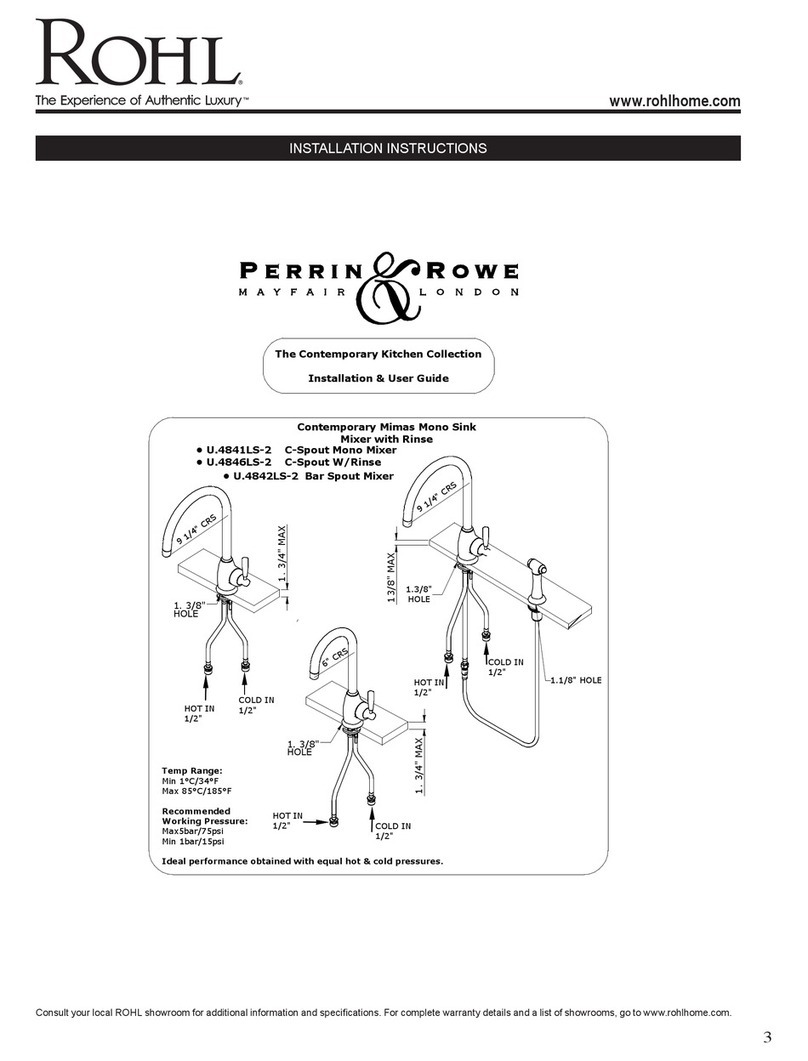

www.rohlhome.com

INSTALLATION INSTRUCTIONS

Consult your local ROHL showroom for additional information and specications. For complete warranty details and a list of showrooms, go to www.rohlhome.com.

Congratulations on the purchase of your Perrin and Rowe Bathroom Product. Correctly

installed and with sensible care, this product will give you many years of trouble free service.

• IMPORTANT INFORMATION •

Please read carefully to ensure correct installation.

Before you proceed... We recommend you engage the services of a registered

plumber to install this product.

For ease of possible future servicing, we also recommend the fitting of

conveniently placed isolating valves.

In addition to the guide below it is essential that the written information overleaf is

carefully read and understood.

• Preparation Check Box for Installer •

Flush the plumbing system before

installing the kitchen product.. Once unpacked, remove clamping plate and

nut ready for installation.

• CARE & MAINTENANCE •

Wipe down after use to avoid water spotting and mineral build up.

Occasional cleaning with warm soapy water, followed by a polish with a soft cloth is all

that is required to keep the plated finish in good condition.

Do not use proprietary abrasive liquids, powders, or pads to clean the tap. Do not use

any products with ammonia bleach or limescale remover. You will damage the plated

finish and void your guarantee.

• BEFORE USE •

• Carefully check the installation for leaks.

•If further building work is to be carried out in the vicinity, cover the tap to avoid damaging

the finish.

• Please ensure that the installation complies with local plumbing codes.

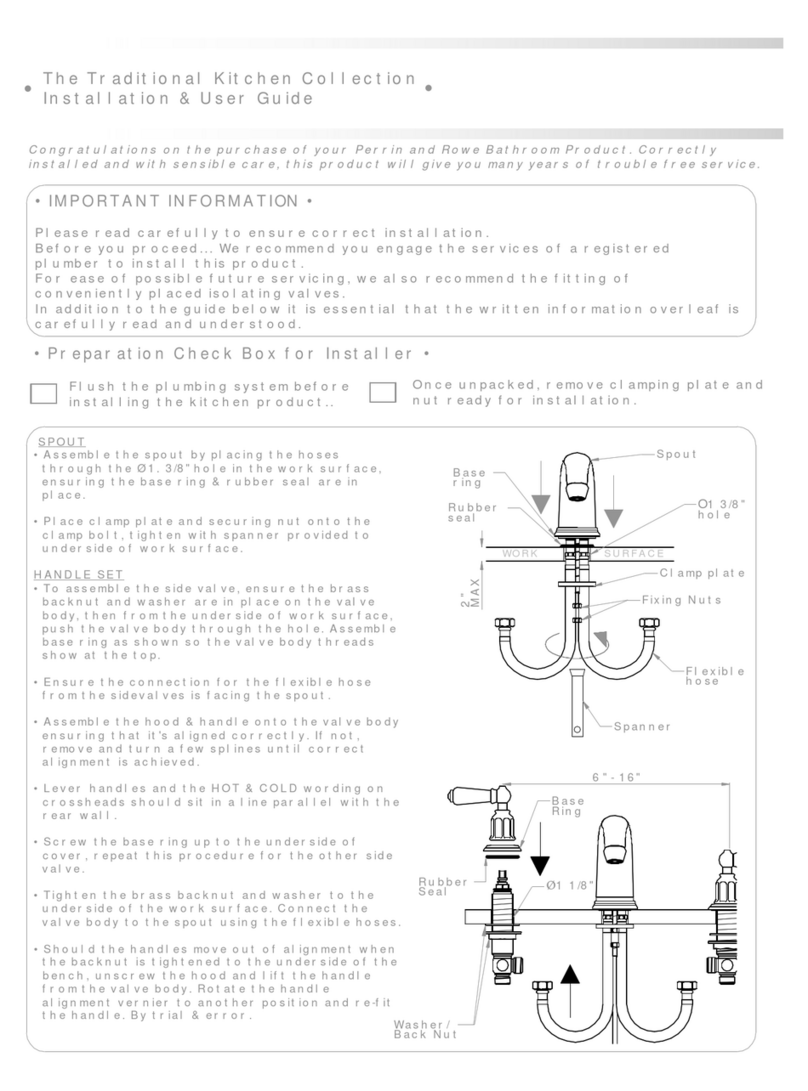

The Traditional Kitchen Collection

Installation & User Guide

••

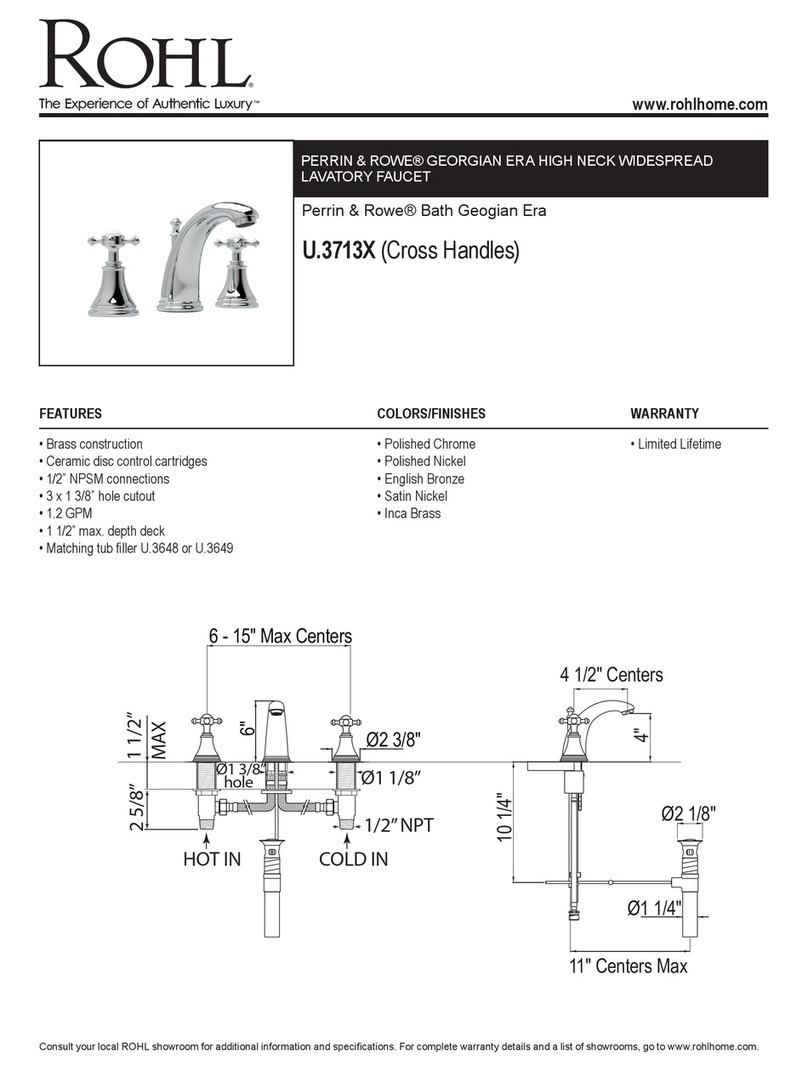

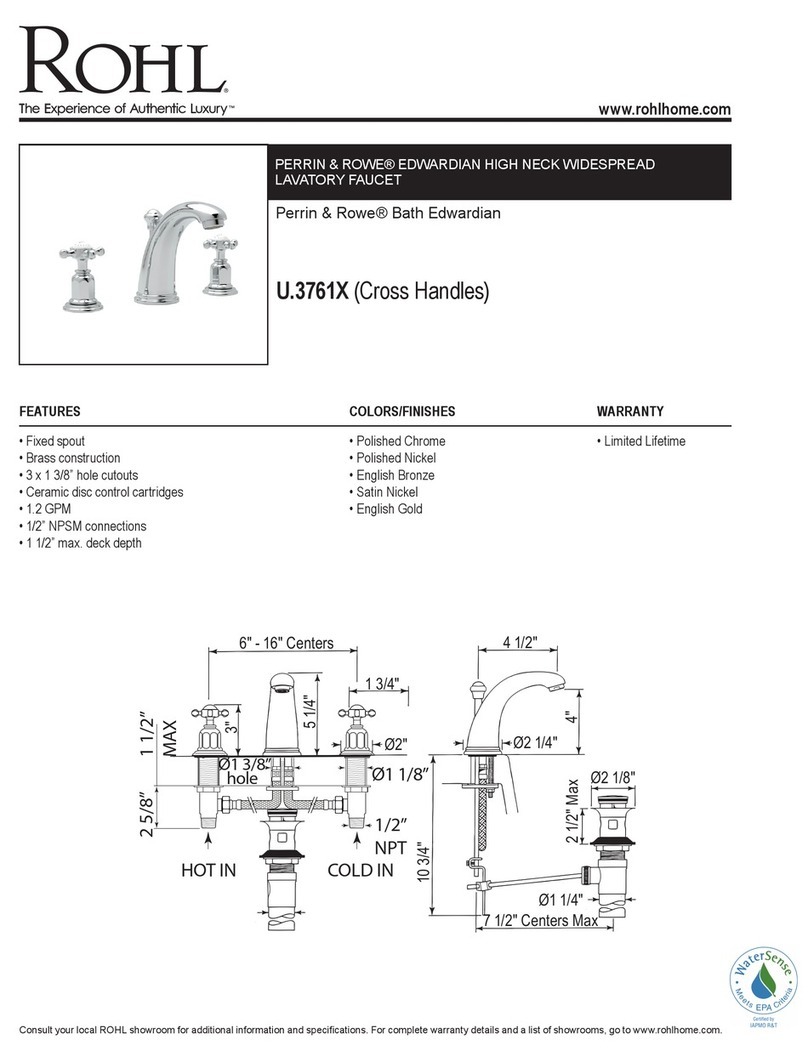

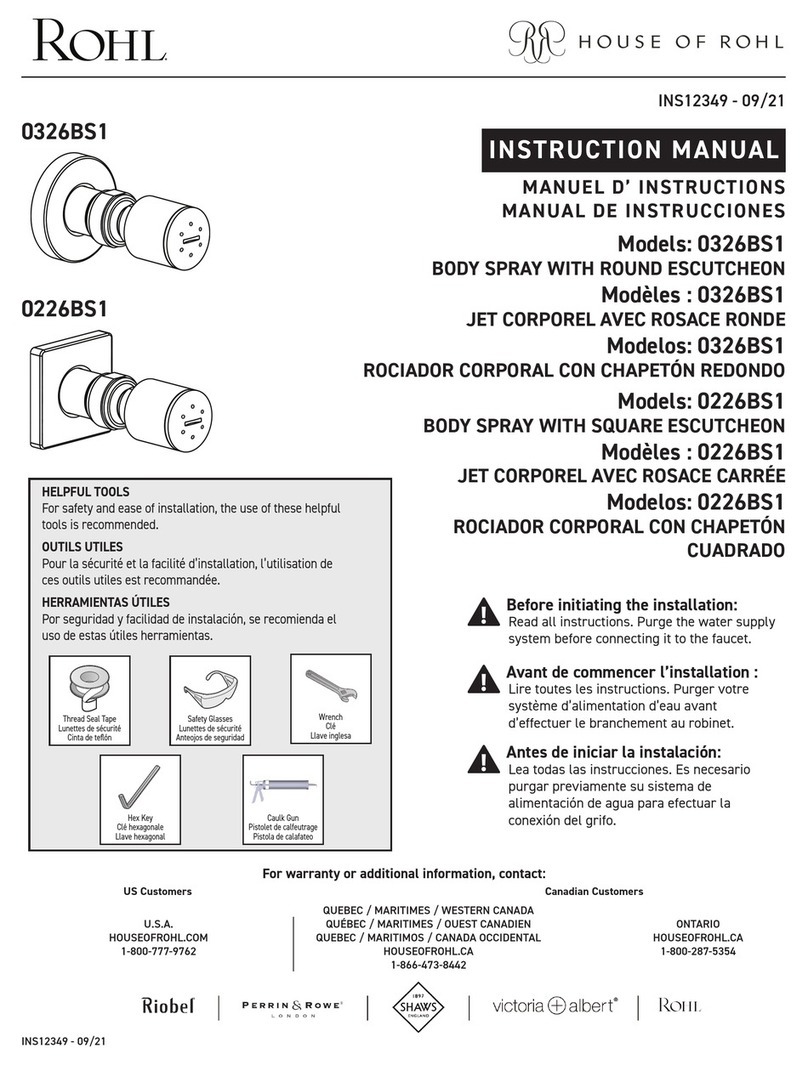

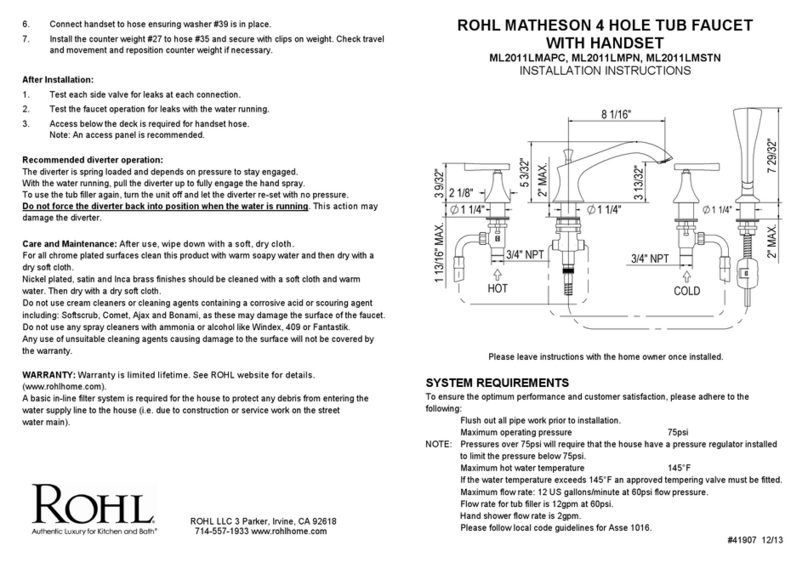

SPOUT

• Assemble the spout by placing the hoses

through the Ø1. 3/8" hole in the work surface,

ensuring the base ring & rubber seal are in

place.

• Place clamp plate and securing nut onto the

clamp bolt, tighten with spanner provided to

underside of work surface.

HANDLE SET

• To assemble the side valve, ensure the brass

backnut and washer are in place on the valve

body, then from the underside of work surface,

push the valve body through the hole. Assemble

base ring as shown so the valve body threads

show at the top.

• Ensure the connection for the flexible hose

from the sidevalves is facing the spout.

• Assemble the hood & handle onto the valve body

ensuring that it's aligned correctly. If not,

remove and turn a few splines until correct

alignment is achieved.

• Lever handles and the HOT & COLDwording on

crossheads should sit in a line parallel with the

rear wall.

• Screw the base ring up to the underside of

cover, repeat this procedure for the other side

valve.

• Tighten the brass backnut and washer to the

underside of the work surface. Connect the

valve body to the spout using the flexible hoses.

• Should the handles move out of alignment when

the backnut is tightened to the underside of the

bench, unscrew the hood and lift the handle

from the valve body. Rotate the handle

alignment vernier to another position and re-fit

the handle. By trial & error.

WORK SURFACE

Spout

Base

ring

Rubber

seal

2"

MAX

Flexible

hose

Clamp plate

Spanner

O1 3/8"

hole

Fixing Nuts

6" - 16"

Rubber

Seal Ø1 1/8"

Base

Ring

Washer/

Back Nut

OPERATION

• This tap is fitted with quarter-turn ceramic

disc valve units. Water flow from off to fully

on is achieved by rotating the handles a

quarter-turn. Ceramic disc valves are

available opening in a clockwise or

anti-clockwise direction. Should the handle of

an installed faucet operate in the wrong

direction, this can be remedied by changing the

ceramic disc valveto the other version.

OPTIONAL LEVER INSERTS

• Perrin & Rowe lever handled faucets are

supplied fitted with brass lever inserts.

These can be replaced with lever inserts made

from porcelain if required.

• To fit replacement lever inserts, rotate the

metal rod running down the centre of the

brass lever insert in an anti-clockwise

direction to unscrew it from the faucet.

Removethe metal spacer and the rubber o-ring

from the rod and slide the brass insert off

the rod.

• When fitting a porcelain lever insert, slide it

onto the rod, re-fit the o-ring and spacer and

screw it back onto the faucet. When fitting a

brass lever insert, slip the thick o-ring

supplied with the insert upthe rod for it to sit

under the thick end of the insert. Then fit the

original o-ring and spacer and screw it back

onto the faucet.