2Eastwood Technical Assistance: 800.343.9353 >> techelp@eastwood.com

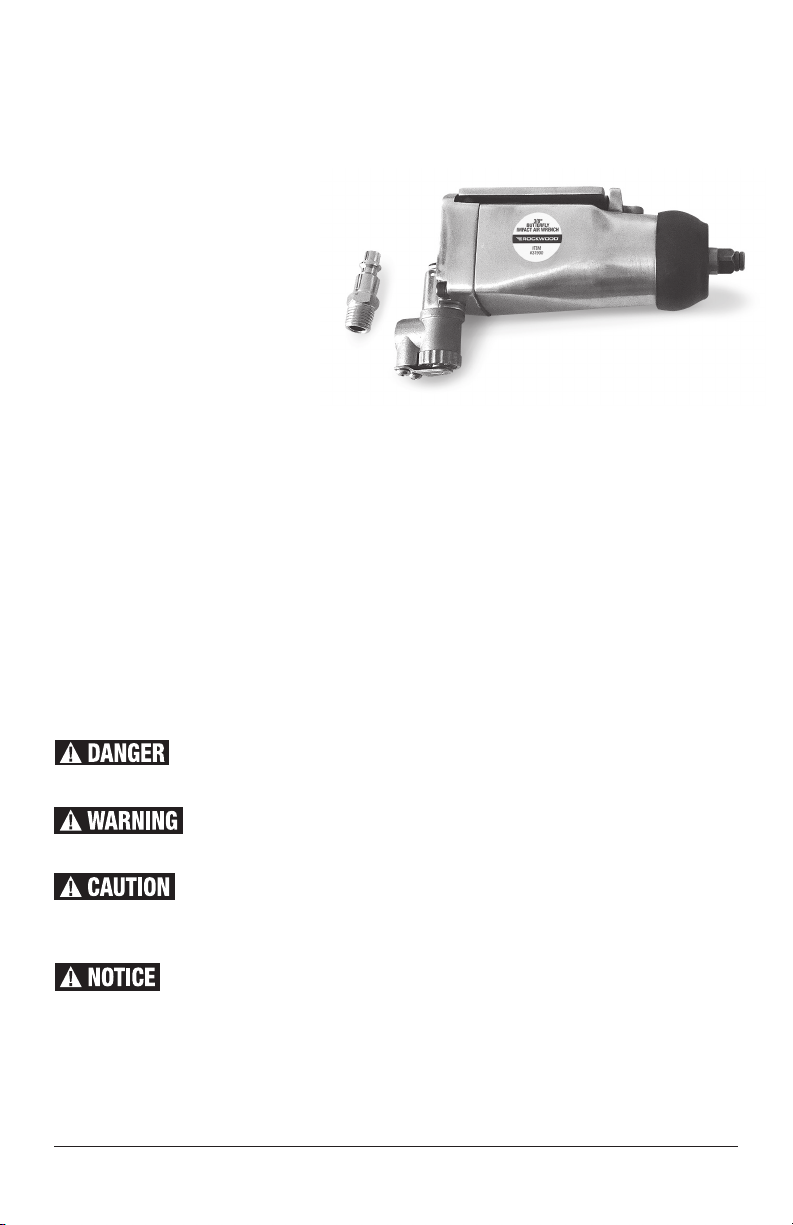

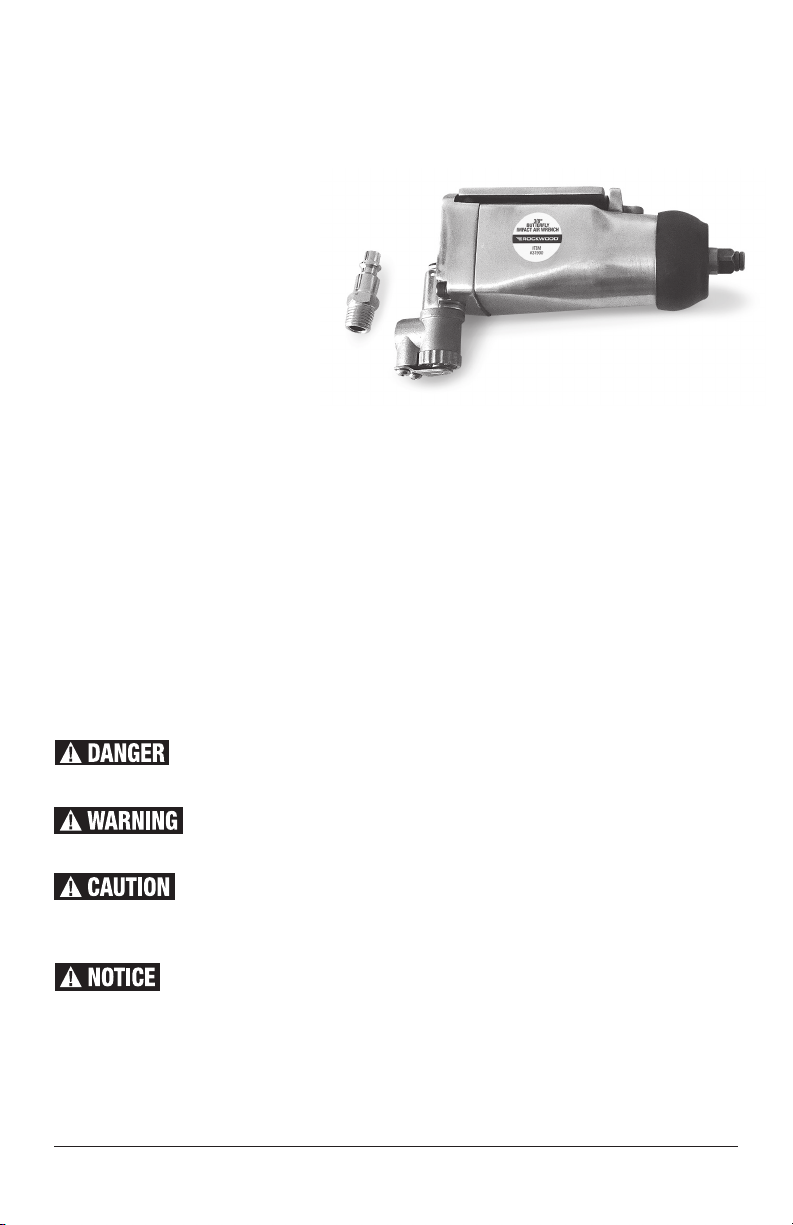

The ROCKWOOD 3/8” “BUTTERFLY” IMPACT AIR WRENCH features a large-capacity five-vane, ball

bearing motor with a twin-headed hammer dog. Fully reversible with an infinitely throttled “Butterfly”

type paddle control.

CONTENTS

(1) 3/8” Butterfly, Inline Impact Wrench

(1) 1/4” MNPT, Male Quick Disconnect

Inlet Fitting

SPECIFICATIONS

Square Drive: 3/8”

RPM: 10,000 free speed

Maximum Torque: 75 ft-lbs [102 N.m]

