Pneumatic presses series M

3

TABLE OF CONTENTS

1 INTRODUCTION.............................................................................................................................................................................................5

2 INTENDED USE OF PNEUMATIC PRESS...................................................................................................................................................5

3 GUARANTEE....................................................................................................................................................................................................5

4 Health and safety .........................................................................................................................................................................................5

4.1 Meaning of the symbols............................................................................................................................................................................. 5

4.2 General safety precautions.......................................................................................................................................................................6

4.3 Safety devices................................................................................................................................................................................................7

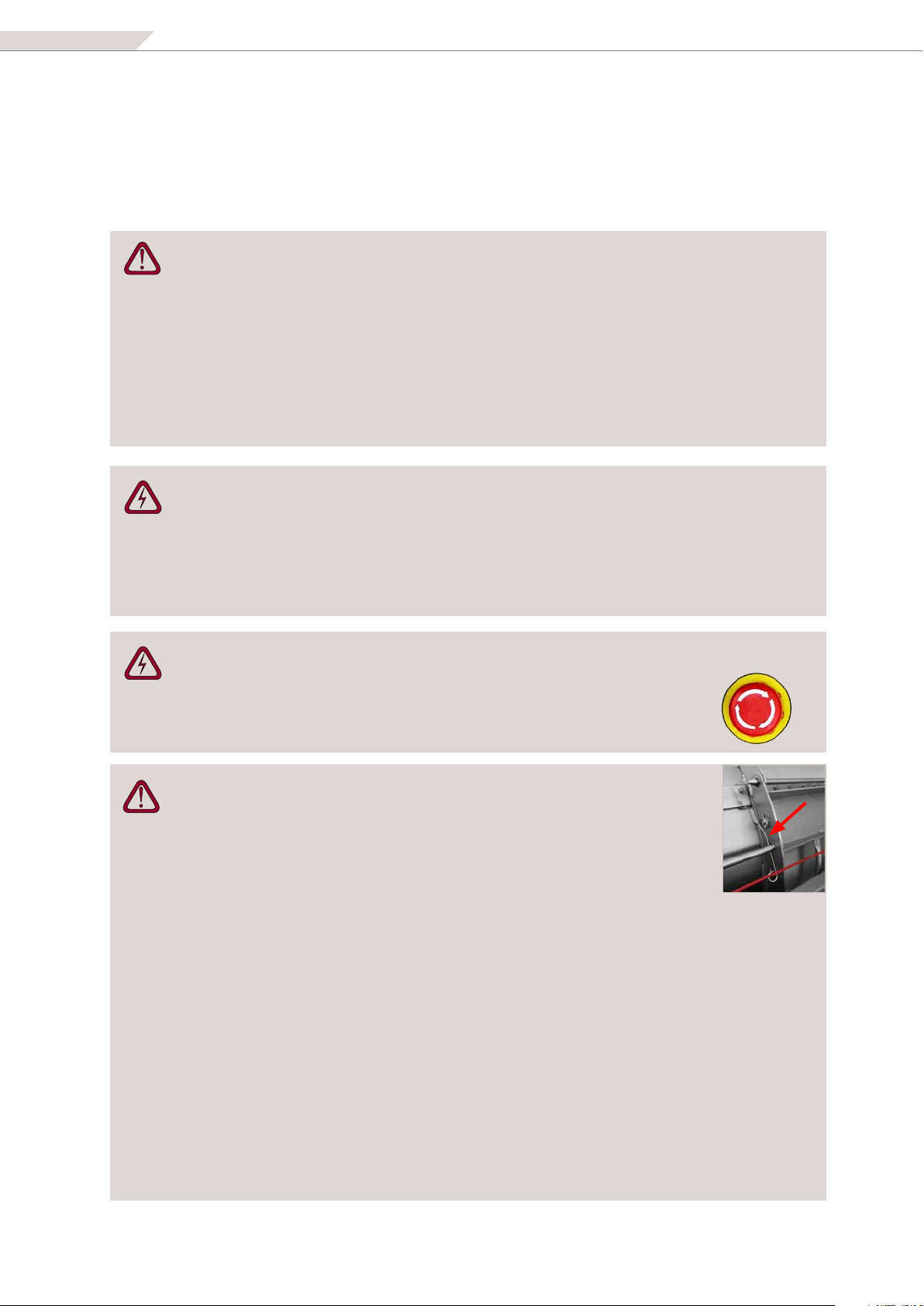

4.3.1 Emergency STOP button.............................................................................................................................................................7

4.3.2 Safety cord .......................................................................................................................................................................................7

4.3.3 Protection against overpressure in the drum....................................................................................................................... 7

4.3.4 Overload relays...............................................................................................................................................................................8

