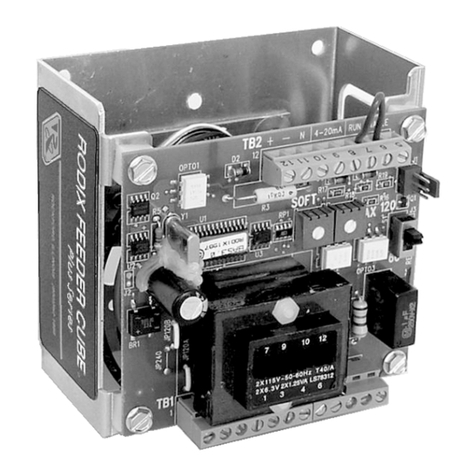

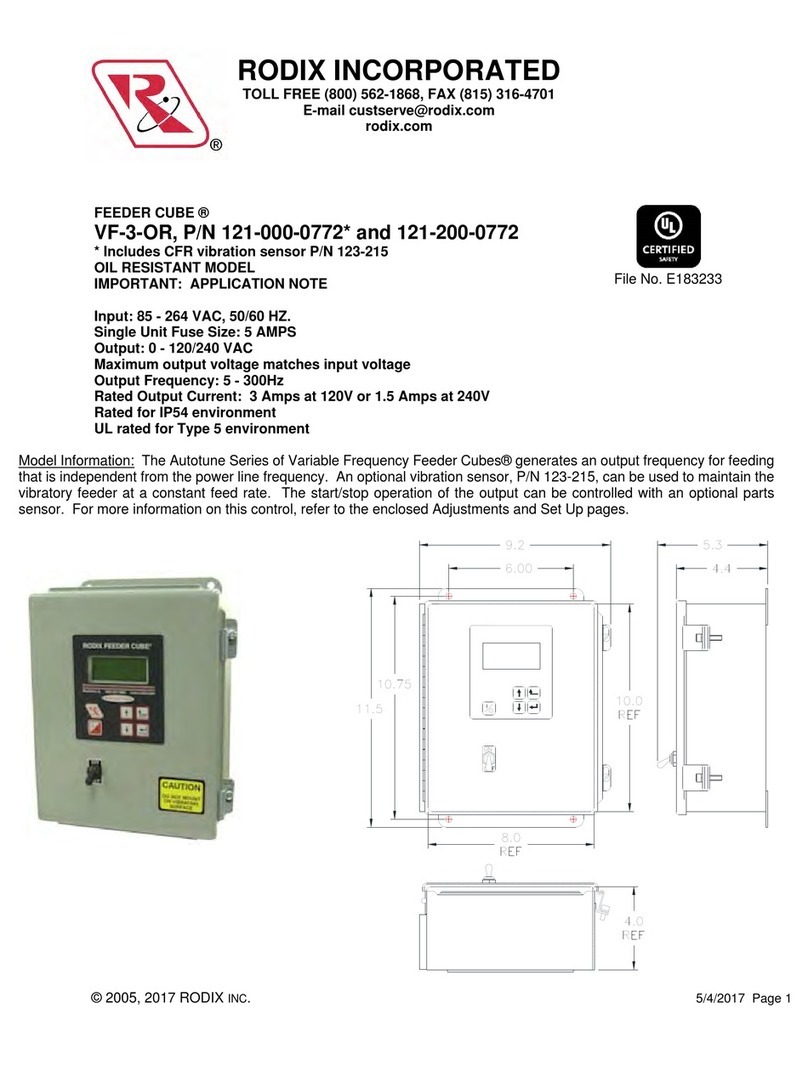

6. External Speed Control Connections

The following methods of remote power level control

can be utilized when desired:

A. CFR sensor can maintain a constant feedrate. Attach

the CFR sensor to terminals ACCEL “-“ (blue) and to

ACCEL “+” (brown). (Then update the software

settings. Sections 11-A and 13-B)

B. 4-20mA signal can be connected by bringing the

positive signal wire to 4-20 “+” and ground to 4-20 “-“.

(Update software settings. Sect 11-B)

C. 0-10VDC Analog input signal can be connected by

bringing the positive signal wire to 0-10V “+” and

ground to 0-10 “-“. (Update the software settings.