Air Consumption: 3 cfm [85 L/min] @ 90 PSI

Inlet thread size: 1/4” FNPT

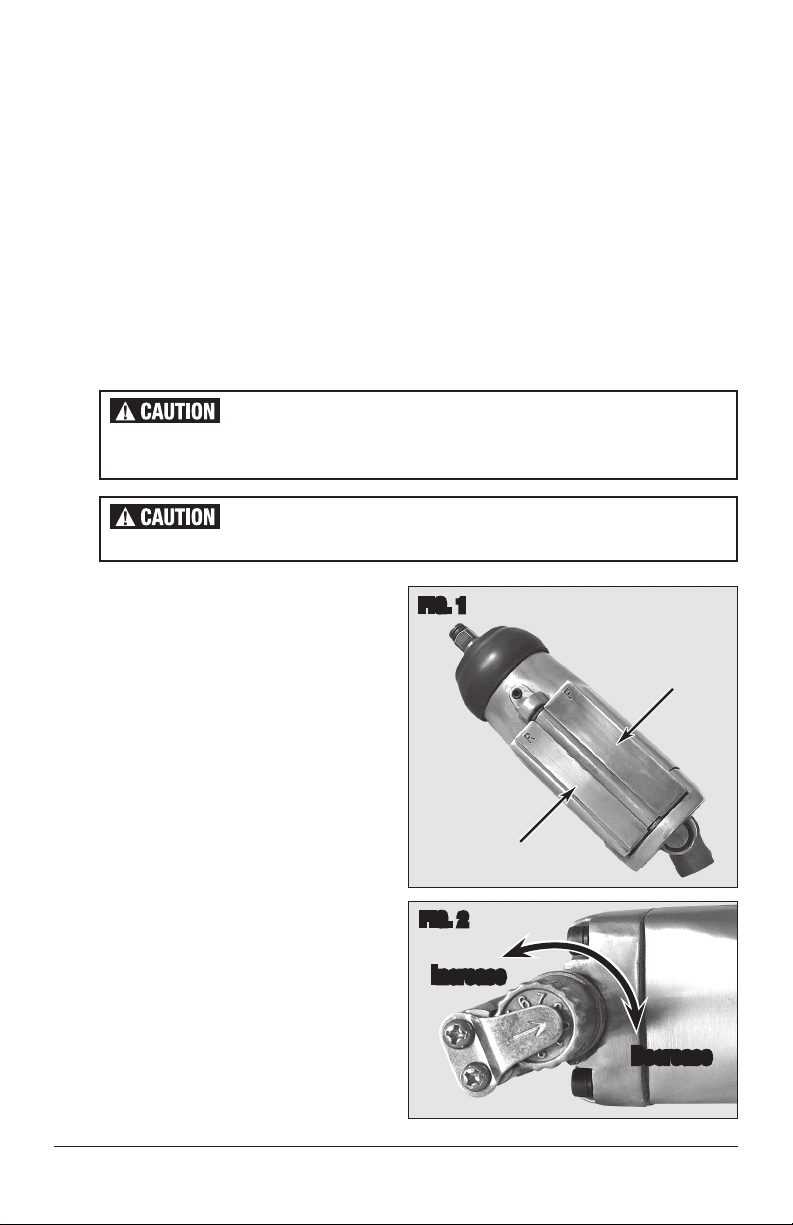

Reversible, variable speed, 5 vane, ball bearing air motor

360° Swivel air inlet with integral torque limiting control knob

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION used with the safety alert symbol, indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

SAFETY INFORMATION

The following explanations are displayed in this manual, on the labeling, and on all other information

provided with this product: