5 Mounting

1. Place the VPPE-... as close to the consumer as possible. This improves control

precision and reduces response times.

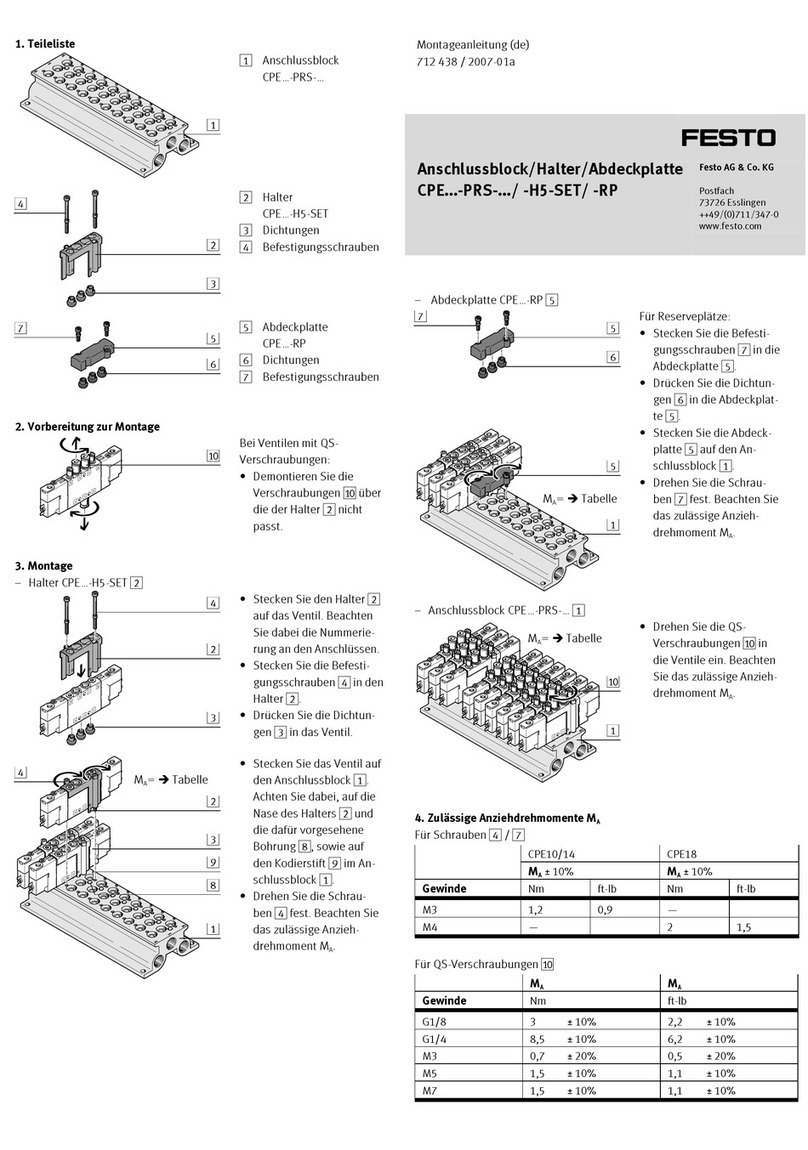

2. Push two screws (M4) into the holes for lateral mounting è Fig.2, 1 or the

holes for front mounting è Fig.2, aB, max. tightening torque: 2Nm.

3. Mount the VPPE-... in the intended position.

NOTICE!

• When installing the VPPE-…-E1T on the mounting rail IPM-PN-08-40x80-AL,

note that the compressed air supply corresponds to the total air consump-

tion. For more information see the assembly instructions for the VAME-PS-

MK.