Section 11-C)

Software Adjustments

Once the electrical connections have been made, the

control can be turned on. The software settings can be

adjusted as desired through the control menu.

Display Messages

The normal operating display shows the status of the

control with regard to input signals and control settings.

See the Control Menu Layout pagefor display message

details.

Navigating The Control Menu

Thecontroluses four programmingkeystoprogramthe

control. The “I/0” key controls run, stop, and over-ride.

A. The ENTER key allows entry to the menu and

access to adjust each setting. Push and hold the

enter key to enter the program mode. If the security

feature has been enabled, enter the proper code.

Once inside the menu, the enter key selects a menu

item or a parameter to adjust. Any changes to the

settings are saved at power-down.

B. The BACK key moves the current menu location up

one level higher than it was before. It is also used to

get back to the normal operating display.

C. The Arrow Down key allows the user to step down

through the program menu or to decrease a setting.

D. The Arrow Up key allows the user to step up

through the program menu or to increase a setting.

E.The“1/0” key allows the user to temporarily stop orto

start the control’s operation. When the LCD status

reads “Stop/Run,” hold the “1/0” key down for just

overasecond, and thecontrol will starttheover-ride

operation. In over-ride mode the output turns on

regardless of I/O connections and status.

See the “Control Menu Layout” chart for the menu

structure. When in the menu mode and no keys are

pressedfor1 minute, thedisplayrevertstothe normal

operating display mode.

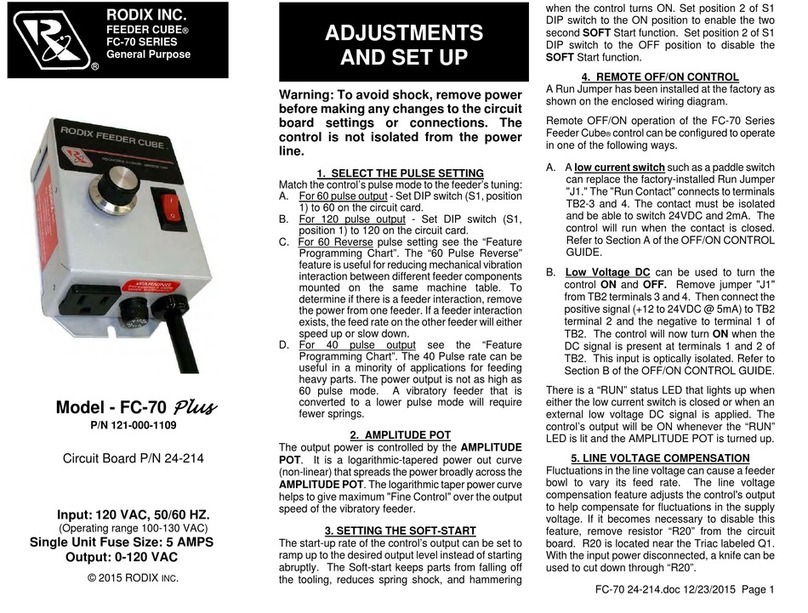

7. Amplitude Power Setting

The output power is controlled by the up and down

arrow keys. The power setting can be adjusted with

the keys unless the security feature lock has been

selected. Once the proper security code has been

entered,thepower setting maybe adjusted underthe

“Power” menu. Note: the power setting may not be

above the maximum power setting or below the

minimum power setting level. The amplitude power

setting is displayed in the following manner:

“A= 50.0%.”

