Roark Tools XTR Series User manual

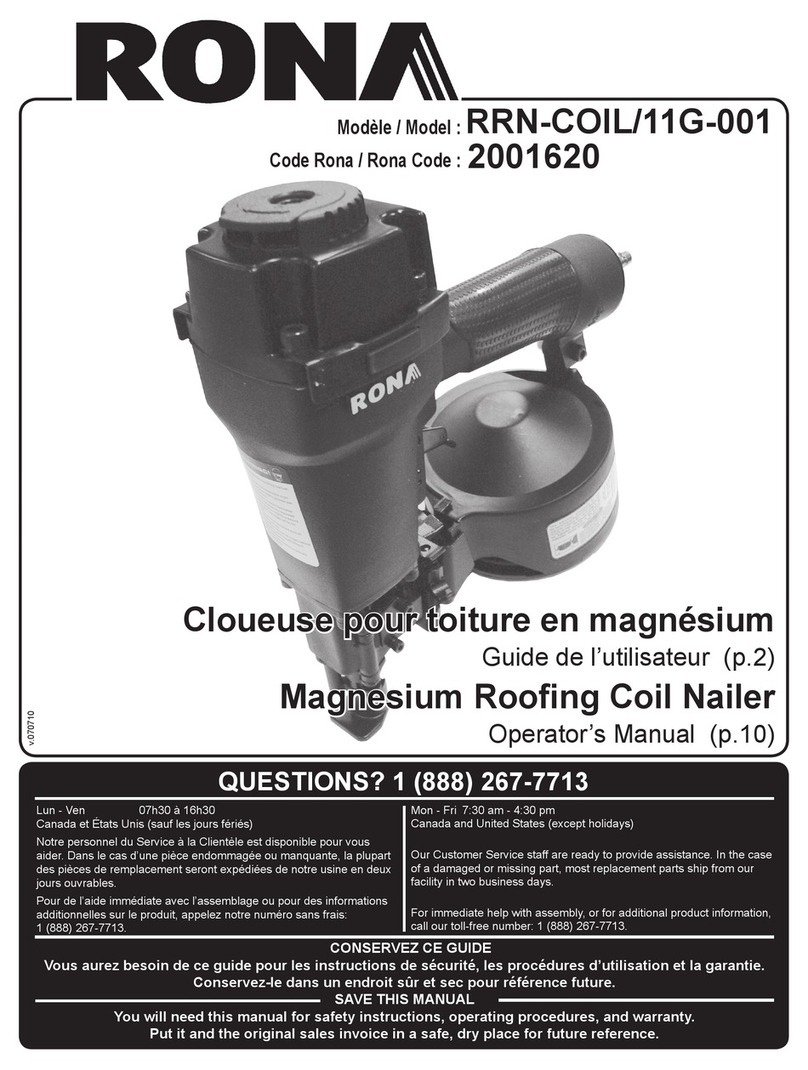

XTR SERIES PNEUMATIC WRENCH OPERATION

AND MAINTENANCE INSTRUCTIONS

Maintenance and Operation Manual For Roark Tools

XTR Pneumatic Torque Wrenches.

Roark Tools XTR Series Pneumatic Wrenches are designed for installing and removing thread fasteners

requiring accurate high torque during bolt installation and breakout.

Roark Tools is not responsible for customer modification of tools for applications on which Roark

Tools was not consulted.

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING TOOL.

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PLACE THE INFORMATION IN THIS

MANUAL INTO THE HANDS OF THE OPERATOR.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

The XTR tools contain alloy components which may

cause a hazard in certain explosive environments.

