6Rockwell Automation Publication 6300P-UM001D-EN-P - September 2023

Preface

Additional Resources These documents contain additional information concerning related products from Rockwell

Automation. You can view or download publications at rok.auto/literature.

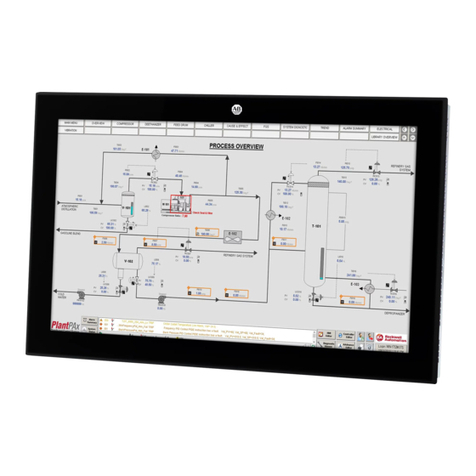

HMI Human Machine

Interface

Software and hardware that allows human operators to: monitor the state of

a process under control, modify control settings to change the control

objective, and manually override automatic control operations

LCD Liquid-crystal display A type of flat-panel screen

LED Light-emitting diode A semiconductor light source that emits light when current flows through it

OS Operating System Software that controls the operation of a PC and directs the processing of

programs

PCAP Projective Captive (versus Resistive) type of touch screen

POST Power on self test Set of routines performed by firmware or software immediately after a panel

PC is powered on, to determine if the hardware is working as expected

PXE Pre-boot Execution

Environment A set of standards that enables a panel PC to load an operating system (OS)

over a network connection

RTC Real-time clock A computer clock, usually in the form of an integrated circuit that is solely

built for keeping time

SSD Solid-state Drive Computer data storage option that functions without any moving parts

UEFI Unified Extensible

Firmware Interface Interface used for the OS to automatically load from the pre-boot operating

environment to an OS that simplifies the boot process and saves time

UPS Uninterruptible

Power Supply Electrical device that provides emergency power to a load when the input

power source or mains power fails

Table 1 - Acronyms (Continued)

Acronym Full Term Definition

Resource Description

6300P Panel PC Installation Instructions, publication 6300P-IN001 Provides basic installation guidelines and instructions for 6300P panel PCs.

6300 Industrial Computer and Monitor Specifications Technical Data,

publication IC-TD003 Provides technical specifications about the 6300M industrial panel monitors.

6300V Remote Video Link (RVL) Receiver Installation Instructions,

publication 6300V-IN004 Provides basic installation guidelines and instructions for 6300V RVL receivers.

6300V Remote Video Link (RVL) Transmitter Installation Instructions,

publication 6300V-IN005 Provides basic installation guidelines and instructions for 6300V RVL transmitters.

6300V Remote Video Link (RVL) Receiver and 6300V RVL Transmitter User

Manual, publication 6300V-UM001 Provides installation guidelines, instructions, and operation for 6300V RVL receivers and

6300V RVL transmitters.

American Standards, Configurations, and Ratings: Introduction to

Motor Circuit Design, publication IC-AT001 Provides an overview of American motor circuit design that is based on methods that are

outlined in the NEC.

EtherNet/IP™ Network Devices User Manual, ENET-UM006 Describes how to configure and use EtherNet/IP™ devices to communicate on the

EtherNet/IP network.

Ethernet Reference Manual, ENET-RM002 Describes basic Ethernet concepts, infrastructure components, and infrastructure features.

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1 Provides general guidelines for installing a Rockwell Automation industrial system.

Industrial Components Preventive Maintenance, Enclosures, and Contact

Ratings Specifications, publication IC-TD002 Provides a quick reference tool for Allen-Bradley® industrial automation controls and

assemblies.

Product Certifications website, rok.auto/certifications. Provides declarations of conformity, certificates, and other certification details.

Safety Guidelines for the Application, Installation, and Maintenance of

Solid-state Control, publication SGI-1.1

Designed to harmonize with NEMA Standards Publication No. ICS 1.1-1987, provides general

guidelines for the application, installation, and maintenance of solid-state control in the

form of individual devices or packaged assemblies incorporating solid-state components.

System Security Design Guidelines Reference Manual, SECURE-RM001 Provides guidance on how to conduct security assessments, implement Rockwell

Automation products in a secure system, harden the control system, manage user access,

and dispose of equipment.

UL Standards Listing for Industrial Control Products, publication

CMPNTS-SR002 Assists original equipment manufacturers (OEMs) with construction of panels to help

confirm that they conform to the requirements of Underwriters Laboratories.