................... 4

1.2.2. Dunker / Rotek AC motor ............................................................................................. 6

1.2.3. Engel DC motor............................................................................................................ 7

2. Safety directives..................................................................................................................... 7

2.1. Applicable directives and standards.................................................................................... 9

3. Design and functional description of belt conveyors .............................................................. 9

4. Shipment and installation ..................................................................................................... 10

4.1. Shipment........................................................................................................................... 10

4.2. Connecting the motor........................................................................................................ 10

4.3. Installation on supports ..................................................................................................... 10

5. Commissioning..................................................................................................................... 11

6. Maintenance......................................................................................................................... 12

6.1. Belt.................................................................................................................................... 12

6.2. Motor................................................................................................................................. 12

6.3. Gearbox ............................................................................................................................ 12

6.4. Return, drive and supporting rollers .................................................................................. 13

6.5. Environmental effects ....................................................................................................... 13

7. Spare parts and customer service........................................................................................ 13