General Description of Roark Tools XTR Series

Pneumatic Torque Wrenches

Torque can be adjusted by regulating the amount of airflow to the torque wrench and by manipulating the air pressure

regulating valve at the Filter/Regulator/Lubricator Unit. On top, an airflow volume control is incorporated at the machine

providing an extended torque range. The accuracy of maintaining a selected torque is subject to the stability of your air

supply. An airflow of 40 SCFM(1.13 cubic metre/minute) guarantees optimum performance even within a non-protected

working

The XTR Series Pneumatic Torque Wrench provides torque settings of up to 5,000 FtLbs. clockwise and

counter clockwise rotation, random positioning of the tool due to its free joint execution.

The use of other than genuine Roark Tools replacement parts may result in safety hazards, de-

creased tool performance, and increased maintenance, and may invalidate all warranties.

Repairs should be made only by authorized personnel. Consult your nearest Roark Tools Authorized

Service center. Refer all communications to the Nearest Roark Tools Office or Distributor.

Noce

Noce

Warning

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY

Warning

USING THE TOOL

Keep Hands, loose clothing and long hair away from the reaction arm and working area during operation.

This tool will exert a strong reaction force. Use proper mechanical support and correct reaction arm positioning to

control these forces. Do not position the reaction arm so that it tilts the tool off the axis of the bolt.

Avoid sharp bends and kinks that will cause server back-up pressure in hoses and lead to premature hose failure.

Use only accessories recommended by Roark Tools.

Use only sockets Industrial Impact Sockets and Accessories.

Use only sockets and accessories that correctly fit the bolt or nut and function without tilting the tool off the axis of

the bolt.

This tool is not insulated against electric shock.

This equipment must not be operated or services unless the operator has read the operating instructions and fully

understands the purpose, consequences and procedures.

Always turn off the air and

disconnect the fitting before

installing, removing, or adjusting

any accessory on this tool, or

before performing any maintenance

on this tool.

Do NOT exceed

Maximum Pressure.

See Torque Chart.

Damage May Occur.

Always wear ear protection

when operating this tool.

The Torque Reaction Arm must be positioned against a

positive stop. Do not use the Arm as a dead handle.

Take all precautions to make certain the operator’s

hand cannot be pinched between the Arm and a solid

object.

Always wear eye protecon when operang or

performing maintenance on this tool.

Do not carry the tool

by the hose.

Keep body stance balanced

and

firm. Do not overreach when

operating this tool.

Do not use damaged, frayed or

deteriorated air/pneumatic

hoses and fittings.

!

Warning

Operation of the Equipment in Accordance with Specified Use

Depending on the working environment and how the XTR Series Pneumatic Torque Wrench is used, local health and

safety regulations may require you protective gear (i.e. Ear Protection, Safety Shoes, Hard Hat, Gloves, Coveralls, etc.)

In case external forces are exerted on the equipment, non-compliance with these regulations may result in injury. EAR

PROTECTION MUST BE WORN WHEN OPERATING THIS TOOL. When in continuous use the grip casing will cool

down considerably – operator should wear protective-working gloves as a consequence.

Operation of the Equipment in Accordance with Specified Use – Con’t

1. Inspect, maintain, operate and install the tool in accordance with all applicable standards and regulations (local, state, country, federal, etc.)

2. Do not remove any labels. Replace any damaged labels immediately.

3. Always use clean, dry air at 90 p.s.i.g. (6.2 bar/620kPa) maximum air pressure at the inlet. Higher pressure may result in hazardous situa-

tions including excessive speed, rupture, or incorrect output torque or force.

4. Be sure all hoses and fittings are the correct size and tightly secured.

5. Ensure an accessible emergency shut off valve has been installed in the air supply line, and make others aware of its location.

6. Install a properly sized safety air fuse upstream of hose and use an anti-whip device across any hose coupling without internal shut-off, to

prevent hose whipping if a hose fails or coupling disconnects.

7. Do not use damaged, frayed or deteriorated air hoses and fittings. Do not paint hoses.

8. Keep clear of whipping air hoses. Shut off the air compressor before approaching a whipping hose.

9. Always turn off the air supply, bleed the air pressure and disconnect the air supply hose before installing, removing or adjusting any accesso-

ry on this tool, or before performing any maintenance on this tool or any accessory.

