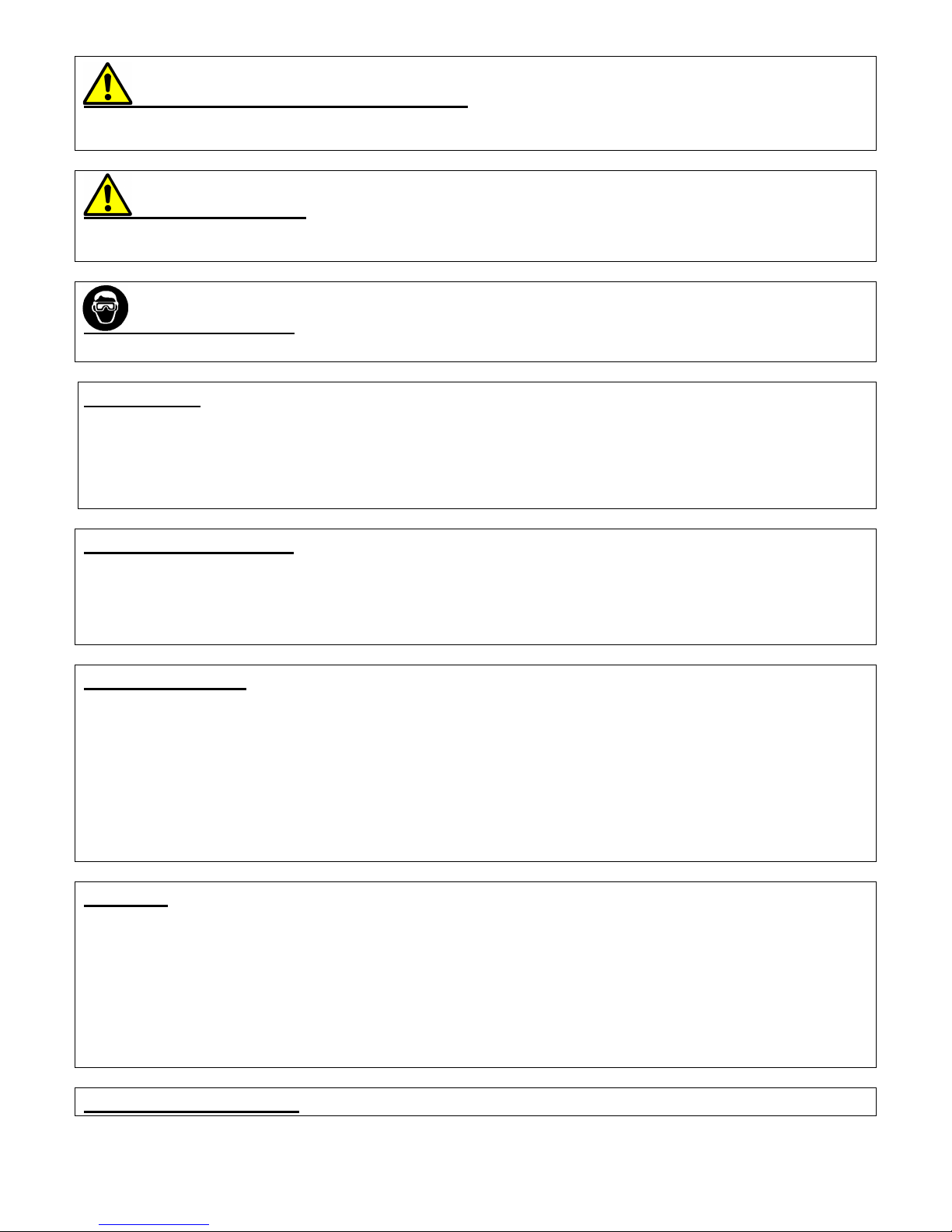

H– Detergent Dial – Allows you to switch between

different detergents without stopping.

I– Detergent Tank Caps – Take these caps off to fill

either detergent tank with pressure washer

approved detergent.