5 PRESS TRANSPORT AND SETTING UP.....................................................................................................................................................8

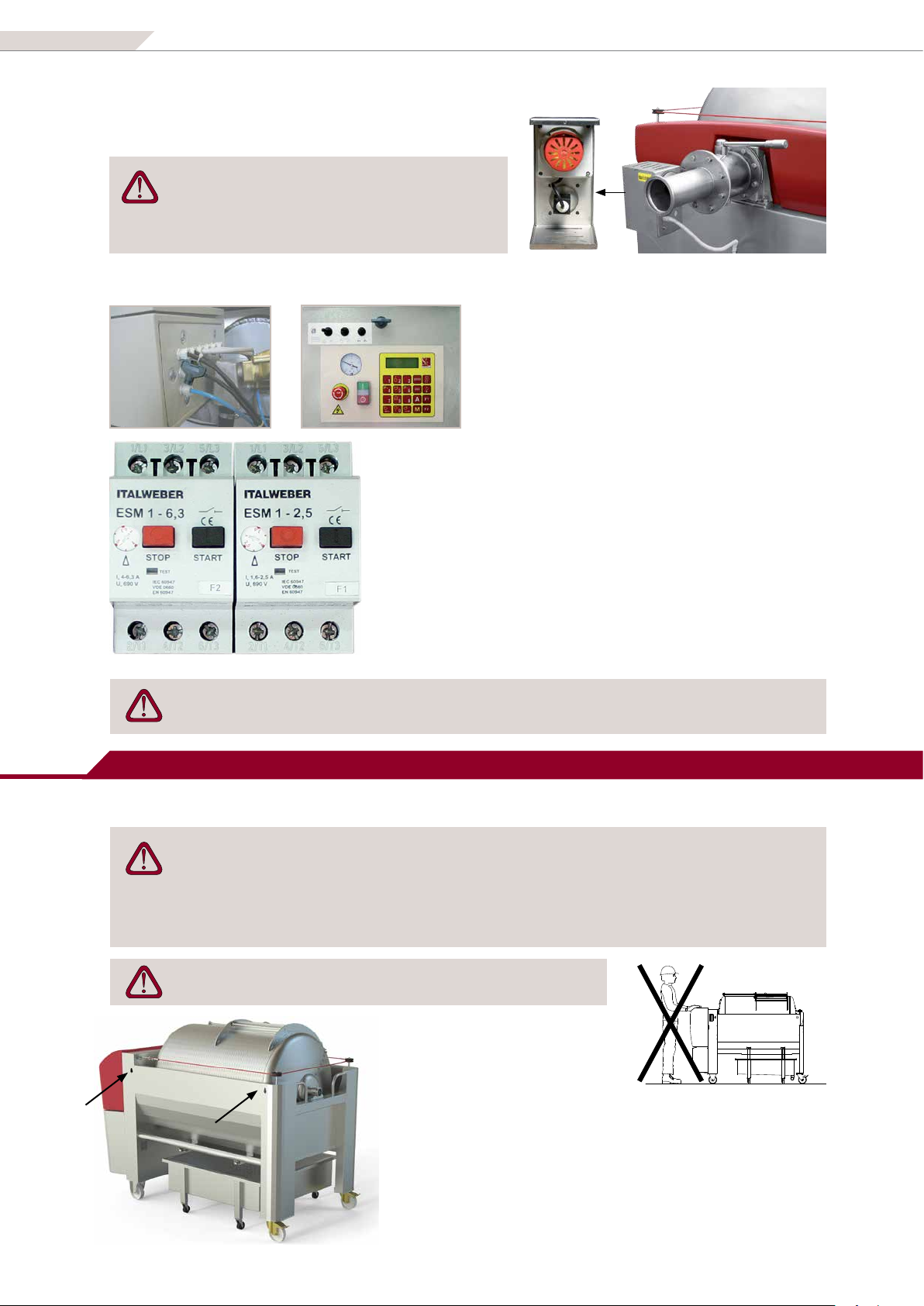

5.1 Transport of the press.................................................................................................................................................................................8

5.2 Mounting and storage of the press........................................................................................................................................................9

6 SWITCHING ON THE PRESS ..................................................................................................................................................................... 10