10. Do not lubricate tools with flammable or volatile liquids such as kerosene, diesel or jet fuel. Use only Roark Tools recommended lubri-

cants.

11. Use only proper cleaning solvents to clean parts. Use only cleaning solvents which meet current safety and health standards. Use clean-

ing solvents in a well ventilated area.

12. Keep work area clean, uncluttered, ventilated and illuminated.

Safety Information When Using The Tool

1. When wearing gloves always be sure that the gloves will not prevent the throttle mechanism from being released.

2. Always wear eye protection when operating or performing maintenance on this tool.

3. Always wear hearing protection when operating this tool.

4. Always use Personal Protective Equipment appropriate to the tool used and material worked. This may include dust mask or other breath-

ing apparatus, safety glasses, ear plugs, gloves, apron, safety shoes, hard hat and other equipment.

5. Prevent exposure and breathing of harmful dust and particles created by the tool use.

a. Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

I. Lead from based paints

II. Crystalline silica from bricks and cement and other masonry products

III. Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work

in a well ventilated area, and work with approved safety equipment, such as dust masks that are specially designed to filter out microscopic

particles.

6. Keep others a safe distance from your work area, or ensure they use appropriate Personal Protective Equipment.

7. Be aware of buried, hidden or other hazards in your work environment. Do not contact or damage cords, conduits, pipes, or hoses that may

contain electrical wires, explosive gases or harmful liquids.

8. Keep hands, loose clothing, long hair and jewelry away from working end of tool.

9. Power tools can vibrate in use. Vibration, repetitive motions or uncomfortable positions may be harmful to your hands and arms. Stop using

any tool if discomfort, tingling feeling or pain occurs. Seek medical advice before resuming.

10. Keep body stance balanced and firm. Do not overreach when operating this tool. Anticipate and be alert for sudden changes in motion, re-

action torques, or forces during start up and operation.

11. DO NOT USE THIS TOOL WHEN TIRED, UNDER THE INFLUENCE OF MEDICATION, DRUGS OR ALCOHOL.

12. Never use a damaged or malfunctioning tool or accessory.

13. Do not modify the tools, safety devices or accessories.

14. Do not use this tool for purposes other than those recommended.

15. Never exceed rated RPM of tool.

PLACING THE TOOL IN SERVICE

1. Must ensure air line is not connected to tool before following the following steps.

2. Ensure the reaction arm is properly attached and secured to splined section on the torque tool.

3. Select your desired square drive size and bolt/nut AF size impact socket or hex-drive socket for use.

4. Secure impact socket on tool square drive with lock pin and securing safety BUNA-N (NITRILE)

O-ring on socket.

5. Use a quality Filter/Lubricator/Regulator Unit that meets airflow requirements or use

For Long Life of the Air Motor,

Use A Quality F/R/L Unit.

Make Sure Airflow Require-

ments are Met

Lubricator Provides Oil to Air

Motor

Filter Serperates Water To Ex-

tend Life of Motor Vanes

An Air Pressure Regulator To

Accurately Set Torque Settings

Important

OPERATING PROCEDURES

Setting Torque on XTR Series Torque Wrenches

1. Torque depends on the air pressure exerted on the air motor under load. Adjusting the F/R/L Unit

Regulator Knob initially sets torque. To decrease torque output turn regulator counter-clockwise to

lower air flow/pressure. All XTR are shipped calibrated per ROARK TOOLS Procedures.

2. Check for Desired Torque Setting for your selected model on the supplied torque chart. On the XTR

F/R/L, adjust air pressure by using the air regulator knob for desired pressure/torque. With the XTR

Series Torque Wrench under load (not on the nut/bolt), press the toggle switch. Once pressure is set

for desired torque output and airflow/pressure, push in on regulator knob to lock unit. While the XTR

Series Torque Wrench is under load, running at free speed (not on the nut/bolt), adjust the XTR F/R/L

pressure at the same time.

A. Setting torque for Bolt Tightening

1. Establish the air pressure required using the Torque Calibrated Chart. Provided with the tool.

2. Push Trigger using tightening Direction per A on below diagram.

3. Adjust the regulator until the correct pressure is shown on the gauge by turning adjustment knob

clockwise.

B. Setting torque for Bolt Loosening

1. Establish maximum air pressure from the Torque Chart.

2. Push Trigger using loosening Direction per B on below diagram.

3. Set the air pressure the same as with tightening.

After extended use of the XTR Series Torque Wrench, Air Pressure Setting should be rechecked and may

require minor adjustment. This is usually caused by variations in your air supply unit providing your airflow

to F/R/L Unit or due to weather conditions.

Within the very first hours of operation a slight amount of grease may leak through the equipment casing.

In this case remove excess to avoid risk of slipping while running the equipment or – for some specific

applications – environmental pollution.

In case of degrading performance or other apparent damage immediately send your XTR Series Torque

Wrench to Roark Tools or contact your Local Representative or Distributor. Unit must be properly pack-

aged for shipping.

Noce

Warning

Important

Unauthorized manipulation of air motor, valves, & F/R/L Unit or tampering with either will result

in loss of warranty! Also for the life of your Roark Tools XTR Series Torque Wrench air supply

should be clean and free of particles, water and other remains. Pollution of hose couplings or

aggressive substances reaching air motor via the supply hose may cause damage to air motor

vanes. Use approved F/R/L Units to obtained oil-enriched and filtered supply. Non-compliance

with the specified operating air pressure will result in higher wear of the motor. Degradation in

performance is likely to result. Also for extreme cold weather use approved cold weather pneu-

matic lubrication to prevent freeze ups

Operang Procedures

Important

Warning

Beware of low-pressure air components. Do not fold or bend the supply hose excessively and

check for damage before use. A damaged hose must not be used, as there is a risk of a hose

burst. This may lead to a wildly lashing hose with a risk of personal injury. Also check air fitting

and connections tightness or damage.

Tightening and Loosening of Nuts or Bolts

Warning

Beware of non fixed freely rotating Reactions Arms or of rotating impact sockets.

Loose clothes, long hair, calbes, etc. are always to be kept away from danger/rotation area. When the

machine is put into operation wearing ear protection, safety shoes and safety glasses is mandatory.

Never Leave a running Pneumatic Torque Wrench unattended and always be ready to switch off the

machine if necessary. Maintain a safe distance of an arms length.

Always place the impact socket or hex driver snugly on the nut or bolt. Faulty nut or bolt connections

may result in exceeding the mechanical stress limit of the material, causing it to break. Parts splintering

off may cause bruises or even life-threatening injuries.

Due to emission of an air-oil mixture, a breathing mask must be worn, especially wen working overhead

in tight secluded spaces.

During Tightening and Loosening of fasteners, always hold/position the XTR Series Torque Wrench perpen-

dicular to fastener axis (in line with the fastener axis...or perpendicular to the nut/bolt head), since either the

impact socket or hex driver and the nut/bolt to be worked on may be deformed or damaged otherwise. Further-

more a safe counter reaction point may not be achieved or cannot be guaranteed any longer. See Illustration

on following page.

The indicated calibrated torque settings have to be considered only as a guideline. Because of variations

in pressure and or mass flow of supply air as well as different screwing applications (soft/hard) deviations

from the normative setting may occur. Due to the CFM required when the tool is running at Free Speed, it

may not be possible to set the regulator to the desired pressure due to air pressure drop off. The CFM

requirement is lower once the tool is under load, so if this happens, set the regulator to the desired PSI

without the tool running. Try tightening down the fastener and check the PSI when the tool stalls. If the

tool stalls at the PSI setting, the desired torque has been reached. If it has stalled before, try adjusting

regulator higher until the correct stall PSI is reached.