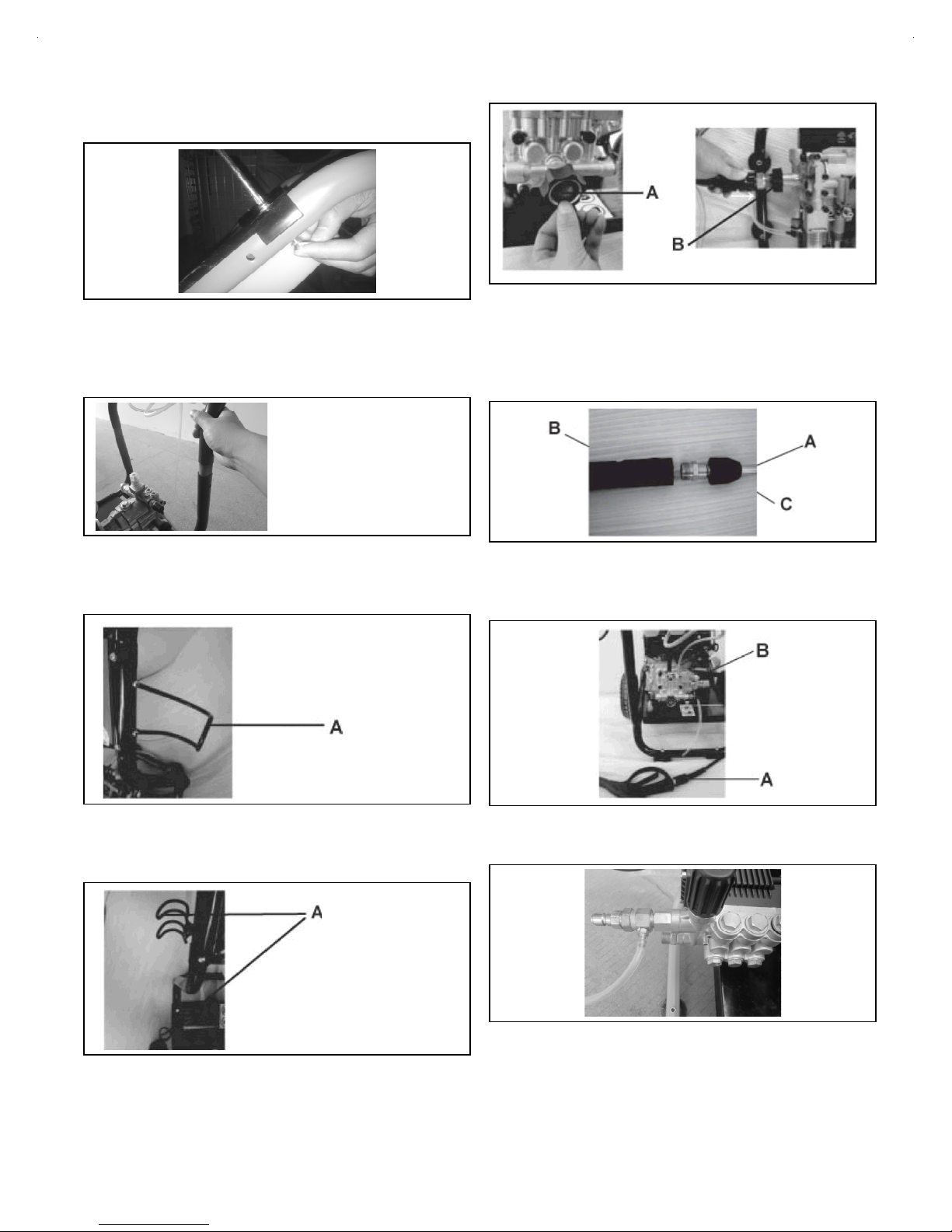

R– Pump – Increases the water pressure.

S– Spark Plug –Should be checked every 100 hours

of operation.

T– Pump outlet – Attach your pressure hose here.

ASSEMBLY & PRE-START CHECK

Before assembling or starting pressure

washer, ensure entire manual has been read.

UNPACK BOX: Remove all parts from box and

remove all bubble wrap and other packaging

materials.

