GE Power Management

MM2 Motor Manager 2 i

TABLE OF CONTENTS

1. INTRODUCTION 1.1 OVERVIEW

1.1.1 DESCRIPTION..............................................................................1-1

1.1.2 FEATURES...................................................................................1-1

1.2 ORDERING

1.2.1 ORDER CODES ...........................................................................1-2

1.2.2 ACCESSORIES............................................................................1-3

1.2.3 SPECIAL ORDER.........................................................................1-3

1.3 SPECIFICATIONS

1.3.1 MM2 SPECIFICATIONS ...............................................................1-4

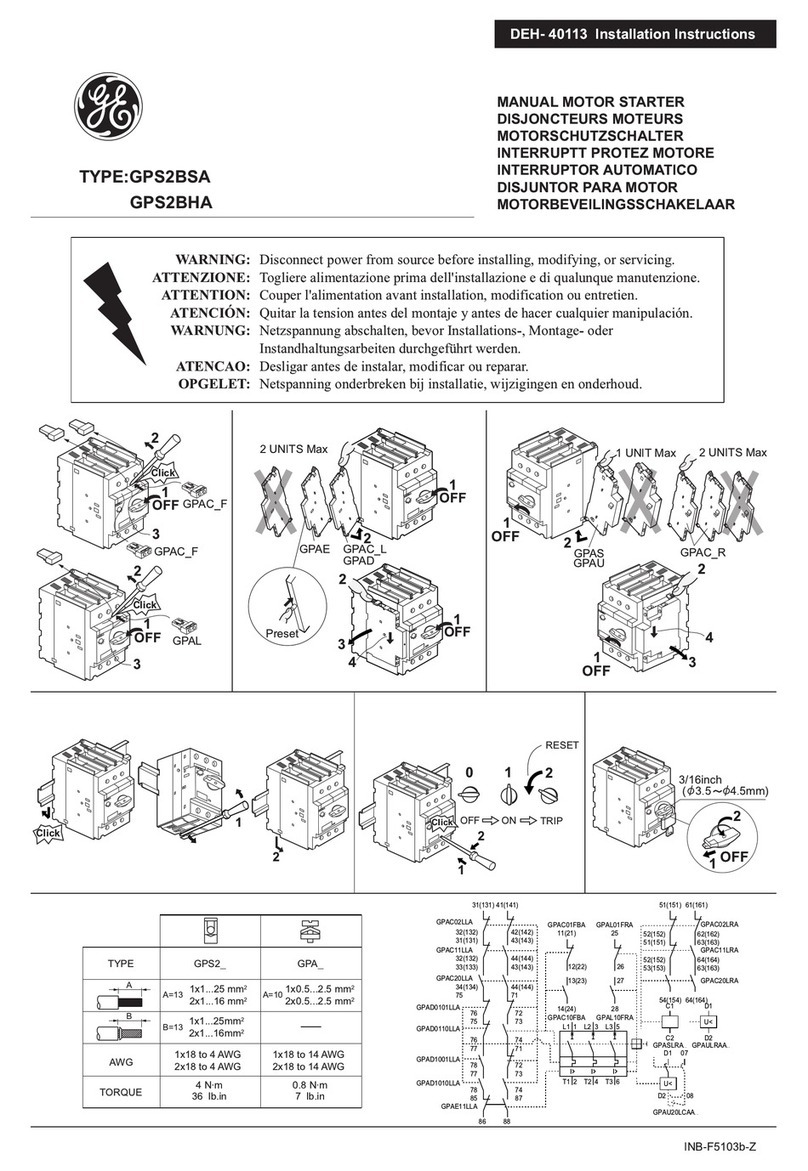

2. INSTALLATION 2.1 MOUNTING

2.1.1 DESCRIPTION..............................................................................2-1

2.2 INPUTS AND OUTPUTS

2.2.1 PHASE CT INPUTS......................................................................2-5

2.2.2 GROUND FAULT CT INPUT ........................................................2-5

2.2.3 SUPPLY VOLTAGE......................................................................2-5

2.2.4 GROUND SURGE ........................................................................2-5

2.2.5 EXTERNAL CONNECTIONS........................................................2-5

2.2.6 THERMISTOR INPUT...................................................................2-6

2.2.7 ANALOG INPUT ...........................................................................2-6

2.2.8 AUX 2 COIL ..................................................................................2-6

2.2.9 OUTPUT RELAYS........................................................................2-6

2.2.10 SWITCH INPUTS..........................................................................2-6

2.2.11 PROGRAMMABLE SWITCH INPUTS..........................................2-6

2.2.12 SERIAL COMMUNICATION PORT ..............................................2-7

2.2.13 STOP ............................................................................................2-7

2.2.14 START A / START B.....................................................................2-8

2.2.15 LOCAL ISOLATOR N/O................................................................2-8

2.2.16 CONTACTOR STATUS................................................................2-8

2.2.17 SWITCH COMMON ......................................................................2-8

2.2.18 DIELECTRIC STRENGTH TESTING ...........................................2-8

3. HARDWARE 3.1 FACEPLATE FUNCTIONS

3.1.1 DESCRIPTION..............................................................................3-1

3.1.2 MESSAGE DISPLAY....................................................................3-1

3.1.3 INDICATOR LEDs.........................................................................3-2

3.2 KEYPAD

3.2.1 SETPOINTS KEY..........................................................................3-3

3.2.2 ACTUAL VALUES KEY.................................................................3-3

3.2.3 STORE KEY..................................................................................3-4

3.2.4 STOP KEY....................................................................................3-4

3.2.5 RESET KEY..................................................................................3-4

3.2.6 START A KEY...............................................................................3-4

3.2.7 START B KEY...............................................................................3-5

3.2.8 MESSAGE UP/DOWN KEYS .......................................................3-5

3.2.9 MESSAGE LEFT/RIGHT KEYS....................................................3-5

3.2.10 VALUE UP/DOWN KEYS .............................................................3-5

3.3 THEORY OF OPERATION

3.3.1 HARDWARE DESCRIPTION........................................................3-6