3

Assembly

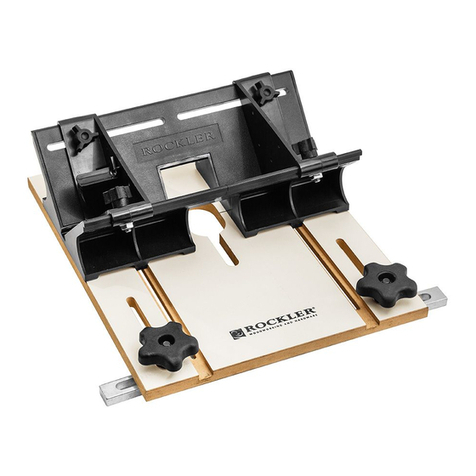

1. With the desired bit (1/2" or 3/4" in diameter) in your

router, position the jig on your router table so the bit

comes through the oblong hole. For best results, use

an up-cut spiral bit (57813 and 63008, sold separately).

Fig. 1.

2. Install the appropriate indexing key in the jig (i.e., the

1/2" key for 1/2" box joints and the 3/4" key for 3/4"

box joints). Be sure to install the key with the flat edge

toward the router bit.

3. Slide the backer sled assembly into the slots in the

MDF base. It might be a tight fit at first. To calibrate the

sled so it won’t bind, slightly loosen the socket head cap

screws at the top of the steel frame. Then gently push

and pull the sled in a slightly twisting motion and

retighten the hex screws. Repeat until the sled slides

smoothly. Fig. 2.

Note: Make sure the washers are installed correctly

so that the screws don’t extend past the bottom of

the sled’s runners and grind into the MDF base. Also,

double-check that the sacrificial fences are not rubbing

too much on the jig, preventing a smooth glide.

Some slight sanding may be necessary.

4. Adjust the height of the router bit above the surface of

the MDF base to match the thickness of your stock plus

a little extra for sanding flush. Fig. 3.

Note: If using the XL Box Joint Jig on a router table

equipped with a router lift, you can drill a hole in the

MDF base to provide access for the adjustment handle.

5. Adjust the gap between the bit and the indexing key to

equal the diameter of the bit. 1/2" box joints, for

example, would require a 1/2" gap between the 1/2"

router bit and the 1/2" indexing key. To adjust the gap,

move the jig side-to-side in the miter track. Then lock

it in place with the 5-star knobs. For best results, use

Rockler’s Precision Brass Setup Bars (36918, sold

separately). Fig. 4.

Note: Use a test piece to be sure your settings are

correct and your joints fit tightly. Fig. 4

Fig. 3

Fig. 2Fig. 1