Noce

Because of the high mechanical stress on the XTR air motor it

is essential to provide the F/R/L Unit with sufficient oil supply.

Non-compliance risks the damage of the vanes of the air mo-

tor. Enriching the supply by adjusting the oil feed on the F/R/L

to 2 to 3 drops per minute will suffice for heavy continuous

equipment use.

1. Place your XTR Series Torque wrench completely over

and on the fastener to be tightened or loosened. (4)

2. Ensure the reaction area / moment is taken up by the Re-

action arm (5). Also ensure reaction is stable and will

support counter torque.

3. Hold XTR Series Torque Wrench perpendicular to fasten-

er axis (6) for the complete duration of rotation process for

tightening or loosening.

4. After depressing the trigger (3) on the piston grip, when

tightening the fastener the Tool will rotate until it becomes

torqued and the XTR Series Torque Wrench Will then

Stall Out

5. The direction will then need to be switched by pressing

counter clockwise button on back of air motor. Then the

trigger will need to be pressing the trigger to release coun-

ter torque load off off the reaction arm. Once this is done

you can move the wrench to the next fastener.

6. For loosening a fasterner, the unit will continue to rotate until the fastener is removed or when fastener is loose by hand

you can stop and move to next fastener.

7. Continue the process for tightening and loosening for each fastener you require.

8. If torque requirements require your application to go in torque increments, then set the XTR Series Torque Wrench to

your first Torque Requirement. Tighten fastener as per your required tightening bolt sequence. Then reset for next setting

on F/R/L unit by adjusting regulating knob.

9. Your personnel can be trained by your Roark Tools Representative or Distributor on use of this product if so desired.

Changing Accessories on the XTR Series Torque Wrench

1. Remove XTR Series from work and back off the regulator knob to decrease the pressure to zero

while depressing toggle switch.

2. Disconnect the air hose to the XTR Series Torque Wrench.

3. Remove and change socket or accessory adaptor for next project. Insure socket or accessory is

properly secured to square drive the locking pin and safety securing the o-ring.

.

Beware of components under pressure. Inadvertent activation of the torque wrench may lead to both a risk of injury as

well as damage to property. When detaching the supply air hose always shut off air to supply first. Non-compliance

with procedure may result in an out of control supply hose thus risking injury personal injury and damage to property

Storing Your XTR Series Torque Wrench

1. Shut off pressurized air to the F/R/L by turning off the air to the F/R/L Unit.

2. Bleed off air by depressing trigger on Pistol Grip.

3. Disconnect Supply Hose to F/R/L and Disconnect air hose at XTR Series Motor.

4. If the XTR Series Torque Wrench is not to be used for an extended period of time, spray pneumatic

lubricating oil into XTR Series Fitting. Reconnect air hose and supply of R/R/L Unit air Inlet Fitting.

Cycle the XTR Series Unit momentarily to ensure good quality amount of lubricating has entered into

air motor. Then stop and shut-off the system as previously mentioned above and store your XTR

Series Torque Wrench in the case that it was shipped in.

Warning

Noise and Vibrations

Sound pressure level, measured in accordance OSHA & German Machinery Noise Information Leaflet-3-

GSGV requirements dated 18 Jan 1991, §1, (1 e) at maximum equipment performance is just over 85 dB

(A). In accordance with §1, (2) of the same leaflet sound pressure levels were measured for different

work cycles, with the sensor at a distance of 1 meter to the geometric center of the machine. Vibrations

become moderate just prior reaching the pre-set torque value. On request XTR Series Pneumatic

Torque Wrenches with lower sound pressure levels (<85 dB(A)) are available as a special modification.

Because this modification comprises a sound absorber, relevant torque values and rpm speed may

change on given unit.

SAVE THESE INSTRUCTIONS. DO NOT DESTROY.

Noce

Table of contents