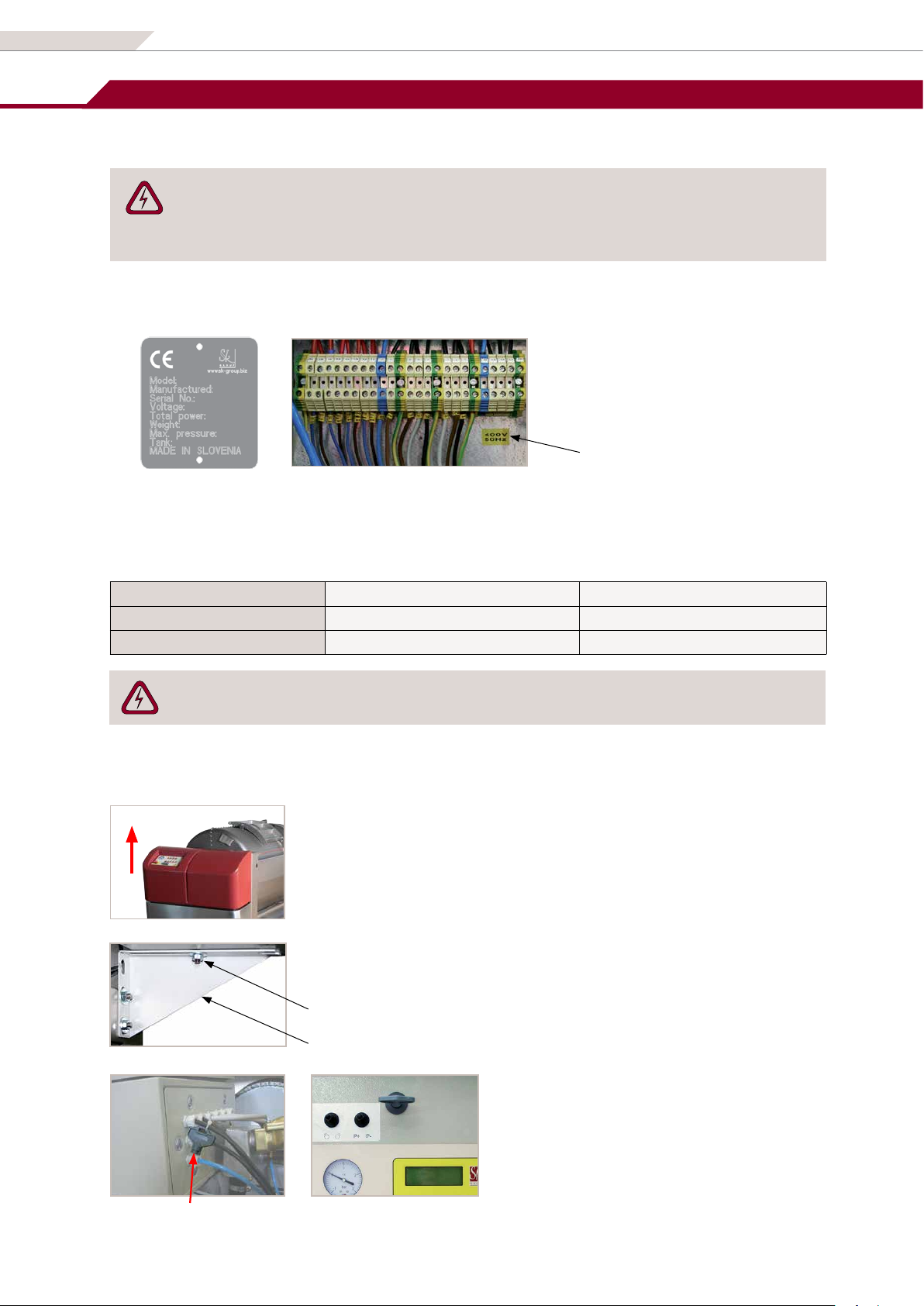

6.1 Electrical connection.................................................................................................................................................................................10

6.2 Rotating direction of the drum..............................................................................................................................................................11

6.3 Press orientation.........................................................................................................................................................................................11

7 GENERAL DATA............................................................................................................................................................................................12

7.1 Technical data (dimensions and capacity) .........................................................................................................................................12

7.2 Pneumatic press operation.....................................................................................................................................................................13

8 DESCRIPTION OF THE PNEUMATIC PRESS...........................................................................................................................................14

8.1 Components ................................................................................................................................................................................................14

8.2 Built-in components..................................................................................................................................................................................14

8.3 Materials........................................................................................................................................................................................................15

8.4 Sliding hatch ................................................................................................................................................................................................15

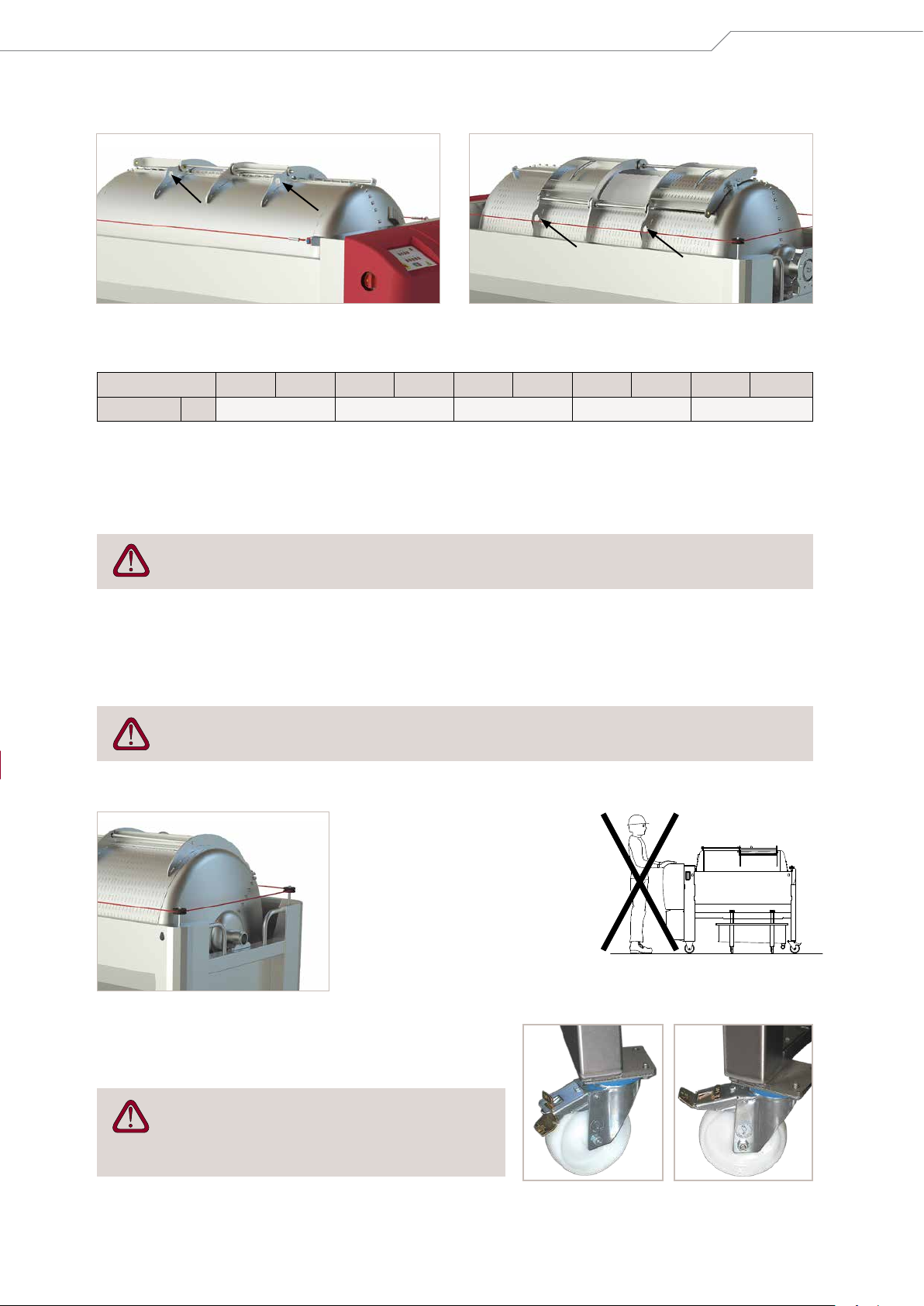

8.5 Press drum....................................................................................................................................................................................................16

8.6 Juice collection pan...................................................................................................................................................................................16

8.7 Control box...................................................................................................................................................................................................17

8.8 Optional equipment..................................................................................................................................................................................18

8.8.1 Strainer on the collection pan outlet ....................................................................................................................................18

8.8.2 Level switch in the collection pan..........................................................................................................................................18

8.8.3 Equipment for macaration (only models PST)....................................................................................................................18

8.8.4 Cooling jacket (as an option in PST models) .......................................................................................................................20

9 OPERATING THE PRESS ............................................................................................................................................................................ 22

9.1 Before use .....................................................................................................................................................................................................22

9.2 Filling of the press......................................................................................................................................................................................22

9.2.1 Filling the press through the hatch........................................................................................................................................22

9.2.2 Filling the press through the central filling connector....................................................................................................22

9.3 Selecting the pressing program............................................................................................................................................................24

9.4 Discharging the press ...............................................................................................................................................................................24

10 CLEANING OF THE PNEUMATIC PRESSES........................................................................................................................................... 25

10.1 Cleaning of the drum interior.................................................................................................................................................................25

10.1.1 Presses with no cleaning opening (PS_5, PS_8) ................................................................................................................25

10.1.2 Presses with a cleaning opening (PS_10, _12, _16)...........................................................................................................26