6 Installation

6.1 Pneumatic installation

1. Remove the covers from the supply ports.

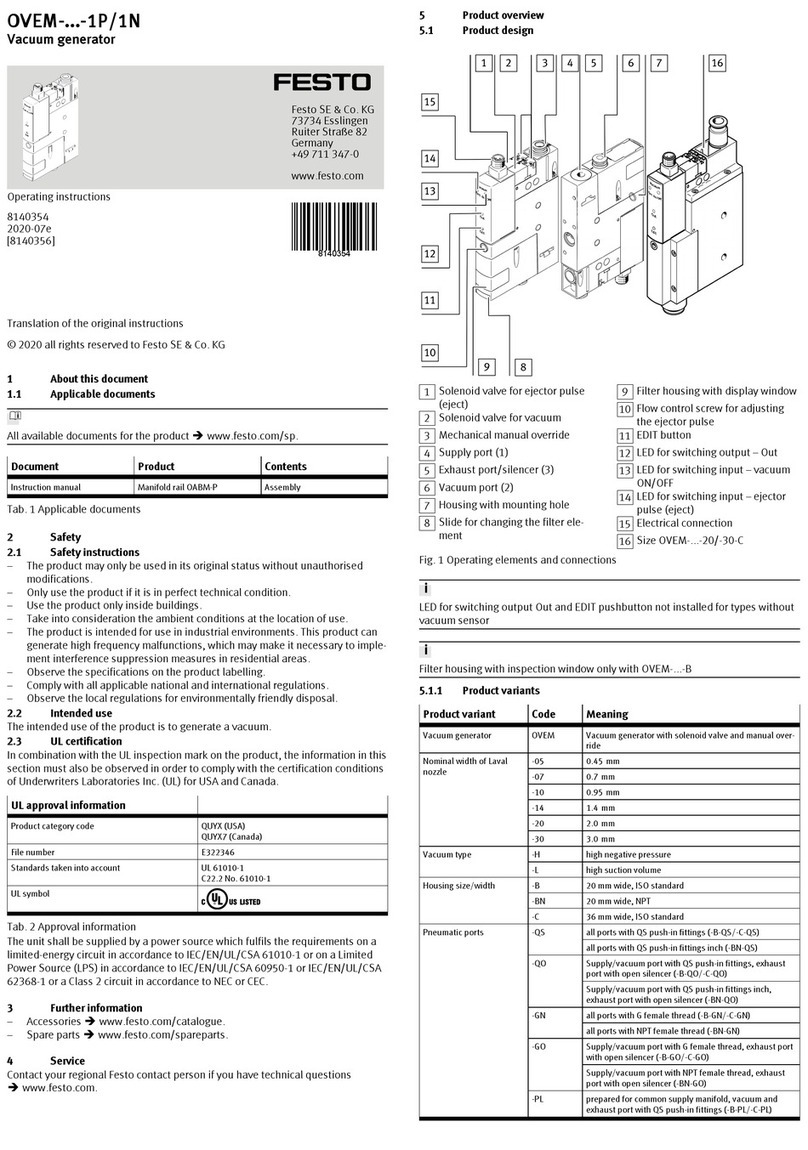

2. Attach the tubing to the following ports (è Fig.2):

Input supply port (1), position 2

Output supply port (2), position aJ

3. Mount a silencer at the exhaust supply port (3) (position aA) or extract the

exhaust air using ducts.

Operating medium

NOTICE!

Too much residual oil content in the compressed air will reduce the service life of

the valve.

• When using organic oils (oils that are based on synthetic esters or native

esters, e.g.rapeseed oil methyl ester), the maximum residual oil content of

0.1mg/m³ must not be exceeded (è Compressed air to ISO 8573-1:2010

[–:–:2]).

The position of the pneumatic ports depends on the variant ordered.

6.2 Electrical installation

WARNING!

Risk of injury due to electric shock.

• For the electrical power supply, use only PELV circuits in accordance with IEC

60204-1/EN 60204-1 (Protective Extra-Low Voltage, PELV).

• Observe the general requirements of IEC 60204-1/EN60204-1 for PELV cir-

cuits.

• Only use voltage sources that ensure a reliable electric separation from the

mains network in accordance with IEC 60204-1/EN 60204-1.

• Use the following connection accessories (è 3 Further information):

– plug socket with cable or

– plug socket cable, pre-assembled.

This ensures that the specified degree of protection IP65 and EMC is achieved.

NOTICE!

To guarantee EMC safety, the device must be earthed as follows:

• Use the earth terminal (è Fig.2, è Fig.3).

• Use the following earthing accessories (included in the scope of delivery):

– Self-tapping screw

– Flat plug

– Contact washer.

• Wire the VPPE-... in accordance with the plug pattern. Preferably use Festo

cables.

Pin Colour 1) Allocation

1 brown +24VDC

2 white Analogue input - setpoint value/-w

3 blue GND

4 black Analogue input - setpoint value/+w

(0…10V or 4…20mA)

5 grey Switching output (24 V) or

Analogue output (0…10V or 4…20 mA)

Actual value/XOUT

1) Colour is only valid for Festo accessory cables

Tab. 3 Pin allocation M12x1 plug, 5-pin

7 Commissioning

NOTICE!

• The VPPE-... interprets setpoint signals less than 0.1 V as 0 V and setpoint sig-

nals less than 4.16 mA as 4 mA. In this case, the output pressure is set to 0

MPa by activation of the exhaust valve. As a result, a defined valve condition

is assured at w = 0.

• Safety position: if the voltage variant setpoint value cable breaks, the output

pressure is set to 0 MPa. If the current variant cable breaks or if the supply

voltage fails, the output pressure is maintained uncontrolled. Leakage results

in a change of pressure over the long term.

1. Connect the VPPE-... with a setpoint value signal. The VPPE has a so-called

“differential input”. The setpoint signal is applied to the contact pin 2 and pin

4, where the lower potential must be connected to the contact pin 2 and the

higher potential to the contact pin 4.

Contact pin 2 (– setpoint value) can be connected to contact pin 3 (GND).

2. Energise the VPPE-... with direct current (supply voltage UV = 24 V DC ± 10%).

3. Pressurise the VPPE-... to at least 0.1MPa higher input pressure (p1) than the

maximum desired output pressure. This sets proportional output pressure

(p2).

The following output pressure range is then allocated to the setpoint value signal

range 0…10V or 4…20mA:

Output pressure range of the variantSetpoint value

signal range 0.2 MPa 0.6 MPa 1 MPa

0…10V or

4…20mA

0.002…0.2 MPa 0.006…0.6 MPa 0.01…1 MPa

Tab. 4 Setpoint value signal range and associated output pressure range

7.1 Recommended parameter sets

The valves in all pressure variants are set at the factory to Preset 2.

PresetPreset recommendation

123

Consumer volume < 0.5 l ~ 0.5 l > 0.5 l

Tab. 5 Recommended parameter sets

7.2 VPPE display and meaning

In the delivery status the display corresponds to the factory setting

è 10.1 Reset to factory settings.

Display Meaning Description

[An] Analogue Output: analogue

[bAr] bar Pressure unit

[Eco] ECO mode Display shutdown (adjustable)

[Frc] Force Manual setpoint specification

[HY] Hysteresis Spread, switch difference

[in] Setpoint value When the v button is pressed (1 sec.), [in]

appears. The setpoint value is displayed when

the button is released.

[Loc] Lock Input locked with PIN code

[n.Hi] Switch normally closed N/C contact (normally closed)

[n.Lo] Switch normally open N/O contact (normally open)

[OFS] Offset Zero point increase

(Outlet pressure without setpoint value)

[out] Actual value When the v button is pressed (1 sec.), [out]

appears. The actual value is displayed when the

button is released.

[PA] Kilopascal Pressure unit (in kPa!)

[Pin] Pin code Enter value for locking

(1…999)

[Pr1] Preset 1 (è 7.1 Recommended parameter sets

[Pr2] Preset 2 (è 7.1 Recommended parameter sets

[Pr3] Preset 3 (è 7.1 Recommended parameter sets

[PSi] psi Pressure unit

[rES] Reset

(factory setting)

Switch on device while pressing V + v + Edit

buttons. Observe note in section

è 10.1 Reset to factory settings.

[rnG] Range Pressure range adjustment

[Snr] Display serial number Switch on device while pressing v + Edit but-

tons: 6-digit serial number is displayed, first

[xxx.] then [xxx] alternating approx. every 2 sec.

[SOF] Display software version Switch on device while pressing V + Edit keys:

software version appears

[SP] Switching point è 6.2 Electrical installation

[SP.H] Switching Point high Upper switching point

è 6.2 Electrical installation

[SP.L] Switching Point low Lower switching point

è 6.2 Electrical installation

[SP.O.] Set Point ok Setpoint value reached

è 6.2 Electrical installation

[unL] Unlock Lock removed

Threshold value comparator è 6.2 Electrical installation

Window comparator è 6.2 Electrical installation

[._..] ECO mode activated A line moves through the display [._..] after x

seconds (adjustable)

Tab. 6 Indication on display