Robertson Harness CRC 600 Series User manual

Robertson Harness

Fort Collins, Colorado

www.RobertsonHarness.com

(970) 682-4470

Usage & Applications

▪

Date Inspected Pass/Fail Comments Signature

▪

▪

▪

Requirements ▪

▪These items are designed to connect the user to a suitable fall protection

anchor to avoid or limit a fall, and may also allow for safe attachment ▪

to appropriate pulley used in zip line and canopy tours. ▪

▪Anchorages selected for personal fall arrest systems must be capable

of sustaining a 5,000 lb. (22.2 kN) static load or twice the maximum arrest ▪

force permitted on the system.

▪These items are designed for a single user unless otherwise specified.

▪Lanyard connections to the harness must be approved connectors to the ▪

appropriate fall arrest attachments on the harness.

▪Robertson Harness recommends a "before use" visual inspection, along

with an annual examination of general condition and function ▪

to be carried out and recorded by a Third Pary "Qualified Person."

Qualifications ▪

▪The Dorsal connection passed ANSI/ASSE Z359.11-2014 Safety Requirements

for Full Body Hanresses for Fall Arrest applicatons

▪This product has been pull tested to >5000 lb. (22.24 kN) ▪

▪Complies to PRCA/ANSI 1.0-1.3 5000 lb. (MBS) minimum breaking strength ▪

▪Complies to ANSI Z359.1 required 5000lb. Breaking strength.

▪Meets and Exceeds ASTM F-1772 Standard Specification for harnesses

used in Rescue, Safety, and Sport Activities. ▪

▪Qualifies ASTM F-1772 12.1.3 Full Body Harness

▪Meets and exceeds CE qualifications and standards.

Inspect harness to ensure that it is in a serviceable condition.

Check webbing for visible signs of wear and tear such as: wear, cuts

burns, frayed edges, or other damage.

Inspect to ensure that all buckles work properly and that they do not

Hand wash the harness in cool water with small amounts of mild soap.

Rinse thoroughly to remove all soap residue. Failure to remove all the

soap will leave webbing stiff and will need to rinsed again.

Do not wash webbing in Woolite.

Repairs or modifications made by anyone other than Robertson

Harness Inc. will void all warranties and liability.

Service Life

Please see the our Service Life documentation for more detail.

Inspect all stitching for abrasion, discoloration and wear to ensure

integrity.

These instructions are provided to the user by the manufacturer and should be saved

for Future Reference.

Users and Operators need to maintain a log of identifying

Remove from service and destroy if the equipment has been exposed

Maximum capacity of harness is 310 lbs. per

ANSI/ASSE Z359.11-2014

Thoroughly inspect harness after any period of extended storage.

Discontinue use of product if it has come in contact with any corrosive or caustic

chemical agents such as acids, bleach, or petroleum products.