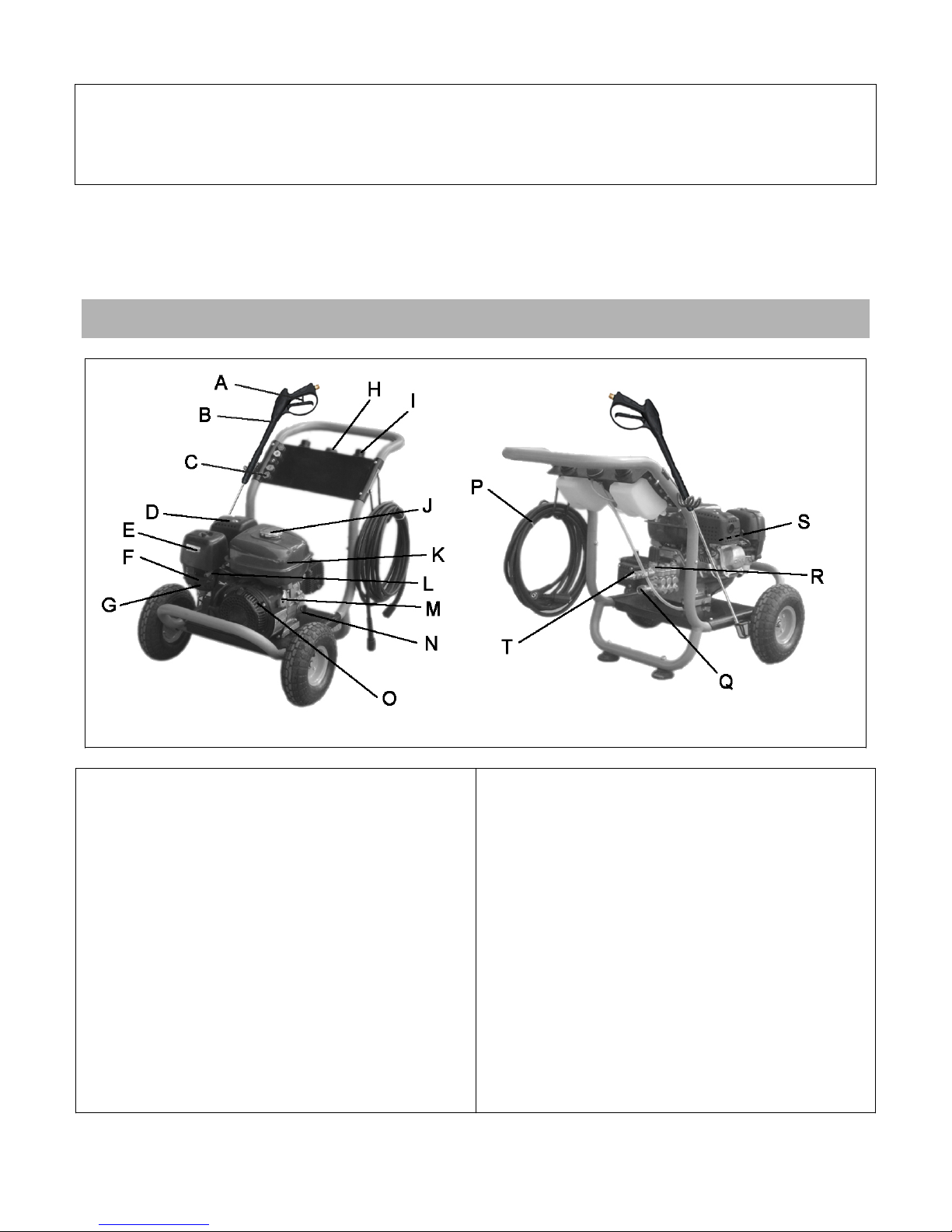

CONTENTS OF BOX:

REF Part Description

A Wheel with axle

B Metal pressure gun and Metal

wand

C 30 ft pressure hose

D Main body of pressure washer

E Pressure washer handle with

5pcs Spray nozzles.

F Gun supporter, Hose

supporter

G Bolts_2(M6_40), Nuts_2(M6) ,

Washers_4 (_6) , Manual_1 ,

Spray tip cleaner_1 , Spark

plug wrench_1 , Screw

driver_1 , Pump Breather_1 ,

O-ring (2 for high pressure

hose, 1 for tip quick connector)

WARNING! Before attempting to start

pressure washer, ensure you complete the

following important steps.

1) Fill gasoline tank with Unleaded Gasoline. This

is a 4-cycle engine with separate reservoirs for

gas and oil. DO NOT use pre-mixed gas! DO

NOT use old gas! Fuel must be purchased

separately.

2) Fill oil tank with SAE 10W-30 oil. Running

pressure washer without oil will severely

damage engine which is not covered by

warranty! Oil must be purchased separately.

3) Ensure both the pressure hose and garden

hose have been correctly attached to the

pressure washer pump. Ensure the water tap is

on and water is running through the hose before

attempting to start engine. Not doing this will

damage the pump!

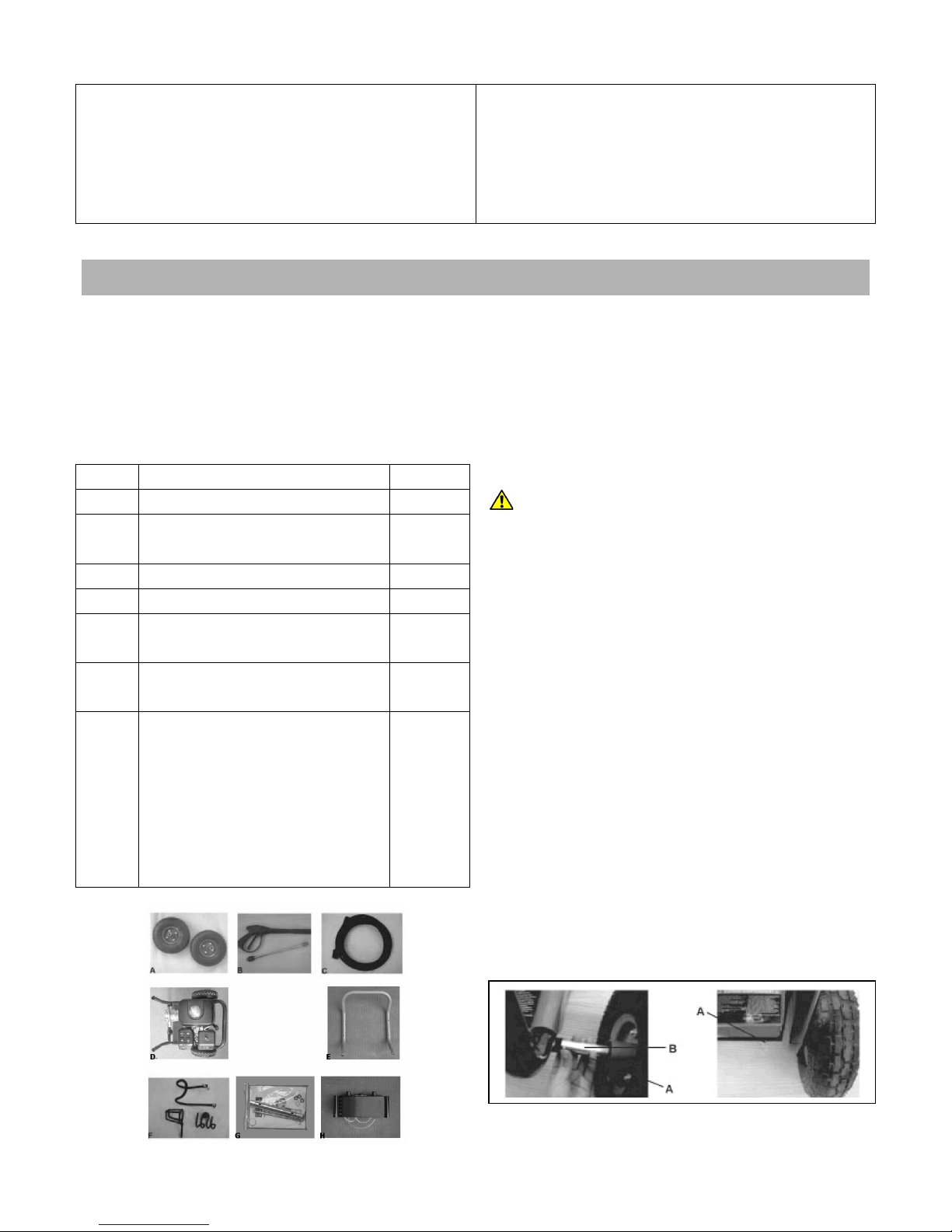

ASSEMBLY INSTRUCTIONS:

1. Install the wheels to the frame by first pressing

its spring loaded pin on wheel axle, then insert

wheel shaft into frame and align spring loaded pin

with hole in frame until the pin snaps. Repeat for

the other wheel.