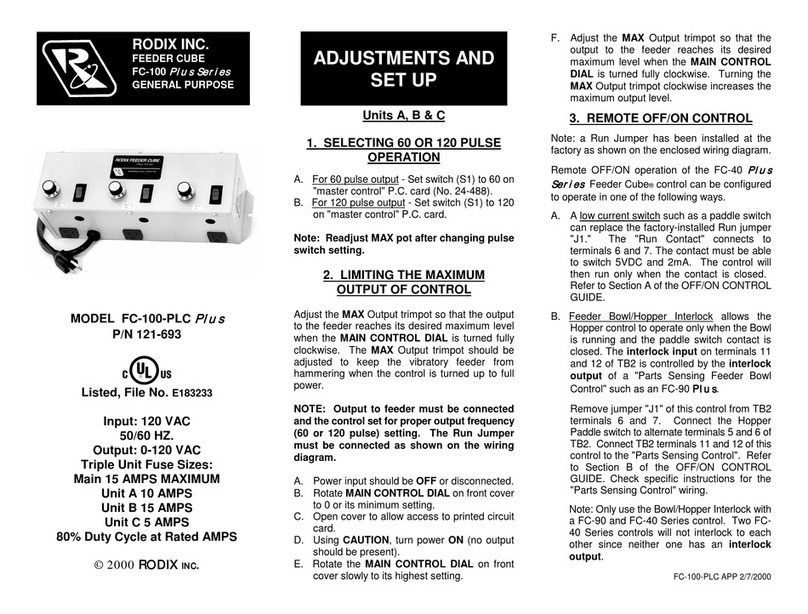

8. Limiting The Maximum Output Of Control

The “Max Amplitude” setting can be adjusted to keep

a vibratory feeder from hammering or vibrating

excessively when the control is turned up to full

power. The maximum power setting can be found

under the “Power” menu. It can be adjusted from

100.0% down to 40.0%.

Caution: it is recommended when using the CFR

feature, that the Max output level of thecontrol should

be limited to prevent feeder coil from overheating.

The amplitude could continue to increase if the

system cannot get back to the desired vibration level.

9. Setting The Minimum Output of Control

The “Min Amplitude” setting can be adjusted to the

desired low level of vibration. The minimum power

setting can be found under the “Power” menu. It can

be adjusted up from 0.0% to 95.0%. Note: the

software does not allow the minimum level to be

within 5.0 counts of the maximum level.

10. Setting The Soft-Start

The start-up of the control’s output can be adjustedto

ramp up to the desired output level instead of starting

abruptly. Soft-start keeps parts from falling off the

tooling, reduces spring shock, and can eliminate

hammering when the control turns ON. The soft start

setting can be found under “Power Settings” menu.

The soft start can be set from 0.0 to 10.0 seconds.

When using the 2 speed operation, the soft start

function is active during the low to high speed

transition.

11. External Speed & Frequency Control

The feeder control’s power level can be controlled by

an external signal from a PLC, CFR sensor, or an

analog source. The “External Speed Connections”

section gives connection details.

A. When the Constant Feed Rate (CFR) sensor is

used, The “Amplitude Source” and “Frequency

Mode” settings should be set to “Auto Track.”

The control should display “Run/CFR” showing

that the sensor is connected. Set the power

setting to the desired feed rate. The control

uses information from the CFR sensor to

maintain a constant vibration level at the

resonate frequency. See the CFR instructions

page for more information.

Caution: it is recommended when using the CFR

feature, that the Max output level of the control

should be limited to prevent the feeder coil from

overheating. The amplitude could continue to

increase if the system cannot get back to the

desired vibration level.

B. 4-20mA signal from a PLC can be used to

remotely vary the output of the control instead of

the keypad. The “Amplitude Source” setting

must be set to 4-20mA to enable it. After the 4-

20mA feature is selected, the control will

automatically turn ON whenever a 4-20mA

signal is applied to the control (TB2 “+ 4-20” &

“-“). When the 4-20mA signal has been

removed, the amplitude setting resets to zero.

The 4-20mA menu selection allows a PLC to

controlboththe outputFrequencyand Amplitude

oronlythe Frequencyor justthe Amplitude. The

amplitude is controlled bythe 4-20mA input.The

Frequency is controlled by the 0-10VDC signal.

The signal adjusts a 100Hz range. The Min

Frequency adjustment specifies the frequency

used when the 0-10VDC input is at 0VDC. The

Max Frequency adjustment can be used to

ignore the upper end of the 0-10VDC signal.

C. 0-10VDC signal from a PLC can be used to

remotelyvarythe output ofthe control insteadof

the keypad. The “Amplitude Source” setting

mustbeset to 0-10VDCto enable it. Afterthe0-

10VDC feature is selected, the control will

automatically turn ON whenever a signal is

applied to the control (TB2- “+0-10” & “-“). When

the 0-10VDC signal has been removed, the

amplitude setting resets to zero.

D. When it is desirable to ignore the external speed

control inputs, the “Manual” setting can be

selected.

VF Application Note page 3_4 Ver1_28.doc 3/8/2013 Page 3