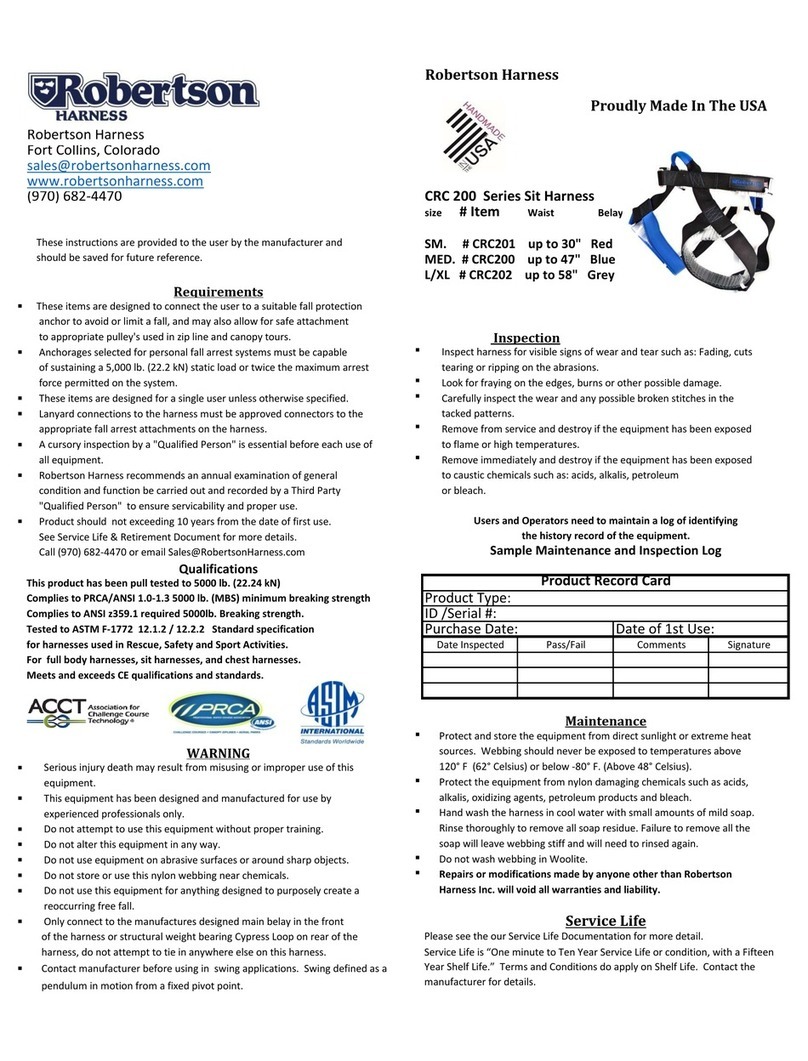

SM. # CRC601 Red - Up to 30" waist / 5'3" Max Height

the history record of the equipment.

alkalis, oxidizing agents, petroleum products and bleach.

M/L. # CRC600 Blue - Up to 47" waist / 6'3" Max Height

L/XL # CRC602 Grey - Up to 58" waist / 6'11" Max Height

Robertson Harness

Proudly Made In The USA

CRC 600 Series w/ Adjustable Dorsal

Full Body Hanresses

Safety Requirements for

Tested to : ANSI / ASSP Z359.11-2014

Inspection

This harness is a basic ANSI rated harness designed specifically for use in the zip-line /

adventure park industry to meet industry standards for workers and customers at

height if Fall Protection is required. The Dorsal D ring is easily adjustable on rear of

the chest. (Rated for Fall Arrest ) Should be used for all Class III full body fall arrest

applications. Attach only ANSI compliant lanyards and shock absorbing/decelerating

devices to dorsal D ring Attachment points on the back dorsal. Maximum free fall

distance is dictated by type of fall protection lanyard or system utilized. Following

current ANSI specifications, Dorsal attachment allows for 6 or 12 ft. free fall if utilizing

energy absorbing lanyards designed for 6 or 12 ft. free fall. Ensure complete

inspection and qualified person verification of fall protection system to meet needed

protection. The "Front" Connection or Belay is for "Suspenstion & Descent Control"

and "ladder access." The "Rear" structural loop and "Front" Belay loop are rated for

"Work Positioning" fall restraint. Harnesses belays are color coded to easily

distinguish sizing. This harness was designed for workers and customers at height in

need of a Dorsal "Fall Arrest" rated connection for leap applications or if able to fall

more than 2'. This harness is intended to support a customer while attached to the

belay loop on the front of the harness for fall restraint. The Dorsal if able to fall

more than 2' - fall arrest. This harness was not intended for use in any SUPERMAN

syle attachments or inverted attachments of ride customers.

Maintenance

Protect and store the equipment from direct sunlight or extreme heat

sources. Webbing should never be exposed to temperatures above

120° F (62° Celsius) or below -80° F. (Above 48° Celsius).

Protect the equipment from nylon damaging chemicals such as acids,

Product Record Card

Product Type:

ID /Serial #:

Purchase Date:

Date of 1st Use:

have any sharp edges, burrs, cracks, or corrosion.

Sample Maintenance and Inspection Log

to flame or high temperatures.

Service Life is “One minute to Ten Year Service Life or condition, with a Fifteen

Year Shelf Life.” Terms and Conditions do apply on Shelf Life. Contact the

manufacturer for details.

WARNING

▪Serious injury or death may result from misuse or improper use of this

equipment.

▪This equipment has been designed and manufactured for use by

experienced professionals only.

▪Do not attempt to use this equipment without proper training.

▪Do not alter this equipment in any way.

▪Do not use equipment on abrasive surfaces or around sharp objects.

▪Do not store or use this nylon webbing near chemicals.

▪Only connect to the Harness in the way the Manufacture designed/designated.

▪Contact manufacturer before using in swing applications. Swing defined as a

pendulum in motion from a fixed pivot point.

▪

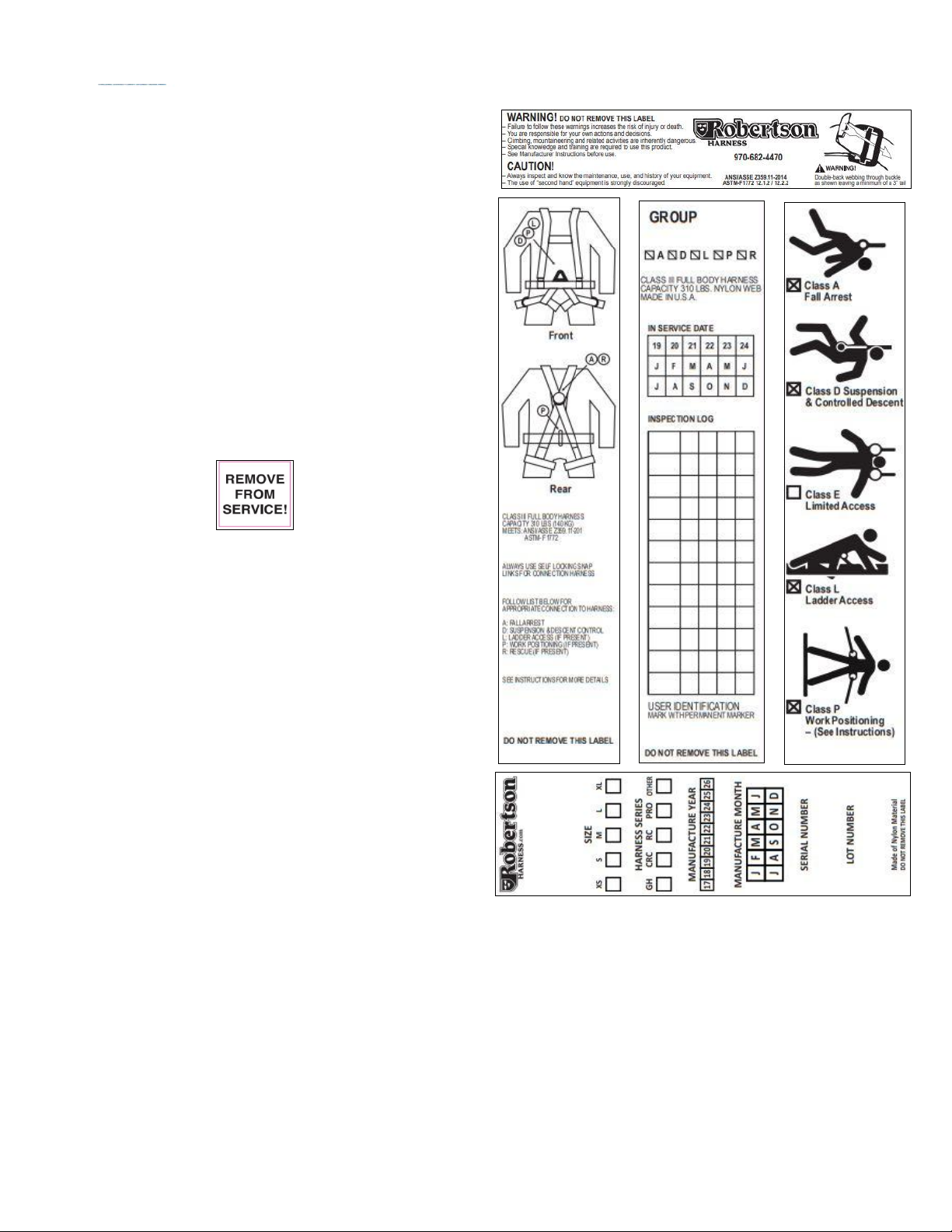

This harness is equipped with a fall arrest indicator and label located just below the

rear dorsal D-ring on the inside of the

webbing that connects the rear of the chest to the rear of the seat portions of the

harness. The label reads REMOVE FROM

SERVICE! If this label is present after a fall occurs, this harness must be immediately

removed and retired from service

▪

This harness has an allowable stretch of 25 inches (63 cm). The user of this harness

must have a safe working distance below them of at least 25 inches (63 cm).

Before Use

The techniques employed in the proper and safe use of this equipment may only be learned

through personal instruction received from an instructor who is well-qualified in all phases

of vertical rope work. Such instruction will include an evaluation of your comprehension

of, and ability to perform the tasks required to safely and efficiently use this equipment.

Never attempt its use until you have received such instructions and are believed competent

by your instructor.

Donning and Fitting the Harness

First inspect the entire harness: See Maintenance, Service, Storage.

▪Step 1: Locate the rear fall arrest D ring located on the rear of harness. Hold the harness

up by this D ring and ensure the straps are not twisted.

▪Step 2: Loosen all adjuster buckles by lifting up on the side tabs located on the front of

the buckle. Adjuster buckles are located on the front of harness waist, on the legs, rear legs,

Dorsal, shoulder straps, and chest strap. Unlace the chest strap.

▪Step 3: Step in to the seat portion of the harness allowing the shoulder straps to hang to

their prospective sides. Tighten the waist portion of the harness to be snug.

▪Step 4: Pull the shoulder straps over your shoulders like putting on a vest. The D ring

should be positioned between the shoulder blades. Lace the chest strap back through

Roll Out

the camlockbuckle as pictured on the "warning label."

▪Step 5: Make certain straps are not tangled and hang freely. Adjust all buckles to be snug

starting with the leg straps, then waist, shoulders, and chest. Always adjust the harness

from the legs working up the harness. It is not necessary to tie-off any adjuster buckles

on this harness.

*Ensure when tightening Buckles you are tightening parallel to the direction of buckle.

Roll out occurs when a hook is snapped into an undersized ring or non-compatible

shaped connector (D ring) causing the hook's gate or keeper to accidentally open and

release. Self-locking and or self closing connection carabiners should be used to

Labeling - Do Not Remove From Harness (located on rear waist)

reduce the possibility of roll out. Do not attach two snap hooks onto one D ring.

After a Fall

Harnesses which have been subject to forces involved in arresting a fall must be

removed from service and destroyed.

When using a hook to connect to an anchor or when coupling components of a

system together. Be certain accidental disengagement "ROLL OUT" cannot occcur.

Limited Warranty

Robertson Harness warrants for one year from the purchase date and only to the original

retail buyer that our products are free from defects in material and workmanship. If the buyer

discovers a warranty related defect, the buyer should return the product to Robertson

Harness. Robertson Harness reserves the option to repair or replace any product returned Date Inspected Pass/Fail Comments Signature

under warranty. That is the extent of our liability under this warranty and, upon the expiration

of the applicable warranty period, all such liabilty shall terminate.

Warranty Exclusions

Robertson Harness does not warrant products against normal wear and tear, unauthorized

modification or alteration, improper maintenance, accident, misuse, negligence, damage, or

if the product is used for a purpose for which it was not designed. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

Except as expressly stated in this warranty, Robertson Harness shall not be liable for direct,

indirect, incidental, or other types of damages arising out of, or resulting from the

use of the product.

Warning

Products manufactured by Robertson Harness are intended for use by professionals

trained and experienced in the use, inspeciton, and maintenance of these products. Many

products which Robertson Harness manufactures are used in high angle environments

which pose a very substantial risk of serious injury or death. You must read and

understand all the manufacturer's instruction before use. Any person purchasing this

equipment assumes all risk for any injury or damage sustained while using any of this

equipment. Failure to follow these warnings increases the risk of injury and death.

Keep this user instructions/information sheet as a permanent record

after it is separated from the harness/belt, and make a copy to be kept

with the harness/belt.

It is suggested that the user refer to this user information sheet before and after each use

of the harness/belt.

Do not alter or intentionally misuse this harness in any way. Any alterations or repairs to

this harness should be conducted by the manufacturer only.

Use caution when using this equipment around moving machinery, electrical hazards, sharp

edges, chemical hazards and high heat environment or flame. Carry the harness/belt

where it will be protected as the harness/belt could melt or burn and fail if exposed to flame

or high temperature.

If you have any questions concerning the condition of your harness/belt, or have any doubt

about putting it into service contact manufacturer.

Robertson Harness

216 Commerce Drive Unit B

Fort Collins, CO 80524

Phone - 970-682-4470

Fax - 970-682-4126

www.RobertsonHarness.com

ID /Serial #:

Purchase Date:

Date of 1st Use:

Product Record Card

Product Type:

This manual suits for next models

3

Other Robertson Harness Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Lanex

Lanex PB-20 instruction manual

SKYLOTEC

SKYLOTEC ANCHOR ROPES Instructions for use

Besto

Besto Buoyancy Aid 50N Instructions for use

TEUFELBERGER

TEUFELBERGER NODUS Manufacturer's information and instructions for use

Troy Lee Designs

Troy Lee Designs Tbone Product owners manual

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Salewa

Salewa MTN SPIKE user manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual